ASTM F2619/F2619M-11

(Specification)Standard Specification for High-Density Polyethylene (PE) Line Pipe

Standard Specification for High-Density Polyethylene (PE) Line Pipe

ABSTRACT

This specification covers the requirements and test methods for high-density polyethylene (PE) materials, line pipes, and fittings used in pressure or non-pressure oil and gas producing applications to convey fluids such as oil, dry or wet gas, multiphase fluids, and non-potable oilfield water. This specification does not apply to pipes for gas distribution applications. PE material compounds suitable for use in the manufacture of pipes and fittings under this specification shall adhere to values of the following properties: density (natural base resin), melt index, flexural modulus, tensile strength at yield, SCG resistance, hydrostatic strength, color and UV stabilization, hydrostatic design stress, and hydrostatic design basis. The line pipes shall meet specific requirements as to workmanship, dimensions (outside diameter, toe-in, outside surface irregularity, ovality, wall thickness, and special sizes), inside surface ductility, tensile elongation, bendback resistance, elevated temperature sustained pressure, short-term strength and pressurization, apparent tensile strength at yield, and carbon black content. And conversely, PE fittings shall be manufactured in accordance with their intended use with correspondingly sized PE line pipes, as follows: socket fusion fittings, butt fusion fittings, electrofusion fittings, fabricated fittings, and transition fittings.

SCOPE

1.1 This specification covers requirements and test methods for high-density polyethylene (PE) materials, pipe and fittings for pressure or non-pressure oil and gas producing applications to convey fluids such as oil, dry or wet gas, multiphase fluids, and non-potable oilfield water. This specification does not cover pipe for gas distribution applications.

1.1.1 For the purposes of this specification, high-density polyethylene material is Specification D 3350 density cell classification 3 or higher. This specification does not cover materials having Specification D 3350 density cell classification less than 3 such as medium or low density polyethylene materials.

1.2 Units—The values stated in either SI or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of each other. Combining values from the two systems may result in non-compliance with the standard. Values in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2619/F2619M −11 AnAmerican National Standard

Standard Specification for

1

High-Density Polyethylene (PE) Line Pipe

ThisstandardisissuedunderthefixeddesignationF2619/F2619M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D1598Test Method for Time-to-Failure of Plastic Pipe

Under Constant Internal Pressure

1.1 This specification covers requirements and test methods

D1599Test Method for Resistance to Short-Time Hydraulic

for high-density polyethylene (PE) materials, pipe and fittings

Pressure of Plastic Pipe, Tubing, and Fittings

forpressureornon-pressureoilandgasproducingapplications

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

to convey fluids such as oil, dry or wet gas, multiphase fluids,

tics

and non-potable oilfield water. This specification does not

D1603Test Method for Carbon Black Content in Olefin

cover pipe for gas distribution applications.

Plastics

1.1.1 For the purposes of this specification, high-density

D2122Test Method for Determining Dimensions of Ther-

polyethylene material is Specification D3350 density cell

moplastic Pipe and Fittings

classification 3 or higher. This specification does not cover

D2290Test Method for Apparent Hoop Tensile Strength of

materialshavingSpecificationD3350densitycellclassification

Plastic or Reinforced Plastic Pipe

less than 3 such as medium or low density polyethylene

D2513Specification for Polyethylene (PE) Gas Pressure

materials.

Pipe, Tubing, and Fittings

1.1.2 See Specification D2513 for polyethylene pipe and

D2683Specification for Socket-Type Polyethylene Fittings

fittingsintendedforuseinthedistributionofnaturalgas,orfor

for Outside Diameter-Controlled Polyethylene Pipe and

use with liquefied petroleum gas.

Tubing

1.2 Units—The values stated in either SI units or inch-

D2837Test Method for Obtaining Hydrostatic Design Basis

pound units are to be regarded separately as standard. The

forThermoplasticPipeMaterialsorPressureDesignBasis

values stated in each system may not be exact equivalents;

for Thermoplastic Pipe Products

therefore,eachsystemshallbeusedindependentlyoftheother.

