ASTM D2797/D2797M-11a(2019)

(Practice)Standard Practice for Preparing Coal Samples for Microscopical Analysis by Reflected Light

Standard Practice for Preparing Coal Samples for Microscopical Analysis by Reflected Light

SIGNIFICANCE AND USE

4.1 Briquets of granular bituminous coals and anthracite prepared in accordance with the laboratory procedures of this practice will have flat, scratch-free surfaces suitable for examination with a microscope using reflected light illumination. The polished surfaces of briquettes prepared by this practice will contain particles representative of the original gross sample.

4.2 Samples prepared by this practice are used for microscopical determination of the reflectance of the organic components in a polished specimen of coal (Test Method D2798) and for microscopical determination of the volume percent of physical components of coal (Test Method D2799).

SCOPE

1.1 This practice covers laboratory procedures for the preparation of granular samples of bituminous coal and anthracite samples for examination with a microscope using reflected light illumination. It does not apply to the preparation of oriented blocks of coal.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2797/D2797M −11a (Reapproved 2019)

Standard Practice for

Preparing Coal Samples for Microscopical Analysis by

Reflected Light

This standard is issued under the fixed designation D2797/D2797M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Maceral Composition of Coal

D4596Practice for Collection of Channel Samples of Coal

1.1 This practice covers laboratory procedures for the

in a Mine

preparationofgranularsamplesofbituminouscoalandanthra-

E11Specification forWovenWireTest Sieve Cloth andTest

citesamplesforexaminationwithamicroscopeusingreflected

Sieves

light illumination. It does not apply to the preparation of

oriented blocks of coal.

3. Summary of Practice

1.2 The values stated in either SI units or inch-pound units

3.1 Arepresentativesampleiscrushedtoaspecifiedparticle

are to be regarded separately as standard. The values stated in

size, air-dried, mixed with a binder, and formed into a briquet.

each system may not be exact equivalents; therefore, each

The briquet is then polished to a flat, scratch-free surface for

system shall be used independently of the other. Combining

examination by vertical illumination.

values from the two systems may result in non-conformance

with the standard.

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 Briquets of granular bituminous coals and anthracite

safety concerns, if any, associated with its use. It is the

prepared in accordance with the laboratory procedures of this

responsibility of the user of this standard to establish appro-

practicewillhaveflat,scratch-freesurfacessuitableforexami-

priate safety, health, and environmental practices and deter-

nation with a microscope using reflected light illumination.

mine the applicability of regulatory limitations prior to use.

The polished surfaces of briquettes prepared by this practice

1.4 This international standard was developed in accor-

will contain particles representative of the original gross

dance with internationally recognized principles on standard-

sample.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4.2 Samples prepared by this practice are used for micro-

mendations issued by the World Trade Organization Technical

scopical determination of the reflectance of the organic com-

Barriers to Trade (TBT) Committee.

ponents in a polished specimen of coal (Test Method D2798)

and for microscopical determination of the volume percent of

2. Referenced Documents

physical components of coal (Test Method D2799).

2.1 ASTM Standards:

D2013Practice for Preparing Coal Samples for Analysis

5. Apparatus

D2234/D2234MPractice for Collection of a Gross Sample

5.1 Grinder, Pulverizer, or Mill, for final crushing of the

of Coal

sample to pass a 850-µm (No. 20) sieve. Mortar and pestle or

D2798Test Method for Microscopical Determination of the

other equipment suitable for reducing the particle size of a

Vitrinite Reflectance of Coal

250-gsamplethatalreadypassesa4.75-mm(No.4)sieveuntil

D2799Test Method for Microscopical Determination of the

all of it passes a 850-µm (No. 20) sieve (see 6.5).

5.2 Coarse Riffle Sampler—a riffle with at least twelve

This practice is under the jurisdiction of ASTM Committee D05 on Coal and 1

divisions of not less than 12.7 mm [ ⁄2 in.] and not greater than

Coke and is the direct responsibility of Subcommittee D05.28 on Petrographic

19.1 mm [ ⁄4 in.].

Analysis of Coal and Coke.

Current edition approved Nov. 1, 2019. Published November 2019. Originally

5.3 Fine Riffle Sampler—a riffle with at least twelve divi-

approvedin1969.Lastpreviouseditionapprovedin2011asD2797/D2797M–11a.

sions of not less than 3.2 mm [ ⁄8 in.] and not greater than

DOI: 10.1520/D2797_D2797M-11AR19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6.4mm [ ⁄4 in.].

