ASTM F1196-94(2000)

(Specification)Standard Specification for Sliding Watertight Door Assemblies

Standard Specification for Sliding Watertight Door Assemblies

SCOPE

1.1 This specification covers the design, manufacture, and testing of sliding watertight door assemblies intended to ensure the watertight integrity of personnel access openings in watertight bulkheads.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1196 – 94 (Reapproved 2000) An American National Standard

Standard Specification for

Sliding Watertight Door Assemblies

This standard is issued under the fixed designation F 1196; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 frame assembly—a rigid frame designed to be at-

tached to a watertight bulkhead. The guide tracks necessary to

1.1 This specification covers the design, manufacture, and

ensure proper door and frame alignment are also included as

testing of sliding watertight door assemblies intended to ensure

part of the frame assembly.

the watertight integrity of personnel access openings in water-

3.1.3 horizontal sliding watertight door—a sliding water-

tight bulkheads.

tight door that opens and closes with a horizontal movement.

1.2 The values stated in inch-pound units are to be regarded

3.1.4 opening hand—the direction in which a horizontal

as the standard. The values given in parentheses are for

sliding watertight door opens. A left-hand opening door opens

information only.

to the left when viewed from the side of the bulkhead on which

2. Referenced Documents the door assembly is located. A right-hand opening door opens

to the right when viewed from the side of the bulkhead on

2.1 ASTM Standards:

which the door assembly is located.

A 36/A 36M Specification for Carbon Structural Steel

3.1.5 pressure head—the pressure which a sliding water-

F 1197 Specification for Sliding Watertight Door Control

tight door assembly is designed to withstand. For a door

Systems

located below the bulkhead deck, it is equivalent to the

2.2 Military Specification:

pressure exerted by a column of water the height of which is

MIL-S-901 Shock Test, H.I. (High Impact); Shipboard Ma-

equal to the vertical distance from the bulkhead deck to the

chinery, Equipment and Systems, Requirements for

door sill in its installed location. For a door located above the

2.3 American Bureau of Shipping:

bulkhead deck, it is equivalent to the pressure exerted by the

Rules for Building and Classing Steel Vessels

maximum head of water for its location, as determined in the

2.4 Code of Federal Regulations:

damage stability calculations.

Title 46, Part 159.010, Independent Laboratory: Accep-

3.1.6 sliding watertight door assembly—a steel door assem-

tance, Listing and Termination

bly and a steel frame assembly fitted with a replaceable

Title 46, Part 163.001, Doors, Watertight, Sliding (and Door

interface between the two that ensures watertightness between

Controls), for Merchant Vessels

door and frame at the design pressure head.

2.5 International Maritime Organization (IMO):

3.1.7 vertical sliding watertight door—a sliding watertight

Assembly Resolution A.517(13), Recommendation on Fire

door that opens and closes with a vertical movement.

