ASTM F1606-95

(Practice)Standard Practice for Rehabilitation of Existing Sewers and Conduits with Deformed Polyethylene (PE) Liner (Withdrawn 2004)

Standard Practice for Rehabilitation of Existing Sewers and Conduits with Deformed Polyethylene (PE) Liner (Withdrawn 2004)

SCOPE

1.1 This practice covers the requirements for the installation of deformed polyethylene (PE) liner for pipeline rehabilitation.

1.2 This practice describes a method by which the PE liner may be installed with little or no excavation.

1.3 This practice applies to the rehabilitation of 3 to 18- in. (76 to 457-mm) diameter pipe in terms of installation. The specifier determines what DR is used based on conditions of the specific application.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice covers the requirements for the installation of deformed polyethylene (PE) liner for pipeline rehabilitation.

Formerly under the jurisdiction of Committee F17 on Plastic Piping Systems, this practice was withdrawn in July 2004. This practice was withdrawn in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1606 – 95

Standard Practice for

Rehabilitation of Existing Sewers and Conduits with

Deformed Polyethylene (PE) Liner

This standard is issued under the fixed designation F 1606; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 Thispracticecoverstherequirementsfortheinstallation 3.1 General—Abbreviations used in this practice are in

ofdeformedpolyethylene(PE)linerforpipelinerehabilitation. accordance with Terminology D1600, and definitions are in

1.2 This practice describes a method by which the PE liner accordance with Terminology F412, unless otherwise indi-

may be installed with little or no excavation. cated.

1.3 This practice applies to the rehabilitation of 3 to 18- in. 3.2 Definitions of Terms Specific to This Standard: Descrip-

(76 to 457-mm) diameter pipe in terms of installation. The tions of Terms Specific to This Standard:

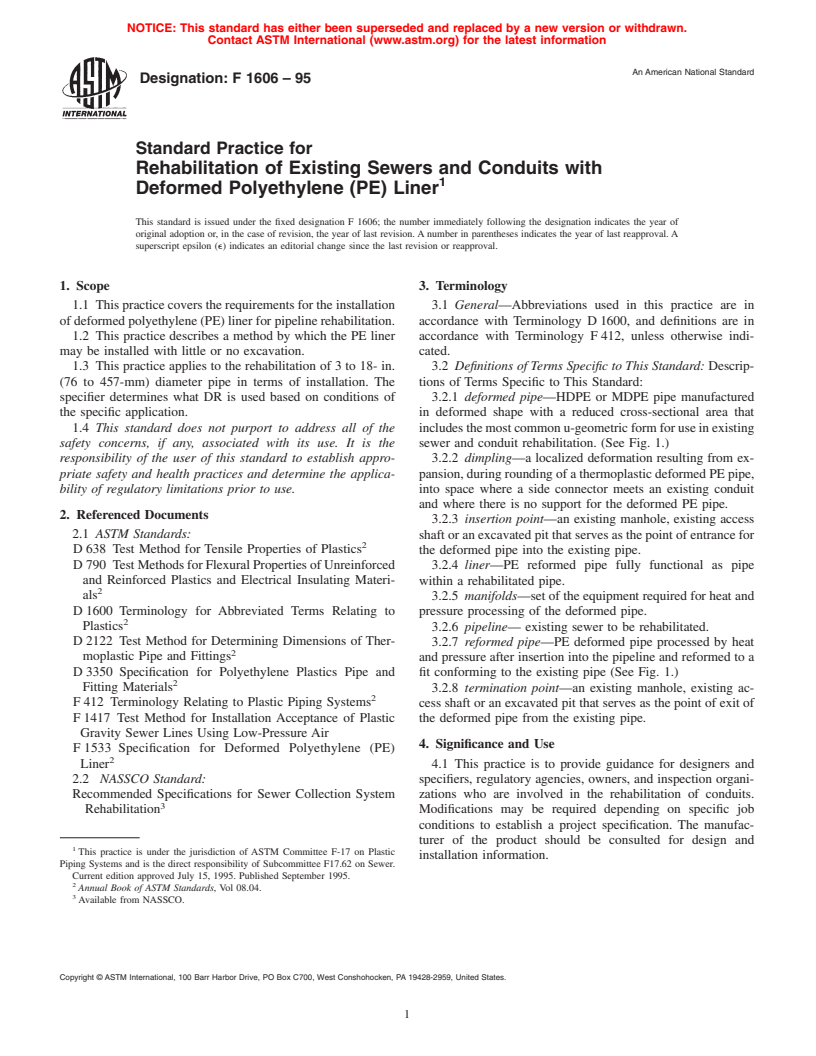

specifier determines what DR is used based on conditions of 3.2.1 deformed pipe—HDPE or MDPE pipe manufactured

the specific application. in deformed shape with a reduced cross-sectional area that

