ASTM F725-89(1996)

(Practice)Standard Practice for Drafting Impact Test Requirements In Thermoplastic Pipe And Fittings Standards

Standard Practice for Drafting Impact Test Requirements In Thermoplastic Pipe And Fittings Standards

SCOPE

1.1 This practice describes a procedure for setting up impact test requirements on the basis of test data obtained by Test Method D2444.

1.2 This practice is applicable to thermoplastic pipe and fittings.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: F 725 – 89 (Reapproved 1996)

Standard Practice for

Drafting Impact Test Requirements In Thermoplastic Pipe

And Fittings Standards

This standard is issued under the fixed designation F 725; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.5 probability graph paper—commercially available

graph paper that provides straight-line plots when the distribu-

1.1 This practice describes a procedure for setting up impact

tion of attributes is normal.

test requirements on the basis of test data obtained by Test

3.1.6 specification format—the rules set forth by the test

Method D 2444.

requirement, including the number of specimens to be tested

1.2 This practice is applicable to thermoplastic pipe and

and the minimum acceptable number of passes.

fittings.

3.1.7 standard deviation—a statistical term that relates to

1.3 This standard does not purport to address all of the

the size of the expected variation in test results.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

NOTE 2—The terms “mean,” “normal distribution,” and “standard

priate safety and health practices and determine the applica- deviation” are dealt with in elementary statistics textbooks.

bility of regulatory limitations prior to use.

4. Summary of Practice

2. Referenced Documents

4.1 Round-robin tests of representative pipe and fittings

2.1 ASTM Standards: specimens are performed to identify the energy levels at which

D 2444 Test Method for Impact Resistance of Thermoplas- 90 % or more of the specimens in acceptable lots will pass. A

tic Pipe and Fittings by Means of a Tup (Falling Weight) preferred test format is listed. The B-tup and the V-block

holder, and room-temperature conditioning and tests are pre-

3. Terminology

ferred choices.

3.1 Definitions of Terms Specific to This Standard:

5. Significance and Use

3.1.1 binomial probability equation—the equation that de-

fines the chance for exactly r specimens to pass, when n are 5.1 This practice is used for drafting impact test specifica-

tested, given p, the chance that a single specimen chosen at tion requirements, and it presupposes no special familiarity

random will pass. It is expressed as follows: with statistical methods. It provides for specification values

that will pass acceptable lots with a high degree of certainty.

n!

r n2r

P 5 p ~1 2 p! (1)

r n The impact test requirement is intended to discriminate be-

r!~n–r!!

tween acceptable materials and manufacturing methods and

those which are not; it is not a simulated service test.

NOTE 1—The factorial of zero is one.

6. Procedure

3.1.2 binomial test—a test that has only two possible results

(for example, pass or fail, heads or tails, true or false).

6.1 Test thermoplastic pipe or fittings specimens in accor-

3.1.3 mean strength—the average strength of the total

dance with Test Method D 2444, and plot the test results on

population (see Note 2).

probability graph paper.

