ASTM E680-79(2018)

(Test Method)Standard Test Method for Drop Weight Impact Sensitivity of Solid-Phase Hazardous Materials

Standard Test Method for Drop Weight Impact Sensitivity of Solid-Phase Hazardous Materials

SIGNIFICANCE AND USE

4.1 This test method does not require an overall rigid standardization of the apparatus. Samples are tested either unconfined or confined in confinement cups. For confined tests, some of the important cup parameters, such as cup material, cup wall thickness, and fit between the cup and the striking pin, are standardized. Data generated from unconfined and confined tests will not, in general, exhibit the same relative scale of sensitivities, and must be identified as confined or unconfined data and compared separately.

4.2 This test method applies to all testing where the intent is to establish a relative sensitivity scale for hazardous materials. It is not intended to prohibit testing process-thickness samples nor prohibit the use of other than standard tool masses and striking diameters to generate data for special purposes or for in-house comparisons. In addition, the test method is not intended to restrict the generation of results at other than the H50 point as may be desirable for hazard analysis techniques.

4.3 The normalized data will serve as a measure of the relative sensitivities of hazardous materials at the 50 % probability of reaction level. The normalized H50 values can also be used in conjunction with additional data relating to other probability of reaction levels (not a part of this test method) to assess hazards associated with the manufacture, transportation, storage, and use of hazardous materials.

SCOPE

1.1 This test method2, 3 is designed to determine the relative sensitivities of solid-phase hazardous materials to drop weight impact stimulus. For liquid-phase materials refer to Test Method D2540.

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E680 −79 (Reapproved 2018)

Standard Test Method for

Drop Weight Impact Sensitivity of Solid-Phase Hazardous

Materials

This standard is issued under the fixed designation E680; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method is one of several test methods being developed by ASTM Committee E27 on

Hazard Potential of Chemicals. This test method is to be used in conjunction with other tests to

characterize the hazard potential of chemicals.

1. Scope D2540 Test Method for Drop-Weight Sensitivity of Liquid

2, 3

Monopropellants (Withdrawn 2003)

1.1 This test method is designed to determine the relative

sensitivities of solid-phase hazardous materials to drop weight

3. Summary of Test Method

impact stimulus. For liquid-phase materials refer to Test

Method D2540. 3.1 Restrictions are placed upon the ranges of impact tool

masses and striking surface diameters that may be used, and a

1.2 This standard may involve hazardous materials,

standard sample thickness is prescribed for all tests. In

operations, and equipment. This standard does not purport to

addition, procedures for sample preparation and treatment, as

address all of the safety concerns, if any, associated with its

well as procedures for detecting reactions through the use of

use. It is the responsibility of the user of this standard to

the human senses, are outlined.

establish appropriate safety, health, and environmental prac-

tices and determine the applicability of regulatory limitations

3.2 Drop-weight impact tests are to be performed using the

7, 8

prior to use.

well-known Bruceton up-and-down method.

1.3 This international standard was developed in accor-

3.3 Outlined is a method for normalizing data generated on

dance with internationally recognized principles on standard-

different impact apparatus.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4. Significance and Use

mendations issued by the World Trade Organization Technical

4.1 This test method does not require an overall rigid

Barriers to Trade (TBT) Committee.

standardization of the apparatus. Samples are tested either

unconfinedorconfinedinconfinementcups.Forconfinedtests,

2. Referenced Documents

some of the important cup parameters, such as cup material,

2.1 ASTM Standards:

cupwallthickness,andfitbetweenthecupandthestrikingpin,

arestandardized.Datageneratedfromunconfinedandconfined

tests will not, in general, exhibit the same relative scale of

This test method is under the jurisdiction ofASTM Committee E27 on Hazard

Potential of Chemicals and is the direct responsibility of Subcommittee E27.02 on

Thermal Stability and Condensed Phases.

Current edition approved Nov. 15, 2018. Published December 2018. Originally The last approved version of this historical standard is referenced on

ɛ1

approved in 1979. Last previous edition approved in 2011 as E680 – 79 (2011) . www.astm.org.