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.4 Sieves—a 4.75-mm (No. 4) and a 850-µm (No. 20) U.S.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Standard Sieve (Specification E11).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2797/D2797M−11a (2019)

5.5 Molds—containerstoholdthecoalbindermixturewhile 5.9 Containers—if samples are to be transported or stored

the binder hardens. before briquets are prepared, glass jars, bottles, or metal cans

5.5.1 The mold shall be capable of withstanding pressures having tight-fitting closures shall be used. Metal cans shall

upto70MPa[10000psi],andshallbemadeofseparableparts have plastic liners.

so that the briquet can be ejected after it has hardened.

5.5.2 Themoldshallbelargeenoughtoprovideaplanearea 6. Materials

of4cm or more on one side of the briquet. (Designs of

6.1 Binder—Any binding material fulfilling the following

suitable 25-mm [1-in.] and 32-mm [1 ⁄4-in.] inside-diameter

requirements may be used for preparing the coal briquet:

molds are shown in Fig. 1).

6.1.1 Thebindershallholdallcoalparticlessecurelyduring

5.6 Mounting Press—a manual or automated press that is grinding, polishing, and observing the sample.

capableofproducingapressureupto35MPa[5000psi]onthe

6.1.2 The binder and the hardening process used shall not

briquet, and has an attachment to eject the briquet after

react with the coal or the atmosphere or expose the coal to

solidificationofthebinder.Aheat-settingautomatedpressshall

thermal oxidation.

be used with an appropriate thermoset binder.

6.1.3 Under the microscope, the binder shall contrast mark-

edly with constituents being measured when immersed in oil

5.7 Grinding and Polishing Equipment—one or several laps

having an index of refraction of about 1.518.

on which the coal briquet can be ground and polished to a flat,

6.1.4 The binder shall be such that a substantially flat and

scratch-free surface. Laps may be made of aluminum, iron,

scratch-free surface can be obtained as a result of the grinding

brass, bronze, lead, glass, wax, or wood. Equipment that has

and polishing procedure.

203-mm [8-in.] diameter disk laps, gear-driven at 160 to

6.1.4.1 Relief, or difference in level, particularly between

170r⁄min,andthathasanautomaticsampleholderattachment

the coal and the binder, is undesirable for reflectance determi-

is suitable. For notes on grinding and polishing practices, see

nation.Although relief depends a great extent on the polishing

Appendix X1.

technique, use of a binder with a hardness comparable to that

5.8 SampleCleaner—someequipmentisessentialforclean-

of the coal is very helpful.

ing coal briquets between the different grinding or polishing

6.1.4.2 Various types of epoxy resins and heat-setting pow-

stages. This may be a simple stream of water or an air jet, but

ders are suitable as a binder.

an ultrasonic cleaner is recommended.

6.2 Release Agent—Any preparation that does not damage

the molds or adversely affect the coal or mounting medium

may be used to coat the inside of the mold and facilitate

ejection of the briquet.

6.3 Grinding Abrasives—Water-resistant, adhesive-backed

siliconcarbidepapersofgritNos.240,320,400,and600.Two

or three of these are used according to a plan such as one of

those listed in Table 1.

6.4 Polishing Abrasives—Aluminum oxide powders of 3-,

1-,0.3-,0.1-,and0.05-µmsizes.Twoorthreeoftheseareused

according to a plan such as one of those listed in Table 1.

6.5 Lap Coverings—Nap-free cloths of cotton and silk, and

chemotextile material backed with water-resistant adhesive.

6.6 Detergent—Any nonoxidizing detergent may be used

for cleaning briquets after each grinding or polishing stage.

7. Sampling

7.1 Obtain samples of coal in accordance with Practice

D2234/D2234M and Practice D4596, when appropriate.

7.2 If the coal sample has not previously been air dried,

bring the sample to room conditions by exposure to the

laboratory atmosphere.

7.3 Crush and divide the gross sample in accordance with

Practice D2013 to obtain a representative 2.36 mm (No.8 )

sieve size subsample (Note 1). Divide to a minimum weight of

NOTE 1—Material: cold rolled or stainless steel. Dimensions a and b

500g (for cleaned coal) or 1000g (for unknown or all other

(inside diameters) are nominally 32 mm [1 ⁄4 in.] and 25 mm [1 in.]. If an

coals.)

automatic polishing attachment is to be used, these dimensions should be

specified to yield a briquet fitting snugly in the briquet holder.

NOTE 1—The terms gross sample and subsample are defined, and the

FIG. 1Molds Suitable for Briquetting Coal Samples quality and amount of the subsample are specified in Practice D2013.

