ASTM D5167-10

(Practice)Standard Practice for Melting of Hot-Applied Joint and Crack Sealant and Filler for Evaluation

Standard Practice for Melting of Hot-Applied Joint and Crack Sealant and Filler for Evaluation

SIGNIFICANCE AND USE

It is intended that this practice be used by manufacturers, users, and testing agencies. The use of this practice establishes a uniform procedure for the melting or heating of hot-applied sealants and fillers. It is not intended to establish test procedures or conditions of test which are associated with each of the joint sealants and fillers.

SCOPE

1.1 This practice establishes the procedure for melting or heating, or both, of hot-applied joint and crack sealants and fillers in preparation for the making of test specimens used in the laboratory evaluations of the sealants and fillers. Refer to the specific standard material specification for sampling requirements, test sample quantity, temperatures and times for melting and heating, and the number of specimens required for testing.

1.2 This practice is applicable to the hot-applied joint and crack sealants and fillers used in both portland cement and asphaltic-concrete pavements.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 WARNING– Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website – http://www.epa.gov/mercury/faq.htm - for additional information. Users should be aware that selling mercury and/or mercury containing products into your state may be prohibited by state law.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautions see Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5167 − 10

StandardPractice for

Melting of Hot-Applied Joint and Crack Sealant and Filler for

1

Evaluation

This standard is issued under the fixed designation D5167; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This practice establishes the procedure for melting or 2.1 ASTM Standards:

heating, or both, of hot-applied joint and crack sealants and D5535 Terminology Relating to Formed-in-Place Sealants

3

fillers in preparation for the making of test specimens used in for Joints and Cracks in Pavements (Withdrawn 2009)

the laboratory evaluations of the sealants and fillers. Refer to E1 Specification for ASTM Liquid-in-Glass Thermometers

the specific standard material specification for sampling E220 Test Method for Calibration of Thermocouples By

requirements, test sample quantity, temperatures and times for Comparison Techniques

melting and heating, and the number of specimens required for E171 Practice for Conditioning and Testing Flexible Barrier

testing. Packaging

1.2 This practice is applicable to the hot-applied joint and

3. Terminology

crack sealants and fillers used in both portland cement and

3.1 Definitions—Refer to Terminology D5535 for defini-

asphaltic-concrete pavements.

tions of the following terms used in this specification: maxi-

1.3 The values stated in either SI units or inch-pound units

mum heating temperature, minimum application temperature.

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each

4. Significance and Use

system shall be used independently of the other. Combining

4.1 It is intended that this practice be used by

values from the two systems may result in non-conformance

manufacturers, users, and testing agencies. The use of this

with the standard.

practice establishes a uniform procedure for the melting or

1.4 WARNING– Mercury has been designated by EPAand

heating of hot-applied sealants and fillers. It is not intended to

many state agencies as a hazardous material that can cause

establish test procedures or conditions of test which are

central nervous system, kidney and liver damage. Mercury, or

associated with each of the joint sealants and fillers.

its vapor, may be hazardous to health and corrosive to

materials. Caution should be taken when handling mercury and

5. Standard Conditions

mercury containing products. See the applicable product Ma-

5.1 The laboratory atmospheric conditions, hereinafter re-

terial Safety Data Sheet (MSDS) for details and EPA’s website

ferred to as standard conditions, shall be as detailed in

– http://www.epa.gov/mercury/faq.htm - for additional infor-

SpecificationE171,23 62°C(73.4 63.6°F)and50 %relative

mation. Users should be aware that selling mercury and/or

humidity 65 %. The material shall be conditioned for 24 h at

mercury containing products into your state may be prohibited

standard conditions before melting or heating.

by state law.

