ASTM E681-09(2023)

(Test Method)Standard Test Method for Concentration Limits of Flammability of Chemicals (Vapors and Gases)

Standard Test Method for Concentration Limits of Flammability of Chemicals (Vapors and Gases)

SIGNIFICANCE AND USE

5.1 The LFL and UFL of gases and vapors define the range of flammable concentrations in air.

5.2 This method measures the LFL and UFL for upward (and partially outward) flame propagation. The limits for downward flame propagation are narrower.

5.3 Limits of flammability may be used to determine guidelines for the safe handling of volatile chemicals. They are used particularly in assessing ventilation requirements for the handling of gases and vapors. NFPA 69 provides guidance for the practical use of flammability limit data, including the appropriate safety margins to use.

5.4 As discussed in Brandes and Ural,4 there is a fundamental difference between the ASTM and European methods for flammability determination. The ASTM methods aim to produce the best representation of flammability parameters, and rely upon the safety margins imposed by the application standards, such as NFPA 69. On the other hand, European test methods aim to result in a conservative representation of flammability parameters. For example, in this standard, LFL is the calculated average of the lowest go and highest no-go concentrations while the European test methods report the LFL as the minimum of the five highest no-go concentrations.

Note 2: For hydrocarbons, the break point between nonflammability and flammability occurs over a narrow concentration range at the lower flammability limit, but the break point is less distinct at the upper limit. For materials found to be non-reproducible per 13.1.1 that are likely to have large quenching distances and may be difficult to ignite, such as ammonia and certain halogenated hydrocarbon, the lower and upper limits of these materials may both be less distinct. That is, a wider range exists between flammable and nonflammable concentrations (see Annex A1).

SCOPE

1.1 This test method covers the determination of the lower and upper concentration limits of flammability of chemicals having sufficient vapor pressure to form flammable mixtures in air at atmospheric pressure at the test temperature. This test method may be used to determine these limits in the presence of inert dilution gases. No oxidant stronger than air should be used.

Note 1: The lower flammability limit (LFL) and upper flammability limit (UFL) are sometimes referred to as the lower explosive limit (LEL) and the upper explosive limit (UEL), respectively. However, since the terms LEL and UEL are also used to denote concentrations other than the limits defined in this test method, one must examine the definitions closely when LEL and UEL values are reported or used.

1.2 This test method is based on electrical ignition and visual observations of flame propagation. Users may experience problems if the flames are difficult to observe (for example, irregular propagation or insufficient luminescence in the visible spectrum), if the test material requires large ignition energy, or if the material has large quenching distances.

1.3 Annex A1 provides a modified test method for materials (such as certain amines, halogenated materials, and the like) with large quenching distances which may be difficult to ignite.

1.4 In other situations where strong ignition sources (such as direct flame ignition) is considered credible, the use of a test method employing higher energy ignition source in a sufficiently large pressure chamber (analogous, for example, to the methods in Test Method E2079 for measuring limiting oxygen concentration) may be more appropriate. In this case, expert advice may be necessary.

1.5 The flammability limits depend on the test temperature and pressure. This test method is limited to an initial pressure of the local ambient or less, with a practical lower pressure limit of approximately 13 kPa (100 mm Hg). The maximum practical operating temperature of this equipment is approximately 150 °C.

1.6 The values stated in SI units are to be regarded as standard. No other units of measuremen...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E681 − 09 (Reapproved 2023)

Standard Test Method for

Concentration Limits of Flammability of Chemicals (Vapors

and Gases)

This standard is issued under the fixed designation E681; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

1.1 This test method covers the determination of the lower

standard.

and upper concentration limits of flammability of chemicals

having sufficient vapor pressure to form flammable mixtures in 1.7 This test method should be used to measure and describe

air at atmospheric pressure at the test temperature. This test the properties of materials, products, or assemblies in response

method may be used to determine these limits in the presence to heat and flame under controlled laboratory conditions and

of inert dilution gases. No oxidant stronger than air should be should not be used to describe or appraise the fire hazard or fire

used. risk of materials, products, or assemblies under actual fire

conditions. However, results of this test method may be used as

NOTE 1—The lower flammability limit (LFL) and upper flammability

elements of a fire risk assessment that takes into account all of

limit (UFL) are sometimes referred to as the lower explosive limit (LEL)

and the upper explosive limit (UEL), respectively. However, since the the factors pertinent to an assessment of the fire hazard of a

terms LEL and UEL are also used to denote concentrations other than the

particular end use.