D3261SpecificationforButtHeatFusionPolyethylene(PE)

Combining values from the two systems may result in non-

Plastic Fittings for Polyethylene (PE) Plastic Pipe and

conformance with the standard.

Tubing

1.3 This standard does not purport to address all of the

D3350Specification for Polyethylene Plastics Pipe and Fit-

safety concerns, if any, associated with its use. It is the tings Materials

responsibility of the user of this standard to establish appro-

D4218Test Method for Determination of Carbon Black

priate safety and health practices and determine the applica- Content in Polyethylene Compounds By the Muffle-

bility of regulatory limitations prior to use.

Furnace Technique

F412Terminology Relating to Plastic Piping Systems

2. Referenced Documents

F1055Specification for Electrofusion Type Polyethylene

2

Fittings for Outside Diameter Controlled Polyethylene

2.1 ASTM Standards:

and Crosslinked Polyethylene (PEX) Pipe and Tubing

D638Test Method for Tensile Properties of Plastics

F1473Test Method for Notch Tensile Test to Measure the

Resistance to Slow Crack Growth of Polyethylene Pipes

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic and Resins

Piping Systems and is the direct responsibility of Subcommittee F17.68 on Energy

F1973Specification for Factory Assembled Anodeless Ris-

Piping Systems.

ers and Transition Fittings in Polyethylene (PE) and

Current edition approved Feb. 1, 2011. Published February 2011. originally

Polyamide 11 (PA11) and Polyamide 12 (PA12) Fuel Gas

approved in 2007. Last previous edition approved in 2007 as F2619/F2619M–07.

DOI: 10.1520/F2619_F2619M-11.

Distribution Systems

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

F2206Specification for Fabricated Fittings of Butt-Fused

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Polyethylene (PE) Plastic Pipe, Fittings, Sheet Stock,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Plate Stock, or Block Stock

