ASTM D3884-09(2017)

(Guide)Standard Guide for Abrasion Resistance of Textile Fabrics (Rotary Platform, Double-Head Method)

Standard Guide for Abrasion Resistance of Textile Fabrics (Rotary Platform, Double-Head Method)

SIGNIFICANCE AND USE

5.1 The measurement of the resistance to abrasion of textile and other materials is very complex. The resistance to abrasion is affected by many factors, such as the inherent mechanical properties of the fibers; the dimensions of the fibers; the structure of the yarns; the construction of the fabrics; and the type, kind, and amount of finishing material added to the fibers, yarns, or fabric.

5.2 The resistance to abrasion is also greatly affected by the conditions of the tests, such as the nature of abradant, variable action of the abradant over the area of specimen abraded, the tension of the specimen, the pressure between the specimen and abradant, and the dimensional changes in the specimens.

5.3 Abrasion tests are all subject to variation due to changes in the abradant during specific tests. The abradant must accordingly be discarded at frequent intervals or checked periodically against a standard. With disposable abradants, the abradant is used only once or discarded after limited use. With permanent abradants that use hardened metal or equivalent surfaces, it is assumed that the abradant will not change appreciably in a specific series of tests. Similar abradants used in different laboratories will not change at the same rate, due to differences in usage. Permanent abradants may also change due to pick up of finishing or other material from test fabrics and must accordingly be cleaned at frequent intervals. The measurement of the relative amount of abrasion may also be affected by the method of evaluation and may be influenced by the judgment of the operator.

5.4 The resistance of textile materials to abrasion as measured on a testing machine in the laboratory is generally only one of several factors contributing to wear performance or durability as experienced in the actual use of the material. While “abrasion resistance” (often stated in terms of the number of cycles on a specified machine, using a specified technique to produce a specified degree o...

SCOPE

1.1 This guide covers the determination of the abrasion resistance of textile fabrics using the rotary platform, double-head tester (RPDH).

Note 1: Other procedures for measuring the abrasion resistance of textile fabrics are given in Test Methods D3885, D3886, D4157, D4158, D4966, and AATCC 93.

1.2 The values stated in SI units are to be regarded as standard: the values in English units are provided as information only and are not exact equivalents.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3884 − 09 (Reapproved 2017)

Standard Guide for

Abrasion Resistance of Textile Fabrics (Rotary Platform,

1

Double-Head Method)

This standard is issued under the fixed designation D3884; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4158 Guide for Abrasion Resistance of Textile Fabrics

(Uniform Abrasion)

1.1 This guide covers the determination of the abrasion

D4850 Terminology Relating to Fabrics and Fabric Test

resistance of textile fabrics using the rotary platform, double-

Methods

head tester (RPDH).

D4966 Test Method for Abrasion Resistance of Textile

NOTE 1—Other procedures for measuring the abrasion resistance of

Fabrics (Martindale Abrasion Tester Method)

textile fabrics are given in Test Methods D3885, D3886, D4157, D4158,

D5034 TestMethodforBreakingStrengthandElongationof

D4966, and AATCC 93.

Textile Fabrics (Grab Test)

1.2 The values stated in SI units are to be regarded as

D5035 Test Method for Breaking Force and Elongation of

standard: the values in English units are provided as informa-

Textile Fabrics (Strip Method)

tion only and are not exact equivalents.

D7255 Test Method for Abrasion Resistance of Leather

1.3 This standard does not purport to address all of the (Rotary Platform, Abraser Method)

safety problems, if any, associated with its use. It is the

2.2 Other Documents:

responsibility of the user of this standard to establish appro-

AATCC 93 Abrasion Resistance of Fabrics: Accelerator

3

priate safety and health practices and determine the applica-

Method

bility of regulatory limitations prior to use.

3. Terminology

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3.1 For all terminology relating to D13.60, Fabric Test

ization established in the Decision on Principles for the

Methods, Specific, refer to Terminology D4850.

Development of International Standards, Guides and Recom-

3.1.1 The following terms are relevant to this standard:

mendations issued by the World Trade Organization Technical

abrasion, abrasion cycle, breaking force.

Barriers to Trade (TBT) Committee.

3.2 For all other terminology related to textiles, refer to

Terminology D123.