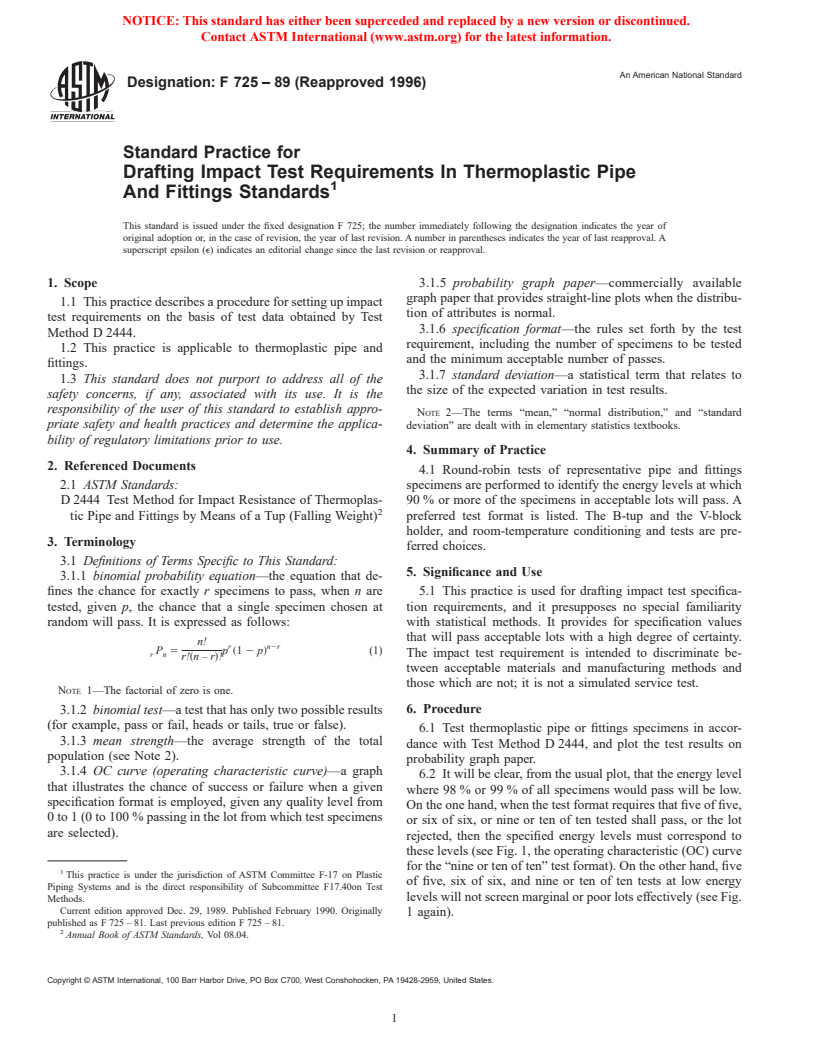

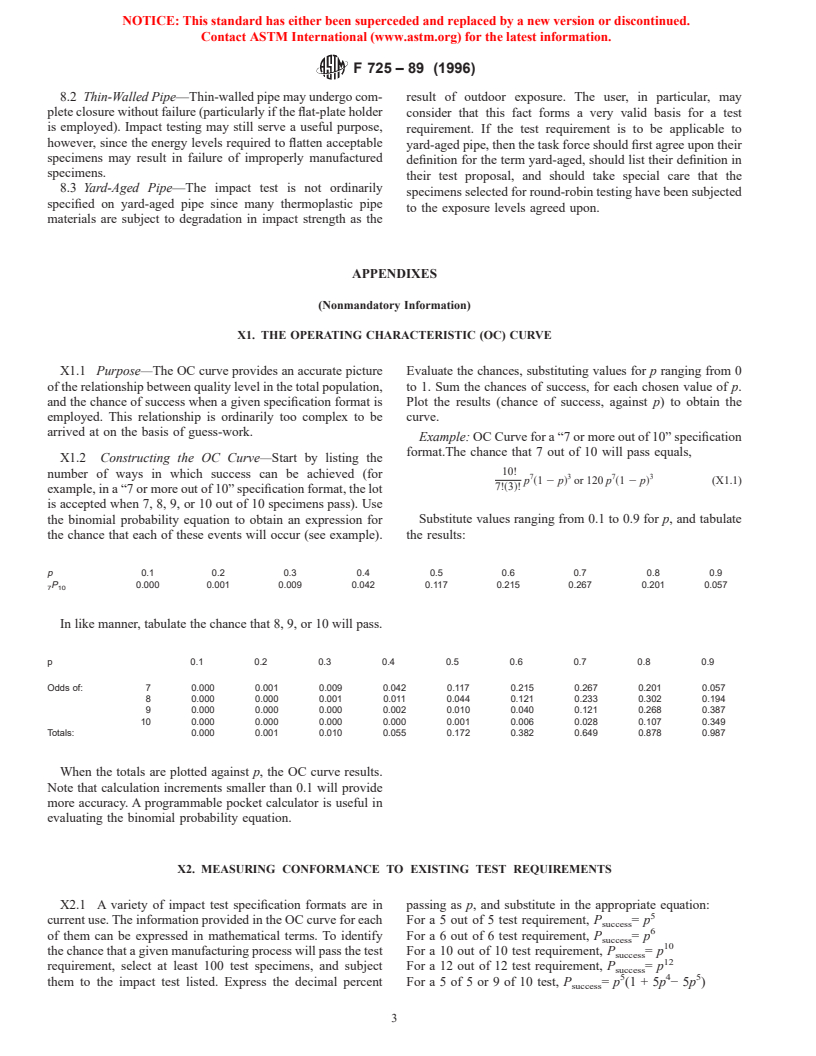

3.1.4 OC curve (operating characteristic curve)—a graph

6.2 It will be clear, from the usual plot, that the energy level

that illustrates the chance of success or failure when a given

where 98 % or 99 % of all specimens would pass will be low.

specification format is employed, given any quality level from

On the one hand, when the test format requires that five of five,

0 to 1 (0 to 100 % passing in the lot from which test specimens

or six of six, or nine or ten of ten tested shall pass, or the lot

are selected).

rejected, then the specified energy levels must correspond to

these levels (see Fig. 1, the operating characteristic (OC) curve

for the “nine or ten of ten” test format). On the other hand, five

This practice is under the jurisdiction of ASTM Committee F-17 on Plastic

of five, six of six, and nine or ten of ten tests at low energy

Piping Systems and is the direct responsibility of Subcommittee F17.40on Test

levels will not screen marginal or poor lots effectively (see Fig.

Methods.

Current edition approved Dec. 29, 1989. Published February 1990. Originally

1 again).

published as F 725 – 81. Last previous edition F 725 – 81.

Annual Book of ASTM Standards, Vol 08.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 725 – 89 (1996)

concentration, and for failures in a range of thin-walled

specimens which would merely flatten on the flat-plate holder.

6.6 Test Conditions—Room-temperature tests are preferred.

They can be performed by the manufacturer on a timely basis,

so that the size of questionable or defective inventories is

minimized. Binomial tests are relatively crude, unless large

numbers of specimens are subjected to test. The expense and

inconvenience of low-temperature conditioning render it a poor

choice (study Fig. 1 together with a data plot performed in

accordance with Test Method D 2444 to fully grasp the merits

of this statement).

7. Multiple-Product Standards

7.1 Many thermoplastic pipe and fittings specifications list

