ASTM E3278-21

(Test Method)Standard Test Method for Bubble Point Pressure of Woven Wire Filter Cloth

Standard Test Method for Bubble Point Pressure of Woven Wire Filter Cloth

SIGNIFICANCE AND USE

5.1 Users of industrial woven wire filter cloth as covered by Specification E2814 commonly desire to specify the largest pore size as determined by converting the pressure result of a bubble point test to an absolute filtration rating in micrometres (also known as microns). This test method requires a comprehensive bubble point test method as well as a valid tortuosity or conversion factor for the calculation. This pore size result may be used as a standard rating of a material specification, a performance evaluation or acceptance criteria for material supplied, or a 1st article inspection requirement during the weaving of the cloth. The test is conducted using sample material cut from a woven roll of cloth, and hence should be indicative of the manufactured lot, given the application of appropriate tolerances.

5.2 While some users may desire a bubble point test conducted on some finished, fabricated filter unit, the test conditions for this type of test are outside the scope of this test method. The geometric test parameters for this type of specimen must be explicitly agreed to by the user and producer, and is to be considered a custom test method.

SCOPE

1.1 This test method is based on a capillary flow test that measures the pressure required to force an air bubble through a flat specimen of industrial woven wire filter cloth wetted under a test liquid of known surface tension. An established physical phenomenon, the pressure is inversely proportional to the pore size. This test method details the methodology to determine the bubble point pressure, and the applicable variables to calculate a standardized pressure. The test is recommended for filter cloth with a minimum test pressure of 1.0 inches of water.

1.2 A means for determining a pore size calculation factor (CF) is provided to allow the calculation of a pore size from the resultant pressure (see 15.2).

1.3 This test method uses mixed unit of measures. The values stated in inch-pound units shall be considered standard with regard to the bubble point pressure, test fixture, and procedures. The values stated in SI units shall be considered standard for the test fluid properties and pore size.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3278 − 21

Standard Test Method for

1

Bubble Point Pressure of Woven Wire Filter Cloth

This standard is issued under the fixed designation E3278; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1638Terminology Relating to Sieves, Sieving Methods,

and Screening Media

1.1 This test method is based on a capillary flow test that

E2814Specification for Industrial Woven Wire Filter Cloth

measures the pressure required to force an air bubble through

3

a flat specimen of industrial woven wire filter cloth wetted 2.2 SAE Standards:

under a test liquid of known surface tension. An established ARP901Bubble-Point Test Method

physical phenomenon, the pressure is inversely proportional to

the pore size. This test method details the methodology to 3. Terminology

determine the bubble point pressure, and the applicable vari-

3.1 Definitions:

ables to calculate a standardized pressure. The test is recom-

3.1.1 For definitions of related terms, refer to Terminology

mended for filter cloth with a minimum test pressure of 1.0

E1638.

inches of water.

3.2 Definitions of Terms Specific to This Standard:

1.2 A means for determining a pore size calculation factor

3.2.1 absolute filtration rating, n—largestporesizefoundin

(CF)isprovidedtoallowthecalculationofaporesizefromthe

the test specimen.

resultant pressure (see 15.2).

3.2.2 hydraulic diameter, n—the diameter equal to four

1.3 This test method uses mixed unit of measures. The

times the pore throat area divided by the pore throat perimeter.

values stated in inch-pound units shall be considered standard

3.2.2.1 Discussion—This diameter can be generated using

with regard to the bubble point pressure, test fixture, and

4,5

procedures. The values stated in SI units shall be considered the PoroDict module in the software GeoDict (see 4.2.2).

standard for the test fluid properties and pore size.

3.2.3 hydraulic diameter bubble point pressure, n—a pres-

1.4 This standard does not purport to address all of the

sure calculated using the hydraulic diameter.

safety concerns, if any, associated with its use. It is the

3.2.3.1 Discussion—This pressure can be generated using

responsibility of the user of this standard to establish appro-

the PoroDict module in the software GeoDict (see 4.2.2), and

priate safety, health, and environmental practices and deter-

is based on a statistically fitted bubble contact angle of 40

mine the applicability of regulatory limitations prior to use.

degrees and the hydraulic diameter.

1.5 This international standard was developed in accor-

3.2.4 percolationpathfittingparticlediameter,n—themaxi-

dance with internationally recognized principles on standard-

mum pore diameter based on the percolation path geometric

ization established in the Decision on Principles for the

pore size analysis.

