ASTM F1645-95

(Test Method)Standard Test Method for Water Migration in Honeycomb Core Materials

Standard Test Method for Water Migration in Honeycomb Core Materials

SCOPE

1.1 This test method covers the determination of water migration in honeycomb core materials.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units given may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1645 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Water Migration in Honeycomb Core Materials

This standard is issued under the fixed designation F 1645; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope specimens be conditioned to constant weight (61 %) under

those conditions before testing.

1.1 This test method covers the determination of water

migration in honeycomb core materials.

7. Procedure

1.2 The values stated in SI units are to be regarded as the

7.1 Determine the density of each specimen per Test

standard. The inch-pound units given may be approximate.

Method C 271, if required.

1.3 This standard does not purport to address all of the

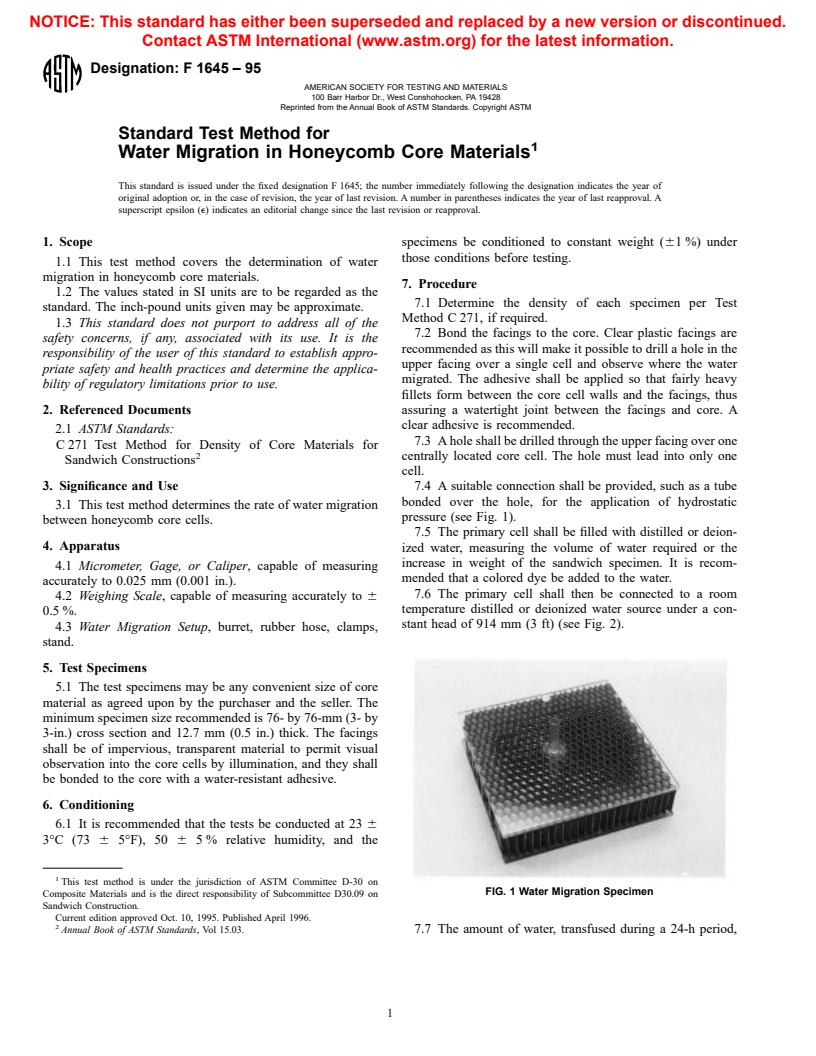

7.2 Bond the facings to the core. Clear plastic facings are

safety concerns, if any, associated with its use. It is the

recommended as this will make it possible to drill a hole in the

responsibility of the user of this standard to establish appro-

upper facing over a single cell and observe where the water

priate safety and health practices and determine the applica-

migrated. The adhesive shall be applied so that fairly heavy

bility of regulatory limitations prior to use.

fillets form between the core cell walls and the facings, thus

2. Referenced Documents assuring a watertight joint between the facings and core. A

clear adhesive is recommended.

