ASTM B3-13(2018)

(Specification)Standard Specification for Soft or Annealed Copper Wire

Standard Specification for Soft or Annealed Copper Wire

ABSTRACT

This specification covers drawn and annealed or soft round bare copper wire for electrical purposes. The matterial shall be copper of such quality and purity that the finished product shall have the properties and characteristics prescribed. Tensile strength, elongation, and resistivity of the wires shall be determined. A micrometer caliper equipped with a vernier shall be used to measure the material dimensions. The wires shall be subjected to surface finish and shall conform to the particularized requirements.

SCOPE

1.1 This specification covers drawn and annealed or soft round bare copper wire for electrical purposes (see Explanatory Note 1).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.2.1 Exception—For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B3 −13 (Reapproved 2018)

Standard Specification for

Soft or Annealed Copper Wire

This standard is issued under the fixed designation B3; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Wires Used as Electrical Conductors

2.3 Other Standards:

1.1 This specification covers drawn and annealed or soft

NBS Handbook 100 —Copper Wire Tables

roundbarecopperwireforelectricalpurposes(seeExplanatory

Note 1).

3. Ordering Information

1.2 The values stated in inch-pound units are to be regarded

3.1 Orders for material under this specification shall include

as standard. The values given in parentheses are mathematical

the following information:

conversions to SI units that are provided for information only

3.1.1 Quantity of each size,

and are not considered standard.

3.1.2 Wire size: diameter in inches (see 5.3 and Table 1),

1.2.1 Exception—For density, resistivity and temperature,

3.1.3 Type of copper, if special (Section 4),

the values stated in SI units are to be regarded as standard.

3.1.4 Package size (see 10.1),

1.3 This standard does not purport to address all of the

3.1.5 Special package marking, if required, and

safety concerns, if any, associated with its use. It is the

3.1.6 Place of inspection (see 7.1).

responsibility of the user of this standard to establish appro-

4. Materials

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4.1 The material shall be copper of such quality and purity

1.4 This international standard was developed in accor-

that the finished product shall have the properties and charac-

dance with internationally recognized principles on standard-

teristics prescribed in this specification.

ization established in the Decision on Principles for the

NOTE 1—Specification B49 defines copper suitable for use.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical 4.2 Copper bars of special qualities, forms, or types, as may

Barriers to Trade (TBT) Committee. be agreed upon between the manufacturer and the purchaser,

and which will conform to the requirements prescribed in this

2. Referenced Documents

specification may also be used.