1.4 This standard does not purport to address all of the includesthemostcommonu-geometricformforuseinexisting

safety concerns, if any, associated with its use. It is the sewer and conduit rehabilitation. (See Fig. 1.)

responsibility of the user of this standard to establish appro- 3.2.2 dimpling—a localized deformation resulting from ex-

priate safety and health practices and determine the applica- pansion,duringroundingofathermoplasticdeformedPEpipe,

bility of regulatory limitations prior to use. into space where a side connector meets an existing conduit

and where there is no support for the deformed PE pipe.

2. Referenced Documents

3.2.3 insertion point—an existing manhole, existing access

2.1 ASTM Standards:

shaftoranexcavatedpitthatservesasthepointofentrancefor

D638 Test Method for Tensile Properties of Plastics the deformed pipe into the existing pipe.

D790 TestMethodsforFlexuralPropertiesofUnreinforced

3.2.4 liner—PE reformed pipe fully functional as pipe

and Reinforced Plastics and Electrical Insulating Materi-

within a rehabilitated pipe.

als 3.2.5 manifolds—set of the equipment required for heat and

D1600 Terminology for Abbreviated Terms Relating to

pressure processing of the deformed pipe.

Plastics 3.2.6 pipeline— existing sewer to be rehabilitated.

D2122 Test Method for Determining Dimensions of Ther-

3.2.7 reformed pipe—PE deformed pipe processed by heat

moplastic Pipe and Fittings and pressure after insertion into the pipeline and reformed to a

D3350 Specification for Polyethylene Plastics Pipe and

fit conforming to the existing pipe (See Fig. 1.)

Fitting Materials 3.2.8 termination point—an existing manhole, existing ac-

F412 Terminology Relating to Plastic Piping Systems

cess shaft or an excavated pit that serves as the point of exit of

F1417 Test Method for Installation Acceptance of Plastic the deformed pipe from the existing pipe.

Gravity Sewer Lines Using Low-Pressure Air

4. Significance and Use

F 1533 Specification for Deformed Polyethylene (PE)

Liner 4.1 This practice is to provide guidance for designers and

2.2 NASSCO Standard: specifiers, regulatory agencies, owners, and inspection organi-

Recommended Specifications for Sewer Collection System zations who are involved in the rehabilitation of conduits.

Rehabilitation Modifications may be required depending on specific job

conditions to establish a project specification. The manufac-

turer of the product should be consulted for design and

This practice is under the jurisdiction of ASTM Committee F-17 on Plastic

installation information.

Piping Systems and is the direct responsibility of Subcommittee F17.62 on Sewer.

Current edition approved July 15, 1995. Published September 1995.

Annual Book of ASTM Standards, Vol 08.04.

Available from NASSCO.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1606

ESCR 3 3

HDB 3 4

Color and UV Stabilizer C, D, or E C, D, or E

5.3 The deformed pipe should be spooled in a continuous

length for storage and shipping to the job site. Handling and

storage should be in accordance with the manufacturer’s

published recommendations.

5.4 Thereshouldbenoevidenceofsplits,cracks,crazingor

breaks in the deformed pipe on the spool. If any of these

conditions are evident, the damaged material should be re-

placed.

6. Installation Recommendations

6.1 Cleaning and Inspection:

6.1.1 Prior to entering access areas, such as manholes, and

performing inspection or cleaning operations, an evaluation of

theatmospheretodeterminethepresenceoftoxicorflammable

vapors or lack of oxygen shall be undertaken in accordance

with local, state, or federal safety regulations.

6.1.2 Cleaning of Pipeline—Internal debris should be re-

(a) Deformed Pipe

moved from the existing pipeline. Gravity pipes should be

cleaned with hydraulically powered equipment, high-velocity

jet cleaners, or mechanically powered equipment, in accor-

dance with NASSCO Recommended Specifications for Sewer

Collection System Rehabilitation.

