ASTM C303-10(2016)e1

(Test Method)Standard Test Method for Dimensions and Density of Preformed Block and Board–Type Thermal Insulation

Standard Test Method for Dimensions and Density of Preformed Block and Board–Type Thermal Insulation

SIGNIFICANCE AND USE

5.1 Dimensional measurements of the product thermal insulation are essential in determining compliance of a product with specification limits. Dimensional measurements of various test specimens are also required by the specific test method.

5.2 Density measurements of the product insulation are useful in determining compliance of a product with specification limits, and in providing a relative gage of product weights. For any one kind of insulation, some important physical and mechanical properties, such as thermal conductivity, heat capacity, strength, etc., bear a specific relationship with its density. In order to design for equipment supports, check the material for the “as received density” where the moisture content of the product as received and then installed has the potential to be consequential.

SCOPE

1.1 This test method covers determination of the dimensions and density of block and board insulation as defined in Terminology C168.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: C303 − 10 (Reapproved 2016)

Standard Test Method for

Dimensions and Density of Preformed Block and

Board–Type Thermal Insulation

This standard is issued under the fixed designation C303; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Editorially corrected 5.2 and 6.2 in November 2016.

1. Scope 4. Summary of Test Method

4.1 The material shall be tested in the “dry” condition or in

1.1 Thistestmethodcoversdeterminationofthedimensions

the “as manufactured and received” condition (see Note 1) but

and density of block and board insulation as defined in

the procedure must be consistent with that as given in the

Terminology C168.

materialspecification.Ifthematerialistobetestedinthe“dry”

1.2 The values stated in inch-pound units are to be regarded

condition it shall be dried to constant mass. If the material

as standard. The values given in parentheses are mathematical

specification does not give conditioning instructions, a condi-

conversions to SI units that are provided for information only

tioning environment of 73°F 6 4°F (23°C 6 2°C) and 50 6

and are not considered standard.

5 % relative humidity per Practice C870 shall be used. From

the measured mass and measured dimensions, the density of

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the the product is calculated.

responsibility of the user of this standard to establish appro-

NOTE 1—Some materials may contain volatiles such as moisture when

priate safety and health practices and determine the applica-

manufactured or shipped, or both.

bility of regulatory limitations prior to use.

5. Significance and Use

2. Referenced Documents

5.1 Dimensional measurements of the product thermal in-

sulation are essential in determining compliance of a product

2.1 ASTM Standards:

with specification limits. Dimensional measurements of vari-

C167 Test Methods for Thickness and Density of Blanket or

ous test specimens are also required by the specific test

Batt Thermal Insulations

method.

C168 Terminology Relating to Thermal Insulation

C390 Practice for Sampling and Acceptance of Thermal

5.2 Density measurements of the product insulation are

Insulation Lots

useful in determining compliance of a product with specifica-

C870 Practice for Conditioning of Thermal Insulating Ma-

tion limits, and in providing a relative gage of product weights.

terials

For any one kind of insulation, some important physical and

mechanical properties, such as thermal conductivity, heat

3. Terminology

capacity, strength, etc., bear a specific relationship with its

density. In order to design for equipment supports, check the

3.1 General—Terminology C168 shall be considered as

material for the “as received density” where the moisture

applicable to the terms used in this test method.

content of the product as received and then installed has the

potential to be consequential.

ThistestmethodisunderthejurisdictionofASTMCommitteeC16onThermal

6. Apparatus

Insulation and is the direct responsibility of Subcommittee C16.32 on Mechanical

Properties.

6.1 Steel measure, (ruler or tape), graduated in millimetres

Current edition approved Oct. 15, 2016. Published November 2016. Originally

or better, suitable for measuring dimensions to 6 1.0 % (see

published as approved in 1952. Last previous edition approved in 2010 as

Note 2).

C303 – 10. DOI: 10.1520/C0303-10R16E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.2 Instrument, such as caliper, dial gage, or micrometer

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

graduated in millimetres or better, with a minimum plate

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. diameter of 6 mm, and a maximum plate of 1.0 by 1.0 in. (25

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C303 − 10 (2016)