2.1 The following documents of the issue in effect at the

5. General Requirements (see Section 8)

time of reference form a part of this specification to the extent

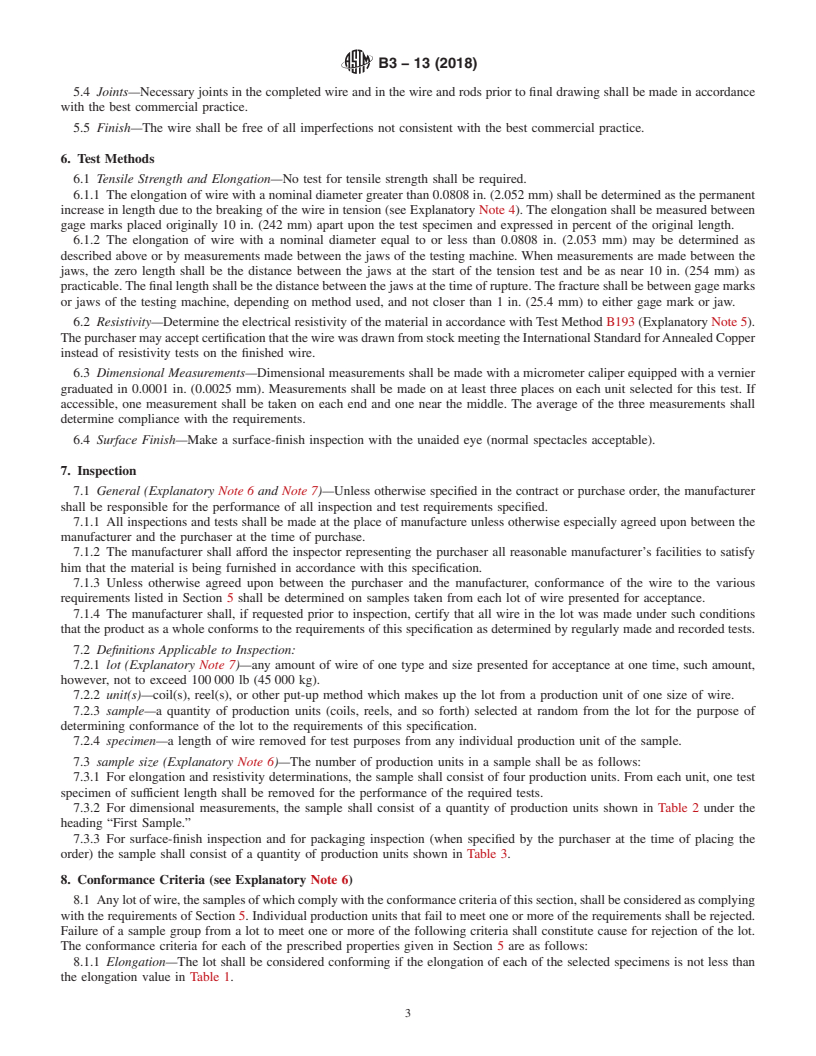

referenced herein: 5.1 Tensile Strength and Elongation—The wire shall con-

2 form to the requirements for elongation prescribed in Table 1

2.2 ASTM Standards:

(see Explanatory Note 2). No requirements for tensile strength

B49 Specification for Copper Rod for Electrical Purposes

are specified. For wire whose nominal diameter is more than

B193 Test Method for Resistivity of Electrical Conductor

0.001 in. (0.025 mm) greater than a size listed in Table 1, but

Materials

less than that of the next larger size, the requirements of the

B258 Specification for Standard Nominal Diameters and

next larger size shall apply.

Cross-Sectional Areas of AWG Sizes of Solid Round

5.2 Resistivity—The electrical resistivity at 20°C shall not

2 2

exceed 875.20Ω·lb/mile (0.15328Ω·g/m ) (see Explanatory

This specification is under the jurisdiction of ASTM Committee B01 on

Note 5).

Electrical Conductorsand is the direct responsibility of Subcommittee B01.04 on

Conductors of Copper and Copper Alloys.

5.3 Dimensions and Permissible Variations—The wire sizes

Current edition approved Oct. 1, 2018. Published October 2018. Originally

shall be expressed as the diameter of the wire in decimal

approved in 1912. Last previous edition approved in 2013 as B3 – 13. DOI:

fractionsofaninchtothenearest0.0001in.(or0.001mm)(see

10.1520/B0003-13R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

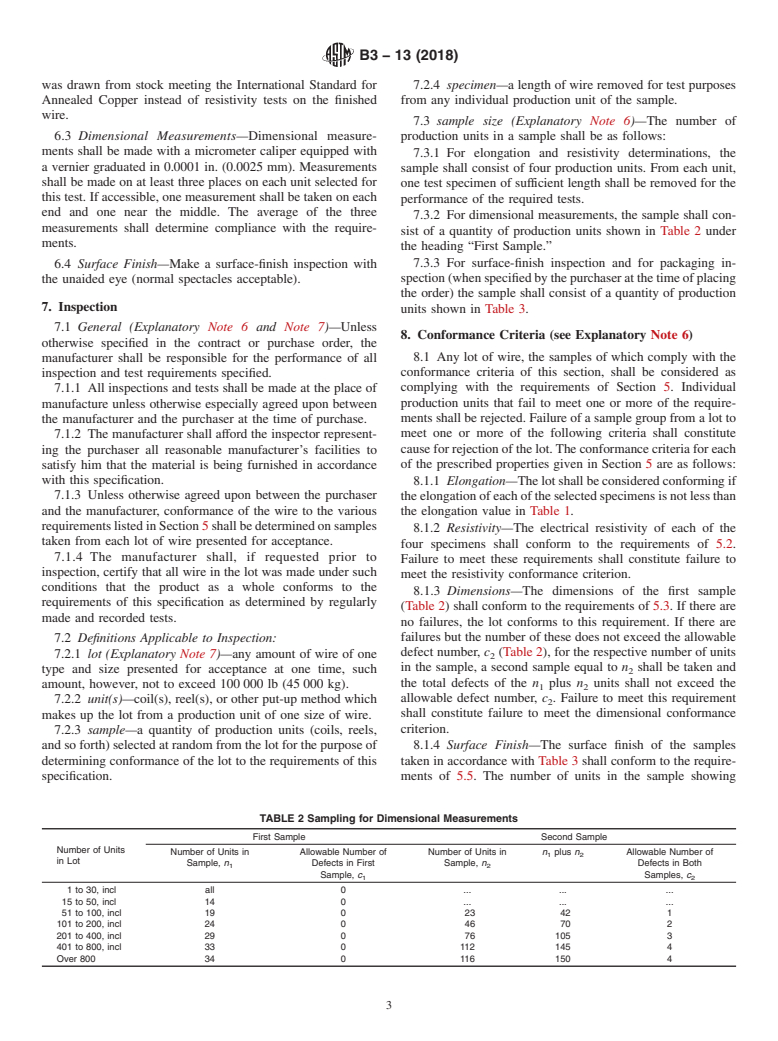

B3−13 (2018)

TABLE 1 Tensile Requirements

Diameter Area at 20°C Elongation in

10 in.

