ASTM B787/B787M-04(2020)

(Specification)Standard Specification for 19 Wire Combination Unilay-Stranded Copper Conductors for Subsequent Insulation

Standard Specification for 19 Wire Combination Unilay-Stranded Copper Conductors for Subsequent Insulation

ABSTRACT

This specification covers electrical contact alloys with the nominal composition of 75% silver, 24.5% copper, and 0.5% nickel in the form of rods, wires, strips, and sheets. Raw materials shall be of such quality and purity that the products, which shall be finished by such operations as cold working, heat treatment, annealing, turning, grinding, or pickling, shall adhere to the chemical composition and mechanical property requirements prescribed here. Besides analysis for the elements silver, copper, and nickel, further analysis is to be made for suspected or indicated impurities, such as zinc, iron, cadmium, and lead, to make sure that their total does not exceed specified limits. Mechanical tests, which are to be conducted at room temperature, shall evaluate the materials' tensile strength, elongation, Rockwell hardness, and area and thickness reduction.

SCOPE

1.1 This specification covers bare combination unilay-stranded conductors made from round copper wires, either uncoated or coated with tin or lead alloy for insulated conductors for electrical purposes. These conductors shall be constructed with a central core wire surrounded by two layers of helically laid wires, resulting in an outer diameter equal to the compressed-stranded equivalent conductor. (See Explanatory Note 1 and Note 2.)

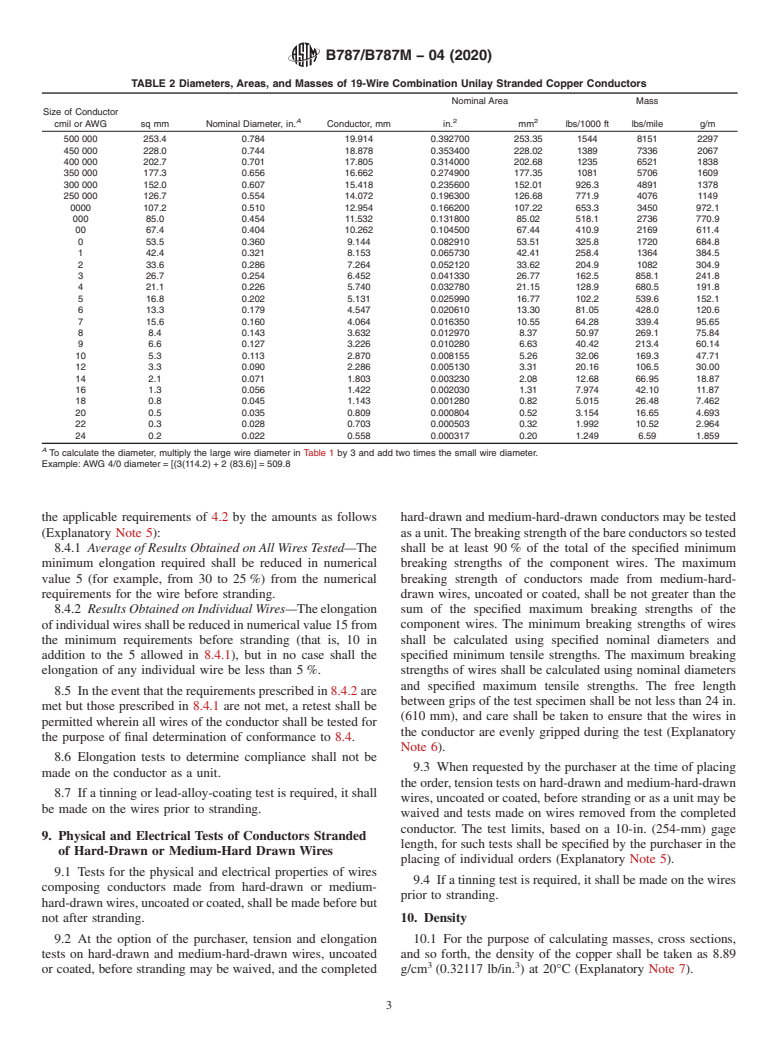

Note 1: For the purpose of this specification, combination unilay conductor is defined as follows: a central core wire surrounded by a layer of six helically laid wires of the same diameter as the core wire with a helically laid outer layer containing six smaller wires alternated between six wires of the same diameter as the wires in the layer underneath. Both layers have a common length and direction of lay (see Fig. 1).

