ASTM B622-04

(Specification)Standard Specification for Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube

Standard Specification for Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube

SCOPE

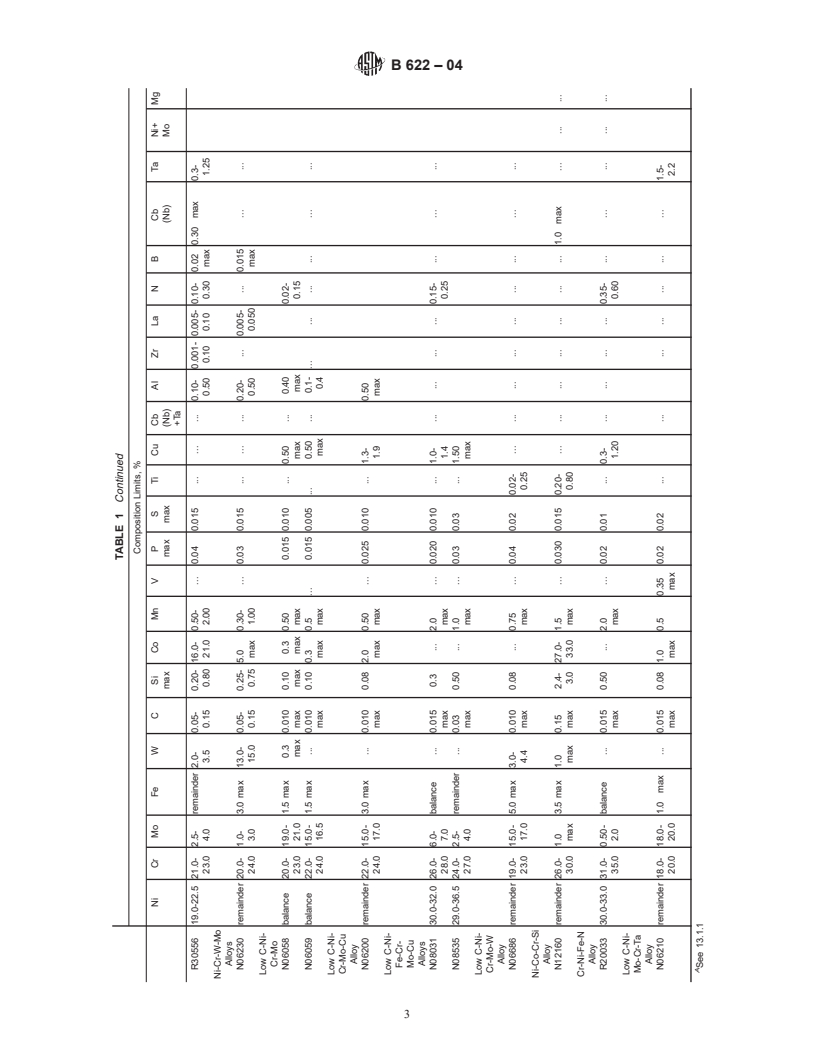

1.1 This specification covers seamless pipe and tube of nickel and nickel-cobalt alloys (UNS N10001, UNS N10242, UNS N10665, UNS N12160, UNS N10675, UNS N10276, UNS N06455, UNS N06007, UNS N08320, UNS N06975, UNS N06002, UNS N06985, UNS N06022, UNS N06035, UNS N08135, UNS N06255, UNS N06058, UNS N06059, UNS N06200, UNS N06030, UNS N08031, UNS R30556, UNS N08535, UNS N06250, UNS N06060, UNS N06230, UNS N06686, UNS N10629, UNS N06210, UNS N10624, and UNS R20033)* as shown in Table 1.