2.1 ASTM Standards:

7.3 A hole shall be drilled through the upper facing over one

C 271 Test Method for Density of Core Materials for

2 centrally located core cell. The hole must lead into only one

Sandwich Constructions

cell.

3. Significance and Use 7.4 A suitable connection shall be provided, such as a tube

bonded over the hole, for the application of hydrostatic

3.1 This test method determines the rate of water migration

pressure (see Fig. 1).

between honeycomb core cells.

7.5 The primary cell shall be filled with distilled or deion-

4. Apparatus

ized water, measuring the volume of water required or the

increase in weight of the sandwich specimen. It is recom-

4.1 Micrometer, Gage, or Caliper, capable of measuring

mended that a colored dye be added to the water.

accurately to 0.025 mm (0.001 in.).

7.6 The primary cell shall then be connected to a room

4.2 Weighing Scale, capable of measuring accurately to 6

temperature distilled or deionized water source under a con-

0.5 %.

stant head of 914 mm (3 ft) (see Fig. 2).

4.3 Water Migration Setup, burret, rubber hose, clamps,

stand.

5. Test Specimens

5.1 The test specimens may be any convenient size of core

material as agreed upon by the purchaser and the seller. The

minimum specimen size recommended is 76- by 76-mm (3- by

3-in.) cross section and 12.7 mm (0.5 in.) thick. The facing

...

This May Also Interest You

SIGNIFICANCE AND USE

5.1 This practice provides supplemental instructions that allow the use of Test Method D7249/D7249M to determine the open-hole (notched) strength of the sandwich panel facesheets for structural design allowables, material specifications, and research and development. Due to the curvature of the flexural test specimen when loaded, the open-hole sandwich facesheet strength from this test may not be equivalent to the open-hole sandwich facesheet strength of sandwich structures subjected to pure edgewise (in-plane) tension or compression.

5.2 Factors that influence the notched facesheet strength and shall therefore be reported include the following: facesheet material, core material, adhesive material, methods of material fabrication, facesheet stacking sequence and overall thickness, core geometry (cell size), core density, adhesive thickness, specimen geometry (including hole diameter, diameter-to-thickness ratio, and width-to-diameter ratio), specimen preparation (especially of the hole), specimen conditioning, environment of testing, specimen alignment, loading procedure, speed of testing, facesheet void content, adhesive void content, and facesheet volume percent reinforcement. Further, notched facesheet strength may be different between precured/bonded and co-cured facesheets of the same material.

SCOPE

1.1 This practice provides instructions for modifying the long beam flexure test method to determine open-hole facesheet properties of flat sandwich constructions subjected to flexure in such a manner that the applied moments produce curvature of the sandwich facesheet planes and result in compressive and tensile forces in the facesheets. Permissible core material forms include those with continuous bonding surfaces (such as balsa wood and foams) as well as those with discontinuous bonding surfaces (such as honeycomb). This practice supplements Test Method D7249/D7249M with provisions for testing specimens that contain a centrally located through-hole.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, to enforce conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.2.1 Within the text, the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard7 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Water permeability is a fundamental physical property that can be used in conjunction with other properties to characterize honeycomb sandwich core materials. Migration testing can be used to characterize and compare the relative permeability of honeycomb core materials to water.

5.2 This test method provides a standard method of characterizing the rate of water migration within honeycomb sandwich core materials for design properties, material specifications, research and development applications, and quality assurance.

5.3 Factors that influence water migration rate characteristics of honeycomb sandwich core materials and shall therefore be reported include the following: core material, methods of material fabrication, core geometry (cell size), core thickness, core thickness uniformity, cell wall thickness, specimen geometry, specimen preparation, specimen conditioning, facing material, facing permeability, adhesive permeability, adhesive thickness, and methods of mass, volume, and water column height measurement.

