ASTM D1574-04(2008)

(Test Method)Standard Test Method for Extractable Matter in Wool and Other Animal Fibers

Standard Test Method for Extractable Matter in Wool and Other Animal Fibers

SCOPE

1.1 This test method covers the determination of the amount of extractable matter in samples of all forms of wool, except grease wool, that is extractable with a non-flammable vapor degreasing and cleaning solvent.

1.2 This test method does not cover the determination of the amounts of different components in the extracted matter nor their identification.

1.3 This test method is suitable for use with other animal fibers. Note 1 - The determination of extractable matter in yarns and in felts is covered in Test Methods D 2257 and D 461. For the determination of alcohol-extractable matter in oven-dry scoured wool, refer to Test Methods D 584 and D 1334.

1.4 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See 5.4 and Note 3.

WITHDRAWN RATIONALE

This test method covers the determination of the amount of extractable matter in samples of all forms of wool, except grease wool, that is extractable with trichlorotrifluoroethane (CCl2-FCClF2).

Formerly under the jurisdiction of Committee D13 on Textiles, this test method was withdrawn in June 2004 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1574 − 04(Reapproved 2008)

Standard Test Method for

Extractable Matter in Wool and Other Animal Fibers

This standard is issued under the fixed designation D1574; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2462 Test Method for Moisture in Wool by Distillation

With Toluene

1.1 This test method covers the determination of the amount

D4845 Terminology Relating to Wool

of extractable matter in samples of all forms of wool, except

grease wool, that is extractable with a non-flammable vapor

3. Terminology

degreasing and cleaning solvent.

3.1 Definitions:

1.2 This test method does not cover the determination of the

3.1.1 For definitions of textile terms used in this test

amounts of different components in the extracted matter nor

method: animal fiber, extractable matter, grease wool, recycled

their identification.

wool, wool and wool, refer to Terminology D4845.

1.3 This test method is suitable for use with other animal

3.2 For definitions of other textile terms used in this test

fibers.

method, refer to Terminology D123.

NOTE 1—The determination of extractable matter in yarns and in felts

is covered in Test Methods D2257 and D461. For the determination of 4. Summary of Test Method

alcohol-extractable matter in oven-dry scoured wool, refer to Test Meth-

4.1 The specimen is extracted in a Soxhlet apparatus with a

ods D584 and D1334.

specified halogenated hydrocarbon solvent. The extract is

1.4 The values stated in SI units are to be regarded as the

filtered, the solvent is evaporated, and both the residue and the

standard.

extracted specimen are dried and weighed. The amount of

1.5 This standard does not purport to address the safety

extractable matter is calculated and reported as a percentage of

concerns, if any, associated with its use. It is the responsibility

the oven-dry mass of the wool specimen, that is, the mass of

of the user of this standard to establish appropriate safety and

the oven-dried extracted specimen plus the mass of the

health practices and determine the applicability of regulatory

oven-dried extracted material.

limitations prior to use. See 5.4 and Note 3.

4.2 Special procedures are provided to correct for errors in

determiningtheamountofextractablematterassummarizedin

2. Referenced Documents

4.1 if it is known or thought to contain volatile components.

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

5. Significance and Use

D461 Test Methods for Felt (Withdrawn 2003)

5.1 Test Method D1574 is considered satisfactory for ac-

D584 Test Method for Wool Content of Raw Wool—

ceptance testing since the method has been used extensively in

Laboratory Scale

the trade for acceptance testing.

D1334 Test Method for Wool Content of Raw Wool—

5.1.1 In case of a dispute arising from differences in

Commercial Scale

reported test results when using Test Method D1574 for

D1576 Test Method for Moisture in Wool by Oven-Drying

acceptance testing of commercial shipments, the purchaser and

D2257 Test Method for Extractable Matter in Textiles

the supplier should conduct comparative tests to determine if

there is a statistical bias between their laboratories. Competent

1 statistical assistance is recommended for the investigation of

This test method is under the jursidiction ofASTM Committee D13 on Textiles

and is the direct responsibility of Subcommittee D13.13 on Wool and Felt.

bias.As a minimum, the two parties should take a group of test

Current edition approved Aug. 1, 2008. Published September 2008. Originally

specimens that are as homogeneous as possible and that are

approved in 1958. Last previous edition approved in 2004 as D1574 – 04. DOI:

from a lot of material of the type in question. The test

10.1520/D1574-04R08.

specimens should then be randomly assigned in equal numbers

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

to each laboratory for testing.The average results from the two

Standards volume information, refer to the standard’s Document Summary page on

laboratories should be compared using Student’s t-test for

the ASTM website.

unpaireddataandanacceptableprobabilitylevelchosenbythe

The last approved version of this historical standard is referenced on

www.astm.org. two parties before the testing is begun. If a bias is found, either

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1574 − 04 (2008)

its cause must be found and corrected or the purchaser and the containers that can be hermetically sealed (such as glass

supplier must agree to interpret future test results in the light of weighingbottles)ifthespecimenistobecooledinadesiccator

the known bias. before weighing in the ambient atmosphere.