1.2 Pipe and tube shall be supplied in the solution annealed and descaled condition. When atmosphere control is used, descaling is not necessary.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 622 – 04

Standard Specification for

1

Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube

This standard is issued under the fixed designation B 622; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* E 8 Test Methods for Tension Testing of Metallic Materials

2

E 29 Practice for Using Significant Digits in Test Data to

1.1 This specification covers seamless pipe and tube of

Determine Conformance with Specifications

nickel and nickel-cobalt alloys (UNS N10001, UNS N10242,

E 55 Practice for Sampling Wrought Nonferrous Metals and

UNS N10665, UNS N12160, UNS N10675, UNS N10276,

Alloys for Determination of Chemical Composition

UNS N06455, UNS N06007, UNS N08320, UNS N06975,

E 1473 Test Methods for Chemical Analysis of Nickel,

UNS N06002, UNS N06985, UNS N06022, UNS N06035,

Cobalt, and High-Temperature Alloys

UNS N08135, UNS N06255, UNS N06058, UNS N06059,

UNS N06200, UNS N06030, UNS N08031, UNS R30556,

3. Terminology

UNS N08535, UNS N06250, UNS N06060, UNS N06230,

3.1 Definitions:

UNS N06686, UNS N10629, UNS N06210, UNS N10624, and

3.1.1 average diameter, n—the average of the maximum

UNS R20033)* as shown in Table 1.

and minimum outside diameters, or the maximum and mini-

1.2 Pipe and tube shall be supplied in the solution annealed

mum inside diameters, as determined at any cross section of

and descaled condition. When atmosphere control is used,

the tube.

descaling is not necessary.

3.1.2 pipe, n—seamless tube conforming to the particular

1.3 The values stated in inch-pound units are to be regarded

dimensions commercially known as standard pipe sizes (Ap-

as the standard. The values given in parentheses are for

pendix X2).

information only.

3.1.3 tube, n—a hollow product of round or any other cross

1.4 This standard does not purport to address all of the

section having a continuous periphery.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to become familiar

4. Ordering Information

with all hazards including those identified in the appropriate

4.1 It is the responsibility of the purchaser to specify all

Material Safety Data Sheet for this product/material as pro-

requirements that are necessary for material ordered under this

vided by the manufacturer, to establish appropriate safety and

specification. Examples of such requirements include, but are

health practices, and determine the applicability of regulatory

not limited to the following:

limitations prior to use.

4.1.1 Alloy (Table 1).

4.1.2 Dimensions:

2. Referenced Documents

3 4.1.2.1 Tube—Outside diameter, minimum or average wall

2.1 ASTM Standards:

thickness, and length.

B 880 Specification for General Requirements for Chemical

4.1.2.2 Pipe—Standard pipe size and schedule (Appendix

Check Analysis Limits for Nickel, Nickel Alloys and

X2).

Cobalt Alloys

4.1.3 Ends—Plain ends cut and deburred will be furnished.

4.1.4 Certification—State if certification or a report of test

1

This specification is under the jurisdiction of ASTM Committee B02 on results is required (Section 16).

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

4.1.5 Samples for Check Analysis—State whether samples

B02.07 on Refined Nickel and Cobalt and Their Alloys.

for check analysis should be furnished (10.2.2).

Current edition approved Feb. 1, 2004. Published February 2004. Originally

4.1.6 Purchaser Inspection—If the purchaser wishes to

approved in 1977. Last previous edition approved in 2000 as B 622 – 00.

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

witness tests or inspection of material at the place of manu-

cation SB-622 in Section II of that Code.

facture, the purchase order must so state, indicating which tests

* New designation established in accordance with ASTM E 527 and SAE J1086,

or inspections are to be witnessed (Section 14).

Practice for Numbering Metals and Alloys (UNS).

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B622–04

2

TABLE 1 Chemical Requirements

Composition Limits, %

Ni Cr Mo Fe W C Si Co Mn V P S Ti Cu Cb Al Zr La N B Cb Ta Ni+ Mg

max max max (Nb) (Nb) Mo

+Ta

Ni-Mo Alloys

A

N10001 remainder 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.