ASTM E69-15

(Test Method)Standard Test Method for Combustible Properties of Treated Wood by the Fire-Tube Apparatus

Standard Test Method for Combustible Properties of Treated Wood by the Fire-Tube Apparatus

SIGNIFICANCE AND USE

4.1 The purpose of this test method is to provide a relative measurement of the combustibility of fire-retardant-treated wood specimens based on their percentage loss in weight under controlled fire exposure conditions (1).3 In addition, other possible data include rate of weight loss, time of flaming and afterglowing, increase in temperature, and maximum vertical flame progress.

4.2 This test method is not sufficiently large scale to evaluate the suitability of a given treated product for building construction, but it is a convenient method to use for purposes of development or as a quality-control test during manufacture.

4.3 This test method gives a procedure for sampling and preparation of test specimens from a lot of treated material in which complete penetration is a requirement. A procedure is also given for the sampling of charges at a treating plant for purposes of quality control of the treatment process.

4.4 This test method has proven useful for evaluating comparative fire performance effectiveness of fire-retardant chemicals and treatment formulations for wood and wood products (2-5).

4.5 In this test method, the specimens are subjected to one or more specific sets of laboratory test conditions. If different test conditions are substituted or the anticipated end-use conditions are changed, it may not be possible by or from this test method to predict changes in the fire-test-response characteristics measured. Therefore, the results are valid only for the fire test exposure conditions described in this procedure.

SCOPE

1.1 This test method covers fire-tube test procedures for fire tests for combustible properties of wood treated to reduce flammability. This test method relates to properties of treated wood, as such, rather than to the performance of a fabrication used as an element of construction. Performance under this test method shall be as prescribed in requirements applicable to materials intended for specific uses.

1.2 This test method is a fire-test-response standard.

1.3 The SI values given in parentheses are provided for information purposes only.

1.4 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E69 − 15

Standard Test Method for

Combustible Properties of Treated Wood by the Fire-Tube

1

Apparatus

This standard is issued under the fixed designation E69; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers fire-tube test procedures for fire 3.1 Definitions—For definitions of terms found in this test

tests for combustible properties of wood treated to reduce method, refer to Terminologies D9 and E176.

flammability. This test method relates to properties of treated

4. Significance and Use

wood, as such, rather than to the performance of a fabrication

used as an element of construction. Performance under this test

4.1 The purpose of this test method is to provide a relative

method shall be as prescribed in requirements applicable to

measurement of the combustibility of fire-retardant-treated

materials intended for specific uses.

woodspecimensbasedontheirpercentagelossinweightunder

3

controlled fire exposure conditions (1). In addition, other

1.2 This test method is a fire-test-response standard.

possible data include rate of weight loss, time of flaming and

1.3 The SI values given in parentheses are provided for

afterglowing, increase in temperature, and maximum vertical

information purposes only.

flame progress.

1.4 This standard is used to measure and describe the

4.2 This test method is not sufficiently large scale to

response of materials, products, or assemblies to heat and

evaluate the suitability of a given treated product for building

flame under controlled conditions, but does not by itself

construction, but it is a convenient method to use for purposes

incorporate all factors required for fire hazard or fire risk

of development or as a quality-control test during manufacture.

assessment of the materials, products, or assemblies under

4.3 This test method gives a procedure for sampling and

actual fire conditions.

preparation of test specimens from a lot of treated material in

1.5 This standard does not purport to address all of the

which complete penetration is a requirement. A procedure is

safety concerns, if any, associated with its use. It is the

also given for the sampling of charges at a treating plant for

responsibility of the user of this standard to establish appro-

purposes of quality control of the treatment process.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 4.4 This test method has proven useful for evaluating

1.6 Fire testing is inherently hazardous. Adequate safe- comparative fire performance effectiveness of fire-retardant

guards for personnel and property shall be employed in chemicals and treatment formulations for wood and wood

conducting these tests. products (2-5).

4.5 In this test method, the specimens are subjected to one

2. Referenced Documents

or more specific sets of laboratory test conditions. If different

2

2.1 ASTM Standards: test conditions are substituted or the anticipated end-use

D9 Terminology Relating to Wood and Wood-Based Prod-

conditions are changed, it may not be possible by or from this

ucts test method to predict changes in the fire-test-response char-

E176 Terminology of Fire Standards

acteristics measured. Therefore, the results are valid only for

the fire test exposure conditions described in this procedure.