SCOPE

1.1 This test method covers the determination of water migration in honeycomb core materials.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.2.1 Within the text, the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Plastic composite materials for use as deck boards, stair treads, guards or handrails are evaluated in accordance with Test Method E84 to comply with building or residential code requirements. This Practice describes specimen mounting procedures for such materials.

5.2 The material to be tested shall be representative of the materials used in actual field installations.

Note 2: Test Method E84 assesses the comparative burning behavior of building materials. Thus, this practice addresses specimen preparation and mounting of materials at use thickness, with full width tunnel coverage.

5.3 The limitations for this procedure are those associated with Test Method E84.

SCOPE

1.1 This practice describes a procedure for specimen preparation and mounting when testing plastic composite materials for use as deck boards, stair treads, guards or handrails to assess flame spread index as a surface burning characteristic using Test Method E84.

1.2 This practice applies to plastic composite materials, including plastic lumber and wood-plastic composites. The test specimens shall be self-supporting or held in place by added supports along the test surface, in accordance with Annex A4 of Test Method E84.

1.3 This practice does not provide pass/fail criteria that can be used as a regulatory tool.

1.4 This practice is applicable to (a) materials that are self-supporting and (b) materials that are not self-supporting but where the test specimen is held in place by added supports throughout the test duration without such severe sagging that it interferes with the effect of the gas flame on the test specimen.

Note 1: Paragraph 1.4 reflects requirements contained in plastic lumber specifications.

1.5 Use the values stated in inch-pound units as the standard in referee decisions. The values in the SI system of units are given in parentheses, for information only; see IEEE/ASTM SI-10 for further details.

1.6 This fire standard cannot be used to provide quantitative measures.

1.7 Fire testing of products and materials is inherently hazardous and adequate safeguards for personnel and property shall be employed in conducting these tests. Fire testing involves hazardous materials, operations and equipment.

1.8 This practice gives instructions on specimen preparation and mounting but the fire-test-response method shall be conducted in accordance with Test Method E84. See also Section 8 for information on operator safety.

1.9 The text of this practice references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered requirements of the standard.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.11 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method utilizes large-scale testing equipment and procedures established at a variety of testing laboratories over the last 30 years.

5.2 This method is useful in evaluating ECPs and their installation to reduce soil loss and sediment concentrations when exposed to defined rainfall conditions and improving water quality exiting the area disturbed by earthwork activity by reducing suspended solids and turbidity.

5.3 This test method is a performance test, but can also be used for acceptance testing to determine product conformance to project specifications. For project-specific conformance, unique project-specific conditions should be considered. Caution is advised since information regarding laboratory specific precision is incomplete at this time, and differences in soil and other environmental and geotechnical conditions may affect ECP performance.

5.4 This standard can also be used as a comparative tool for evaluating the erosion control characteristics of different ECPs and can also be used to gain agency approvals.

Note 1: The quality of the result produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D3740 provides a means of evaluating some of those factors.

SCOPE

1.1 This test method is used to evaluate the ability of erosion control products (ECP) to protect slopes from rainfall-induced erosion using an adjustable tilting bed slope. The standard slopes range from 2.5:1 to 4:1 (H:V) having target rainfall intensities between 4.0 and 5.0 in./h [100 and 125 mm/h].

1.2 There are three main elements the ECPs must have the ability to perform: 1. Absorb the impact force of raindrops, thereby reducing soil particle loosening and detachment through “splash” mechanisms; 2. Slow runoff and encourage infiltration, thereby reducing soil particle displacement and transport through “overland flow” mechanisms; and 3. Trap soil particles beneath the ECP. When comparing data from different ECPs under consideration, it is important to keep the test conditions the same for the ECPs being evaluated, for example, the rainfall intensity rate and the slope.

1.3 The results of this test method can be used to evaluate performance and acceptability, and can be used to compare the effectiveness of different ECPs. This method provides a comparative evaluation of an ECP to baseline bare soil conditions under controlled and documented conditions. This test method can provide information about a product that is under consideration for a specific application where no performance information currently exists.