(254 mm),

2 2

in. mm cmils in. mm

%min

0.4600 11.684 211 600 0.1662 107.0 35

0.4096 10.404 167 800 0.1318 85.0 35

0.3648 9.266 133 100 0.1045 67.4 35

0.3249 8.252 105 600 0.08291 53.5 35

0.2893 7.348 83 690 0.06573 42.4 30

0.2576 6.543 66 360 0.05212 33.6 30

0.2294 5.827 52 620 0.04133 26.7 30

0.2043 5.189 41 740 0.03278 21.2 30

0.1819 4.620 33 090 0.02599 16.8 30

0.1620 4.115 26 240 0.02061 13.3 30

0.1443 3.665 20 820 0.01635 10.5 30

0.1285 3.264 16 510 0.01297 8.37 30

0.1144 2.906 13 090 0.01028 6.63 30

0.1019 2.588 10 380 0.008155 5.26 25

0.0907 2.304 8 230 0.00646 4.17 25

0.0808 2.052 6 530 0.00513 3.31 25

0.0720 1.829 5 180 0.00407 2.63 25

0.0641 1.628 4 110 0.00323 2.08 25

0.0571 1.450 3 260 0.00256 1.65 25

0.0508 1.290 2 580 0.00203 1.31 25

0.0453 1.151 2 050 0.00161 1.04 25

0.0403 1.024 1 620 0.00128 0.823 25

0.0359 0.912 1 290 0.00101 0.654 25

0.0320 0.813 1 020 0.000804 0.517 25

0.0285 0.724 812 0.000638 0.411 25

0.0253 0.643 640 0.000503 0.324 25

0.0226 0.574 511 0.000401 0.259 25

0.0201 0.511 404 0.000317 0.205 20

0.0179 0.455 320 0.000252 0.162 20

0.0159 0.404 253 0.000199 0.128 20

0.0142 0.361 202 0.000158 0.102 20

0.0126 0.320 159 0.000125 0.081 20

0.0113 0.287 128 0.000100 0.065 20

0.0100 0.254 100 0.0000785 0.051 15

0.0089 0.226 79.2 0.0000622 0.040 15

0.0080 0.203 64.0 0.0000503 0.032 15

0.0071 0.180 50.4 0.0000396 0.026 15

0.0063 0.160 39.7 0.0000312 0.020 15

0.0056 0.142 31.4 0.0000246 0.016 15

0.0050 0.127 25.0 0.0000196 0.013 15

0.0045 0.114 20.2 0.000 0159 0.010 15

0.0040 0.102 16.0 0.0000126 0.0081 15

0.0035 0.089 12.2 0.00000962 0.0062 15

0.0031 0.079 9.61 0.00000755 0.0049 15

Explanatory Note 3). For diameters under 0.0100 in. (0.254 tension (see Explanatory Note 4). The elongation shall be

mm), the wire shall not vary from the specified diameter by measured between gage marks placed originally 10 in. (242

more than plus and minus 0.0001 in. (0.0025 mm), and for

mm) apart upon the test specimen and expressed in percent of

diameters of 0.0100 in. (0.254 mm) and over the wire shall not the original length.

vary from the specified diameter by more than plus and minus

6.1.2 The elongation of wire with a nominal diameter equal

1 %, expressed to the nearest 0.0001 in. (or 0.001 mm).

to or less than 0.0808 in. (2.053 mm) may be determined as

describedaboveorbymeasurementsmadebetweenthejawsof

5.4 Joints—Necessary joints in the completed wire and in

the testing machine. When measurements are made between

the wire and rods prior to final drawing shall be made in

the jaws, the zero length shall be the distance between the jaws

accordance with the best commercial practice.

at the start of the tension test and be as near 10 in. (254 mm)

5.5 Finish—The wire shall be free of all imperfections not

as practicable. The final length shall be the distance between

consistent with the best commercial practice.

the jaws at the time of rupture. The fracture shall be between

gage marks or jaws of the testing machine, depending on

6. Test Methods

method used, and not closer than 1 in. (25.4 mm) to either gage

6.1 Tensile Strength and Elongation—No test for tensile

mark or jaw.

strength shall be required.