1

This test method is under the jurisdiction of ASTM Committee D07 on Wood 5. Apparatus

and is the direct responsibility of Subcommittee D07.07 on Fire Performance of

5.1 The apparatus for conducting the fire-tube test shall

Wood.

Current edition approved Dec. 1, 2015. Published February 2016. Originally consist of the fire-tube assembly and accessory equipment as

approved in 1946. Last previous edition approved in 2007 as E69 – 02 (2007). DOI:

follows:

10.1520/E0069-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to the list of references at the end of

the ASTM website. this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

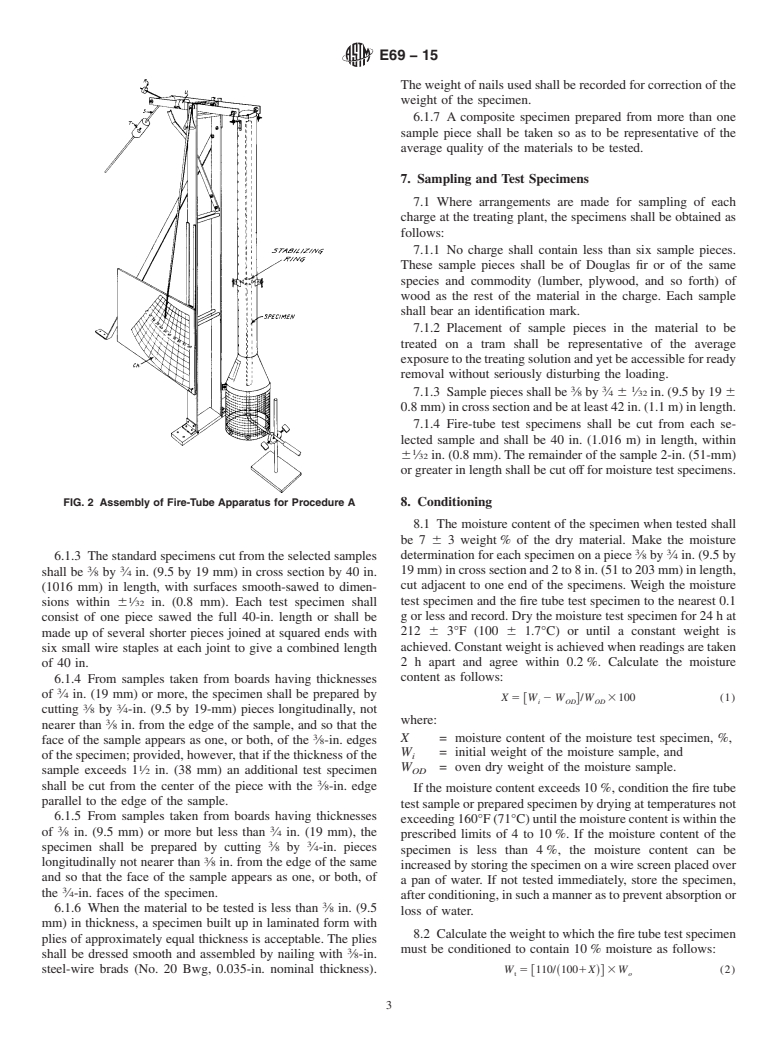

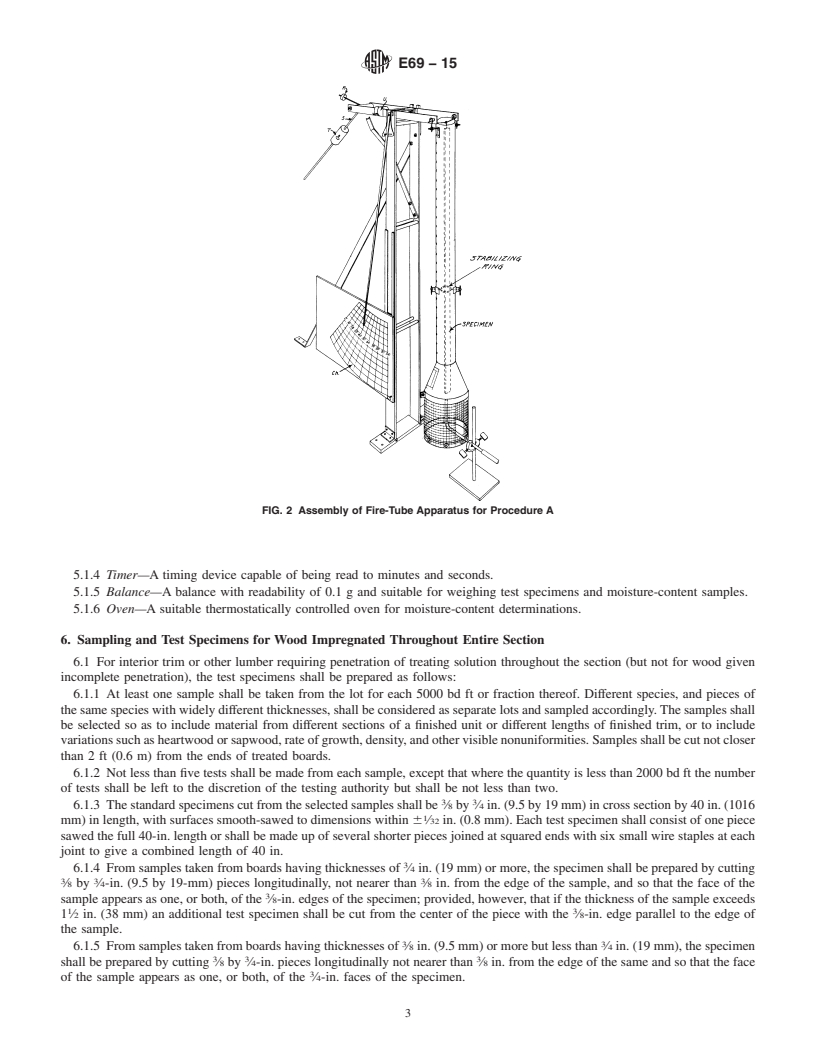

E69−15

5.1.1 Fire-Tube Assembly—A specially constructed balance 5.1.6 Oven—Asuitable thermostatically controlled oven for

designed to indicate directly the percentage loss of weight moisture-content determinations.

suffered by the test specimen when exposed to a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E69 − 02 (Reapproved 2007) E69 − 15

Standard Test Method for

Combustible Properties of Treated Wood by the Fire-Tube

1

Apparatus

This standard is issued under the fixed designation E69; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers fire-tube test procedures for fire tests for combustible properties of wood treated to reduce

flammability. This test method relates to properties of treated wood, as such, rather than to the performance of a fabrication used

as an element of construction. Performance under this test method shall be as prescribed in requirements applicable to materials

intended for specific uses.

1.2 This test method is a fire-test-response standard.

1.3 The SI values given in parentheses are provided for information purposes only.

1.4 This standard should be used to measure and describe the properties of materials, products, or assemblies in response to

heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk

of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire

risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular

end use. This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials,