DOI: 10.1520/E0680-79R18. Becker, K. R., and Watson, R. W., “A Critique for Drop Weight Impact

This test method is a modification of and contains concepts proposed by Testing,” Proceedings of the Conference on the Standardization of Safety and

Hercules, Inc. personnel at Allegheny Ballistics Laboratory. The method was Performance Tests for Energetic Materials, Vol 1, September 1977, pp. 415–430.

outlined by personnel of Pittsburgh Mining and Safety Research Center, U.S. Publication ARLCD-SP-77004, U.S. Army Armament Research and Development

Bureau of Mines, Pittsburgh, Pa. For additional information see Footnote 3. Command, Dover, N.J.

3 7

Smith, D., and Richardson, R. H., “Interpretation of Impact Sensitivity Test Dixon, W. J., and Massey, F. J. Jr., Introduction to Statistical Analysis,

Data,” Pyrodynamics, PYDYA, Vol 6, 1968, pp. 159–178. McGraw-Hill Book Co., Inc., 1957, pp. 319–327.

4 8

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Statistical Research Group, Princeton University, “Statistical Analysis for a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM New Procedure in Sensitivity Experiments,” AMP Report No. 101.1R, SRG-P, No.

Standards volume information, refer to the standard’s Document Summary page on 40, Submitted to Applied Mathematics Panel, National Defense Research

the ASTM website. Committee, July 1944, p. 58.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E680−79 (2018)

sensitivities, and must be identified as confined or unconfined 6.2 The masses of the drop weight (m ) and intermediate

data and compared separately. weight (m ) should, preferably, be equal. However, the inter-

mediate weight mass may be less than that of the drop weight

4.2 This test method applies to all testing where the intent is

mass so long as the mass ratio m /m is 0.6 or greater. This

2 1

to establish a relative sensitivity scale for hazardous materials.

ensures that the force-time stimulus a test sample is subjected

It is not intended to prohibit testing process-thickness samples

to will be nonoscillatory in nature, and ensures that the transfer

nor prohibit the use of other than standard tool masses and

ofenergyfromthedropweighttotheintermediateweightdoes

striking diameters to generate data for special purposes or for

not vary significantly.

in-house comparisons. In addition, the test method is not

6.3 The mass of the drop weight should be between 1.0 to

intended to restrict the generation of results at other than the

H point as may be desirable for hazard analysis techniques. 3.5 kg.

6.4 The hardness of all tooling surfaces involved in the

4.3 The normalized data will serve as a measure of the

relative sensitivities of hazardous materials at the 50 % prob- impact (drop weight, intermediate weight, and anvil) should

have a Rockwell C Hardness of 55 to 59 HRC.

abilityofreactionlevel.Thenormalized H valuescanalsobe

used in conjunction with additional data relating to other

6.5 The diameter of the striking surface of the intermediate

probability of reaction levels (not a part of this test method) to 3 3

weight shall be 9.52 to 19.05 mm ( ⁄8 to ⁄4 in.). These limits

assess hazards associated with the manufacture, transportation,

were determined simply on the basis that data have been

storage, and use of hazardous materials.

successfully normalized for tool diameters in this range.

6.6 The finish on the striking surface of the intermediate

5. Definitions

weight and of the anvil, though not highly critical in tests with

5.1 H value—a drop height with a 50 % probability of

50 solid explosives, should be a No. 8 grind (8 µin.) or finer. If

reaction, as determined experimentally by the Bruceton up-

substantially different surface finishes are used, the data

and-down method.

obtained should be accompanied by a footnote specifying the

finish used.

5.2 impact tools—the drop weight, intermediate weight, and

anvil.

6.7 Inconfinedtests,theconfinementcupshallbefabricated

from Type 302 stainless steel. The cup base thickness shall

5.3 drop weight—that weight which is raised to a selected

range from 0.13 to 0.15 mm (0.005 to 0.006 in.). The outer

height and released. This weight does not impact the sample

periphery of the striking pin shall be in contact with a small

directly; rather it strikes another stationary weight that is in

portion of the arc joining the side and bottom of the cup.

contact with the sample.