1.4 This test method covers the use of three different soil types, ECP installation: sprayed, rolled, or dry applied, and a runoff collection procedure. This test is typically performed indoors, but may be performed outside as long as certain requirements are met. Partially enclosed facilities are acceptable providing the environmental conditions are met.

1.5 Units—The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard. Reporting of test results in units other than inch-pound shall not be regarded as nonconformance with this standard.

1.5.1 The gravitational system of inch-pound units is used when dealing with inch-pound units. In the system, the pound (lbf) represents a unit of force (weight), while the units for mass is s...

- Standard15 pagesEnglish languagesale 15% off

- Standard15 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This guide identifies proper layout, installation, and hydration procedures along with equipment for use by GCCM designers, inspectors, and installers.

4.2 Applications—Typical GCCM applications may include but are not limited to:

4.2.1 Hydraulic structure armoring or protection, including but not limited to: ditches, swales, canals, flumes, and other similar structures.

4.2.2 Slope protection.

4.2.3 Berm and bund lining and protection.

4.2.4 Culvert invert lining.

4.2.5 Scour protection at culvert inlets and outlets.

4.2.6 Remediation of existing concrete channels and structures.

4.2.7 Lining of outfalls and spillways.

4.2.8 Mow strips or weed suppression.

4.2.9 Lagoons and secondary containment berms (using GCCBs).

SCOPE

1.1 This guide covers directions for the installation of geosynthetic cementitious composite mat (GCCM) materials under field conditions typically present in erosion control, hydraulic structure armoring and protection, and protection applications. This guide also covers directions for the installation of a special category of GCCMs known as geosynthetic cementitious composite barrier (GCCB) materials, under field conditions typically present in geotechnical or civil engineering applications, with the purpose of reducing or preventing the flow of fluid through the construction.

1.2 The values in SI units are to be regarded as the standard. Values in inch-pound units are in parentheses for information.

1.3 This guide contains general guidelines. It is not intended to replace project-specific installation requirements. In the event of a conflict between the two, the requirements of the project specifications will supersede the requirements of this guide.

1.4 This is not an all-inclusive guide, and some projects will be beyond the scope of this guide.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide8 pagesEnglish languagesale 15% off

- Guide8 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 The use of nonreinforced geomembranes as barrier materials has created a need for a test method to evaluate the quality of chemical fusion seams produced by methods other than thermal fusion. This test method is used for quality control purposes and is intended to provide quality control and quality assurance personnel with a method to evaluate seam quality.

4.2 This test method utilizes two methods of sampling and specimen preparation for the purpose of providing a method of specimen preparation when overlapping of the seam does or does not produce a flap suitable for testing purposes.

SCOPE

1.1 This test method describes destructive quality control and quality assurance tests used to determine the integrity of geomembrane seams produced by adhesive and chemical fusion methods. These test procedures are intended for nonreinforced geomembranes only. This test method utilizes two sampling techniques; Method A is for seams produced without a testing flap, while Method B is for seams that produce a testing flap.

1.2 The rationale behind the two methods is that most seaming processes produce some type of flap on the back side or front side, or both, of the seam to perform peel testing. However, there are some processes in the industry that do not produce any type of flap to perform seam peel testing, and this is where the additional method is needed.

1.3 This method is intended for use with polyvinyl chloride (PVC)-based material seams, but is not limited to PVC.

1.4 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.5 Hazardous Materials—Always consult the proper Material Safety Data Sheets for any hazardous materials used for proper ventilation and protection.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Thickness is one of the basic physical properties used to control the quality of rolled erosion control products. Thickness values may aid in the calculation of other rolled erosion control product parameters. Thickness, however, is not generally an indication of field performance and generally should not be used in specifications. This test method is developed to aid manufacturers, designers, and end users in comparing the thickness of rolled erosion control products through the use of an accepted ASTM standard.

5.2 The thickness of rolled erosion control products may vary considerably depending on the pressure applied to the specimen during measurement. Where observed changes occur, thickness decreases when applied pressure is increased. To minimize variation, specific sample size and applied pressure are indicated in this test method to ensure all results are comparable.

