ASTM D3744/D3744M-18

(Test Method)Standard Test Method for Aggregate Durability Index

Standard Test Method for Aggregate Durability Index

SIGNIFICANCE AND USE

4.1 This test method assigns an empirical value to the relative amount, fineness, and character of clay-like material that may be generated in an aggregate when subjected to mechanical degradation.

4.2 The procedure has been used in limited geographical areas of the United States, and the results have been correlated with aggregate performance in various construction applications, including: aggregate base, permeable material for backfill, fine concrete aggregate, and riprap for rock slope protection.3,4

4.3 A minimum durability index is permitted to be specified to prohibit the use of an aggregate in various construction applications that is prone to degradation, resulting in generation of clay-like fines.

4.4 This test method provides a rapid test for evaluation of the quality of a new aggregate source. Research has indicated it may also be suitable for use instead of the sodium sulfate soundness test for evaluating the durability characteristics of fine aggregate for use in portland cement concrete, thereby reducing the need for time-consuming and expensive soundness tests.3

4.5 Although the application of this method has been limited to aggregates for specific construction uses, the possibility exists for expanding the application of this method to control the quality of aggregates used in other areas of construction, such as aggregates for use in bituminous paving mixtures, coarse aggregate for use in portland cement concrete, and aggregate for use as railroad ballast.

Note 1: The text of this test method references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the test method.

Note 2: The quality of the results produced by this standard are dependent on the competence of the personnel performing the procedure and the capability, calibration, and maintenance of the equipment used. Agencies that meet the criteria of Specification...

SCOPE

1.1 This test method covers the determination of a durability index of an aggregate. The calculated durability index is a value indicating the relative resistance of an aggregate to production of detrimental clay-like fines when subjected to the prescribed mechanical methods of degradation.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.2.1 Measurements of volume and mass are only given in SI units because they are the only units typically used in practice when performing this test method.

1.2.2 Measurements in Section 11, Section 15, Eq 3, Eq 4, and Table 1 are only given in inch-pound units because the equipment used in these sections is only manufactured using the inch-pound system.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3744/D3744M − 18

Standard Test Method for

1

Aggregate Durability Index

This standard is issued under the fixed designation D3744/D3744M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C127Test Method for Relative Density (Specific Gravity)

and Absorption of Coarse Aggregate

1.1 Thistestmethodcoversthedeterminationofadurability

C136/C136MTest Method for Sieve Analysis of Fine and

index of an aggregate. The calculated durability index is a

Coarse Aggregates

value indicating the relative resistance of an aggregate to

C702/C702MPractice for Reducing Samples of Aggregate

production of detrimental clay-like fines when subjected to the

to Testing Size

prescribed mechanical methods of degradation.

D75/D75MPractice for Sampling Aggregates

1.2 Units—The values stated in either SI units or inch-

D2419Test Method for Sand Equivalent Value of Soils and

pound units are to be regarded separately as standard. The

Fine Aggregate

values stated in each system may not be exact equivalents;

D3666Specification for Minimum Requirements for Agen-

therefore,eachsystemshallbeusedindependentlyoftheother.

cies Testing and Inspecting Road and Paving Materials

Combining values from the two systems may result in noncon-

D4753Guide for Evaluating, Selecting, and Specifying Bal-

formance with the standard.

ances and Standard Masses for Use in Soil, Rock, and

1.2.1 Measurements of volume and mass are only given in

Construction Materials Testing

SI units because they are the only units typically used in

E11Specification forWovenWireTest Sieve Cloth andTest

practice when performing this test method.

Sieves

1.2.2 Measurements in Section 11, Section 15, Eq 3, Eq 4,

and Table 1 are only given in inch-pound units because the

3. Summary of Test Method

equipment used in these sections is only manufactured using

the inch-pound system. 3.1 This test method was developed to permit prequalifica-

tion of aggregates proposed for use in the construction of

1.3 This standard does not purport to address all of the

transportation facilities. This test establishes an aggregate’s

safety concerns, if any, associated with its use. It is the

resistance to generating fines when agitated in the presence of

responsibility of the user of this standard to establish appro-

water. Separate and different test procedures are used to

priate safety, health, and environmental practices and deter-

evaluate the coarse and the fine portions of an aggregate.

