ASTM D8172/D8172M-18(2023)e1

(Test Method)Standard Test Method for Shear and Peel Strength of Solvent-Welded Seams with Nonreinforced Geomembranes

Standard Test Method for Shear and Peel Strength of Solvent-Welded Seams with Nonreinforced Geomembranes

SIGNIFICANCE AND USE

4.1 The use of nonreinforced geomembranes as barrier materials has created a need for a test method to evaluate the quality of chemical fusion seams produced by methods other than thermal fusion. This test method is used for quality control purposes and is intended to provide quality control and quality assurance personnel with a method to evaluate seam quality.

4.2 This test method utilizes two methods of sampling and specimen preparation for the purpose of providing a method of specimen preparation when overlapping of the seam does or does not produce a flap suitable for testing purposes.

SCOPE

1.1 This test method describes destructive quality control and quality assurance tests used to determine the integrity of geomembrane seams produced by adhesive and chemical fusion methods. These test procedures are intended for nonreinforced geomembranes only. This test method utilizes two sampling techniques; Method A is for seams produced without a testing flap, while Method B is for seams that produce a testing flap.

1.2 The rationale behind the two methods is that most seaming processes produce some type of flap on the back side or front side, or both, of the seam to perform peel testing. However, there are some processes in the industry that do not produce any type of flap to perform seam peel testing, and this is where the additional method is needed.

1.3 This method is intended for use with polyvinyl chloride (PVC)-based material seams, but is not limited to PVC.

1.4 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.5 Hazardous Materials—Always consult the proper Material Safety Data Sheets for any hazardous materials used for proper ventilation and protection.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D8172/D8172M − 18 (Reapproved 2023)

Standard Test Method for

Shear and Peel Strength of Solvent-Welded Seams with

Nonreinforced Geomembranes

This standard is issued under the fixed designation D8172/D8172M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorially updated designation in May 2023.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This test method describes destructive quality control

mendations issued by the World Trade Organization Technical

and quality assurance tests used to determine the integrity of

Barriers to Trade (TBT) Committee.

geomembrane seams produced by adhesive and chemical

fusion methods. These test procedures are intended for nonre-

2. Referenced Documents

inforced geomembranes only. This test method utilizes two

2.1 ASTM Standards:

sampling techniques; Method A is for seams produced without

D76/D76M Specification for Tensile Testing Machines for

a testing flap, while Method B is for seams that produce a

Textiles

testing flap.

D4439 Terminology for Geosynthetics

1.2 The rationale behind the two methods is that most

seaming processes produce some type of flap on the back side 3. Terminology

or front side, or both, of the seam to perform peel testing.

3.1 Refer to Terminology D4439 for definitions of terms

However, there are some processes in the industry that do not

applying to this test method.

produce any type of flap to perform seam peel testing, and this

3.2 Definitions:

is where the additional method is needed.

3.2.1 adhesive, n—seams are typically produced by apply-

1.3 This method is intended for use with polyvinyl chloride

ing an adhesive to both sides of the sheet to be bonded, and

(PVC)-based material seams, but is not limited to PVC.

then pressure is applied to the top sheet with the bottom sheet

1.4 Units—The values stated in either SI units or inch-

supported by a flat, firm surface.

pound units are to be regarded separately as standard. The

3.2.1.1 Discussion—Heat and pressure are commonly used

values stated in each system may not be exact equivalents; as part of the bodied chemical fusion process.

therefore, each system shall be used independently of the other.

3.2.2 bodied chemical agent, n—a chemical fluid containing

Combining values from the two systems may result in noncon-

a portion of the parent geomembrane polymer that dissolves

formance with the standard.

the surface of the geomembranes to be bonded.

1.5 Hazardous Materials—Always consult the proper Ma-

3.2.3 bodied chemical fusion seams, n—use of a bodied

terial Safety Data Sheets for any hazardous materials used for

chemical agent to dissolve the surfaces of the geomembranes

proper ventilation and protection.

for bonding.