2. Referenced Documents

2

2.1 ASTM Standards:

4. Summary of Test Method

D123 Terminology Relating to Textiles

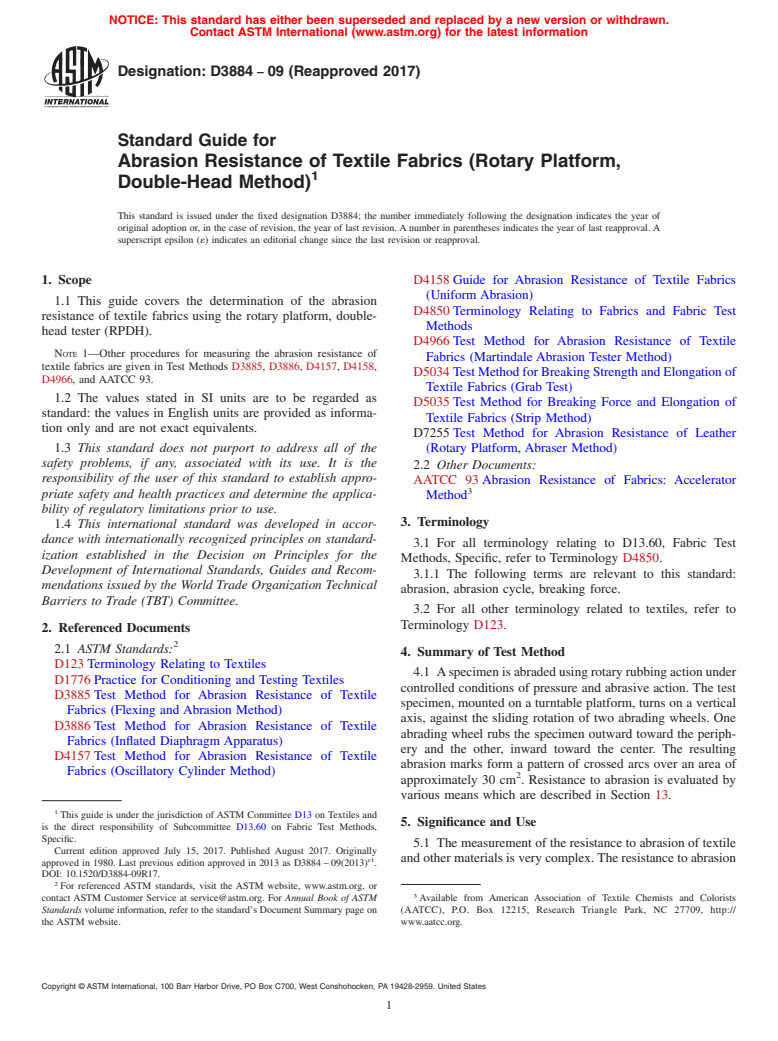

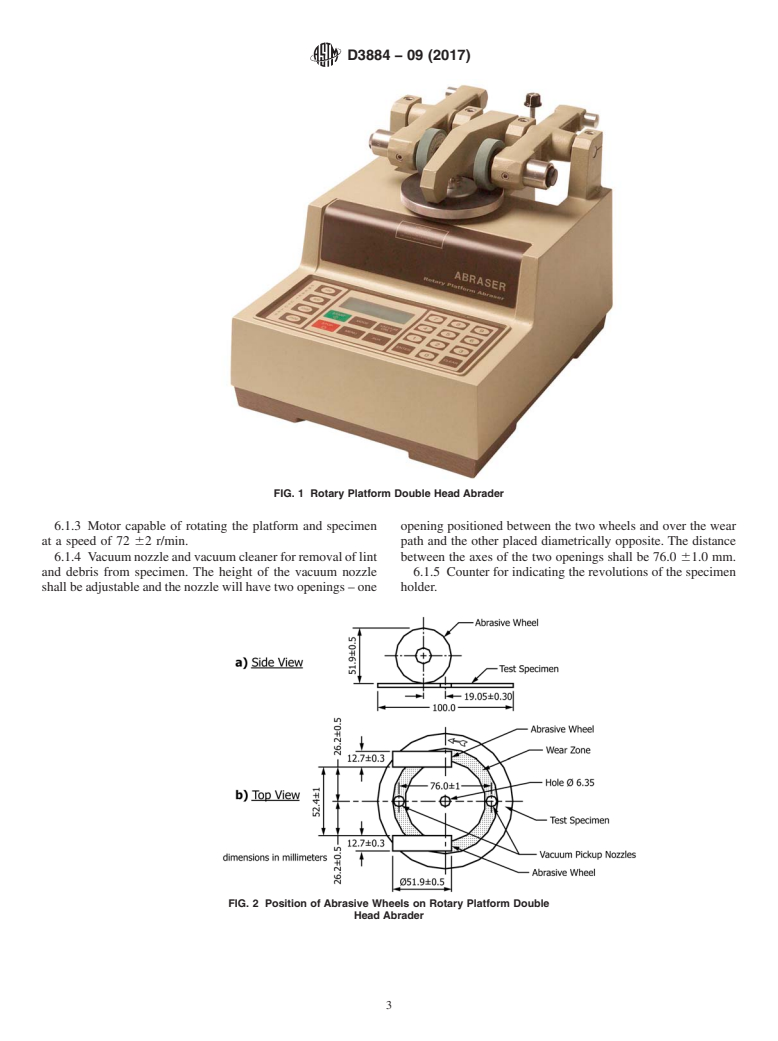

4.1 Aspecimenisabradedusingrotaryrubbingactionunder

D1776 Practice for Conditioning and Testing Textiles

controlled conditions of pressure and abrasive action. The test

D3885 Test Method for Abrasion Resistance of Textile

specimen, mounted on a turntable platform, turns on a vertical

Fabrics (Flexing and Abrasion Method)

axis, against the sliding rotation of two abrading wheels. One

D3886 Test Method for Abrasion Resistance of Textile

abrading wheel rubs the specimen outward toward the periph-

Fabrics (Inflated Diaphragm Apparatus)

ery and the other, inward toward the center. The resulting

D4157 Test Method for Abrasion Resistance of Textile

abrasion marks form a pattern of crossed arcs over an area of

Fabrics (Oscillatory Cylinder Method)

2

approximately 30 cm . Resistance to abrasion is evaluated by

various means which are described in Section 13.

1

This guide is under the jurisdiction of ASTM Committee D13 on Textiles and

5. Significance and Use

is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

Specific.

5.1 The measurement of the resistance to abrasion of textile

Current edition approved July 15, 2017. Published August 2017. Originally

ɛ1

and other materials is very complex.The resistance to abrasion

approved in 1980. Last previous edition approved in 2013 as D3884 – 09(2013) .

DOI: 10.1520/D3884-09R17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Association of Textile Chemists and Colorists

Standards volume information, refer to the standard’s Document Summary page on (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://

the ASTM website. www.aatcc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3884 − 09 (2017)

is affected by many factors, such as the inherent mechanical a definite need for measuring the relative resistance to

properties of the fibers; the dimensions of the fibers; the abrasion, this is one of the several procedures that is useful to

structure of the yarns; the construction of the fabrics; and the help minimize the inherent