products, or assemblies under actual fire conditions.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.6 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these

tests.

2. Referenced Documents

2

2.1 ASTM Standards:

D9 Terminology Relating to Wood and Wood-Based Products

E176 Terminology of Fire Standards

3. Terminology

3.1 Definitions—For definitions of terms found in this test method, refer to Terminologies D9 and E176.

4. Significance and Use

4.1 The purpose of this test method is to provide a relative measurement of the combustibility of fire-retardant-treated wood

3

specimens based on their percentage loss in weight under controlled fire exposure conditions (1). In addition, other possible data

include rate of weight loss, time of flaming and afterglowing, increase in temperature, and maximum vertical flame progress.

4.2 This test method is not sufficiently large scale to evaluate the suitability of a given treated product for building construction,

but it is a convenient method to use for purposes of development or as a quality-control test during manufacture.

1

This test method is under the jurisdiction of ASTM Committee D07 on Wood and is the direct responsibility of Subcommittee D07.07 on Fire Performance of Wood.

Current edition approved April 1, 2007Dec. 1, 2015. Published April 2007February 2016. Originally approved in 1946. Last previous edition approved in 20022007 as

E69 – 02.E69 – 02 (2007). DOI: 10.1520/E0069-02R07.10.1520/E0069-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The boldface numbers in parentheses refer to the list of references at the end of this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E69 − 15

4.3 This test method gives a procedure for sampling and preparation of test specimens from a lot of treated material in which

complete penetration is a requirement. A procedure is also given for the sampling of charges at a treating plant for purposes of

quality control of the treatment process.

4.4 This test method has proven useful for evaluating comparative fire performance effectiveness of fire-retardant chemicals and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.