ASTM D3938-18(2023)

(Guide)Standard Guide for Determining or Confirming Care Instructions for Apparel and Other Textile Products

Standard Guide for Determining or Confirming Care Instructions for Apparel and Other Textile Products

SIGNIFICANCE AND USE

4.1 This is a guide to help a manufacturer distributor, or importer establish a reasonable basis for care information.

4.1.1 The manufacturer, distributor, or importer should possess, prior to sale, reliable evidence that the product was not harmed when refurbished reasonably often according to the instructions. Additionally, they should possess reliable evidence that the product, or a fair sample of the product, would be harmed when refurbished by methods warned against on the label.

4.2 This guide is intended for general use by those who wish to evaluate whether apparel or other textile products will perform in an acceptable manner when refurbished according to particular care instructions.

4.3 Refurbished products are evaluated against previously selected product specifications to determine whether the products can be refurbished successfully by following the instructions on the care label or other care instructions.

SCOPE

1.1 This guide may be used to determine and confirm the appropriate care label instructions for apparel, piece goods, and other textile products excluding textile floor coverings and upholstery.

1.2 This guide encompasses the following care procedures: home laundering, professional textile care, and other alternative cleaning methods.

1.3 This guide includes provision for evaluating the complete textile product and the product components.

1.4 This guide covers the performance characteristics as a result of refurbishing that are important in determining the acceptability of a textile product.

1.5 This guide is appropriate for the evaluation of all garments and household textiles that are sold with care labels.

1.5.1 This guide may also be used in connection with the evaluation of similar materials that do not have a care label.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3938 − 18 (Reapproved 2023)

Standard Guide for

Determining or Confirming Care Instructions for Apparel

and Other Textile Products

This standard is issued under the fixed designation D3938; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3136 Terminology Relating to Care Labeling for Apparel,

Textile, Home Furnishing, and Leather Products (With-

1.1 This guide may be used to determine and confirm the

drawn 2023)

appropriate care label instructions for apparel, piece goods, and

D5489 Guide for Care Symbols for Care Instructions on

other textile products excluding textile floor coverings and

Textile Products

upholstery.

2.2 AATCC Methods:

1.2 This guide encompasses the following care procedures:

Technical Manual of the American Association of Textile

home laundering, professional textile care, and other alterna-

Chemists and Colorists

tive cleaning methods.

2.3 Other Standards:

1.3 This guide includes provision for evaluating the com- Federal Trade Commission Trade Regulation Rule. Care

plete textile product and the product components.

Labeling of Textile Wearing Apparel and Certain Piece

Goods. Effective July 3, 1972, most recent version (cited

1.4 This guide covers the performance characteristics as a

as 16 CFR 423)

result of refurbishing that are important in determining the

CAN/CGSB-86.1 The National Standard of Canada – Care

acceptability of a textile product.

Labelling of Textiles (most recent version)

1.5 This guide is appropriate for the evaluation of all

garments and household textiles that are sold with care labels.

3. Terminology

1.5.1 This guide may also be used in connection with the

3.1 For all terminology relating to D13.61, Apparel, refer to

evaluation of similar materials that do not have a care label.

Terminology D3136.

1.6 This standard does not purport to address all of the

3.1.1 The following terms are relevant to this standard: care

safety concerns, if any, associated with its use. It is the

instructions, main components.

responsibility of the user of this standard to establish appro-

3.2 For all other terms are related to textiles, refer to

priate safety, health, and environmental practices and deter-

Terminology D123.

mine the applicability of regulatory limitations prior to use.

3.3 Definitions:

1.7 This international standard was developed in accor-

3.3.1 For definitions of other textile terms used in this guide,

dance with internationally recognized principles on standard-

refer to Terminology D123. For definitions of terms related to

ization established in the Decision on Principles for the

care instructions, refer to Terminology D3136.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4. Significance and Use

Barriers to Trade (TBT) Committee.

4.1 This is a guide to help a manufacturer distributor, or

2. Referenced Documents

importer establish a reasonable basis for care information.