Development of International Standards, Guides and Recom-

3.2.4.1 Discussion—This diameter can be generated using

mendations issued by the World Trade Organization Technical

the PoroDict module in the software GeoDict (see 4.2.2), and

Barriers to Trade (TBT) Committee.

which results have been shown to correspond to the results of

glass bead testing (see Specification E2814, Table 1).

2. Referenced Documents

2

3.2.5 pore size, n—themaximumequivalentsphericaldiam-

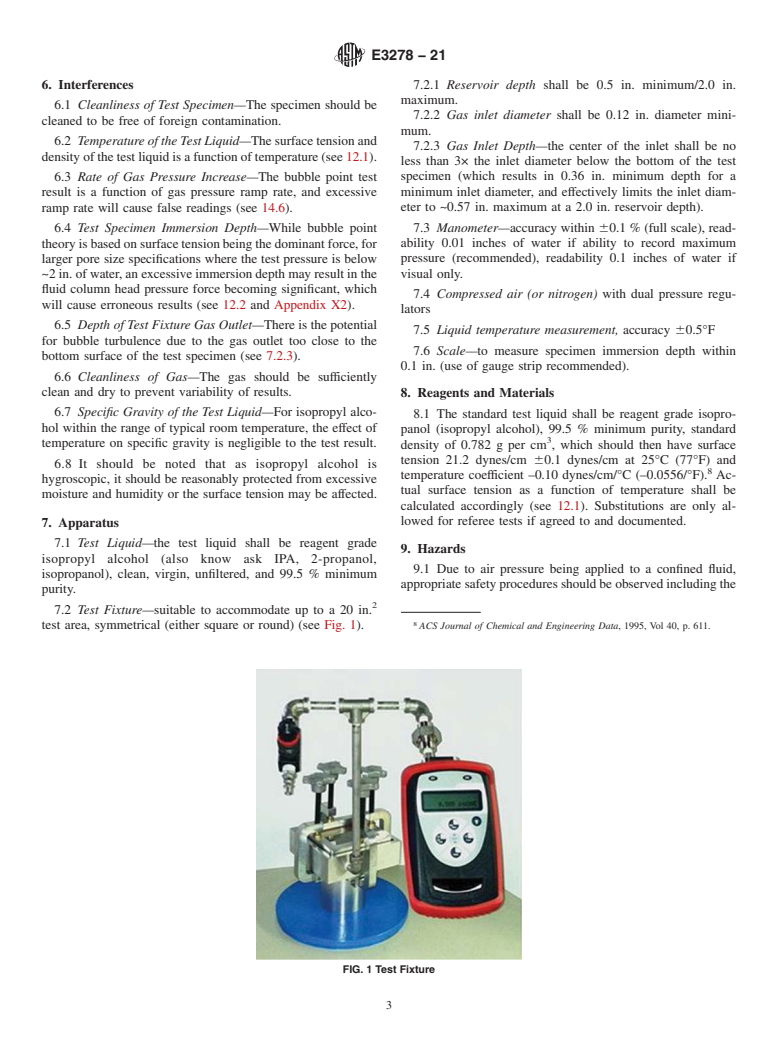

2.1 ASTM Standards:

eter of an opening in the filter cloth.

1

This test method is under the jurisdiction ofASTM Committee E29 on Particle

3

and Spray Characterization and is the direct responsibility of Subcommittee E29.01 AvailablefromSAEInternational(SAE),400CommonwealthDr.,Warrendale,

on Sieves, Sieving Methods, and Screening Media. PA 15096, http://www.sae.org.

4

Current edition approved May 1, 2021. Published September 2021. DOI: GeoDict is a trademark of Math2Market GmbH, Kaiserslautern, Germany.

5

10.1520/E3278-21. The sole source of supply of this simulation program known to the committee

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or atthistimeisGeoDictbyMath2MarketGmbH,Kaiserslautern,Germany.Ifyouare

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM aware of alternative suppliers, please provide this information to ASTM Interna-

Standards volume information, refer to the standard’s Document Summary page on tional Headquarters.Your comments will receive careful consideration at a meeting

1

the ASTM website. of the responsible technical committee, which you may attend.

Copyright © ASTM Interna

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.