6.1.1 The elongation of wire with a nominal diameter 6.2 Resistivity—Determine the electrical resistivity of the

greater than 0.0808 in. (2.052 mm) shall be determined as the material in accordance with Test Method B193 (Explanatory

permanent increase in length due to the breaking of the wire in Note 5). The purchaser may accept certification that the wire

B3−13 (2018)

was drawn from stock meeting the International Standard for 7.2.4 specimen—a length of wire removed for test purposes

Annealed Copper instead of resistivity tests on the finished from any individual production unit of the sample.

wire.

7.3 sample size (Explanatory Note 6)—The number of

6.3 Dimensional Measurements—Dimensional measure- production units in a sample shall be as follows:

ments shall be made with a micrometer caliper equipped with

7.3.1 For elongation and resistivity determinations, the

a vernier graduated in 0.0001 in. (0.0025 mm). Measurements

sample shall consist of four production units. From each unit,

shall be made on at least three places on each unit selected for

one test specimen of sufficient length shall be removed for the

this test. If accessible, one measurement shall be taken on each

performance of the required tests.

end and one near the middle. The average of the three

7.3.2 For dimensional measurements, the sample shall con-

measurements shall determine compliance with the require-

sist of a quantity of production units shown in Table 2 under

ments.

the heading “First Sample.”

7.3.3 For surface-finish inspection and for packaging in-

6.4 Surface Finish—Make a surface-finish inspection with

spection(whenspecifiedbythepurchaseratthetimeofplacing

the unaided eye (normal spectacles acceptable).

the order) the sample shall consist of a quantity of production

7. Inspection

units shown in Table 3.

7.1 General (Explanatory Note 6 and Note 7)—Unless

8. Conformance Criteria (see Explanatory Note 6)

otherwise specified in the contract or purchase order, the

manufacturer shall be responsible for the performance of all 8.1 Any lot of wire, the samples of which comply with the

conformance criteria of this section, shall be considered as

inspection and test requirements specified.

7.1.1 All inspections and tests shall be made at the place of complying with the requirements of Section 5. Individual

production units that fail to meet one or more of the require-

manufacture unless otherwise especia

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B3 − 13 (Reapproved 2018)

Standard Specification for

Soft or Annealed Copper Wire

This standard is issued under the fixed designation B3; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Wires Used as Electrical Conductors

2.3 Other Standards:

1.1 This specification covers drawn and annealed or soft

NBS Handbook 100 —Copper Wire Tables

round bare copper wire for electrical purposes (see Explanatory

Note 1).

3. Ordering Information

1.2 The values stated in inch-pound units are to be regarded

3.1 Orders for material under this specification shall include

as standard. The values given in parentheses are mathematical

the following information:

conversions to SI units that are provided for information only

3.1.1 Quantity of each size,

and are not considered standard.

3.1.2 Wire size: diameter in inches (see 5.3 and Table 1),

1.2.1 Exception—For density, resistivity and temperature,

3.1.3 Type of copper, if special (Section 4),

the values stated in SI units are to be regarded as standard.

3.1.4 Package size (see 10.1),

1.3 This standard does not purport to address all of the

3.1.5 Special package marking, if required, and

safety concerns, if any, associated with its use. It is the

3.1.6 Place of inspection (see 7.1).

responsibility of the user of this standard to establish appro-

4. Materials

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4.1 The material shall be copper of such quality and purity

1.4 This international standard was developed in accor-

that the finished product shall have the properties and charac-

dance with internationally recognized principles on standard-

teristics prescribed in this specification.

ization established in the Decision on Principles for the

NOTE 1—Specification B49 defines copper suitable for use.

Development of International Standards, Guides and Recom-

4.2 Copper bars of special qualities, forms, or types, as may

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. be agreed upon between the manufacturer and the purchaser,

and which will conform to the requirements prescribed in this

2. Referenced Documents

specification may also be used.

2.1 The following documents of the issue in effect at the

5. General Requirements (see Section 8)

time of reference form a part of this specification to the extent

5.1 Tensile Strength and Elongation—The wire shall con-

referenced herein:

2 form to the requirements for elongation prescribed in Table 1

2.2 ASTM Standards:

(see Explanatory Note 2). No requirements for tensile strength

B49 Specification for Copper Rod for Electrical Purposes

are specified. For wire whose nominal diameter is more than

B193 Test Method for Resistivity of Electrical Conductor

0.001 in. (0.025 mm) greater than a size listed in Table 1, but

Materials

less than that of the next larger size, the requirements of the

B258 Specification for Standard Nominal Diameters and

next larger size shall apply.

Cross-Sectional Areas of AWG Sizes of Solid Round

5.2 Resistivity—The electrical resistivity at 20°C shall not

2 2

exceed 875.20 Ω·lb/mile (0.15328 Ω·g/m ) (see Explanatory

This specification is under the jurisdiction of ASTM Committee B01 on

Note 5).