Although this permits greater energy losses in working the

5.4 intermediate weight—the stationary weight in contact

metal inside the cup than if the whole striking surface engaged

with the sample.

only the flat portion of the metal in the base of the cup, it does

5.5 anvil—thesmooth,hardenedsurfaceuponwhichthetest ensure better confinement with less flow of test material up the

sample or cup containing the sample rests. sides of the striking pin and cup. A typical confinement cup is

showninFig.1.This,togetherwiththestrikingpindimensions

5.6 unconfined test—atestinwhichthetestsampleisplaced

shown in Fig. 2, provide some insight on a suitable mating

directly upon the anvil with no lateral confinement.

between the striking pin and cup.

5.7 confined test—a test in which the test sample is con-

tained within a confinement cup (sample container), and the

confinement cup is then placed upon the anvil.

5.8 confinement cup—the metal sample container used in

confined tests.

5.9 guide bushing—the steel bushing that surrounds, aligns,

and holds the stationary intermediate weight in place.

5.10 guide system—the rails, wires, and shaft that guide the

drop weight during its fall.

5.11 striking surface—the hardened, smooth, circular bot-

tom surface of the intermediate tool that is in contact with the

test sample.

5.12 impact apparatus or machine—the total apparatus

including the foundation parts, guide rails, electromagnet lift,

winch, and tools.

6. Apparatus

6.1 A complete impact apparatus is the specialized appara-

FIG. 1Confinement Cup Used as a Sample Container in Confined

tus necessary for this test method. Tests

E680−79 (2018)