6.1.3 Inspection of Pipelines—Inspection of pipelines

should be performed by experienced personnel trained in

locating breaks, obstacles, and service connections by closed

circuit television. The interior of the pipeline should be

carefully inspected to determine the location of any conditions

thatmaypreventproperinsertionofthedeformedpipe,suchas

protruding service taps, collapsed or crushed pipe, out-of-

roundness, significant line sags, and deflected joints. All such

conditions should be noted in the plans so that they can be

corrected prior to liner installation. If a user desires to ignore

any of the obstacles with PE liner pipe, the contractor should

inform the user about expected results.

6.1.4 Line Obstructions—Theinsideoftheexistingpipeline

should be clear of obstructions that will prevent the proper

insertionandfullexpansionofthedeformedpipe.Obstructions

(b) Reformed Pipe

could include dropped or offset joints of more than 12.5% of

inside pipe diameter; service connections that protrude into the

NOTE 1—This figure is intended only for clarification of terms specific

pipemorethan12.5%oftheinsidediameteror1-in.(25mm),

to this practice and shows representative deformed and reformed pipe

whicheverisless;andotherobstructionsincross-sectionalarea

shapes.Otherdeformedpipeshapesmaymeetthegeneralrequirementsof

of more than 14% based on the inside diameter of the existing

this practice.

pipe. If inspection reveals an obstruction that cannot be

FIG. 1 Deformed Pipe and Reformed Pipe—Clarification of Terms

removedbycleaningorrodding,thenapointrepairexcavation

should be made to uncover and remove or repair the obstruc-

5. Materials

tion. Typically, bends along the pipe length in excess of 30°

5.1 The deformed PE liner should be in accordance with

and changes in pipe size cannot be accommodated. Such

Specification F1533.

conditions require access at these points for termination and

5.2 The following are minimum cell classification numbers

start of a new insertion.

for HDPE polyethylene pipe based on Specification D3350.

6.2 Bypassing—If flow cannot be interrupted for the neces-

Specification D3350 should be consulted for property value

saryduration,bypassingofflowisrequiredaroundthesections

limits based on these cells.

of the existing pipeline designated for rehabilitation. The

Type PE 2406 PE 3408

bypass should be made by plugging the line at the point

Density 2 3

upstreamofthepipetobereconstructedandbypassingtheflow

Melt 3 4

Flexural Modulus 4 5 to a downstream point or adjacent system. The bypass lines,

Tensile Strength 3 4

pump, and pump-sump pit dimensions, if required, should be

F 1606

of adequate capacity and size to handle the flow during the theinteriorofthepipelinebymeansofatelevisioncameraand

installation period. Services within this work area will be a remote control cutting device unless otherwise specified by

temporarily out of service. the owner.

NOTE 2—Inmanycases,agoodsealisprovidedwheretheformedpipe

NOTE 1—Public advisory services will be required to notify all parties

dimples at service connections. However, this practice should not be

whose service laterals will be out of commission and to advise against

construed to provide a 100% watertight seal at all service connections. If

water usage until the main line is back in service.

total elimination of infiltration and inflow is desired, other means, which

6.3 Insertion:

are beyond the scope of this practice, may be necessary to seal service

connections and to rehabilitate service lines and manholes.

6.3.1 The spool of deformed pipe should be positioned near

the insertion point. A cable should be strung through the

6.8 Thenumericinformationgivenfortheprocessingofthe

existing conduit and attached to the deformed pipe. The

liner are the standard practical information. Where the specific

deformed pipe should be pulled (with a power winch and the

cases require, such as long pipelines, unusually difficult con-

cable) directly through the insertion point to the termination

ditions, extremely fragile pipelines and unique jobs, the pro-

point. Pulling forces should be limited so as not to exceed the

cessing parameters may vary. The final outcome of the pro-

axial strain limits of the deformed pipe. The measured pulling

cessing should comply with this practice. The design engineer

operation limits pulling force to allowable tensile stress (1500

should determine the applicable processing parameters in

psi or 50% of the yield) times the pipe wall cross sectional

accordance with the manufacturer’s specific specifications and

area.

instructions.