Electrical Conductorsand is the direct responsibility of Subcommittee B01.04 on

Conductors of Copper and Copper Alloys.

5.3 Dimensions and Permissible Variations—The wire sizes

Current edition approved Oct. 1, 2018. Published October 2018. Originally

shall be expressed as the diameter of the wire in decimal

approved in 1912. Last previous edition approved in 2013 as B3 – 13. DOI:

fractions of an inch to the nearest 0.0001 in. (or 0.001 mm) (see

10.1520/B0003-13R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B3 − 13 (2018)

TABLE 1 Tensile Requirements

Diameter Area at 20°C Elongation in

10 in.

(254 mm),

2 2

in. mm cmils in. mm

% min

0.4600 11.684 211 600 0.1662 107.0 35

0.4096 10.404 167 800 0.1318 85.0 35

0.3648 9.266 133 100 0.1045 67.4 35

0.3249 8.252 105 600 0.08291 53.5 35

0.2893 7.348 83 690 0.06573 42.4 30

0.2576 6.543 66 360 0.05212 33.6 30

0.2294 5.827 52 620 0.04133 26.7 30

0.2043 5.189 41 740 0.03278 21.2 30

0.1819 4.620 33 090 0.02599 16.8 30

0.1620 4.115 26 240 0.02061 13.3 30

0.1443 3.665 20 820 0.01635 10.5 30

0.1285 3.264 16 510 0.01297 8.37 30

0.1144 2.906 13 090 0.01028 6.63 30

0.1019 2.588 10 380 0.008155 5.26 25

0.0907 2.304 8 230 0.00646 4.17 25

0.0808 2.052 6 530 0.00513 3.31 25

0.0720 1.829 5 180 0.00407 2.63 25

0.0641 1.628 4 110 0.00323 2.08 25

0.0571 1.450 3 260 0.00256 1.65 25

0.0508 1.290 2 580 0.00203 1.31 25

0.0453 1.151 2 050 0.00161 1.04 25

0.0403 1.024 1 620 0.00128 0.823 25

0.0359 0.912 1 290 0.00101 0.654 25

0.0320 0.813 1 020 0.000804 0.517 25

0.0285 0.724 812 0.000638 0.411 25

0.0253 0.643 640 0.000503 0.324 25

0.0226 0.574 511 0.000401 0.259 25

0.0201 0.511 404 0.000317 0.205 20

0.0179 0.455 320 0.000252 0.162 20

0.0159 0.404 253 0.000199 0.128 20

0.0142 0.361 202 0.000158 0.102 20

0.0126 0.320 159 0.000125 0.081 20

0.0113 0.287 128 0.000100 0.065 20

0.0100 0.254 100 0.0000785 0.051 15

0.0089 0.226 79.2 0.0000622 0.040 15

0.0080 0.203 64.0 0.0000503 0.032 15

0.0071 0.180 50.4 0.0000396 0.026 15

0.0063 0.160 39.7 0.0000312 0.020 15

0.0056 0.142 31.4 0.0000246 0.016 15

0.0050 0.127 25.0 0.0000196 0.013 15

0.0045 0.114 20.2 0.000 0159 0.010 15

0.0040 0.102 16.0 0.0000126 0.0081 15

0.0035 0.089 12.2 0.00000962 0.0062 15

0.0031 0.079 9.61 0.00000755 0.0049 15

Explanatory Note 3). For diameters under 0.0100 in. (0.254 tension (see Explanatory Note 4). The elongation shall be

mm), the wire shall not vary from the specified diameter by measured between gage marks placed originally 10 in. (242

more than plus and minus 0.0001 in. (0.0025 mm), and for mm) apart upon the test specimen and expressed in percent of

diameters of 0.0100 in. (0.254 mm) and over the wire shall not

the original length.

vary from the specified diameter by more than plus and minus

6.1.2 The elongation of wire with a nominal diameter equal

1 %, expressed to the nearest 0.0001 in. (or 0.001 mm).

to or less than 0.0808 in. (2.053 mm) may be determined as

described above or by measurements made between the jaws of

5.4 Joints—Necessary joints in the completed wire and in

the testing machine. When measurements are made between

the wire and rods prior to final drawing shall be made in

the jaws, the zero length shall be the distance between the jaws

accordance with the best commercial practice.

at the start of the tension test and be as near 10 in. (254 mm)

5.5 Finish—The wire shall be free of all imperfections not

as practicable. The final length shall be the distance between

consistent with the best commercial practice.

the jaws at the time of rupture. The fracture shall be between

gage marks or jaws of the testing machine, depending on

6. Test Methods

method used, and not closer than 1 in. (25.4 mm) to either gage

6.1 Tensile Strength and Elongation—No test for tensile

mark or jaw.

strength shall be required.