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

3.2 A sample of coarse aggregate is prepared to a specific

dance with internationally recognized principles on standard-

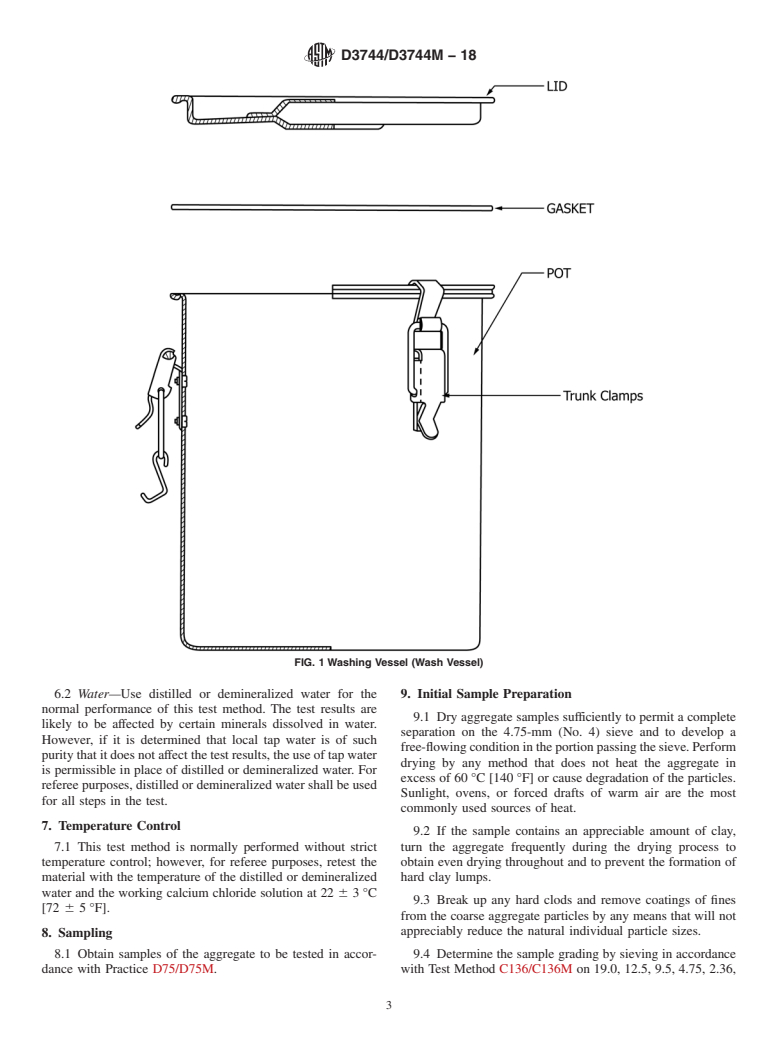

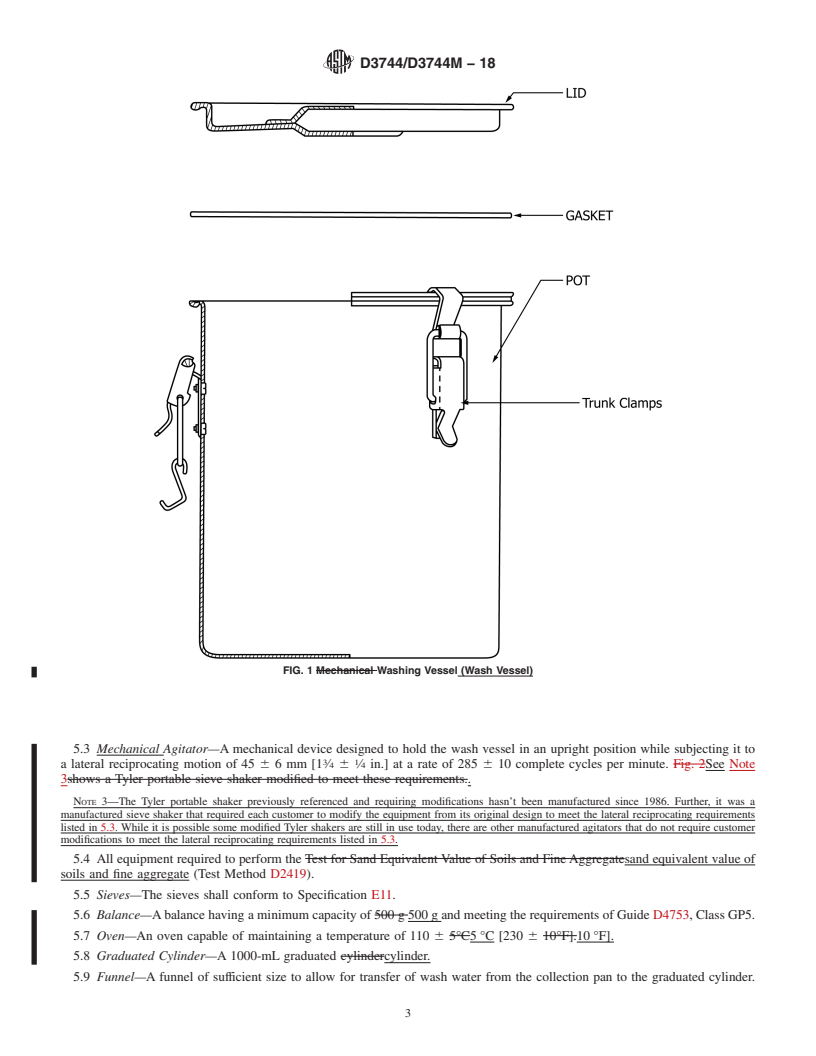

grading and then washed in a washing vessel secured in a

ization established in the Decision on Principles for the

mechanical agitator for 2 min. After discarding the minus

Development of International Standards, Guides and Recom-

4.75-mm (No. 4) material, dry the washed test sample.

mendations issued by the World Trade Organization Technical

3.3 The coarse aggregate test sample is then mechanically

Barriers to Trade (TBT) Committee.

agitated in the washing vessel for a period of 10 min. A

representative portion of the resulting wash water and minus

2. Referenced Documents

75-µm (No. 200) size fines is collected and mixed with a stock

2

2.1 ASTM Standards:

calciumchloridesolutionandplacedinaplasticcylinder.After

a 20-min sedimentation time, the level of the sediment column

is read. The height of the sediment value is then used to

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

calculate the durability index of the coarse aggregate (D ).

and Paving Materials and is the direct responsibility of Subcommittee D04.51 on c

Aggregate Tests.

3.4 The fine aggregate sample is prepared by washing a

Current edition approved Sept. 1, 2018. Published September 2018. Originally

specific quantity of the material in the washing vessel secured

approvedin1979.Lastpreviouseditionapprovedin2011asD3744/D3744M–11a.

DOI: 10.1520/D3744_D3744M-18.

in a mechanical agitator for 2 min.All minus 75-µm (No. 200)

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

size material is washed from the sample through a 75-µm (No.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

200) sieve and discarded.The plus 75-µm (No. 200) fraction is

Standards volume information, refer to

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3744/D3744M − 11a D3744/D3744M − 18

Standard Test Method for

1

Aggregate Durability Index

This standard is issued under the fixed designation D3744/D3744M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of a durability index of an aggregate. The calculated durability index is a value

indicating the relative resistance of an aggregate to production of detrimental clay-like fines when subjected to the prescribed