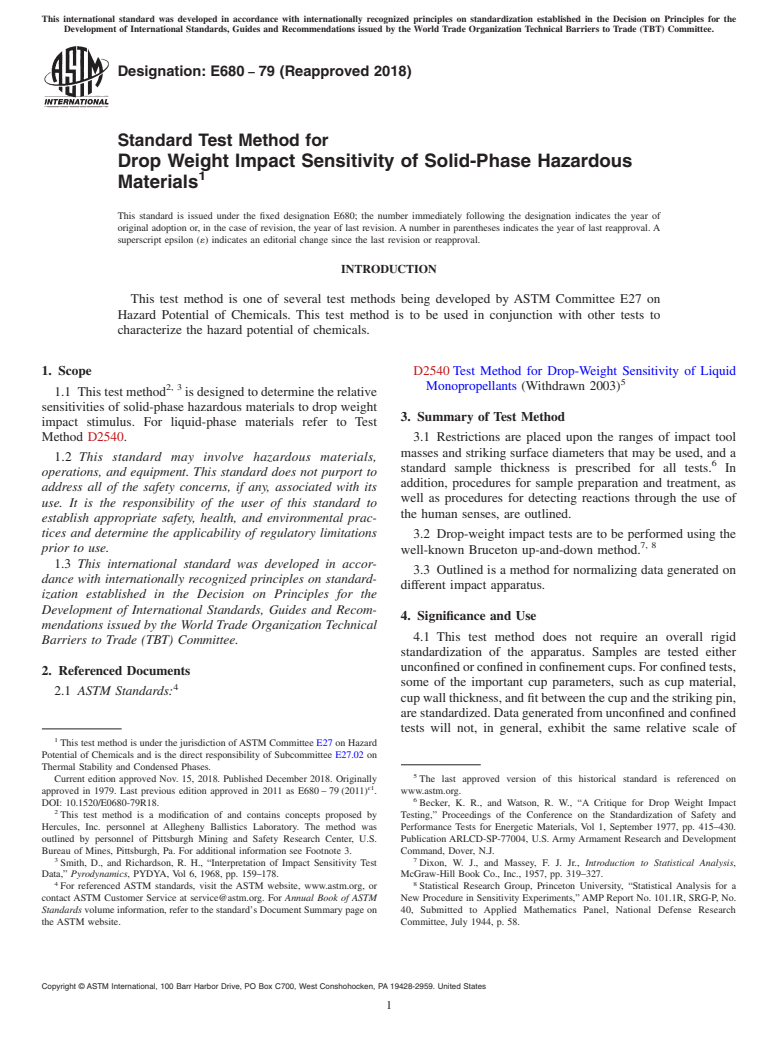

FIG. 2Intermediate Weight Assembly

6.8 Experience has shown that an appreciable difference in

the behavior of the apparatus can result from the manner in

which it is mounted. Thus, the machine should be mounted on,

and firmly attached to, a solid concrete foundation, preferably

anchored to the foundation of a building (see Test Method

D2540).

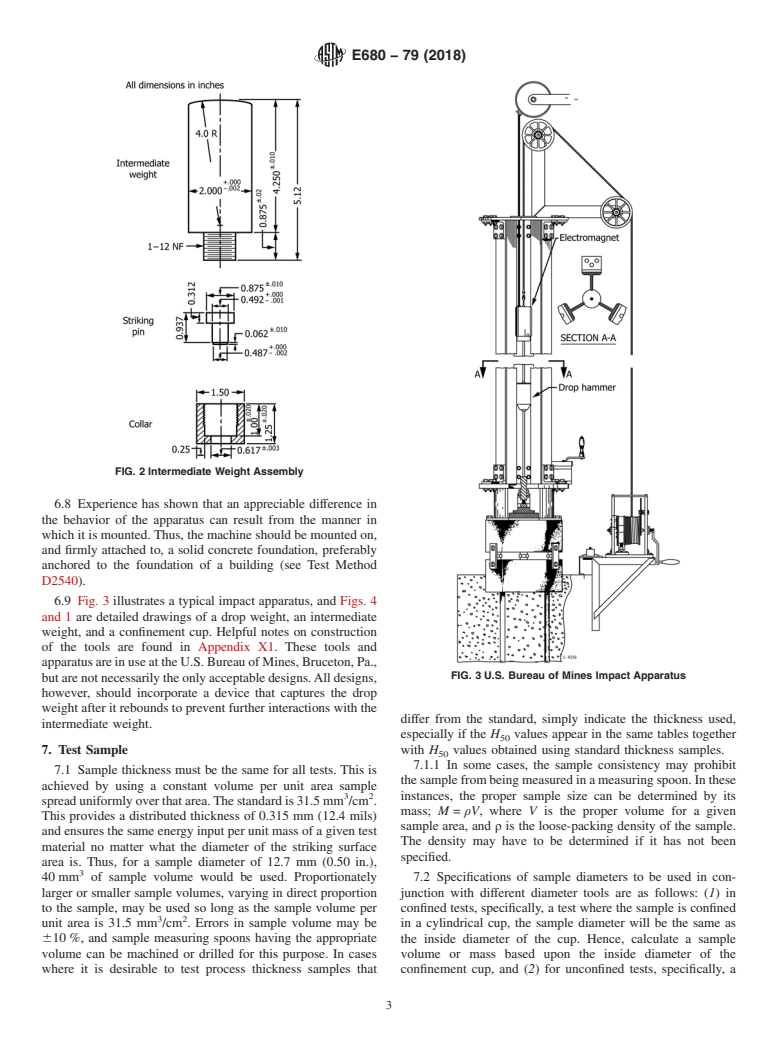

6.9 Fig. 3 illustrates a typical impact apparatus, and Figs. 4

and 1 are detailed drawings of a drop weight, an intermediate

weight, and a confinement cup. Helpful notes on construction

of the tools are found in Appendix X1. These tools and

apparatusareinuseattheU.S.BureauofMines,Bruceton,Pa.,

FIG. 3U.S. Bureau of Mines Impact Apparatus

butarenotnecessarilytheonlyacceptabledesigns.Alldesigns,

however, should incorporate a device that captures the drop

weight after it rebounds to prevent further interactions with the

differ from the standard, simply indicate the thickness used,

intermediate weight.