6.2 Resistivity—Determine the electrical resistivity of the

6.1.1 The elongation of wire with a nominal diameter

greater than 0.0808 in. (2.052 mm) shall be determined as the material in accordance with Test Method B193 (Explanatory

permanent increase in length due to the breaking of the wire in Note 5). The purchaser may accept certification that the wire

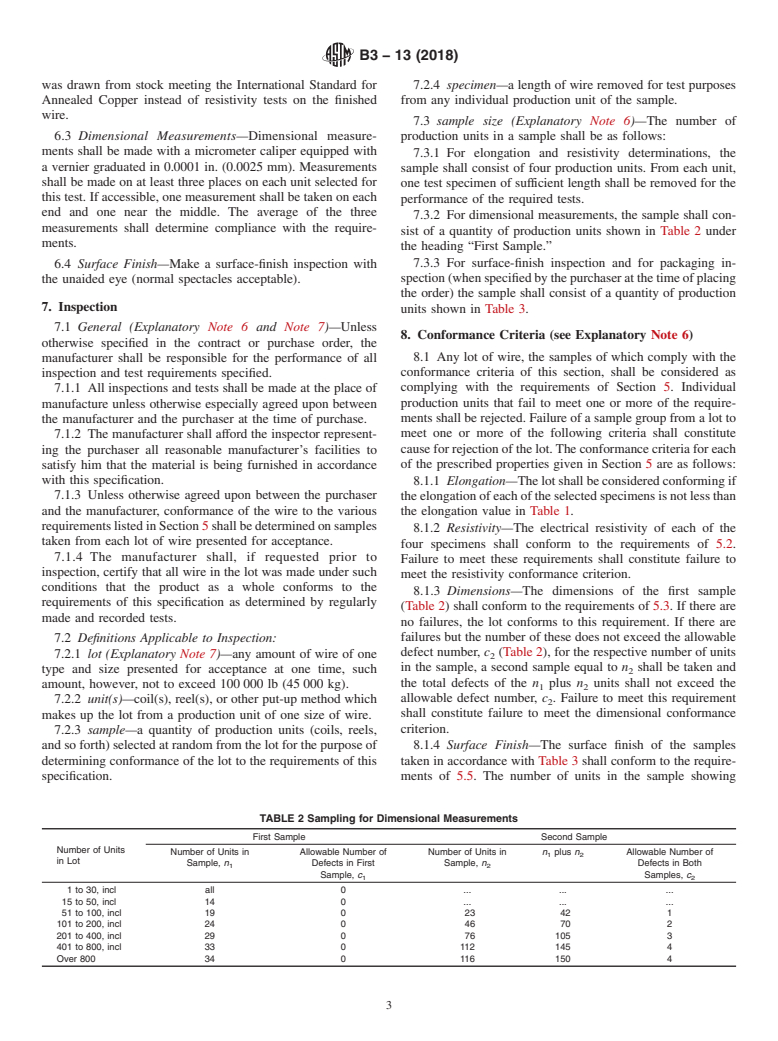

B3 − 13 (2018)

was drawn from stock meeting the International Standard for 7.2.4 specimen—a length of wire removed for test purposes

Annealed Copper instead of resistivity tests on the finished from any individual production unit of the sample.

wire.

7.3 sample size (Explanatory Note 6)—The number of

6.3 Dimensional Measurements—Dimensional measure- production units in a sample shall be as follows:

ments shall be made with a micrometer caliper equipped with

7.3.1 For elongation and resistivity determinations, the

a vernier graduated in 0.0001 in. (0.0025 mm). Measurements

sample shall consist of four production units. From each unit,

shall be made on at least three places on each unit selected for

one test specimen of sufficient length shall be removed for the

this test. If accessible, one measurement shall be taken on each

performance of the required tests.

end and one near the middle. The average of the three

7.3.2 For dimensional measurements, the sample shall con-

measurements shall determine compliance with the require-

sist of a quantity of production units shown in Table 2 under

ments.

the heading “First Sample.”

6.4 Surface Finish—Make a surface-finish inspection with 7.3.3 For surface-finish inspection and for packaging in-

spection (when specified by the purchaser at the time of placing

the unaided eye (normal spectacles acceptable).

the order) the sample shall consist of a quantity of production

7. Inspection

units shown in Table 3.