limits defined in this test method, one must examine the definitions closely

1.8 This standard may involve hazardous materials,

when LEL and UEL values are reported or used.

operations, and equipment. This standard does not purport to

1.2 This test method is based on electrical ignition and

address all of the safety concerns, if any, associated with its

visual observations of flame propagation. Users may experi-

use. It is the responsibility of the user of this standard to

ence problems if the flames are difficult to observe (for

establish appropriate safety, health, and environmental prac-

example, irregular propagation or insufficient luminescence in

tices and determine the applicability of regulatory limitations

the visible spectrum), if the test material requires large ignition

prior to use. Specific precautionary statements are given in

energy, or if the material has large quenching distances.

Section 8.

1.3 Annex A1 provides a modified test method for materials

1.9 This international standard was developed in accor-

(such as certain amines, halogenated materials, and the like)

dance with internationally recognized principles on standard-

with large quenching distances which may be difficult to ignite.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.4 In other situations where strong ignition sources (such

mendations issued by the World Trade Organization Technical

as direct flame ignition) is considered credible, the use of a test

Barriers to Trade (TBT) Committee.

method employing higher energy ignition source in a suffi-

ciently large pressure chamber (analogous, for example, to the

2. Referenced Documents

methods in Test Method E2079 for measuring limiting oxygen

concentration) may be more appropriate. In this case, expert

2.1 ASTM Standards:

advice may be necessary.

E171 Practice for Conditioning and Testing Flexible Barrier

Packaging

1.5 The flammability limits depend on the test temperature

E582 Test Method for Minimum Ignition Energy and

and pressure. This test method is limited to an initial pressure

Quenching Distance in Gaseous Mixtures

of the local ambient or less, with a practical lower pressure

E1445 Terminology Relating to Hazard Potential of Chemi-

limit of approximately 13 kPa (100 mm Hg). The maximum

cals

practical operating temperature of this equipment is approxi-

E1515 Test Method for Minimum Explosible Concentration

mately 150 °C.

of Combustible Dusts

This test method is under the jurisdiction of ASTM Committee E27 on Hazard

Potential of Chemicals and is the direct responsibility of Subcommittee E27.04 on

Flammability and Ignitability of Chemicals. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2023. Published May 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1979. Last previous edition approved in 2015 as E681 – 09 (2015). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E0681-09R23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E681 − 09 (2023)

E2079 Test Methods for Limiting Oxygen (Oxidant) Con- methods aim to result in a conservative representation of

centration in Gases and Vapors flammability parameters. For example, in this standard, LFL is

the calculated average of the lowest go and highest no-go

2.2 NFPA Standard:

NFPA 69 Standard on Explosion Prevention Systems concentrations while the European test methods report the LFL

as the minimum of the five highest no-go concentrations.

3. Terminology

NOTE 2—For hydrocarbons, the break point between nonflammability

and flammability occurs over a narrow concentration range at the lower

3.1 Definitions:

flammability limit, but the break point is less distinct at the upper limit.

3.1.1 lower limit of flammability or lower flammable limit

For materials found to be non-reproducible per 13.1.1 that are likely to

(LFL)—the minimum concentration of a combustible sub-

have large quenching distances and may be difficult to ignite, such as

ammonia and certain halogenated hydrocarbon, the lower and upper limits

stance that is capable of propagating a flame in a homogeneous

of these materials may both be less distinct. That is, a wider range exists

mixture of the combustible and a gaseous oxidizer under the

between flammable and nonflammable concentrations (see Annex A1).

specified conditions of test.

3.1.2 propagation of flame—as used in this test method, the

6. Interferences

upward and outward movement of the flame front from the

6.1 This test method is not applicable to certain readily

ignition source to the vessel walls or at least to within 13 mm

oxidized chemicals. If significant oxidation takes place when

( ⁄2 in.) of the wall, which is determined by visual observation.

the vapors are mixed with air, unreliable results may be

By outward, it is meant a flame front that has a horizontal

obtained. Flow systems designed to minimize hold-up time

component to the movement away from the ignition source.

may be required for such materials.

3.1.3 upper limit of flammability or upper flammable limit

6.2 Measured flammable limits are influenced by flame

(UFL)—the maximum concentration of a combustible sub-

quenching effects of the test vessel walls. The test vessel

stance that is capable of propagating a flame in a homogeneous

employed in this test method is of sufficient size to eliminate

mixture of the combustible and a gaseous oxidizer under the

the effects of the flame quenching for most materials (and

specified conditions of test.

conditions).