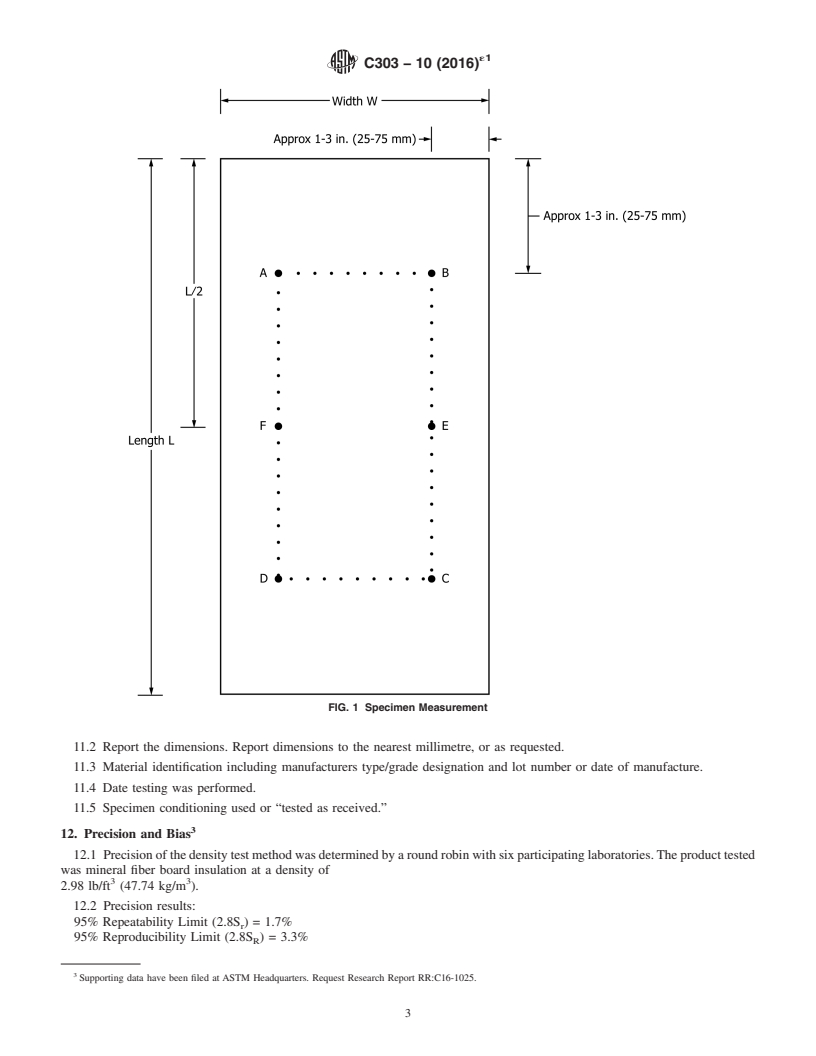

by 25 mm).This instrument shall be suitable for measuring the there shall be an additional two thickness measurements for

2 2

dimensions to 61.0 %. This instrument shall not cause defor- each additional 10 ft (1 m ) in size. These would be in the

mation of the product when measuring it. Ensure that the central section of the specimen as shown by locations E and F.

pressure exerted by this measuring plate does not exceed 0.040 There shall also be an additional length or width measurement

psi or 5psf (0.245 kPa). for each additional meter increase in length or width over 3 ft

(1 m) long. These measurement positions shall be spaced

6.3 Pin probe depth gage per Test Methods C167.

approximately equally within the original measurement area

6.4 Scales,accuratetowithin0.0lb(5g

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: C303 − 10 (Reapproved 2016) C303 − 10 (Reapproved 2016)

Standard Test Method for

Dimensions and Density of Preformed Block and

Board–Type Thermal Insulation

This standard is issued under the fixed designation C303; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Editorially corrected 5.2 and 6.2 in November 2016.

1. Scope

1.1 This test method covers determination of the dimensions and density of block and board insulation as defined in

Terminology C168.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C167 Test Methods for Thickness and Density of Blanket or Batt Thermal Insulations

C168 Terminology Relating to Thermal Insulation

C390 Practice for Sampling and Acceptance of Thermal Insulation Lots

C870 Practice for Conditioning of Thermal Insulating Materials

3. Terminology

3.1 General—Terminology C168 shall be considered as applicable to the terms used in this test method.

4. Summary of Test Method

4.1 The material shall be tested in the “dry” condition or in the “as manufactured and received” condition (see Note 1) but the

procedure must be consistent with that as given in the material specification. If the material is to be tested in the “dry” condition

it shall be dried to constant mass. If the material specification does not give conditioning instructions, a conditioning environment

of 73°F 6 4°F (23°C 6 2°C) and 50 6 5 % relative humidity per Practice C870 shall be used. From the measured mass and

measured dimensions, the density of the product is calculated.

NOTE 1—Some materials may contain volatiles such as moisture when manufactured or shipped, or both.

5. Significance and Use

5.1 Dimensional measurements of the product thermal insulation are essential in determining compliance of a product with

specification limits. Dimensional measurements of various test specimens are also required by the specific test method.

5.2 Density measurements of the product insulation are useful in determining compliance of a product with specification limits,

and in providing a relative gage of product weights. For any one kind of insulation, some important physical and mechanical

properties, such as thermal conductivity, heat capacity, strength, etc., bear a specific relationship with its density. In order to design

This test method is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.32 on Mechanical

Properties.

Current edition approved Oct. 15, 2016. Published November 2016. Originally published as approved in 1952. Last previous edition approved in 2010 as C303 – 10. DOI:

10.1520/C0303-10R16.10.1520/C0303-10R16E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C303 − 10 (2016)

for equipment supports, check the material for the “as received density” where the moisture content of the product as received and

then installed may has the potential to be consequential.

6. Apparatus

6.1 Steel measure, (ruler or tape), graduated in millimetres or better, suitable for measuring dimensions to 6 1.0 % (see Note

2).

6.2 Instrument, such as caliper, dial gage, or micrometer graduated in millimetres or better, with a minimum plate diameter of

6 mm, and a maximum plate of 1.0 by 1.0 in. (25 by 25 mm). This instrument shall be suitable for measuring the dimensions to

61.0 %. This instrument shall not cause deformation of the product when measuring it. The Ensure that the pressure exerted by

this measuring plate shoulddoes not exceed 0.040 psi or 5psf (0.245 kPa).

6.3 Pin probe depth gage per Test Methods C167.

6.4 Scales, accurate to within 0.0lb (5g) or within 1 % of the specimen mass (whichever is less). If the material specification

calls for a greater accuracy, this shall take precedence. If the samples are to be conditioned per Practice C870 the accuracy shall

be within 0.1 %.

6.5 Drying Oven.

NOTE 2—Generally a rule or instrument is used for dimensions les

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.