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D3884 − 09 (Reapproved 2013) D3884 − 09 (Reapproved 2017)

Standard Guide for

Abrasion Resistance of Textile Fabrics (Rotary Platform,

1

Double-Head Method)

This standard is issued under the fixed designation D3884; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—This standard was corrected back to a Guide editorially in February 2014. No content was changed.

1. Scope

1.1 This guide covers the determination of the abrasion resistance of textile fabrics using the rotary platform, double-head tester

(RPDH).

NOTE 1—Other procedures for measuring the abrasion resistance of textile fabrics are given in Test Methods D3885, D3886, D4157, D4158, D4966,

and AATCC 93.

1.2 The values stated in SI units are to be regarded as standard: the values in English units are provided as information only

and are not exact equivalents.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning and Testing Textiles

D3885 Test Method for Abrasion Resistance of Textile Fabrics (Flexing and Abrasion Method)

D3886 Test Method for Abrasion Resistance of Textile Fabrics (Inflated Diaphragm Apparatus)

D4157 Test Method for Abrasion Resistance of Textile Fabrics (Oscillatory Cylinder Method)

D4158 Guide for Abrasion Resistance of Textile Fabrics (Uniform Abrasion)

D4850 Terminology Relating to Fabrics and Fabric Test Methods

D4966 Test Method for Abrasion Resistance of Textile Fabrics (Martindale Abrasion Tester Method)

D5034 Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

D5035 Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method)

D7255 Test Method for Abrasion Resistance of Leather (Rotary Platform, Abraser Method)

2.2 Other Documents:

3

AATCC 93 Abrasion Resistance of Fabrics: Accelerator Method

3. Terminology

3.1 For all terminology relating to D13.60, Fabric Test Methods, Specific, refer to Terminology D4850.

3.1.1 The following terms are relevant to this standard: abrasion, abrasion cycle, breaking force.

3.2 For all other terminology related to textiles, refer to Terminology D123.

1

This guide is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods, Specific.