D2797/D2797M−11a (2019)

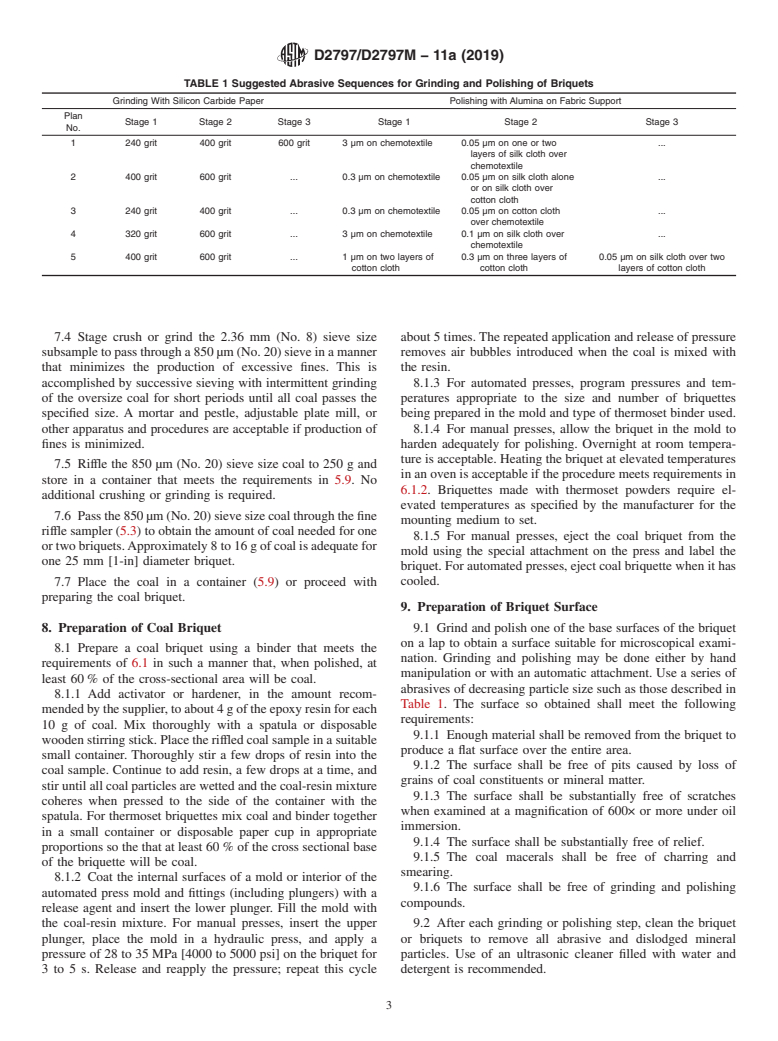

TABLE 1 Suggested Abrasive Sequences for Grinding and Polishing of Briquets

Grinding With Silicon Carbide Paper Polishing with Alumina on Fabric Support

Plan

Stage 1 Stage 2 Stage 3 Stage 1 Stage 2 Stage 3

No.

1 240 grit 400 grit 600 grit 3 µm on chemotextile 0.05 µm on one or t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2797/D2797M − 11a D2797/D2797M − 11a (Reapproved 2019)

Standard Practice for

Preparing Coal Samples for Microscopical Analysis by

Reflected Light

This standard is issued under the fixed designation D2797/D2797M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers laboratory procedures for the preparation of granular samples of bituminous coal and anthracite samples

for examination with a microscope using reflected light illumination. It does not apply to the preparation of oriented blocks of coal.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and

determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D2013 Practice for Preparing Coal Samples for Analysis

D2234/D2234M Practice for Collection of a Gross Sample of Coal

D2798 Test Method for Microscopical Determination of the Vitrinite Reflectance of Coal

D2799 Test Method for Microscopical Determination of the Maceral Composition of Coal

D4596 Practice for Collection of Channel Samples of Coal in a Mine

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

3. Summary of Practice

3.1 A representative sample is crushed to a specified particle size, air-dried, mixed with a binder, and formed into a briquet. The

briquet is then polished to a flat, scratch-free surface for examination by vertical illumination.

4. Significance and Use

4.1 Briquets of granular bituminous coals and anthracite prepared in accordance with the laboratory procedures of this practice

will have flat, scratch-free surfaces suitable for examination with a microscope using reflected light illumination. The polished

surfaces of briquettes prepared by this practice will contain particles representative of the original gross sample.