FIG. 1 Cross Section of Conductor

1.2 For the purpose of this specification, normal conductor classification (Class AA, A, B, C) is not applicable as these conductors are intended for subsequent insulation. The descriptive term combination unilay-stranded shall be used in place of conductor classification.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3.1 For conductor sizes designated by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding values, stated or derived, in inch-pound units.

1.3.2 For conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.3.3 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B787/B787M −04 (Reapproved 2020)

Standard Specification for

19 Wire Combination Unilay-Stranded Copper Conductors

for Subsequent Insulation

This standard is issued under the fixed designation B787/B787M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.1 This specification covers bare combination unilay-

mine the applicability of regulatory limitations prior to use.

stranded conductors made from round copper wires, either

1.5 This international standard was developed in accor-

uncoated or coated with tin or lead alloy for insulated conduc-

dance with internationally recognized principles on standard-

tors for electrical purposes. These conductors shall be con-

ization established in the Decision on Principles for the

structed with a central core wire surrounded by two layers of

Development of International Standards, Guides and Recom-

helically laid wires, resulting in an outer diameter equal to the

mendations issued by the World Trade Organization Technical

compressed-stranded equivalent conductor. (See Explanatory

Barriers to Trade (TBT) Committee.

Note 1 and Note 2.)

NOTE 1—For the purpose of this specification, combination unilay 2. Referenced Documents

conductor is defined as follows: a central core wire surrounded by a layer

2.1 The following documents of the issue in effect on date

of six helically laid wires of the same diameter as the core wire with a

of material purchase form a part of this specification to the

helically laid outer layer containing six smaller wires alternated between

six wires of the same diameter as the wires in the layer underneath. Both extent referenced herein.

layers have a common length and direction of lay (see Fig. 1).

2.2 ASTM Standards:

1.2 For the purpose of this specification, normal conductor

B1Specification for Hard-Drawn Copper Wire

classification (Class AA, A, B, C) is not applicable as these

B2Specification for Medium-Hard-Drawn Copper Wire

conductorsareintendedforsubsequentinsulation.Thedescrip-

B3Specification for Soft or Annealed Copper Wire

tivetermcombinationunilay-strandedshallbeusedinplaceof

B33Specification for Tin-Coated Soft or Annealed Copper

conductor classification.

Wire for Electrical Purposes

B189Specification for Lead-Coated and Lead-Alloy-Coated

1.3 The values stated in either SI units or inch-pound units

Soft Copper Wire for Electrical Purposes

are to be regarded separately as standard. The values stated in

B246Specification for Tinned Hard-Drawn and Medium-

each system may not be exact equivalents; therefore, each

Hard-Drawn Copper Wire for Electrical Purposes

system shall be used independently of the other. Combining

B263Test Method for Determination of Cross-Sectional

values from the two systems may result in non-conformance

Area of Stranded Conductors

with the standard.

B354Terminology Relating to Uninsulated Metallic Electri-

1.3.1 For conductor sizes designated byAWG or kcmil, the

cal Conductors

requirementsinSIunitshavebeennumericallyconvertedfrom

corresponding values, stated or derived, in inch-pound units. 2.3 Other Standard:

NBS Handbook 100Copper Wire Tables of the National

1.3.2 For conductor sizes designated by SI units only, the

requirements are stated or derived in SI units. Bureau of Standards

1.3.3 For density, resistivity, and temperature, the values

3. Ordering Information

stated in SI units are to be regarded as standard.