6.3.2 After the insertion is complete, the tension from the

winch should be relieved and the deformed pipe should be

7. Inspection and Acceptance

cutoff at the insertion point and restrained at the termination

7.1 The installation may be inspected by closed-circuit

point. Allowances for pipe length normalization should be

television. The reformed pipe should be continuous over the

made to attain correct length.

entire length of the insertion and conform to the walls of the

6.4 Reforming:

existing pipe evidenced by visible joint deformation and

6.4.1 Temperatures and pressures should be monitored and mirroring of existing pipe irregularities. Variations from true

recordedthroughouttheinstallationprocesstoensurethateach lineandgrademaybeinherentbecauseoftheconditionsofthe

phase of the process is achieved at the required levels. original piping. No infiltration of groundwater through the

reformedwallshouldbeobserved.Allserviceentrancesshould

Temperature gages should be placed near the upstream and

downstream manholes to measure the liner’s outside tempera- be accounted for and unobstructed.

ture. 7.2 Leakage Testing—If required by the owner or desig-

nated in the contract documents or purchase order, or both,

6.4.2 Steam and air pressure are applied through the inlet

gravitypipesshouldbetestedforleakage.Thistestshouldtake

manifold and the deformed pipe should be reformed to

place after the reformed pipe has cooled down to ambient

conform to the existing pipe wall. The deformed pipe shall be

temperature.Thistestislimitedtopipelengthswithnoservice

pressurized up to 14.5 psig (100 kPa) max, at a steam

laterals. One of the following two methods should be used:

temperature in excess of 235°F (112.8°C), and less than 260°F

7.2.1 Exfiltration Test Method—This test involves plugging

(126.7°C), while the termination point valves, located at the

the reformed pipe at both ends and filling it with water. The

outlet manifold, are kept open to provide heat flow. The

allowable water exfiltration for any length of pipe between

minimum temperature needed at the outside of the HDPE pipe

terminationpoints shouldnot exceed 50 gal/in. ofinternalpipe

should be 185 6 9°F (85 6 5°C). The pressure should then be

diameter per mile per day, providing that all air has been bled

increased in increments up to a maximum of 26 psig (179.4

from the line. The leakage quantity should be gauged by the

kPa). Maximum pressure may be lower, depending on DR and

water level in a temporary standpipe placed in the upstream

condition of the pipeline.

plug. During exfiltration testing, the maximum internal pipe

6.4.3 The reforming pressure should be maintained to en-

pressure at the lowest end should not exceed 10 ft (3.0 m) of

sure complete expansion of the pipe and to allow for dimpling

water or 4.3 psi (29.7 kPa). The water level inside of the

at side connections.

standpipe should be 2 ft (0.6 m) higher than the top of the pipe

6.5 Cool Down—The reformed pipe should be cooled to a

or 2 ft (0.6 m) higher than the groundwater level, whichever is

temperature of 100°F (38°C). The pressure should then be

greater. The test should be conducted for a minimum of 1 h.

slowly increased to approximately 33 psig (227.7 kPa), while

7.2.2 Air Test—Thistestshouldbeconductedinaccordance

applying air or water for continued cooling. The equipment

with Test Method F1417.

should be disconnected after ambient temperature is attained.

NOTE 3—The leakage test is intended to evaluate the watertightness of

6.6 After the reformed pipe has cooled down, the terminat-

the mainline only.

ing ends should be trimmed to a minimum of 3 in. (76.2 mm)

beyond the existing pipe to account for possible shrinkage

7.3 Foreachinsertionlengthdesignatedbytheownerinthe

during cooling to ground temperatures.

contract documents or purchase order, a reformed field sample

6.7 Service Connections—Afterthelinerhasbeenreformed should be prepared at the insertion or termination point, or

and stabilized, the existing active service connections should both. The mold pipe shall be of like diameter to the existing

be reconnected. This should be done without excavation from pipe. The sample may be taken from one reformed pipe

F 1606

A,B

TABLE 1 Dimensions and Tolerances

diameter length removable sleeve. The following test proce-

dures should be followed after the sample is expanded,

Outside

Minimum Wall Thickness, in.

cooled-down and removed from the mold pipe.

Diameter, Outside Diameter

7.3.1 Dimensions:

in. Tolerances, in. DR17 DR24 DR26 DR32.5

7.3.1.1 Reformed Pipe Diameter—The average outside di-

3.00 +.00–.015 0.176 0.124 0.115 —

ameter of the reformed pipe shall meet the requirements given 4.00 +.00–.015 0.234 0.166 0.15

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.