large numbers of products. Test Method D 2444 requires that at

least 100 test specimens shall be employed for each single test

run in order that the impact properties can be measured with

useful accuracy. The cost of round-robin tests on each size of

FIG. 1 O.C. Curve for Nine or Ten of Ten

the products in the standard may approach or exceed the value

of the information to be obtained.

6.3 A format which will accept reliably when 90 % or more

7.2 Testing costs can be significantly reduced by performing

of the specimens in acceptable lots would pass, and reject preliminary tests on the largest sizes listed, to determine

reliably when 60 % or fewer would pass, is as follows:

whether or not a cut-off point exists above which all specimens

6.3.1 “X.X Test ten specimens. When nine or ten pass, will pass at an energy level of 300 ft·lbf (407 J) (ordinarily the

accept the lot. When six or fewer pass, reject the lot. When

highest test energy level listed in a thermoplastic pipe or

seven or eight pass, test ten additional specimens. When 17 or fittings impact test requirement).

more of 20 pass, accept the lot. When 13 or fewer of 20 pass,

7.2.1 Following these tests, a limited number of represen-

reject the lot. When 14, 15, or 16 pass, test 20 additional tative sizes can be selected, and round-robin testing performed.

specimens. When 32 or more of 40 pass, accept the lot. When

7.2.2 The results of these tests are analyzed. List the energy

31 or fewer pass, reject the lot.”

levels where the failure level was 10 % for each size tested, and

6.3.2 The OC curve for this format is illustrated in Fig. 2.

divide the energy levels by the specimen volumes in cubic

6.4 Specimen Length—The pipe specimen length should be

inches. Plot the results against the specimen outside diameters,

6 in. (150 mm).

and label the points if it is a multiple SDR specification. In a

6.5 Choice of Tup and Holder—The B tup is preferred. It

specification which included 25 sizes of pipe, and seven SDR

provides a good compromise between energy concentration in

series,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.