ASTM E2555-07(2018)

(Practice)Standard Practice for Factors and Procedures for Applying the MIL-STD-105 Plans in Life and Reliability Inspection

Standard Practice for Factors and Procedures for Applying the MIL-STD-105 Plans in Life and Reliability Inspection

SIGNIFICANCE AND USE

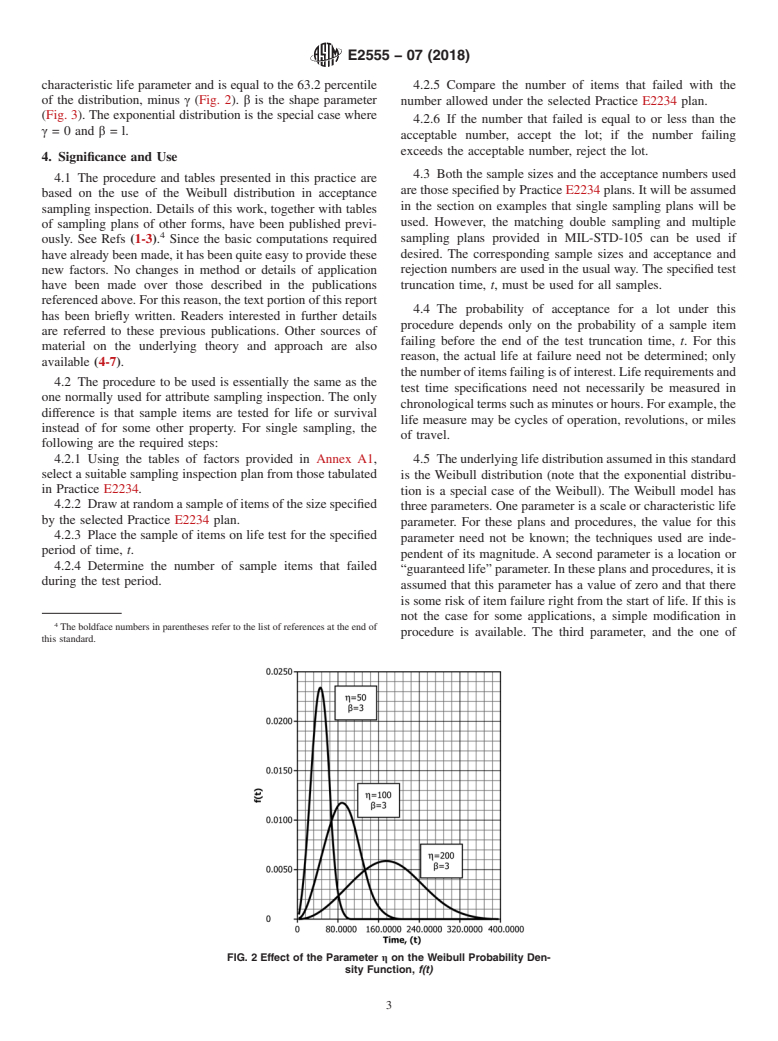

4.1 The procedure and tables presented in this practice are based on the use of the Weibull distribution in acceptance sampling inspection. Details of this work, together with tables of sampling plans of other forms, have been published previously. See Refs (1-3).4 Since the basic computations required have already been made, it has been quite easy to provide these new factors. No changes in method or details of application have been made over those described in the publications referenced above. For this reason, the text portion of this report has been briefly written. Readers interested in further details are referred to these previous publications. Other sources of material on the underlying theory and approach are also available (4-7).

4.2 The procedure to be used is essentially the same as the one normally used for attribute sampling inspection. The only difference is that sample items are tested for life or survival instead of for some other property. For single sampling, the following are the required steps:

4.2.1 Using the tables of factors provided in Annex A1, select a suitable sampling inspection plan from those tabulated in Practice E2234.

4.2.2 Draw at random a sample of items of the size specified by the selected Practice E2234 plan.

4.2.3 Place the sample of items on life test for the specified period of time, t.

4.2.4 Determine the number of sample items that failed during the test period.

4.2.5 Compare the number of items that failed with the number allowed under the selected Practice E2234 plan.

4.2.6 If the number that failed is equal to or less than the acceptable number, accept the lot; if the number failing exceeds the acceptable number, reject the lot.

4.3 Both the sample sizes and the acceptance numbers used are those specified by Practice E2234 plans. It will be assumed in the section on examples that single sampling plans will be used. However, the matching double sampling and multiple sampling plans provided in MIL-...