1.5 This standard does not purport to address all of the

6. Apparatus

safety concerns, if any, associated with its use. It is the

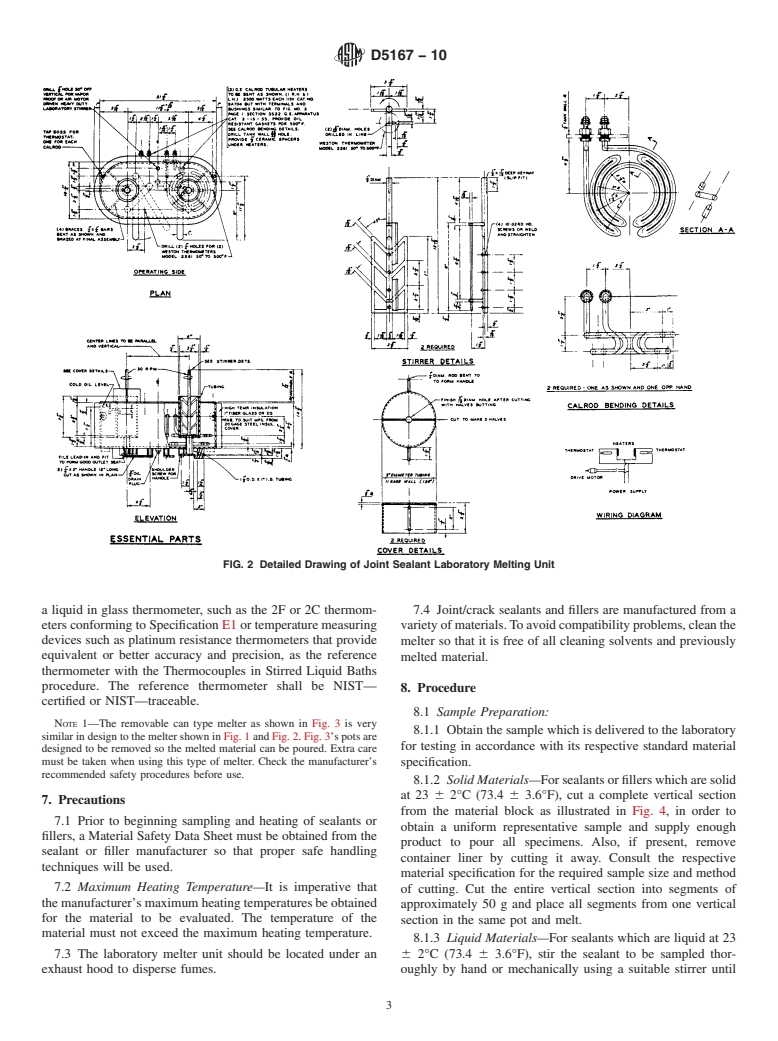

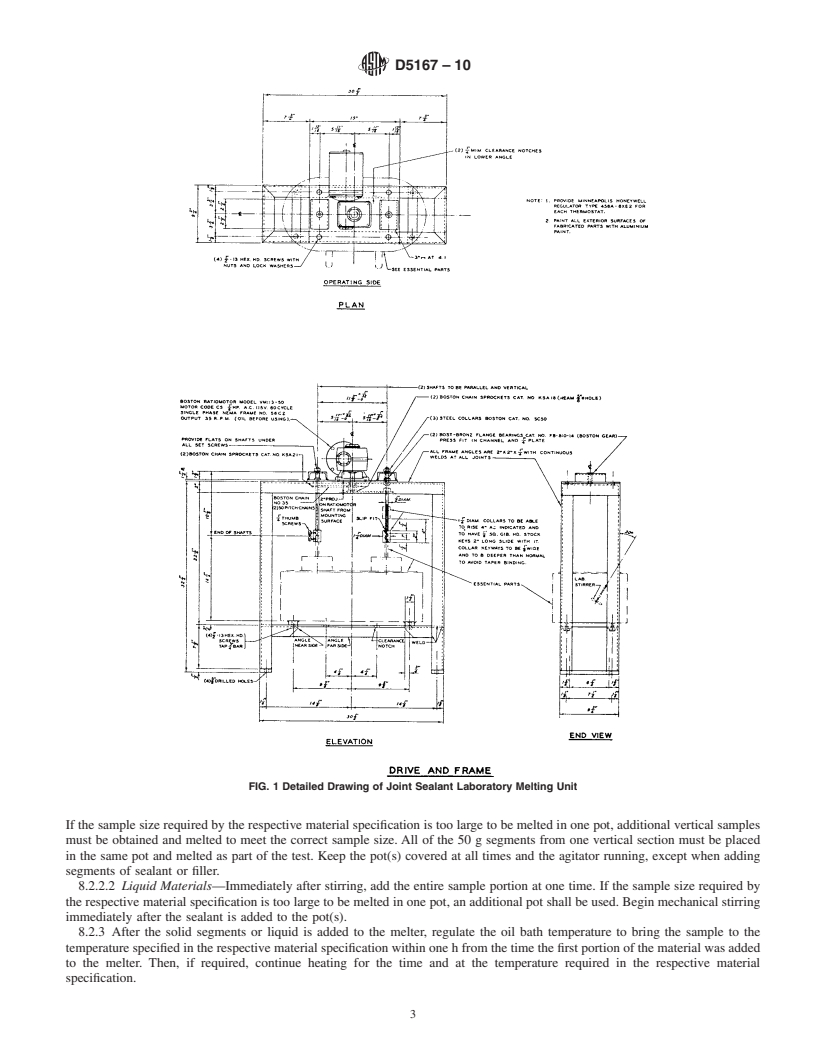

6.1 Laboratory Melter:

responsibility of the user of this standard to establish appro-

6.1.1 The equipment for melting of the joint sealant or filler

priate safety and health practices and determine the applica-

shall be an oil jacketed melter equipped with a mechanical

bility of regulatory limitations prior to use. For specific

agitator for the oil bath and material in the melting vat.

precautions see Section 7.

1 2

This practice is under the jurisdiction of ASTM Committee D04 on Road and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Paving Materials and is the direct responsibility of Subcommittee D04.33 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Formed In-Place Sealants for Joints and Cracks in Pavements. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2010. Published March 2011. Originally the ASTM website.

3

approved in 1991. Last previous edition approved in 2003 as D5167 – 03. DOI: The last approved version of this historical standard is referenced on

10.1520/D5167-10. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5167 − 10

6.1.2 The heat transfer oil shall be a high flash point oil, that 6.1.5 Except when adding the sealant or filler sample, or

is, in excess of 315°C (600°F). checking temperature, t

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5167–03 Designation: D5167 – 10

Standard Practice for

Melting of Hot-Applied Joint and Crack Sealant and Filler for

1

Evaluation

This standard is issued under the fixed designation D5167; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice establishes the procedure for melting or heating, or both, of hot-applied joint and crack sealants and fillers in

preparation for the making of test specimens used in the laboratory evaluations of the sealants and fillers. Refer to the specific

standard material specification for sampling requirements, test sample quantity, temperatures and times for melting and heating,

and the number of specimens required for testing.

1.2 This practice is applicable to the hot-applied joint and crack sealants and fillers used in both portland cement and

asphaltic-concrete pavements.