Test Procedures for“ A,” “B,” and “F” Class Divisions

4. Classification

3. Terminology

4.1 Sliding watertight doors consist of four types:

3.1 Definitions:

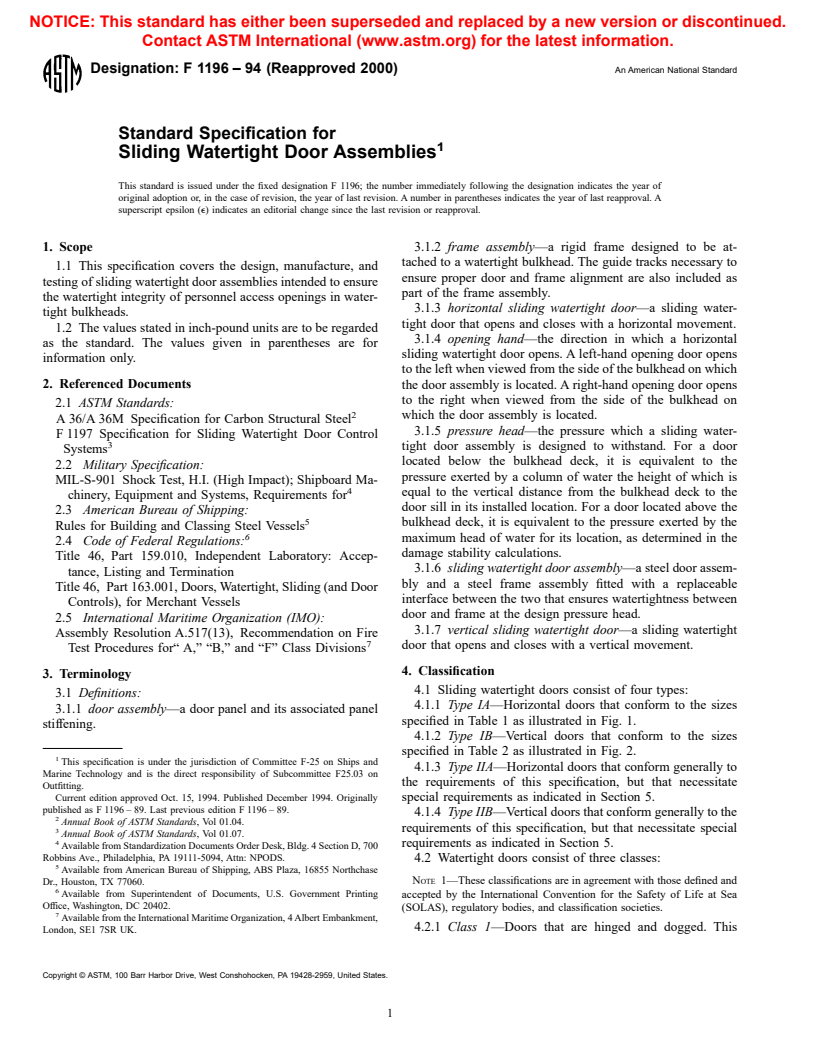

4.1.1 Type IA—Horizontal doors that conform to the sizes

3.1.1 door assembly—a door panel and its associated panel

specified in Table 1 as illustrated in Fig. 1.

stiffening.