SCOPE

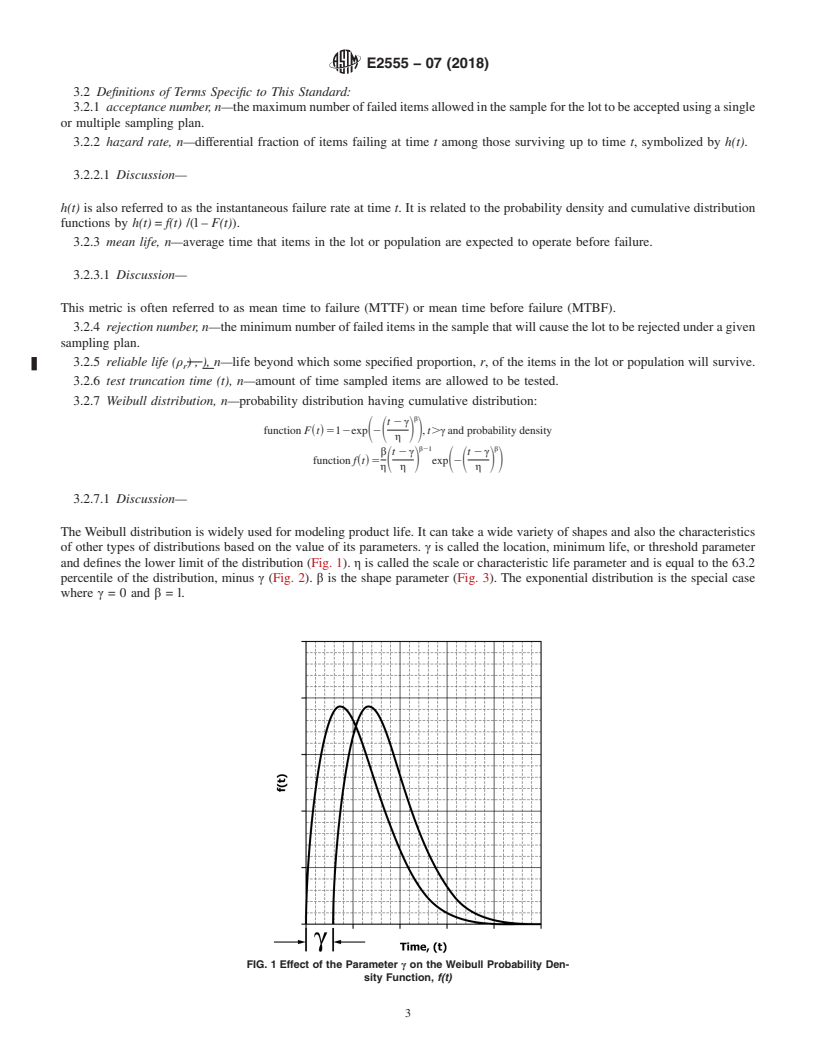

1.1 This practice presents a procedure and related tables of factors for adapting Practice E2234 (equivalent to MIL-STD-105) sampling plans to acceptance sampling inspection when the item quality of interest is life length or reliability. Factors are provided for three alternative criteria for lot evaluation: mean life, hazard rate, and reliable life. Inspection of the sample is by attributes with testing truncated at the end of some prearranged period of time. The Weibull distribution, together with the exponential distribution as a special case, is used as the underlying statistical model.

1.2 A system of units is not specified by this practice.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2555 − 07 (Reapproved 2018) An American National Standard

Standard Practice for

Factors and Procedures for Applying the MIL-STD-105 Plans

1

in Life and Reliability Inspection

This standard is issued under the fixed designation E2555; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Documents:

MIL-STD-105ESampling Procedures and Tables for In-

1.1 This practice presents a procedure and related tables of

3

spection by Attributes

factors for adapting Practice E2234 (equivalent to MIL-STD-

105) sampling plans to acceptance sampling inspection when

3. Terminology

the item quality of interest is life length or reliability. Factors

3.1 Definitions:

are provided for three alternative criteria for lot evaluation:

3.1.1 TheterminologydefinedinTerminologyE456applies

mean life, hazard rate, and reliable life. Inspection of the

to this practice unless modified herein.

sampleisbyattributeswithtestingtruncatedattheendofsome

3.1.2 acceptancequalitylevel(AQL),n—qualitylimitthatis

prearranged period of time. The Weibull distribution, together

theworsttolerableprocessaveragewhenacontinuingseriesof

with the exponential distribution as a special case, is used as

lots is submitted for acceptance sampling. E2234

the underlying statistical model.

3.1.2.1 Discussion—This term is often referred to as the

1.2 A system of units is not specified by this practice.

“acceptance quality limit.”

1.3 This standard does not purport to address all of the

3.1.2.2 Discussion—Thisdefinitionsupersedesthatgivenin

safety concerns, if any, associated with its use. It is the

MIL-STD-105E.

responsibility of the user of this standard to establish appro-

3.1.2.3 Discussion—A sampling plan and an AQL are cho-

priate safety, health, and environmental practices and deter-

sen in accordance with the risk assumed. Use of a value of

mine the applicability of regulatory limitations prior to use.

