ASTM F2561-20

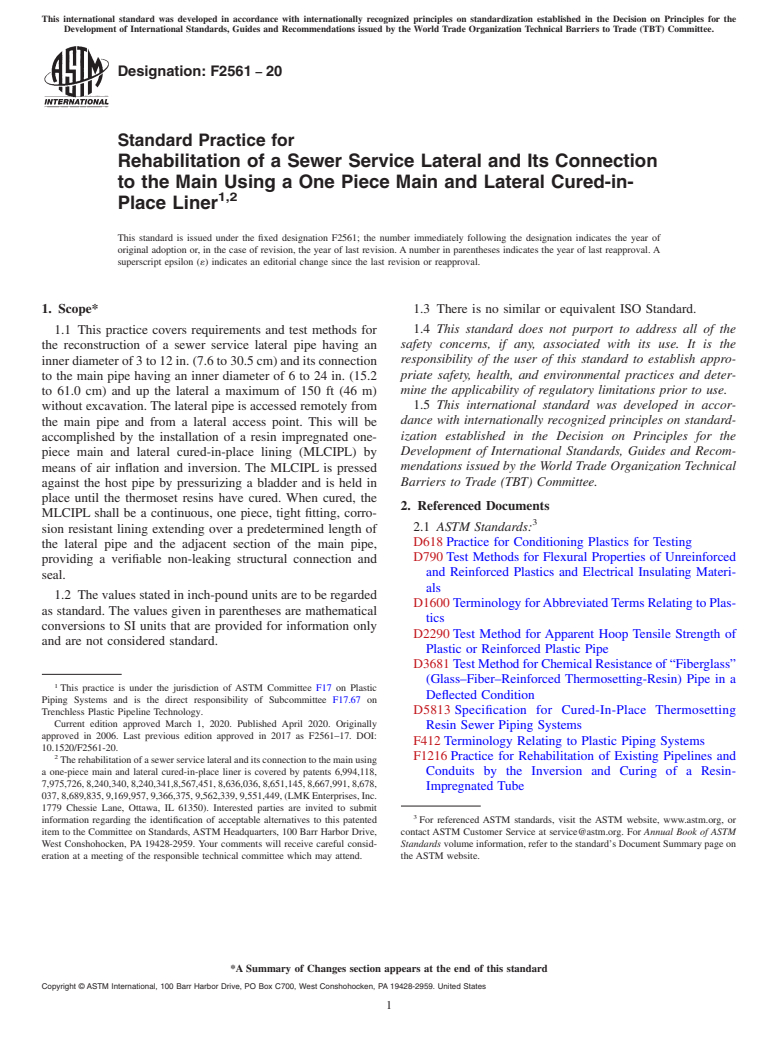

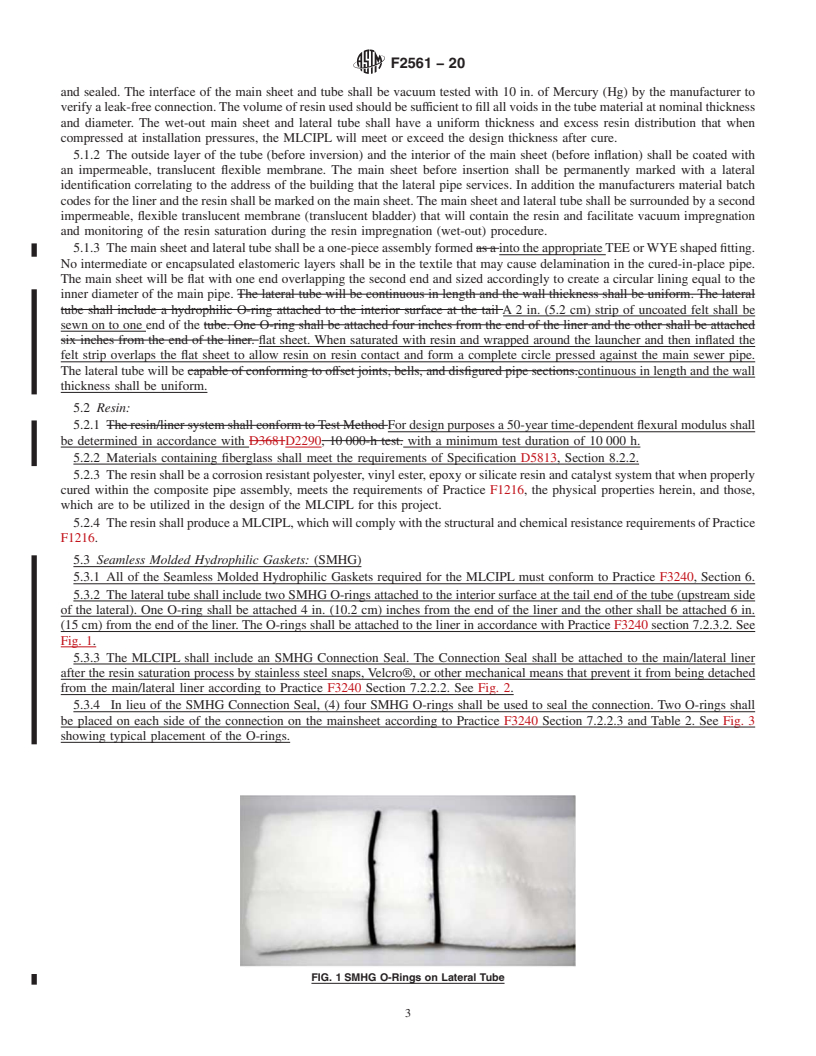

(Practice)Standard Practice for Rehabilitation of a Sewer Service Lateral and Its Connection to the Main Using a One Piece Main and Lateral Cured-in-Place Liner