1.6 This standard does not purport to address all of the

3.2.4 chemical agent, n—a chemical fluid that dissolves the

safety concerns, if any, associated with its use. It is the

surface of the geomembrane to be bonded.

responsibility of the user of this standard to establish appro-

3.2.5 chemical fusion seams, n—use of a chemical agent to

priate safety, health, and environmental practices and deter-

dissolve the surface of the geomembrane for bonding.

mine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accor-

4. Significance and Use

dance with internationally recognized principles on standard-

4.1 The use of nonreinforced geomembranes as barrier

materials has created a need for a test method to evaluate the

This test method is under the jurisdiction of ASTM Committee D35 on

Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomem-

branes. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2023. Published May 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2018. Last previous edition approved in 2018 as D8172 – 18. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D8172_D8172M-18R23E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D8172/D8172M − 18 (2023)

quality of chemical fusion seams produced by methods other

than thermal fusion. This test method is used for quality control

purposes and is intended to provide quality control and quality

assurance personnel with a method to evaluate seam quality.

4.2 This test method utilizes two methods of sampling and

specimen preparation for the purpose of providing a method of

specimen preparation when overlapping of the seam does or

does not produce a flap suitable for testing purposes.

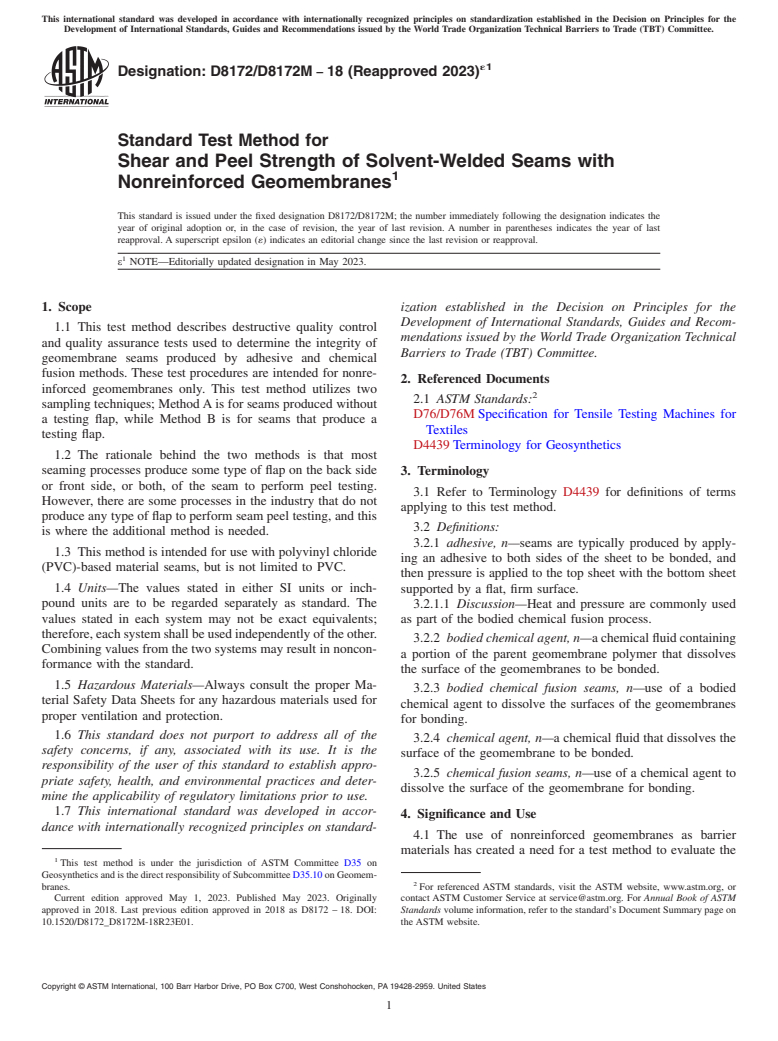

5. Apparatus

5.1 Tensile Testing Machine—Constant rate of extension

(CRE) equipment meeting the requirements of Specification

D76/D76M. The load cell shall be accurate to within 1 % of the

applied force used. The drive mechanism shall be able to

control the rate of extension to within 1 % of the targeted rate.

The maximum allowable error in recorded grip displacement

shall be 1 % of the recorded values. The maximum allowable

variation in nominal gage length on repeated return of the

clamps to their starting position shall be less than 0.25 mm

[0.01 in.].