AQL for a certain defect or group of defects indicates that the

1.4 This international standard was developed in accor-

sampling plan will accept the great majority of the lots or

dance with internationally recognized principles on standard-

batchesprovidedtheprocessaveragelevelofpercentdefective

ization established in the Decision on Principles for the

(or defects per hundred units) in these lots or batches are no

Development of International Standards, Guides and Recom-

greater than the designated value ofAQL. Thus, theAQL is a

mendations issued by the World Trade Organization Technical

designated value of percent defective (or defects per hundred

Barriers to Trade (TBT) Committee.

units) for which lots will be accepted most of the time by the

sampling procedure being used. The sampling plans provided

2. Referenced Documents

herein are so arranged that the probability of acceptance at the

2

2.1 ASTM Standards:

designated AQL value depends upon the sample size, being

E456Terminology Relating to Quality and Statistics

generally higher for large samples than for small ones, for a

E2234Practice for Sampling a Stream of Product by Attri-

given AQL. The AQL alone does not identify the chances of

butes Indexed by AQL

accepting or rejecting individual lots or batches but more

directly relates to what might be expected from a series of lots

1

or batches, provided the steps indicated in this refer to the

ThispracticeisunderthejurisdictionofASTMCommitteeE11onQualityand

Statistics and is the direct responsibility of Subcommittee E11.40 on Reliability.

operating characteristic curve of the plan to determine the

Current edition approved April 1, 2018. Published May 2018. Originally

relative risks.

approved in 2007. Last previous version approved in 2012 as E2555–07 (2012).

DOI: 10.1520/E2555-07R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM MIL-STD-105Eisalsocommonlyreferredtoas“MIL-STD-105.”Itisvirtually

Standards volume information, refer to the standard’s Document Summary page on identical in content to its predecessor, MIL-STD-105D.These documents are out of

the ASTM website. print.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2555 − 07 (2018)

3.1.3 consumer’s risk, n—probability that a lot having 3.2 Definitions of Terms Specific to This Standard:

specified rejectable quality level will be accepted under a 3.2.1 acceptance number, n—the maximum number of

defined sampling plan. failed items allowed in the sample f

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2555 − 07 (Reapproved 2012) E2555 − 07 (Reapproved 2018)An American National Standard

Standard Practice for

Factors and Procedures for Applying the MIL-STD-105 Plans

1

in Life and Reliability Inspection

This standard is issued under the fixed designation E2555; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice presents a procedure and related tables of factors for adapting Practice E2234 (equivalent to MIL-STD-105)

sampling plans to acceptance sampling inspection when the item quality of interest is life length or reliability. Factors are provided

for three alternative criteria for lot evaluation: mean life, hazard rate, and reliable life. Inspection of the sample is by attributes with

testing truncated at the end of some prearranged period of time. The Weibull distribution, together with the exponential distribution

as a special case, is used as the underlying statistical model.

1.2 A system of units is not specified by this practice.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E456 Terminology Relating to Quality and Statistics

E2234 Practice for Sampling a Stream of Product by Attributes Indexed by AQL

2.2 Other Documents:

3

MIL-STD-105E Sampling Procedures and Tables for Inspection by Attributes

3. Terminology

3.1 Definitions:

3.1.1 The terminology defined in Terminology E456 applies to this practice unless modified herein.

3.1.2 acceptance quality level (AQL), n—quality limit that is the worst tolerable process average when a continuing series of

lots is submitted for acceptance sampling. E2234

3.1.2.1 Discussion—

This term is often referred to as the “acceptance quality limit.”

3.1.2.2 Discussion—

This definition supersedes that given in MIL-STD-105E.

3.1.2.3 Discussion—

1

This practice is under the jurisdiction of ASTM Committee E11 on Quality and Statistics and is the direct responsibility of Subcommittee E11.40 on Reliability.

Current edition approved May 1, 2012April 1, 2018. Published May 2012May 2018. Originally approved in 2007. Last previous version approved in 20072012 as

E2555 – 07.E2555 – 07 (2012). DOI: 10.1520/E2555-07R12.10.1520/E2555-07R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

MIL-STD-105E is also commonly referred to as “MIL-STD-105.” It is virtually identical in content to its predecessor, MIL-STD-105D. These documents are out of print.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2555 − 07 (2018)

A sampling plan and an AQL are chosen in accordance with the risk assumed. Use of a value of AQL for a certain defect or group

of defects indicates that the sampling plan will accept the great majority of the lots or batches provided the process average level

of percent defective (or defects per hundred units) in these lots or batches are no greater than the designated value of AQL. Thus,

the AQL is a designated value of percent defective (or defects per hundred units) for which lots will be accepted most of the time

by the sampling procedure being used. The sampling plans provided herein are so arranged that the probability of acceptance at

the designated AQL value depends upon the sample size, being generally higher for large samples than for small ones, for a given

AQL. The AQL alone does not identify the chances of accepting or rejecting individual lots or batches but more directly relates

to what might be e

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.