1.3The values stated in SI units are to be regarded as the standard. The values in parentheses are provided for information

purposes only.

1.4

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4 WARNING– Mercury has been designated by EPAand many state agencies as a hazardous material that can cause central

nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website – http://www.epa.gov/mercury/faq.htm - for additional information. Users should be aware

that selling mercury and/or mercury containing products into your state may be prohibited by state law.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific precautions see Section 7.

2. Referenced Documents

2

2.1 ASTM Standards:

D5535 Terminology Relating to Formed-in-Place Sealants for Joints and Cracks in Pavements

E1 Specification for ASTM Liquid-in-Glass Thermometers

E77Test Method for Inspection and Verification of Thermometers 220 Test Method for Calibration of Thermocouples By

Comparison Techniques

E171 Specification for Atmospheres for Conditioning and Testing Flexible Barrier Materials

3. Terminology

3.1 Definitions—RefertoTerminologyD5535fordefinitionsofthefollowingtermsusedinthisspecification: maximum heating

temperature, minimum application temperature.

4. Significance and Use

4.1 It is intended that this practice be used by manufacturers, users, and testing agencies. The use of this practice establishes

a uniform procedure for the melting or heating of hot-applied sealants and fillers. It is not intended to establish test procedures or

conditions of test which are associated with each of the joint sealants and fillers.

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.33 on Formed-

In-Place Sealants for Joints and Cracks in Pavements.

Current edition approved July 10, 2003.Dec. 1, 2010. Published September 2003.March 2011. Originally approved in 1991. Last previous edition approved in 19972003

as D5167–91 (1997). D5167 – 03. DOI: 10.1520/D5167-103.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5167 – 10

5. Standard Conditions

5.1 The laboratory atmospheric conditions, hereinafter referred to as standard conditions, shall be as detailed in Specification

E171171,, 23 6 2°C (73.4 6 3.6°F) and 50 % relative humidity 65 %. The material shall be conditioned

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.