3.1 Orders for materials under this specification shall in-

1.4 This standard does not purport to address all of the

clude the following information:

safety concerns, if any, associated with its use. It is the

3.1.1 Quantity of each size,

1 2

This specification is under the jurisdiction of ASTM Committee B01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Conductors of Copper and Copper Alloys. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Jan. 1, 2020. Published January 2020. Originally the ASTM website.

approved in 1988. Last previous edition approved in 2014 as B787/B787M–04 Available from National Institute of Standards and Technology (NIST), 100

(2014). DOI: 10.1520/B0787_B0787M-04R20. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B787/B787M − 04 (2020)

4.2 Before stranding, the copper wire used shall meet all of

therequirementsofthefollowingASTMspecificationsthatare

applicable to its type:

4.2.1 Specification B3.

4.2.2 Specification B33.

4.2.3 Specification B2.

4.2.4 Specification B1.

4.2.5 Specification B189.

FIG. 1 Cross Section of Conductor

4.2.6 Specification B246.

4.3 In combination unilay stranded conductors, the central

3.1.2 Conductor Size: Circular-mil area or American Wire

core wire shall be made of the same type and temper as the

Gage, AWG (Section 7 and Table 1),

layers, unless otherwise specified.

3.1.3 Stranding (see Explanatory Note 3),

3.1.4 Temper (see 4.2), 5. Joints

3.1.5 Whether coated or uncoated; if coated, designate type

5.1 Welds and brazes may be made in rods or in wires prior

of coating (see 4.1 and 4.2),

tofinaldrawing.Weldsandbrazesmaybemadeinthefinished

3.1.6 Details of special-purpose lays, if required (see 6.2),

individual wires composing the conductor, but shall not be

3.1.7 When physical tests shall be made (see 9.2 and 9.3),

closer together than 50 ft (15.24 m) for hard and medium-hard

3.1.8 Package size (see 15.1),

conductors, and 1 ft in a layer for soft conductors.

3.1.9 Lagging, if required (see 15.2),

3.1.10 Special package marking, if required (Section 15),

6. Lay

and

6.1 For combination unilay conductors the lay of a layer of

3.1.11 Place of inspection (Section 13).

wires shall be not less than 8 nor more than 16 times the

outside diameter of the outer layer.

4. Requirements for Wires

6.2 Other lays for special purposes shall be furnished by

4.1 The purchaser shall designate the type of wire and the

specialagreementbetweenthemanufacturerandthepurchaser

kind of coating, if any, to be used in the conductor.

(Explanatory Note 4).

TABLE 1 Construction Requirements for 19-Wire Combination 6.3 The direction of lay shall be left-hand unless the

Unilay Stranded Copper Conductors

direction of lay is specified otherwise by the purchaser.

Size, American (or

A B

Brown and 7. Construction (Explanatory Note 3)

Wire D Wire D

1 2

Cross-Sectional Area Sharpe) Diameter, Diameter,

7.1 The cross-sectional areas, numbers, and diameters of

cmil sq mm Wire Gage mils mm mils mm

500 000 253.4 175.6 4.5 128.5 3.3

wires in the various conductors shall conform to the require-

450 000 228.0 166.6 4.2 121.9 3.1

ments prescribed in Table 1.

400 000 202.7 157.1 4.0 115.0 2.9

350 000 177.3 146.9 3.7 107.5 2.7

7.2 ThediametersofthewireslistedinTable2arenominal.

300 000 152.0 136.0 3.5 99.6 2.5

In order to produce an essentially round 19-wire construction,

250 000 126.7 124.2 3.2 90.9 2.3

211 600 107.2 0000 114.2 2.4 83.6 2.1 the outer 12-wire layer in the combination unilay product is

167 800 85.0 000 101.7 2.6 74.5 1.9

comprised of 6 wires of the same diameter as the wires in the

133 100 67.4 00 90.6 2.3 66.3 1.7

7-wire core, and 6 wires approximately 25% smaller. The

105 600 53.5 0 80.7 2.0 59.1 1.5

2-wire sizes are alternated around the 7-wire core (Fig. 1).