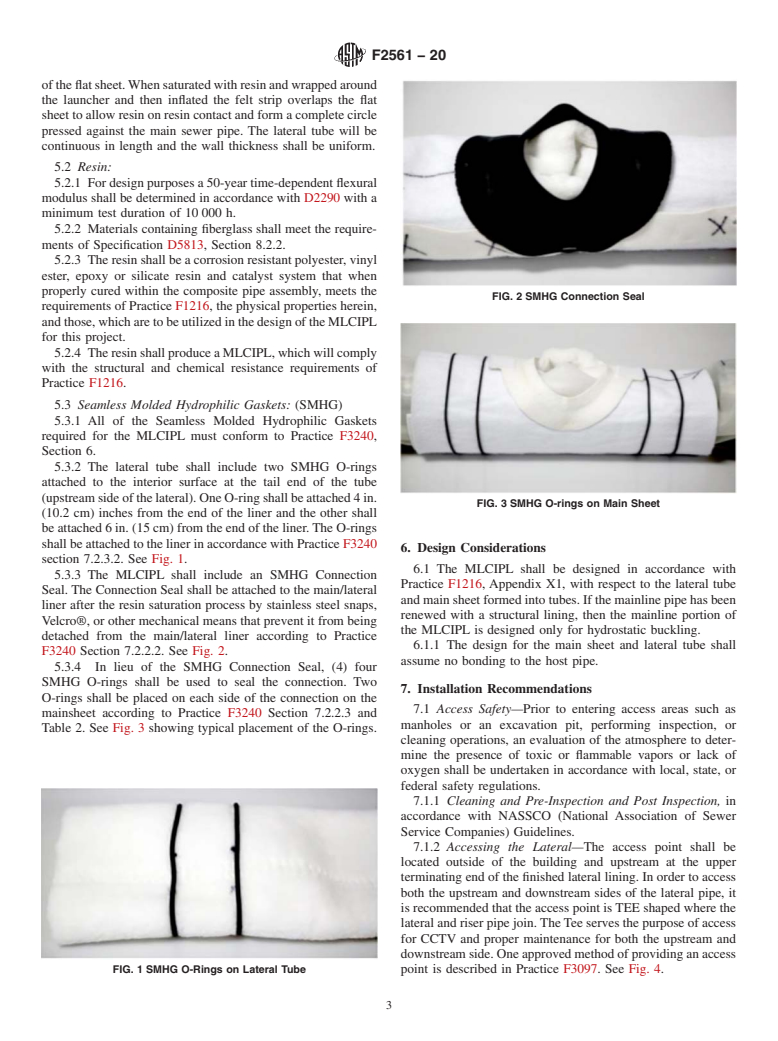

Standard Practice for Rehabilitation of a Sewer Service Lateral and Its Connection to the Main Using a One Piece Main and Lateral Cured-in-Place Liner