5.3 This test method may be used for acceptance testing of commercial shipments of rolled erosion control products, but caution is advised since information on between-laboratory precision is incomplete. Comparative tests in accordance with 5.3.1 may be advised.

5.3.1 In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. At a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are formed from a lot of material of the type in question. The test specimens should be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using Student’s t-test for unpaired data and an acceptable probability level chosen by the two parties before the testing is begun. If b...

SCOPE

1.1 This test method covers the measurement of the nominal thickness of rolled erosion control products.

1.2 This test method does not provide thickness values for rolled erosion control products under variable compressive stresses. This test method determines nominal thickness, not necessarily minimum thickness.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This practice provides minimum requirements for the application of Direct-applied Exterior Finish Systems. The requirements for materials, mixtures, and details shall be contained in the project plans and specifications.

SCOPE

1.1 This practice covers the minimum requirements and procedures for field application of Direct-applied Exterior Finish Systems (DEFS). Direct-applied exterior finish systems are coating systems applied over various substrates with non-metallic reinforcing mesh, in which the base coat ranges from not less than 1/16 in. (1.6 mm) to 3/32 in. (2.4 mm) in dry thickness, depending on the mass of the reinforcing mesh. This base coat is subsequently covered with a finish coat that is available in a variety of textures and colors.

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric values given in parentheses are approximate and are provided for information purposes only.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard6 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This practice is intended to create specimens of GCCM products appropriate for testing for the determination of index properties. Cured (hardened) samples are not necessarily intended to represent a field application of GCCM products, but would be representative of the correct amount of water applied to a known style of product and provide a basis for consistent and repeatable index property testing.

SCOPE

1.1 This standard practice specifies a set of instructions for preparing samples of geosynthetic cementitious composite mat (GCCM) for index property testing.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D6026.

1.3.1 For purposes of comparing measured or calculated value(s) with specified limits, the measured or calculated value(s) shall be rounded to the nearest decimal or significant digits in the specified limits.

1.3.2 The procedures used to specify how data are collected/recorded or calculated in this practice are regarded as the industry standard. In addition, they are representative of the significant digits that generally should be measured. The procedures used do not consider material variation, purpose for obtaining the data, special purpose studies, or any considerations for the user’s objectives; and it is common practice to increase or reduce the significant digits of reported data to be commensurate with these considerations. It is beyond the scope of this practice to consider significant digits used in the analytical methods for engineering design.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Some specific hazards statements are given in Section 7 on Hazards.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This practice provides supplemental instructions that allow the use of Test Method D7249/D7249M to determine the open-hole (notched) strength of the sandwich panel facesheets for structural design allowables, material specifications, and research and development. Due to the curvature of the flexural test specimen when loaded, the open-hole sandwich facesheet strength from this test may not be equivalent to the open-hole sandwich facesheet strength of sandwich structures subjected to pure edgewise (in-plane) tension or compression.

5.2 Factors that influence the notched facesheet strength and shall therefore be reported include the following: facesheet material, core material, adhesive material, methods of material fabrication, facesheet stacking sequence and overall thickness, core geometry (cell size), core density, adhesive thickness, specimen geometry (including hole diameter, diameter-to-thickness ratio, and width-to-diameter ratio), specimen preparation (especially of the hole), specimen conditioning, environment of testing, specimen alignment, loading procedure, speed of testing, facesheet void content, adhesive void content, and facesheet volume percent reinforcement. Further, notched facesheet strength may be different between precured/bonded and co-cured facesheets of the same material.

SCOPE

1.1 This practice provides instructions for modifying the long beam flexure test method to determine open-hole facesheet properties of flat sandwich constructions subjected to flexure in such a manner that the applied moments produce curvature of the sandwich facesheet planes and result in compressive and tensile forces in the facesheets. Permissible core material forms include those with continuous bonding surfaces (such as balsa wood and foams) as well as those with discontinuous bonding surfaces (such as honeycomb). This practice supplements Test Method D7249/D7249M with provisions for testing specimens that contain a centrally located through-hole.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, to enforce conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.2.1 Within the text, the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard7 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.