7.1 General (Explanatory Note 6 and Note 7)—Unless

8. Conformance Criteria (see Explanatory Note 6)

otherwise specified in the contract or purchase order, the

8.1 Any lot of wire, the samples of which comply with the

manufacturer shall be responsible for the performance of all

inspection and test requirements specified. conformance criteria of this section, shall be considered as

complying with the requirements of Section 5. Individual

7.1.1 All inspections and tests shall be made at the place of

production units that fail to meet one or more of the require-

manufacture unless otherwise especially agreed upon between

ments shall be rejected. Failure of a sample group from a lot to

the manufacture

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B3 − 13 B3 − 13 (Reapproved 2018)

Standard Specification for

Soft or Annealed Copper Wire

This standard is issued under the fixed designation B3; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers drawn and annealed or soft round bare copper wire for electrical purposes (see Explanatory Note

1).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.2.1 Exception—For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect at the time of reference form a part of this specification to the extent

referenced herein:

2.2 ASTM Standards:

B49 Specification for Copper Rod for Electrical Purposes

B193 Test Method for Resistivity of Electrical Conductor Materials

B258 Specification for Standard Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires Used as

Electrical Conductors

2.3 Other Standards:

NBS Handbook 100 Copper—Copper Wire Tables

3. Ordering Information

3.1 Orders for material under this specification shall include the following information:

3.1.1 Quantity of each size,

3.1.2 Wire size: diameter in inches (see 5.3 and Table 1),

3.1.3 Type of copper, if special (Section 4),

3.1.4 Package size (see 10.1),

3.1.5 Special package marking, if required, and

3.1.6 Place of inspection (see 7.1).

4. Materials

4.1 The material shall be copper of such quality and purity that the finished product shall have the properties and characteristics

prescribed in this specification.

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductorsand is the direct responsibility of Subcommittee B01.04 on Conductors

of Copper and Copper Alloys.

Current edition approved Oct. 1, 2013Oct. 1, 2018. Published October 2013October 2018. Originally approved in 1912. Last previous edition approved in 20122013 as

B3 – 12.B3 – 13. DOI: 10.1520/B0003-13.10.1520/B0003-13R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B3 − 13 (2018)

TABLE 1 Tensile Requirements

Diameter Area at 20°C Elongation in

10 in.

(254 mm),

2 2

in. mm cmils in. mm

% min

Diameter Area at 20°C Elongation in

10 in.

(254 mm),

2 2

in. mm cmils in. mm

% min

0.4600 11.684 211 600 0.1662 107.0 35

0.4096 10.404 167 800 0.1318 85.0 35

0.3648 9.266 133 100 0.1045 67.4 35

0.3249 8.252 105 600 0.08291 53.5 35

0.2893 7.348 83 690 0.06573 42.4 30

0.2576 6.543 66 360 0.05212 33.6 30

0.2294 5.827 52 620 0.04133 26.7 30

0.2043 5.189 41 740 0.03278 21.2 30

0.1819 4.620 33 090 0.02599 16.8 30

0.1620 4.115 26 240 0.02061 13.3 30

0.1443 3.665 20 820 0.01635 10.5 30

0.1285 3.264 16 510 0.01297 8.37 30

0.1144 2.906 13 090 0.01028 6.63 30

0.1019 2.588 10 380 0.008155 5.26 25

0.0907 2.304 8 230 0.00646 4.17 25

0.0808 2.052 6 530 0.00513 3.31 25

0.0720 1.829 5 180 0.00407 2.63 25

0.0641 1.628 4 110 0.00323 2.08 25

0.0571 1.450 3 260 0.00256 1.65 25

0.0508 1.290 2 580 0.00203 1.31 25

0.0453 1.151 2 050 0.00161 1.04 25

0.0403 1.024 1 620 0.00128 0.823 25

0.0359 0.912 1 290 0.00101 0.654 25

0.0320 0.813 1 020 0.000804 0.517 25

0.0285 0.724 812 0.000638 0.411 25

0.0253 0.643 640 0.000503 0.324 25

0.0226 0.574 511 0.000401 0.259 25

0.0201 0.511 404 0.000317 0.205 20

0.0179 0.455 320 0.000252 0.162 20

0.0159 0.404 253 0.000199 0.128 20

0.0142 0.361 202 0.000158 0.102 20

0.0126 0.320 159 0.000125 0.081 20

0.0113 0.287 128 0.000100 0.065 20

0.0100 0.254 100 0.0000785 0.051 15

0.0089 0.226 79.2 0.0000622 0.040 15

0.0080 0.203 64.0 0.0000503 0.032 15

0.0071 0.180 50.4 0.0000396 0.026 15

0.0063 0.160 39.7 0.0000312 0.020 15

0.0056 0.142 31.4 0.0000246 0.016 15

0.0050 0.127 25.0 0.0000196 0.013 15

0.0045 0.114 20.2 0.000 0159 0.010 15

0.0040 0.102 16.0 0.0000126 0.0081 15

0.0035 0.089 12.2 0.00000962 0.0062 15

0.0031 0.079 9.61 0.00000755 0.0049 15

NOTE 1—Specification B49 defines copper suitable for use.