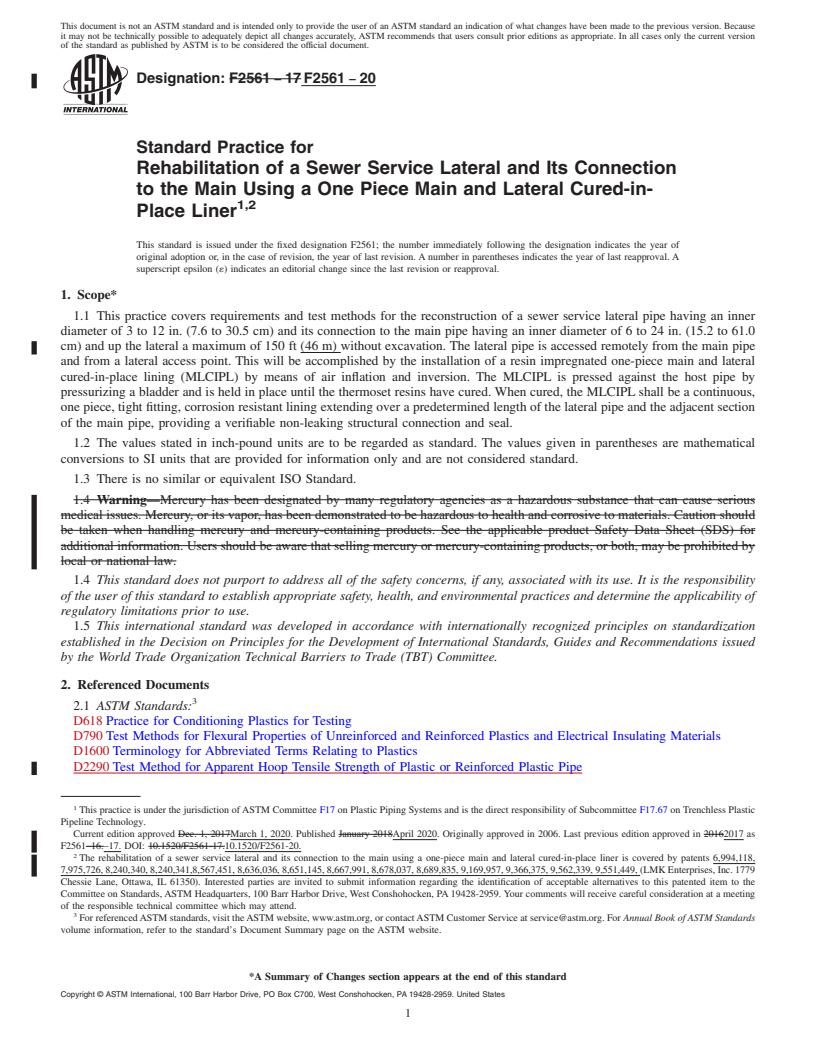

SIGNIFICANCE AND USE

4.1 This practice is for use by designers and specifiers, regulatory agencies, owners, and inspection organizations who are involved in the rehabilitation of sewer service laterals and its connection to the main through the use of a resin-impregnated tube installed within an existing sewer lateral. As for any practice, modifications may be required for specific job conditions.

SCOPE

1.1 This practice covers requirements and test methods for the reconstruction of a sewer service lateral pipe having an inner diameter of 3 to 12 in. (7.6 to 30.5 cm) and its connection to the main pipe having an inner diameter of 6 to 24 in. (15.2 to 61.0 cm) and up the lateral a maximum of 150 ft (46 m) without excavation. The lateral pipe is accessed remotely from the main pipe and from a lateral access point. This will be accomplished by the installation of a resin impregnated one-piece main and lateral cured-in-place lining (MLCIPL) by means of air inflation and inversion. The MLCIPL is pressed against the host pipe by pressurizing a bladder and is held in place until the thermoset resins have cured. When cured, the MLCIPL shall be a continuous, one piece, tight fitting, corrosion resistant lining extending over a predetermined length of the lateral pipe and the adjacent section of the main pipe, providing a verifiable non-leaking structural connection and seal.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 There is no similar or equivalent ISO Standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2561 − 20

Standard Practice for

Rehabilitation of a Sewer Service Lateral and Its Connection

to the Main Using a One Piece Main and Lateral Cured-in-

1,2

Place Liner

This standard is issued under the fixed designation F2561; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.3 There is no similar or equivalent ISO Standard.

1.4 This standard does not purport to address all of the

1.1 This practice covers requirements and test methods for

safety concerns, if any, associated with its use. It is the

the reconstruction of a sewer service lateral pipe having an

responsibility of the user of this standard to establish appro-

innerdiameterof3to12in.(7.6to30.5cm)anditsconnection

priate safety, health, and environmental practices and deter-

to the main pipe having an inner diameter of 6 to 24 in. (15.2

mine the applicability of regulatory limitations prior to use.

to 61.0 cm) and up the lateral a maximum of 150 ft (46 m)

1.5 This international standard was developed in accor-

without excavation. The lateral pipe is accessed remotely from

dance with internationally recognized principles on standard-

the main pipe and from a lateral access point. This will be

ization established in the Decision on Principles for the

accomplished by the installation of a resin impregnated one-

Development of International Standards, Guides and Recom-

piece main and lateral cured-in-place lining (MLCIPL) by

mendations issued by the World Trade Organization Technical

means of air inflation and inversion. The MLCIPL is pressed

Barriers to Trade (TBT) Committee.

against the host pipe by pressurizing a bladder and is held in

place until the thermoset resins have cured. When cured, the

2. Referenced Documents

MLCIPL shall be a continuous, one piece, tight fitting, corro-

3

2.1 ASTM Standards:

sion resistant lining extending over a predetermined length of

D618 Practice for Conditioning Plastics for Testing

the lateral pipe and the adjacent section of the main pipe,

D790 Test Methods for Flexural Properties of Unreinforced

providing a verifiable non-leaking structural connection and

and Reinforced Plastics and Electrical Insulating Materi-

seal.

als

1.2 The values stated in inch-pound units are to be regarded

D1600 Terminology forAbbreviatedTerms Relating to Plas-

as standard. The values given in parentheses are mathematical

tics

conversions to SI units that are provided for information only

D2290 Test Method for Apparent Hoop Tensile Strength of

and are not considered standard.