4.2 Samples prepared by this practice are used for microscopical determination of the reflectance of the organic components in

a polished specimen of coal (Test Method D2798) and for microscopical determination of the volume percent of physical

components of coal (Test Method D2799).

This practice is under the jurisdiction of ASTM Committee D05 on Coal and Coke and is the direct responsibility of Subcommittee D05.28 on Petrographic Analysis

of Coal and Coke.

Current edition approved June 1, 2011Nov. 1, 2019. Published July 2011November 2019. Originally approved in 1969. Last previous edition approved in 2011 as

D2797 – 11.D2797/D2797M – 11a. DOI: 10.1520/D2797_D2797M-11A.10.1520/D2797_D2797M-11AR19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2797/D2797M − 11a (2019)

5. Apparatus

5.1 Grinder, Pulverizer, or Mill, for final crushing of the sample to pass a 850-μm (No. 20) sieve. Mortar and pestle or other

equipment suitable for reducing the particle size of a 250-g sample that already passes a 4.75-mm (No. 4) sieve until all of it passes

a 850-μm (No. 20) sieve (see 6.5).

5.2 Coarse Riffle Sampler—a riffle with at least twelve divisions of not less than 12.7 mm [ ⁄2 in.] and not greater than 19.1 mm

[ ⁄4 in.].

5.3 Fine Riffle Sampler—a riffle with at least twelve divisions of not less than 3.2 mm [ ⁄8 in.] and not greater than 6.4 mm

6.4 mm [ ⁄4 in.].

5.4 Sieves—a 4.75-mm (No. 4) and a 850-μm (No. 20) U.S. Standard Sieve (Specification E11).

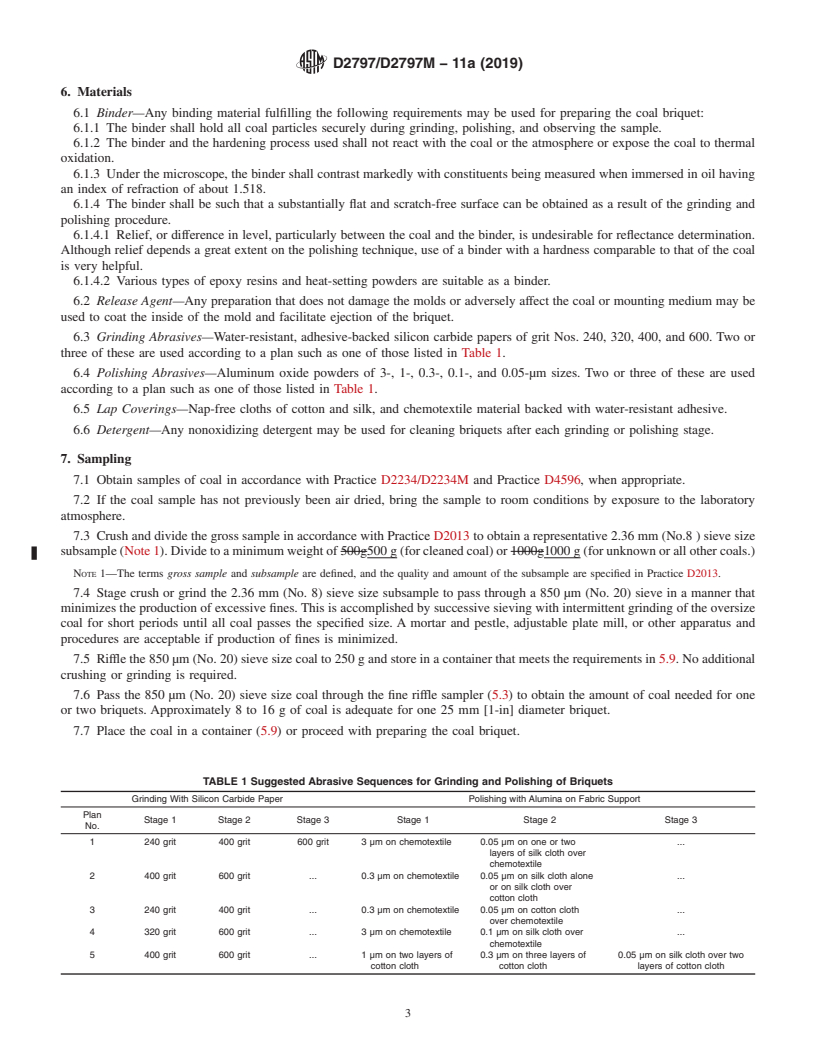

5.5 Molds—containers to hold the coal binder mixture while the binder hardens.

5.5.1 The mold shall be capable of withstanding pressures up to 70 MPa [10 000 psi], and shall be made of separable parts so

that the briquet can be ejected after it has hardened.