3.2 Additional terms can be found in Terminology E1445.

NOTE 3—There may be quenching effects, particularly on tests run at

subambient pressures. For materials that may be difficult to ignite (see

4. Summary of Test Method

Note 2), tests in a larger vessel or different ignition sources (see Annex

4.1 A uniform mixture of a gas or vapor with air is ignited

A1, 12 L flask) may show flame propagation that is not seen in the 5 L

flask with spark or exploding wire igniters. This test method is a small

in a closed vessel, and the upward and outward propagation of

scale test and this possible limitation must be considered in hazard

the flame away from the ignition source is noted by visual

assessments.

observation. The concentration of the flammable component is

6.3 The oxygen concentration in the air has an important

varied between trials until the composition that will just sustain

effect on the UFL. Typically, room air is used. If cylinder air is

propagation of the flame is determined.

used to simulate room air it must have an oxygen concentration

5. Significance and Use

of 20.94 % 6 0.1 %. Reconstituted air in cylinders has vari-

ability in the oxygen concentration and must be verified for

5.1 The LFL and UFL of gases and vapors define the range

oxygen concentration.

of flammable concentrations in air.

5.2 This method measures the LFL and UFL for upward

7. Apparatus

(and partially outward) flame propagation. The limits for

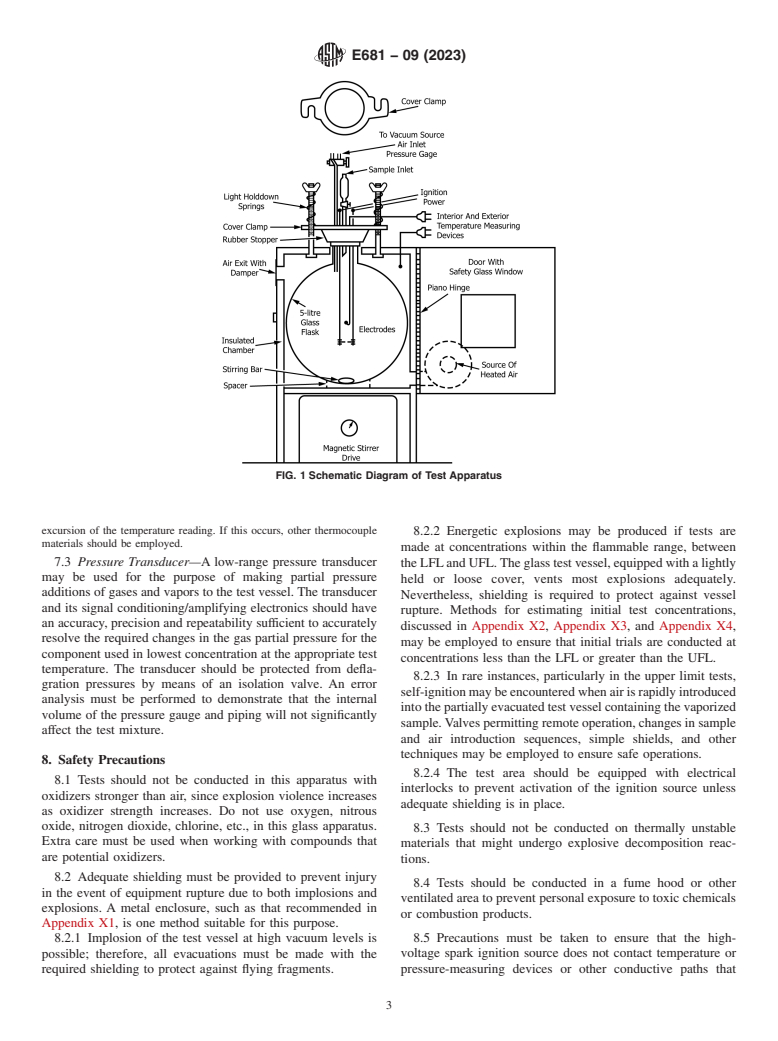

7.1 Fig. 1 is a schematic diagram of the apparatus; details

downward flame propagation are narrower.

and dimensions are presented in Appendix X1. The apparatus

5.3 Limits of flammability may be used to determine guide-

consists of a glass test vessel, an insulated chamber equipped

lines for the safe handling of volatile chemicals. They are used

with a source of controlled-temperature air, an ignition device

particularly in assessing ventilation requirements for the han-

with an appropriate power supply, a magnetic stirrer, and a

dling of gases and vapors. NFPA 69 provides guidance for the

cover equipped with the necessary operating connections and

practical use of flammability limit data, including the appro-

components.

priate safety margins to use.