4.1.1 The manufacturer, distributor, or importer should

2.1 ASTM Standards:

possess, prior to sale, reliable evidence that the product was not

D123 Terminology Relating to Textiles

harmed when refurbished reasonably often according to the

This guide is under the jurisdiction of ASTM Committee D13 on Textiles and

is the direct responsibility of Subcommittee D13.62 on Labeling. The last approved version of this historical standard is referenced on

Current edition approved Dec. 1, 2023. Published December 2023. Originally www.astm.org.

approved in 1993. Last previous edition approved in 2018 as D3938 – 18. DOI: Available from American Association of Textile Chemists and Colorists, P.O.

10.1520/D3938-18R23. Box 12215, Research Triangle Park, NC 27709. http://www.aatcc.org.

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Federal Trade Commission, 600 Pennsylvania Avenue, N.W.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Washington, DC 20580. http://www.ftc.gov.

Standards volume information, refer to the standard’s Document Summary page on Available from Canadian Government Publishing Centre, Supply and Services

the ASTM website. Canada, Publication Section, Hull (Quebec) K1A OS9.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3938 − 18 (2023)

instructions. Additionally, they should possess reliable evi- 7.3 Change in Appearance:

dence that the product, or a fair sample of the product, would

7.3.1 Loss or change of color.

be harmed when refurbished by methods warned against on the

7.3.2 Staining or self-staining, that is transference, or run-

label.

ning of original color from one product to another or from one

area to another area on the same product.

4.2 This guide is intended for general use by those who wish

7.3.3 Distortion and loss or change in surface appearance or

to evaluate whether apparel or other textile products will

structure (such as, pilling, fuzzing, snagging, or matting; or

perform in an acceptable manner when refurbished according

loss of nap, flocking, embossing, or fabric smoothness; or other

to particular care instructions.

effects).

4.3 Refurbished products are evaluated against previously

7.3.4 Change in appearance of components including base

selected product specifications to determine whether the prod-

fabrics and items such as zippers, linings, interfacings, inter-

ucts can be refurbished successfully by following the instruc-

linings sewing thread, waist bands, pockets, seam bindings or

tions on the care label or other care instructions.

tape, textile trim, nontextile trim, and labels.

7.3.5 Other changes in appearance not listed in 7.3.1 – 7.3.4.

5. Summary of Guide

7.4 Change in Performance:

5.1 This guide describes general procedures for determining

7.4.1 Loss of claimed functional properties (stated or im-

and confirming instructions on a care label for a textile product.

plied) such as durable press, water repellency, anti-static,

5.2 General procedures include setting minimum or maxi-

flame-resistant, or soil release.

mum performance specifications for the product, selecting

7.4.2 Loss of performance of construction or design due to

appropriate standards and test methods to match the care label

impairment or malfunction of items such as seams, bonding,

instructions, conducting the testing and evaluation process, and

trim, closures, or other hardware.

writing the report.

7.4.3 Failure of textile structure resulting from laundering

5.3 The products are evaluated for changes in dimension,

or dry cleaning (for example, delamination).

hand, appearance, or performance characteristics as a result of

7.4.4 Other changes in performance not listed in 7.4.1 –

refurbishing.

7.4.3.

6. General Considerations

8. Selection of Test Methods and Performance

6.1 Care instructions can be determined by testing the

Specifications

component parts or by testing the completed textile product or

8.1 If the textile product to be evaluated has no care label,

both if necessary.

determine a set of care instructions suitable for the item.

6.1.1 When confirming the care label, the testing shall be

8.1.1 On making the final determination consider factors

done on the completed textile product.

such as fiber content, fabric construction, item construction,

6.2 The test methods and evaluation processes selected to

findings, color and finish applications, and end use.

represent the washing, bleaching, drying, ironing, and dry-

8.2 If the textile product to be evaluated has an attached care

cleaning care label instructions shall simulate at least 3

label, then confirm the care by using the designated instructions

complete refurbishing cycles.

on the label.

6.2.1 The actual number of complete refurbishing cycles

shall be agreed upon by the purchaser and the supplier.

8.3 Select the product characteristics listed in Section 7 that

6.2.2 One complete refurbishing cycle includes either (1)

are to be evaluated for the samples to be tested.

laundering including washing and drying, and, if appropriate,

8.3.1 The product characteristics are not limited to those

bleaching and/or ironing; (2) drycleaning and pressing; or, (3)

examples listed, but may include all items which are agreed

wet cleaning and restorative treatment.

upon between the purchaser and supplier.