Plastic or Reinforced Plastic Pipe

D3681 TestMethodforChemicalResistanceof“Fiberglass”

(Glass–Fiber–Reinforced Thermosetting-Resin) Pipe in a

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

Deflected Condition

Piping Systems and is the direct responsibility of Subcommittee F17.67 on

D5813 Specification for Cured-In-Place Thermosetting

Trenchless Plastic Pipeline Technology.

Current edition approved March 1, 2020. Published April 2020. Originally

Resin Sewer Piping Systems

approved in 2006. Last previous edition approved in 2017 as F2561–17. DOI:

F412 Terminology Relating to Plastic Piping Systems

10.1520/F2561-20.

2 F1216 Practice for Rehabilitation of Existing Pipelines and

Therehabilitationofasewerservicelateralanditsconnectiontothemainusing

a one-piece main and lateral cured-in-place liner is covered by patents 6,994,118, Conduits by the Inversion and Curing of a Resin-

7,975,726,8,240,340,8,240,341,8,567,451,8,636,036,8,651,145,8,667,991,8,678,

Impregnated Tube

037,8,689,835,9,169,957,9,366,375,9,562,339,9,551,449,(LMKEnterprises,Inc.

1779 Chessie Lane, Ottawa, IL 61350). Interested parties are invited to submit

3

information regarding the identification of acceptable alternatives to this patented For referenced ASTM standards, visit the ASTM website, www.astm.org, or

item to the Committee on Standards, ASTM Headquarters, 100 Barr Harbor Drive, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

West Conshohocken, PA 19428-2959. Your comments will receive careful consid- Standards volume information, refer to the standard’s Document Summary page on

eration at a meeting of the responsible technical committee which may attend. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

----------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2561 − 17 F2561 − 20

Standard Practice for

Rehabilitation of a Sewer Service Lateral and Its Connection

to the Main Using a One Piece Main and Lateral Cured-in-

1,2

Place Liner

This standard is issued under the fixed designation F2561; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers requirements and test methods for the reconstruction of a sewer service lateral pipe having an inner

diameter of 3 to 12 in. (7.6 to 30.5 cm) and its connection to the main pipe having an inner diameter of 6 to 24 in. (15.2 to 61.0

cm) and up the lateral a maximum of 150 ft (46 m) without excavation. The lateral pipe is accessed remotely from the main pipe

and from a lateral access point. This will be accomplished by the installation of a resin impregnated one-piece main and lateral

cured-in-place lining (MLCIPL) by means of air inflation and inversion. The MLCIPL is pressed against the host pipe by

pressurizing a bladder and is held in place until the thermoset resins have cured. When cured, the MLCIPL shall be a continuous,

one piece, tight fitting, corrosion resistant lining extending over a predetermined length of the lateral pipe and the adjacent section

of the main pipe, providing a verifiable non-leaking structural connection and seal.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 There is no similar or equivalent ISO Standard.

1.4 Warning—Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious

medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Caution should

be taken when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for

additional information. Users should be aware that selling mercury or mercury-containing products, or both, may be prohibited by

local or national law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2290 Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.67 on Trenchless Plastic

Pipeline Technology.

Current edition approved Dec. 1, 2017March 1, 2020. Published January 2018April 2020. Originally approved in 2006. Last previous edition approved in 20162017 as

F2561–16.–17. DOI: 10.1520/F2561-17.10.1520/F2561-20.

2

The rehabilitation of a sewer service lateral and its connection to the main using a one-piece main and lateral cured-in-place liner is covered by patents 6,994,118,

7,975,726, 8,240,340, 8,240,341,8,567,451, 8,636,036, 8,651,145, 8,667,991, 8,678,037, 8,689,835, 9,169,957, 9,366,375, 9,562,339, 9,551,449, (LMK Enterprises, Inc. 1779

Chessie Lane, Ottawa, IL 61350). Interested parties are invited to submit information regarding the identification of acceptable alternatives to this patented item to the

Committee on Standards, ASTM Headquarters, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959. Your comments will receive careful consideration at a meeting

of the responsible technical committee which may attend.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.