7.2 If tests are to be conducted at an elevated temperature,

5.4 As discussed in Brandes and Ural, there is a fundamen-

the test vessel may be heated as described in Appendix X1. The

tal difference between the ASTM and European methods for

heating system must be capable of controlling the gas tempera-

flammability determination. The ASTM methods aim to pro-

ture inside the test vessel to within 63 °C both temporally and

duce the best representation of flammability parameters, and

spatially. An appropriate device such as a thermocouple must

rely upon the safety margins imposed by the application

be used to monitor the gas temperature within the test vessel.

standards, such as NFPA 69. On the other hand, European test

Active (connected) volumes beyond the test vessel itself should

be held above the condensation temperature of all components

in the material being tested. Electrical heating tapes must be

Available from National Fire Protection Association (NFPA), 1 Batterymarch

Park, Quincy, MA 02169-7471, http://www.nfpa.org.

employed for heating components to the desired temperature.

Brandes, E., and Erdem, A. U., “Towards a Global Standard for Flammability

Determination,” 42nd Annual Loss Prevention Symposium, New Orleans, LA, April NOTE 4—Certain bare wire thermocouples may cause catalytic oxida-

2008. tion of test vapors, as evidenced by a persistent high-temperature

E681 − 09 (2023)

FIG. 1 Schematic Diagram of Test Apparatus

excursion of the temperature reading. If this occurs, other thermocouple

8.2.2 Energetic explosions may be produced if tests are

materials should be employed.

made at concentrations within the flammable range, between

7.3 Pressure Transducer—A low-range pressure transducer

the LFL and UFL. The glass test vessel, equipped with a lightly

may be used for the purpose of making partial pressure

held or loose cover, vents most explosions adequately.

additions of gases and vapors to the test vessel. The transducer

Nevertheless, shielding is required to protect against vessel

and its signal conditioning/amplifying electronics should have

rupture. Methods for estimating initial test concentrations,

an accuracy, precision and repeatability sufficient to accurately

discussed in Appendix X2, Appendix X3, and Appendix X4,

resolve the required changes in the gas partial pressure for the

may be employed to ensure that initial trials are conducted at

component used in lowest concentration at the appropriate test

concentrations less than the LFL or greater than the UFL.

temperature. The transducer should be protected from defla-

8.2.3 In rare instances, particularly in the upper limit tests,

gration pressures by means of an isolation valve. An error

self-ignition may be encountered when air is rapidly introduced

analysis must be performed to demonstrate that the internal

into the partially evacuated test vessel containing the vaporized

volume of the pressure gauge and piping will not significantly

sample. Valves permitting remote operation, changes in sample

affect the test mixture.

and air introduction sequences, simple shields, and other

techniques may be employed to ensure safe operations.

8. Safety Precautions

8.2.4 The test area should be equipped with electrical

8.1 Tests should not be conducted in this apparatus with

interlocks to prevent activation of the ignition source unless

oxidizers stronger than air, since explosion violence increases

adequate shielding is in place.

as oxidizer strength increases. Do not use oxygen, nitrous

oxide, nitrogen dioxide, chlorine, etc., in this glass apparatus.

8.3 Tests should not be conducted on thermally unstable

Extra care must be used when working with compounds that

materials that might undergo explosive decomposition reac-

are potential oxidizers.

tions.

8.2 Adequate shielding must be provided to prevent injury

8.4 Tests should be conducted in a fume hood or other

in the event of equipment rupture due to both implosions and

ventilated area to prevent personal exposure to toxic chemicals

explosions. A metal enclosure, such as that recommended in

or combustion products.

Appendix X1, is one method suitable for this purpose.

8.5 Precautions must be taken to ensure that the high-

8.2.1 Implosion of the test vessel at high vacuum levels is

voltage spark ignition source does not contact temperature or

possible; therefore, all evacuations must be made with the

required shielding to protect against flying fragments. pressure-measuring devices or other conductive paths that

E681 − 09 (2023)

could create an electrical hazard to personnel or instrumenta- necessary to heat or insulate cover components and feed lines

tion outside the shielded area. Careful attention to electrical separately to prevent vapor condensation.

insulation integrity can reduce the possibility

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.