6.3 Test results that meet or exceed the preset specifications

8.4 Select test methods that are representative of the care

for product characteristics indicate that the determined or

instructions.

labeled care instructions represented by testing are appropriate

8.4.1 The test procedures must be at least as severe as the

for the tested product.

conditions specified in the care instruction.

8.4.2 Where less common care instructions, for example,

7. Product Characteristics for Evaluation as a Result of

“wipe with a damp cloth,” are to be used, an appropriate care

Refurbishing

practice shall be used to evaluate the product.

7.1 Change in Dimensions:

8.5 Select test methods for evaluation of functional proper-

7.1.1 Shrinkage.

ties such as those listed in 7.4.1.

7.1.2 Growth.

7.1.3 Distortion caused by uneven growth or shrinkage

8.6 Select the performance specification level for each

(skewness).

product characteristic to be evaluated.

7.2 Change in Hand: 8.6.1 Product specifications should be agreed upon by the

7.2.1 Changes in the physical properties related to the hand purchaser and supplier, or the end-use standards of ASTM

of fabrics listed in Annex A3 of Terminology D123. Committee D13 shall be used.

D3938 − 18 (2023)

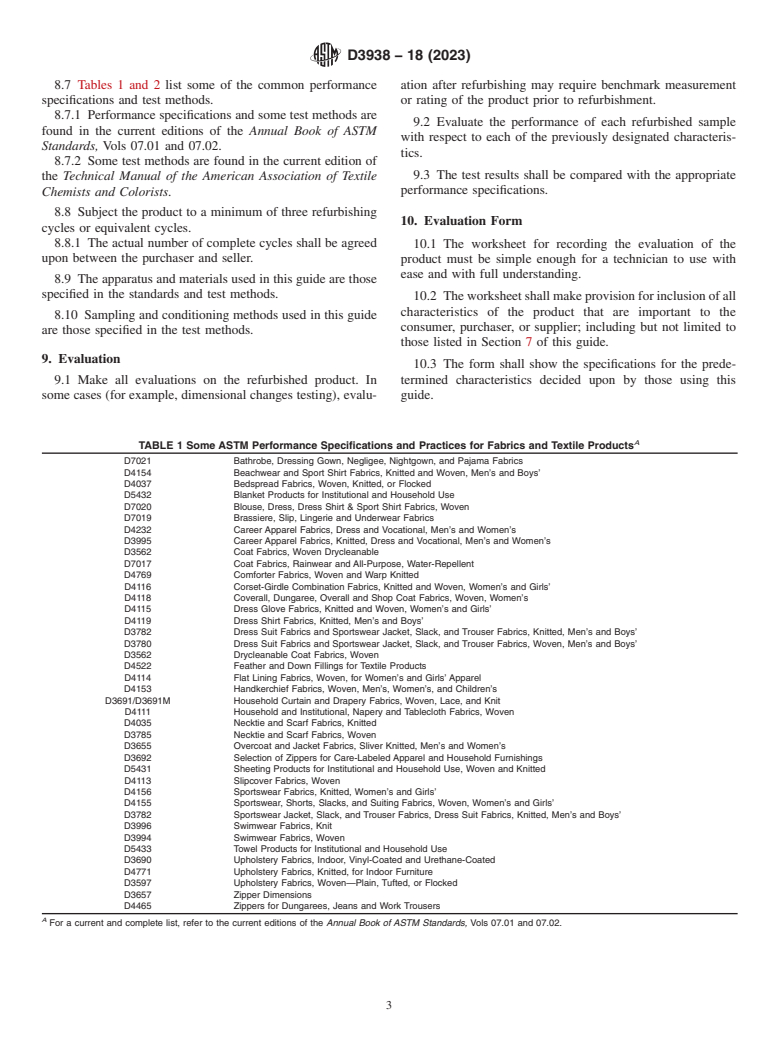

8.7 Tables 1 and 2 list some of the common performance ation after refurbishing may require benchmark measurement

specifications and test methods. or rating of the product prior to refurbishment.

8.7.1 Performance specifications and some test methods are

9.2 Evaluate the performance of each refurbished sample

found in the current editions of the Annual Book of ASTM

with respect to each of the previously designated characteris-

Standards, Vols 07.01 and 07.02.

tics.

8.7.2 Some test methods are found in the current edition of

9.3 The test results shall be compared with the appropriate

the Techn

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.