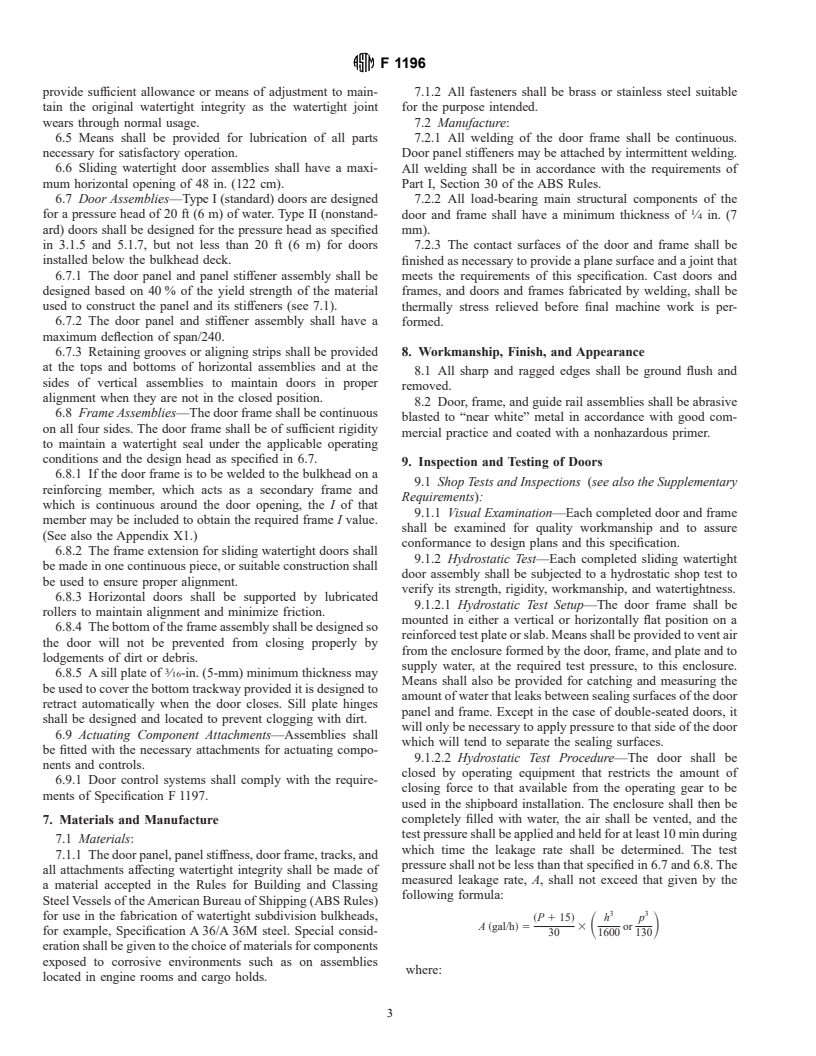

4.1.2 Type IB—Vertical doors that conform to the sizes

specified in Table 2 as illustrated in Fig. 2.

This specification is under the jurisdiction of Committee F-25 on Ships and

4.1.3 Type IIA—Horizontal doors that conform generally to

Marine Technology and is the direct responsibility of Subcommittee F25.03 on

the requirements of this specification, but that necessitate

Outfitting.

special requirements as indicated in Section 5.

Current edition approved Oct. 15, 1994. Published December 1994. Originally

published as F 1196 – 89. Last previous edition F 1196 – 89.

4.1.4 Type IIB—Vertical doors that conform generally to the

Annual Book of ASTM Standards, Vol 01.04.

requirements of this specification, but that necessitate special

Annual Book of ASTM Standards, Vol 01.07.

requirements as indicated in Section 5.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

4.2 Watertight doors consist of three classes:

Available from American Bureau of Shipping, ABS Plaza, 16855 Northchase

Dr., Houston, TX 77060. NOTE 1—These classifications are in agreement with those defined and

Available from Superintendent of Documents, U.S. Government Printing

accepted by the International Convention for the Safety of Life at Sea

Office, Washington, DC 20402.

(SOLAS), regulatory bodies, and classification societies.

Available from the International Maritime Organization, 4 Albert Embankment,

4.2.1 Class 1—Doors that are hinged and dogged. This

London, SE1 7SR UK.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1196

TABLE 1 Type IA Door Dimensions

A, B, C, D, E, F,

Size Door Size

A

in. in. in. in. in. in.

1 2 ft. 2 in. by 5 ft. 6 in. 26 66 64 76 17 78

2 2 ft. 6 in. by 5 ft. 0 in. 30 60 72 84 16 72

3 2 ft. 6 in. by 6 ft. 0 in. 30 72 72 84 18 84

4 3 ft. 0 in. by 5 ft. 6 in. 36 66 84 96 18 78

A

1 in. = 25.4 mm.

FIG. 2 Type IB Door and Frame

5.1.7 Pressure head (if other than standard),

5.1.8 Supplementary requirements (if any),

5.1.9 Additional requirements as contracted by the manu-

facturer and purchaser, and

5.1.10 ASTM specification designation.

6. Design

6.1 Sliding watertight door assemblies shall be designed to

FIG. 1 Type IA Door and Frame

maintain watertightness within the limits set forth in this

specification. Doors shall be designed to open and close within

TABLE 2 Type IB Door Dimensions

the limitations specified in Specification F 1197.

A, B, C, D, E, 6.2 Assemblies shall be of substantial and rigid construction

Size Door Size

A

in. in. in. in. in.

to ensure that doors can be closed under the design pressure

1 2 ft. 2 in. by 5 ft. 6 in. 26 66 142 155 17

head.

2 2 ft. 6 in. by 5 ft. 0 in. 30 60 130 143 16

6.3 There shall be a replaceable interface between the door

3 2 ft. 6 in. by 6 ft. 0 in. 30 72 154 167 18

4 3 ft. 0 in. by 5 ft. 6 in. 36 66 142 155 18 and frame assemblies, such as a brass rubbing strip or resilient

A

gasket, to ensure watertightness between door and frame at the

1 in. = 25.4 mm.

design pressure head.