5.5.2 The mold shall be large enough to provide a plane area of 4 cm or more on one side of the briquet. (Designs of suitable

25-mm [1-in.] and 32-mm [1 ⁄4-in.] inside-diameter molds are shown in Fig. 1).

5.6 Mounting Press—a manual or automated press that is capable of producing a pressure up to 35 MPa [5000 psi] on the

briquet, and has an attachment to eject the briquet after solidification of the binder. A heat-setting automated press shall be used

with an appropriate thermoset binder.

5.7 Grinding and Polishing Equipment—one or several laps on which the coal briquet can be ground and polished to a flat,

scratch-free surface. Laps may be made of aluminum, iron, brass, bronze, lead, glass, wax, or wood. Equipment that has 203-mm

[8-in.] diameter disk laps, gear-driven at 160 to 170170 r r/min, ⁄min, and that has an automatic sample holder attachment is

suitable. For notes on grinding and polishing practices, see Appendix X1.

5.8 Sample Cleaner—some equipment is essential for cleaning coal briquets between the different grinding or polishing stages.

This may be a simple stream of water or an air jet, but an ultrasonic cleaner is recommended.

5.9 Containers—if samples are to be transported or stored before briquets are prepared, glass jars, bottles, or metal cans having

tight-fitting closures shall be used. Metal cans shall have plastic liners.

NOTE 1—Material: cold rolled or stainless steel. Dimensions a and b (inside diameters) are nominally 32 mm [1 ⁄4 in.] and 25 mm [1 in.]. If an

automatic polishing attachment is to be used, these dimensions should be specified to yield a briquet fitting snugly in the briquet holder.

FIG. 1 Molds Suitable for Briquetting Coal Samples

D2797/D2797M − 11a (2019)

6. Materials

6.1 Binder—Any binding material fulfilling the following requirements may be used for preparing the coal briquet:

6.1.1 The binder shall hold all coal particles securely during grinding, polishing, and observing the sample.

6.1.2 The binder and the hardening process used shall not react with the coal or the atmosphere or expose the coal to thermal

oxidation.

6.1.3 Under the microscope, the binder shall contrast markedly with constituents being measured when immersed in oil having

an index of refraction of about 1.518.

6.1.4 The binder shall be such that a substantially flat and scratch-free surface can be obtained as a result of the grinding and

polishing procedure.

6.1.4.1 Relief, or difference in level, particularly between the coal and the binder, is undesirable for reflectance determination.

Although relief depends a great extent on the polishing technique, use of a binder with a hardness comparable to that of the coal

is very helpful.

6.1.4.2 Various types of epoxy resins and heat-setting powders are suitable as a binder.

6.2 Release Agent—Any preparation that does not damage the molds or adversely affect the coal or mounting medium may be

used to coat the inside of the mold and facilitate ejection of the briquet.

6.3 Grinding Abrasives—Water-resistant, adhesive-backed silicon carbide papers of grit Nos. 240, 320, 400, and 600. Two or

three of these are used according to a plan such as one of those listed in Table 1.

6.4 Polishing Abrasives—Aluminum oxide powders of 3-, 1-, 0.3-, 0.1-, and 0.05-μm sizes. Two or three of these are used

according to a plan such as one of those listed in Table 1.

6.5 Lap Coverings—Nap-free cloths of cotton and silk, and chemotextile material backed with water-resistant adhesive.

6.6 Detergent—Any nonoxidizing detergent may be used for cleaning briquets after each grinding or polishing stage.

7. Sampling

7.1 Obtain samples of coal in accordance with Practice D2234/D2234M and Practice D4596, when appropriate.

7.2 If the coal sample has not previously been air dried, bring the sample to room conditions by exposure to the laboratory

atmosphere.

7.3 Crush and divide the gross sample in accordance with Practice D2013 to obtain a representative 2.36 mm (No.8 ) sieve size

subsample (Note 1). Divide to a minimum weight of 500g500 g (for cleaned coal) or 1000g1000 g (for unknown or all other coals.)

NOTE 1—The terms gross sample and subsample are defined, and the quality and amount of the subsample are specified in Practice D2013.

7.4 Stage crush or grind the 2.36 mm (No. 8) sieve size subsample to pass through a 850 μm (No. 20) sieve in a manner that

minimizes the pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.