83 690 42.4 1 71.8 1.8 52.6 1.3

66 360 33.6 2 64.0 1.6 46.8 1.2

52 620 26.7 3 57.0 1.4 41.7 1.1

8. Physical and Electrical Tests of Conductors Stranded

41 740 21.1 4 50.7 1.3 37.1 0.9

of Soft Wires

33 090 16.8 5 45.2 1.1 33.1 0.8

26 240 13.3 6 40.2 1.0 29.4 0.7

8.1 Tests for the electrical properties of wires composing

20 820 10.5 7 35.8 0.9 26.2 0.7

conductors made from soft or annealed copper wire, bare or

16 510 8.4 8 31.9 0.8 23.4 0.6

13 090 6.6 9 28.4 0.7 20.8 0.5

coated, shall be made before stranding.

10 380 5.3 10 25.3 0.6 18.5 0.5

6530 3.3 12 20.1 0.5 14.7 0.4 8.2 Tests for the physical properties of soft or annealed

4110 2.1 14 15.9 0.4 11.7 0.3

copper wire, bare or coated, may be made upon the wires

2580 1.3 16 12.6 0.3 9.2 0.2

before stranding or upon wires removed from the complete

1620 0.8 18 10.0 0.3 7.3 0.2

1020 0.5 20 7.9 0.2 5.8 0.1 strandedconductor,butneednotbemadeuponboth.Careshall

640 0.3 22 6.3 0.2 4.6 0.1

be taken to avoid mechanical injury to wire removed from the

404 0.2 24 5.0 0.1 3.7 0.1

conductor for the purpose of testing.

A

Equation to calculate D :

8.3 The physical properties of wire when tested before

Cross2Sectional Area

stranding shall conform to the applicable requirements of 4.2.

Œ

16.2149

B 8.4 The physical properties of wires removed from the

Equation to calculate D : D × 0.732.

2 1

completed stranded conductor shall be permitted to vary from

B787/B787M − 04 (2020)

TABLE 2 Diameters, Areas, and Masses of 19-Wire Combination Unilay Stranded Copper Conductors

Nominal Area Mass

Size of Conductor

A 2 2

cmil or AWG sq mm Nominal Diameter, in. Conductor, mm in. mm lbs/1000 ft lbs/mile g/m