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

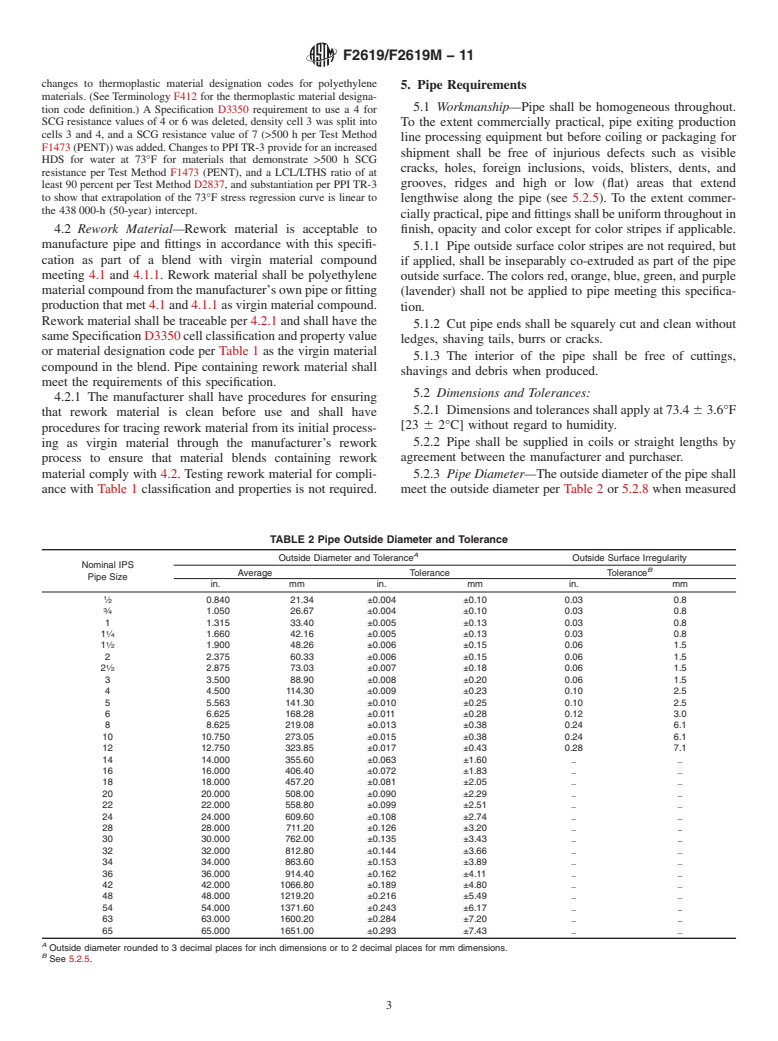

F2619/F2619M−11

2.2 Other Documents: 3.2.3 production run, n—thecontinuousextrusionofpipeof

CFR49Part192TransportationofNaturalandOtherGasby aspecificdiameter,wallthicknessandmaterialcompound(see

3

Pipeline: Minimum Federal Safety Standards 4.1)

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F2619/F2619M–07 Designation: F2619/F2619M – 11

Standard Specification for

1

High-Density Polyethylene (PE) Line Pipe

ThisstandardisissuedunderthefixeddesignationF2619/F2619M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers requirements and test methods for high-density polyethylene (PE) materials, pipe and fittings for

pressure or non-pressure oil and gas producing applications to convey fluids such as oil, dry or wet gas, multiphase fluids, and

non-potable oilfield water. This specification does not cover pipe for gas distribution applications.

1.1.1 For the purposes of this specification, high-density polyethylene material is Specification D3350 density cell classification

3 or higher. This specification does not cover materials having Specification D3350 density cell classification less than 3 such as

medium or low density polyethylene materials.

1.1.2 See Specification D2513 for polyethylene pipe and fittings intended for use in the distribution of natural gas, or for use

with liquefied petroleum gas.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of eachthe other. Combining

values from the two systems may result in non-compliancenon-conformance with the standard.Values in parentheses are provided

for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D638 Test Method for Tensile Properties of Plastics

D1598 Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1603 Test Method for Carbon Black Content in Olefin Plastics

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2290 Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe by Split Disk Method

D2513 Specification for Polyethylene (PE) Gas Pressure Pipe, Tubing, and Fittings

D2683 Specification for Socket-Type Polyethylene Fittings for Outside Diameter-Controlled Polyethylene Pipe and Tubing

D2837 Test Method for Obtaining Hydrostatic Design Basis for Thermoplastic Pipe Materials or Pressure Design Basis for

Thermoplastic Pipe Products

D3261 Specification for Butt Heat Fusion Polyethylene (PE) Plastic Fittings for Polyethylene (PE) Plastic Pipe and Tubing

D3350 Specification for Polyethylene Plastics Pipe and Fittings Materials

D4218 Test Method for Determination of Carbon Black Content in Polyethylene Compounds By the Muffle-FurnaceTechnique

F412 Terminology Relating to Plastic Piping Systems

F1055 Specification for Electrofusion Type Polyethylene Fittings for Outside Diameter Controlled Polyethylene Pipe and

Tubing

F1473 Test Method for Notch Tensile Test to Measure the Resistance to Slow Crack Growth of Polyethylene Pipes and Resins

F1973 Specification for Factory Assembled Anodeless Risers and Transition Fittings in Polyethylene (PE) and Polyamide 11

(PA11) and Polyamide 12 (PA12) Fuel Gas Distribution Systems

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas.

Current edition approved Nov. 15, 2007. Published December 2007. DOI: 10.1520/F2619_F2619M-07.

Current edition approved Feb. 1, 2011. Published February 2011. originally approved in 2007. Last previous edition approved in 2007 as F2619/F2619M–07. DOI:

10.1520/F2619_F2619M-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Bo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.