4.2 Copper bars of special qualities, forms, or types, as may be agreed upon between the manufacturer and the purchaser, and

which will conform to the requirements prescribed in this specification may also be used.

5. General Requirements (see Section 8)

5.1 Tensile Strength and Elongation—The wire shall conform to the requirements for elongation prescribed in Table 1 (see

Explanatory Note 2). No requirements for tensile strength are specified. For wire whose nominal diameter is more than 0.001 in.

(0.025 mm) greater than a size listed in Table 1, but less than that of the next larger size, the requirements of the next larger size

shall apply.

2 2

5.2 Resistivity—The electrical resistivity at 20°C shall not exceed 875.20 Ω·lb/mile (0.15328 Ω·g/m ) (see Explanatory Note

5).

5.3 Dimensions and Permissible Variations—The wire sizes shall be expressed as the diameter of the wire in decimal fractions

of an inch to the nearest 0.0001 in. (or 0.001 mm) (see Explanatory Note 3). For diameters under 0.0100 in. (0.254 mm), the wire

shall not vary from the specified diameter by more than plus and minus 0.0001 in. (0.0025 mm), and for diameters of 0.0100 in.

(0.254 mm) and over the wire shall not vary from the specified diameter by more than plus and minus 1 %, expressed to the nearest

0.0001 in. (or 0.001 mm).

B3 − 13 (2018)

5.4 Joints—Necessary joints in the completed wire and in the wire and rods prior to final drawing shall be made in accordance

with the best commercial practice.

5.5 Finish—The wire shall be free of all imperfections not consistent with the best commercial practice.

6. Test Methods

6.1 Tensile Strength and Elongation—No test for tensile strength shall be required.

6.1.1 The elongation of wire with a nominal diameter greater than 0.0808 in. (2.052 mm) shall be determined as the permanent

increase in length due to the breaking of the wire in tension (see Explanatory Note 4). The elongation shall be measured between

gage marks placed originally 10 in. (242 mm) apart upon the test specimen and expressed in percent of the original length.

6.1.2 The elongation of wire with a nominal diameter equal to or less than 0.0808 in. (2.053 mm) may be determined as

described above or by measurements made between the jaws of the testing machine. When measurements are made between the

jaws, the zero length shall be the distance between the jaws at the start of the tension test and be as near 10 in. (254 mm) as

practicable. The final length shall be the distance between the jaws at the time of rupture. The fracture shall be between gage marks

or jaws of the testing machine, depending on method used, and not closer than 1 in. (25.4 mm) to either gage mark or jaw.

6.2 Resistivity—Determine the electrical resistivity of the material in accordance with Test Method B193 (Explanatory Note 5).

The purchaser may accept certification that the wire was drawn from stock meeting the International Standard for Annealed Copper

instead of resistivity tests on the finished wire.

6.3 Dimensional Measurements—Dimensional measurements shall be made with a micrometer caliper equipped with a vernier

graduated in 0.0001 in. (0.0025 mm). Measurements shall be made on at least three places on each unit selected for this test. If

accessible, one measurement shall be taken on each end and one near the middle. The average of the three measurements shall

determine compliance with the requirements.

6.4 Surface Finish—Make a surface-finish inspection with the unaided eye (normal spectacles acceptable).

7. Inspection

7.1 General (Explanatory Note 6 and Note 7)—Unless otherwise specified in the contract or purchase order, the manufacturer

shall be responsible for the performance of all inspection and test requirements specified.

7.1.1 All inspections and tests shall be made at the place of manufacture unless otherwise especially agreed upon between the

manufacturer and the purchaser at the time of purchase.

7.1.2 The manufacturer shall afford the inspector representing the purchaser all reasonable manufacturer’s facilities to satisfy

him that the material is being furnished in accordance with this specification.

7.1.3 Unless otherwise agreed upon between the purchaser and the manufacturer, conformance of the wire to the various

requirements listed in Section 5 shall be determined on samples taken from each lot of wire presented for acceptance.

7.1.4 The manufacturer shall, if requested prior to inspection, certify that all wire in the lot was made under such conditions

that the product as a whole conforms to the requirements of this specification as determined by regularly made and recorded tests.

7.2 Definitions Applicable to Inspection:

7.2.1 lot (Explanatory Note 7)—any amount of wire of one type and size presented for acceptance at one time, such amount,

ho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.