6.3.1 The replaceable interface may be incorporated into the

specification is not applicable to this class of door.

door assembly, the frame assembly, or both.

4.2.2 Class 2—Sliding doors that are operable both locally

6.3.2 Assemblies shall be designed and constructed so as to

and remotely by hand gear.

be capable of preventing the passage of smoke and flame, and

4.2.3 Class 3—Sliding doors that are operable both locally

heat when specified by the purchaser, to the end of the 1-h

and remotely by hand and by power.

standard fire test described by IMO Assembly Resolution

5. Ordering Information

A.517(13) to at least the same degree as the adjacent bulkhead.

5.1 The following shall be specified when ordering: A fire test is not required if the assembly design incorporates

5.1.1 Quantity, details that have been demonstrated to prevent the passage of

5.1.2 Type, smoke and flame.

5.1.3 Class, 6.3.3 Assembles shall be designed in such a manner that the

5.1.4 Size, replaceable interface will be protected from damage when the

5.1.5 Opening hand, door is in the open position.

5.1.6 Door and frame material, 6.4 Sliding watertight door assemblies shall be designed to

F 1196

provide sufficient allowance or means of adjustment to main- 7.1.2 All fasteners shall be brass or stainless steel suitable

tain the original watertight integrity as the watertight joint for the purpose intended.

wears through normal usage. 7.2 Manufacture:

6.5 Means shall be provided for lubrication of all parts 7.2.1 All welding of the door frame shall be continuous.

necessary for satisfactory operation. Door panel stiffeners may be attached by intermittent welding.

6.6 Sliding watertight door assemblies shall have a maxi- All welding shall be in accordance with the requirements of

mum horizontal opening of 48 in. (122 cm). Part I, Section 30 of the ABS Rules.

6.7 Door Assemblies—Type I (standard) doors are designed 7.2.2 All load-bearing main structural components of the

for a pressure head of 20 ft (6 m) of water. Type II (nonstand- door and frame shall have a minimum thickness of ⁄4 in. (7

ard) doors shall be designed for the pressure head as specified mm).

in 3.1.5 and 5.1.7, but not less than 20 ft (6 m) for doors

7.2.3 The contact surfaces of the door and frame shall be

installed below the bulkhead deck. finished as necessary to provide a plane surface and a joint that

6.7.1 The door panel and panel stiffener assembly shall be meets the requirements of this specification. Cast doors and

designed based on 40 % of the yield strength of the material frames, and doors and frames fabricated by welding, shall be

used to construct the panel and its stiffeners (see 7.1). thermally stress relieved before final machine work is per-

6.7.2 The door panel and stiffener assembly shall have a formed.

maximum deflection of span/240.

8. Workmanship, Finish, and Appearance

6.7.3 Retaining grooves or aligning strips shall be provided

at the tops and bottoms of horizontal assemblies and at the

8.1 All sharp and ragged edges shall be ground flush and

sides of vertical assemblies to maintain doors in proper

removed.

alignment when they are not in the closed position.

8.2 Door, frame, and guide rail assemblies shall be abrasive

6.8 Frame Assemblies—The door frame shall be continuous

blasted to “near white” metal in accordance with good com-

on all four sides. The door frame shall be of sufficient rigidity

mercial practice and coated with a nonhazardous primer.

to maintain a watertight seal under the applicable operating

conditions and the design head as specified in 6.7.

9. Inspection and Testing of Doors

6.8.1 If the door frame is to be welded to the bulkhead on a

9.1 Shop Tests and Inspections (see also the Supplementary

reinforcing member, which acts as a secondary frame and

Requirements):

which is continuous around the door opening, the I of that

9.1.1 Visual Examination—Each completed door and frame

member may be included to obtain the required frame I value.

shall be examined for quality workmanship and to assure

(See also the Appendix X1.)

conformance to design plans and this specification.

6.8.2 The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.