especially if the H values appear in the same tables together

7. Test Sample with H values obtained using standard thickness samples.

7.1.1 In some cases, the sample consistency may prohibit

7.1 Sample thickness must be the same for all tests. This is

thesamplefrombeingmeasuredinameasuringspoon.Inthese

achieved by using a constant volume per unit area sample

3 2 instances, the proper sample size can be determined by its

spreaduniformlyoverthatarea.Thestandardis31.5mm /cm .

mass; M= ρV, where V is the proper volume for a given

This provides a distributed thickness of 0.315 mm (12.4 mils)

sample area, andρ is the loose-packing density of the sample.

and ensures the same energy input per unit mass of a given test

The density may have to be determined if it has not been

material no matter what the diameter of the striking surface

specified.

area is. Thus, for a sample diameter of 12.7 mm (0.50 in.),

40 mm of sample volume would be used. Proportionately 7.2 Specifications of sample diameters to be used in con-

larger or smaller sample volumes, varying in direct proportion junction with different diameter tools are as follows: (1)in

to the sample, may be used so long as the sample volume per confined tests, specifically, a test where the sample is confined

3 2

unit area is 31.5 mm /cm . Errors in sample volume may be in a cylindrical cup, the sample diameter will be the same as

610 %, and sample measuring spoons having the appropriate the inside diameter of the cup. Hence, calculate a sample

volume can be machined or drilled for this purpose. In cases volume or mass based upon the inside diameter of the

where it is desirable to test process thickness samples that confinement cup, and (2) for unconfined tests, specifically, a

E680−79 (2018)

8.1.1 Physical Condition of Equipment—Inspect the guide

rails, or wires, or shafts periodically for evidence of nicks,

frays, dirt, or other physical impairments, and eliminate any

defects that might impede the drop weight in its fall. Inspect

the drop weight, intermediate weight, and anvil, making

especially sure that all metal surfaces that are involved in the

collision process are free from defects. Make sure that the

intermediate weight slides through and rotates freely in the

guide bushing without significant side play. Recondition or

replace the bottom surface (striking surface) of the intermedi-

ateweightortopsurfaceoftheanviliftheyshowanyevidence

of wear. Use a new, clean confinement cup each trial in

confined tests if confinement cups (sample containers) are

used.

8.1.2 Alignment—Align the guide system, allowing the drop

weight to fall along a path perpendicular to the plane of the

earth within 60.25 deg. Misalignments of this magnitude can

easily be detected using a plumb line, since a 0.25-deg

misalignment amounts to a 13-mm displacement over a

3000-mm length.

8.1.2.1 Align the bottom face (striking surface) of the

intermediate weight and the top surface of the anvil. These

surfaces must be both plane and parallel. A convenient way to

check this is with Prussian blue dye. Place a small amount of

the dye on a piece of paper and insert the paper between the

intermediate tool striking surface and anvil. By hand lower the

FIG. 4Drop Weight Assembly

intermediate tool onto the area of the paper containing the dye.

Lift the intermediate tool and insert a clean piece of paper.

test where the sample is spread directly upon the anvil, use

Lower and raise the tool a number of times on different areas

about a 0.33-mm (13-mil) thick template made from plastic,

of the clean paper, making many different imprints. Be careful

metal,ortapehavingacircularholecutinit.Placethetemplate

nottomakeajudgmentsolelyonthebasisofthefirstorsecond

on the anvil, pile the sample in the hole, and scrape level with

imprint, since an excess of dye might smear and cover up

a spatula or straight edge. The hole diameter should, in all

defects. If the two surfaces are not parallel, a portion of one

cases, be somewhat larger than the tool contact surface

sideofthecirclewillbemissing.Aconvextoolstrikingsurface

diameter. Leave the template in place during the impact trial.

willproduceacirclehavingadiameterlessthanthatofthetool

The larger size w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.