5.2 Grip Faces—The clamping force and the clamp surfaces

shall hold the specimen firmly without causing damage. One of

the grips shall be self aligning to compensate for uneven

distribution of force across the specimen.

5.3 Clamp faces shall be adequate to grip the specimen in

the dimension parallel to the direction of test and wide enough

to grip the full width of the specimen.

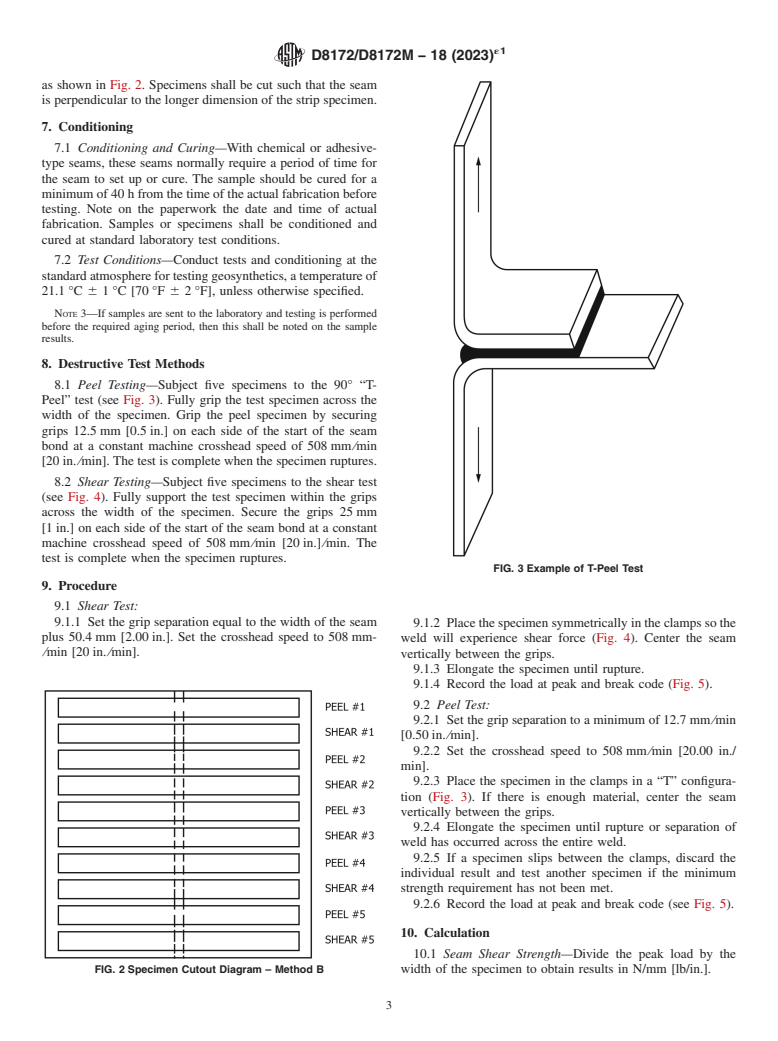

6. Sampling, Test Specimens, and Test Units

6.1 Method A—Use this method when overlapping of the

geomembrane material during the seaming process does not

produce a flap suitable for peel testing across the seam. Seams

tested using this procedure should have a minimum seam width

of 1 in. for testing. If the seams to be tested are less than 1 in.

in width, further calculations may be required as noted in 10.2.

FIG. 1 Specimen Cutout Diagram – Method A

6.1.1 Seam Samples – Method A—Cut the sample. Approxi-

mately a 760 mm [30 in.] length of seam shall be cut out with

a minimum of 102 mm [4 in.] of material on either side of the

6.1.4 Shear Specimen Preparation—Cut five shear speci-

seam for shear testing.

mens from the remaining portion of the sample across the seam

6.1.2 Peel Specimen Preparation—Place two cuts across the

as shown in Fig. 1. Cut to produce a specimen 25 mm [nominal

seam and initiate a peel in both directions of the cut and on the

1.0 in.] wide by a minimum of 150 mm [nominal 6 in.] long.

two ends of the sam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.