Current edition approved July 1, 2013July 15, 2017. Published September 2013August 2017. Originally approved in 1980. Last previous edition approved in 20092013

ɛ1

as D3884 – 09.D3884 – 09(2013) . DOI: 10.1520/D3884-09R13E01.10.1520/D3884-09R17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Association of Textile Chemists and Colorists (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://www.aatcc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3884 − 09 (2017)

4. Summary of Test Method

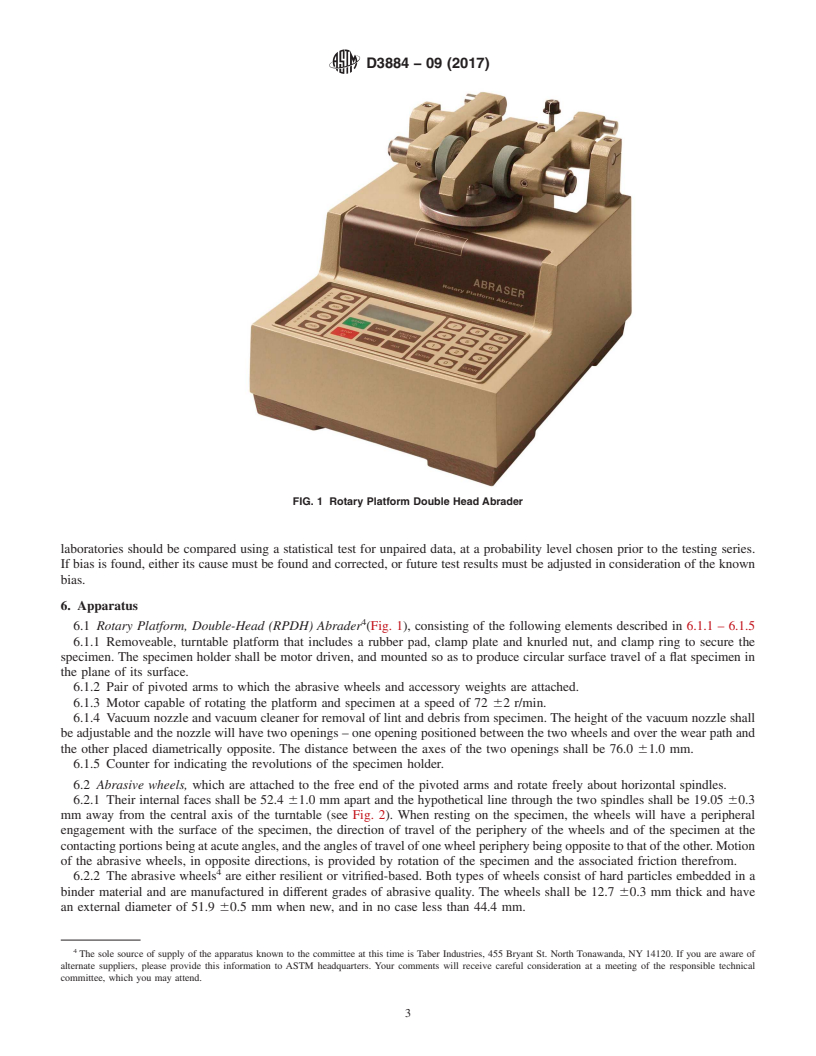

4.1 A specimen is abraded using rotary rubbing action under controlled conditions of pressure and abrasive action. The test

specimen, mounted on a turntable platform, turns on a vertical axis, against the sliding rotation of two abrading wheels. One

abrading wheel rubs the specimen outward toward the periphery and the other, inward toward the center. The resulting abrasion

2

marks form a pattern of crossed arcs over an area of approximately 30 cm . Resistance to abrasion is evaluated by various means

which are described in Section 13.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.