500 000 253.4 0.784 19.914 0.392700 253.35 1544 8151 2297

450 000 228.0 0.744 18.878 0.353400 228.02 1389 7336 2067

400 000 202.7 0.701 17.805 0.314000 202.68 1235 6521 1838

350 000 177.3 0.656 16.662 0.274900 177.35 1081 5706 1609

300 000 152.0 0.607 15.418 0.235600 152.01 926.3 4891 1378

250 000 126.7 0.554 14.072 0.196300 126.68 771.9 4076 1149

0000 107.2 0.510 12.954 0.166200 107.22 653.3 3450 972.1

000 85.0 0.454 11.532 0.131800 85.02 518.1 2736 770.9

00 67.4 0.404 10.262 0.104500 67.44 410.9 2169 611.4

0 53.5 0.360 9.144 0.082910 53.51 325.8 1720 684.8

1 42.4 0.321 8.153 0.065730 42.41 258.4 1364 384.5

2 33.6 0.286 7.264 0.052120 33.62 204.9 1082 304.9

3 26.7 0.254 6.452 0.041330 26.77 162.5 858.1 241.8

4 21.1 0.226 5.740 0.032780 21.15 128.9 680.5 191.8

5 16.8 0.202 5.131 0.025990 16.77 102.2 539.6 152.1

6 13.3 0.179 4.547 0.020610 13.30 81.05 428.0 120.6

7 15.6 0.160 4.064 0.016350 10.55 64.28 339.4 95.65

8 8.4 0.143 3.632 0.012970 8.37 50.97 269.1 75.84

9 6.6 0.127 3.226 0.010280 6.63 40.42 213.4 60.14

10 5.3 0.113 2.870 0.008155 5.26 32.06 169.3 47.71

12 3.3 0.090 2.286 0.005130 3.31 20.16 106.5 30.00

14 2.1 0.071 1.803 0.003230 2.08 12.68 66.95 18.87

16 1.3 0.056 1.422 0.002030 1.31 7.974 42.10 11.87

18 0.8 0.045 1.143 0.001280 0.82 5.015 26.48 7.462

20 0.5 0.035 0.809 0.000804 0.52 3.154 16.65 4.693

22 0.3 0.028 0.703 0.000503 0.32 1.992 10.52 2.964

24 0.2 0.022 0.558 0.000317 0.20 1.249 6.59 1.859

A

To calculate the diameter, multiply the large wire diameter in Table 1 by 3 and add two times the small wire diameter.

Example: AWG 4/0 diameter = [(3(114.2) + 2 (83.6)] = 509.8

the applicable requirements of 4.2 by the amounts as follows hard-drawnandmedium-hard-drawnconductorsmaybetested

(Explanatory Note 5): asaunit.Thebreakingstrengthofthebareconductorssotested

8.4.1 AverageofResultsObtainedonAllWiresTested—The shall be at least 90% of the total of the specified minimum

minimum elongation required shall be reduced in numerical breaking strengths of the component wires. The maximum

value 5 (for example, from 30 to 25%) from the numerical breaking strength of conductors made from medium-hard-

requirements for the wire before stranding. drawn wires, uncoated or coated, shall be not greater than the

8.4.2 ResultsObtainedonIndividualWires—Theelongation sum of the specified maximum breaking strengths of the

ofindividualwiresshallbereducedinnumericalvalue15from component wires. The minimum breaking strengths of wires

the minimum requirements before stranding (that is, 10 in shall be calculated using specified nominal diameters and

addition to the 5 allowed in 8.4.1), but in no case shall the specified minimum tensile strengths. The maximum breaking

elongation of any individual wire be less than 5%. strengths of wires shall be calculated using nominal diameters

and specified maximum tensile strengths. The free length

8.5 Intheeventthattherequirementsprescribedin8.4.2are

between grips of the test specimen shall be not less than 24 in.

met but those prescribed in 8.4.1 are not met, a retest shall be

(610 mm), and care shall be taken to ensure that the wires in

permittedwhereinallwiresoftheconductorshallbetestedfor

the conductor are evenly gripped during the test (Explanatory

the purpose of final determination of conformance to 8.4.

Note 6).

8.6 Elongation tests to determine compliance shall not be

9.3 When requested by the purchaser at the time of placing

made on the conductor as a unit.

theorder,tensiontestsonhard-drawnandmedium-hard-drawn

8.7 If a tinning or lead-alloy-coating test is required, it shall

wires,uncoatedorcoated,beforestrandingorasaunitmaybe

be made on the wires prior to stranding.

waived and tests made on wires removed from the completed

conductor. The test limits, based on a 10-in. (254-mm) gage

9. Physical and Electrical Tests of Conductors Stranded

length, for such tests shall be specified by the purchaser in the

of Hard-Drawn or Medium-Hard Drawn Wires

placing of individual orders (Explanatory Note 5).

9.1 Tests for the physical and electrical properties of wires

9.4 Ifatinningtestisrequired,itshallbemadeonthewires

composing conductors made from hard-drawn or medium-

prior to stranding.

hard-drawnwires,uncoatedorcoated,shallbemadebeforebut

not after stranding. 10. Density

9.2 At the option of the purchaser, tension and elongation 10.1 For the purpose of calculating masses, cross sections,

tests on hard-drawn and medium-hard-drawn wires, uncoated and so forth, the density of the copper shall be taken as 8.89

3 3

or coated, before stranding may be waived, and the completed g/cm (0.32117 lb/in. ) at 20°C (Explanatory Note 7).

B787/B787M − 04 (2020)

11. Mass and Resistance 13.2 All inspections and tests shall be made at the place of

manufacture unless otherwise especially agreed upon between

11.1 The mass and electrical resistance of a unit length of

the manufacturer and the purchaser at the time of purchase.

stranded conductor are a function of the length of lay. The

ap

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.