mechanical methods of degradation.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in non-conformancenonconformance with the standard.

1.2.1 Measurements of volume and mass are only given in SI units because they are the only units typically used in practice

when performing this test method.

1.2.2 Measurements in Section 11, Section 15, Eq 3Equation, Eq 43, Equation 4, Table 1, and Figure 2, and Table 1 are only

given in inch-pound units because the equipment used in these sections is only manufactured using the inch-pound system.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C127 Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate

C136C136/C136M Test Method for Sieve Analysis of Fine and Coarse Aggregates

C702C702/C702M Practice for Reducing Samples of Aggregate to Testing Size

D75D75/D75M Practice for Sampling Aggregates

D2419 Test Method for Sand Equivalent Value of Soils and Fine Aggregate

D3666 Specification for Minimum Requirements for Agencies Testing and Inspecting Road and Paving Materials

D4753 Guide for Evaluating, Selecting, and Specifying Balances and Standard Masses for Use in Soil, Rock, and Construction

Materials Testing

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

3. Summary of Test Method

3.1 This test method was developed to permit prequalification of aggregates proposed for use in the construction of

transportation facilities. Basically, the This test establishes an aggregate’s resistance to generating fines when agitated in the

presence of water. Separate and different test procedures are used to evaluate the coarse and the fine portions of a material.an

aggregate.

3.2 A sample of coarse aggregate is prepared to a specific grading and then washed in a mechanical washing vessel for a 2-min

agitation time. secured in a mechanical agitator for 2 min. After discarding the minus 4.75-mm (No. 4) material, dry the washed

test sample.

1

This test method is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.51 on Aggregate

Tests.

Current edition approved Dec. 1, 2011Sept. 1, 2018. Published December 2011September 2018. Originally approved in 1979. Last previous edition approved in 2011 as

D3744 – 11.D3744/D3744M – 11a. DOI: 10.1520/D3744_D3744_D3744M–11A10.1520/D3744_D3744M-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3744/D3744M − 18

3.3 The coarse aggregate test sample is then mechanically agitated in the mechanical washing vessel for a period of 10 min.

A representative portion o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.