5.2 This test method may be used to estimate the quantity of 6.6 Balance, having a capacity adequate for weighing

oil, grease, and waxy materials remaining on or in wool fibers specimens, flasks, and containers and having a sensitivity of

afterscouring,orthequantityoflubricantaddedbeforecarding 0.001 g.

or remaining after carding, or the quantity of such materials 5

6.7 Solvent—Ensolv.

added or removed in subsequent processing operations.

7. Sampling

5.3 The residues obtained in this test may be subjected to

chemicalanalysisforidentificationandassayofthecomponent 7.1 Lot Sample—As a lot sample for acceptance testing,

materials, if desired.

unless otherwise agreed upon between purchaser and supplier,

take at random the number of packages of wool from a lot as

5.4 The specified solvent in this test method does not

directed in Table 1. Consider packages of wool as the primary

remove some materials, such as soaps, that may be present in

sampling unit.

wool and hence in some cases may reflect more closely the

added content of some extractables in wool such as oils. When

7.2 Laboratory Sample—Consider the package of wool in

such materials are present and an estimate of their quantity is

the lot sample as the laboratory sample.

desired, some other solvent or combination of solvents should

7.3 Test Specimen—From each package in the laboratory

beusedasspecifiedinamaterialspecificationorbyagreement.

sample take at random two specimens each weighing 10 61g.

TheinformationintheAnnexofthistestmethodmaybeuseful

7.3.1 If the determination of volatile matter in extractables,

for this purpose. Various solvents have been used in the past,

as described in 9.5.2, is to be undertaken, weigh the test

and are still used to some extent. Many of these solvents are

specimen to the nearest 0.001 g and record this mass as T.This

undesirable, however, because of flammability, toxic or anes-

specimen is for extraction.

thetic effects, or unpleasant odors. Trichlorotrifluoroethane is

7.3.2 For each test specimen taken for extraction, take a

nonflammable, has a very low level of toxicity, and a high

second test specimen for moisture determination, weighing

degree of stability and is a good solvent for most fatty or

between50and70g.Weightothenearest0.05gthesametime

mineral oils, greases, and waxes. The specified solvent, under

the extraction test specimen is weighed so that the moisture

conditions of the test, was found in interlaboratory test not to

content of the two specimens at the time of weighing will be

extract wool protein.

identical.

NOTE2—Sincethespecifiedsolventisprimarilyasolventforoilsrather

8. Conditioning

than soap, the extractable matter obtained in this procedure may be

considered a measure of commercial oil content.

8.1 Neither preconditioning nor conditioning is necessary.

NOTE 3—Due to the hazardous nature of some of the solvents listed in

Table A1.1, the user should refer to the manufacturer’s recommendations

9. Procedure

for use before using under the conditions of this test method.

9.1 Wrap the specimen in a single sheet of fresh filter paper

6. Apparatus and Reagents

(or place in an extraction thimble free of matter extractable by

the specified solvent) and insert the assemblage in the extrac-

6.1 Soxhlet Extraction Apparatus, including an extraction

tion tube. Make certain that all open edges of the filter paper or

tube, condenser, and flask. A large extraction tube having a

thimble extend above the siphon tube.

standard-taper joints T55/50 and 24/40 and a 300-mL flask are

recommended, but any size capable of holding at least a 10-g

9.2 Attach to the extraction tube a 300-mL flask that has

specimen is satisfactory.

previouslybeendriedat105 63°C,cooledinadesiccator,and

weighed to the nearest 1 mg.

6.2 Heater for Extraction Apparatus, preferably electric,

thermostatically controlled, and of a design that avoids direct

9.3 Slowly pour sufficient solvent over the specimen to start

heating of the flask above the lowest solution level.

thesiphoningaction.(Ifathimbleisusedtoholdthespecimen,

pour the solvent onto the specimen within the thimble). When

6.3 Drying Oven, ventilated either by natural convection or

forced draft, thermostatically controlled and maintained at 105

6 3°C throughout the oven chamber. 5

This solvent is available from Enviro Tech International Inc., West LeMoyne,

4 Melrose Park, IL 60160 (www.ensolv.com).

6.4 Filter Paper, medium speed, retentive, in large sheets,

580 by 580 mm (23 by 23 in.), or in circles large enough to

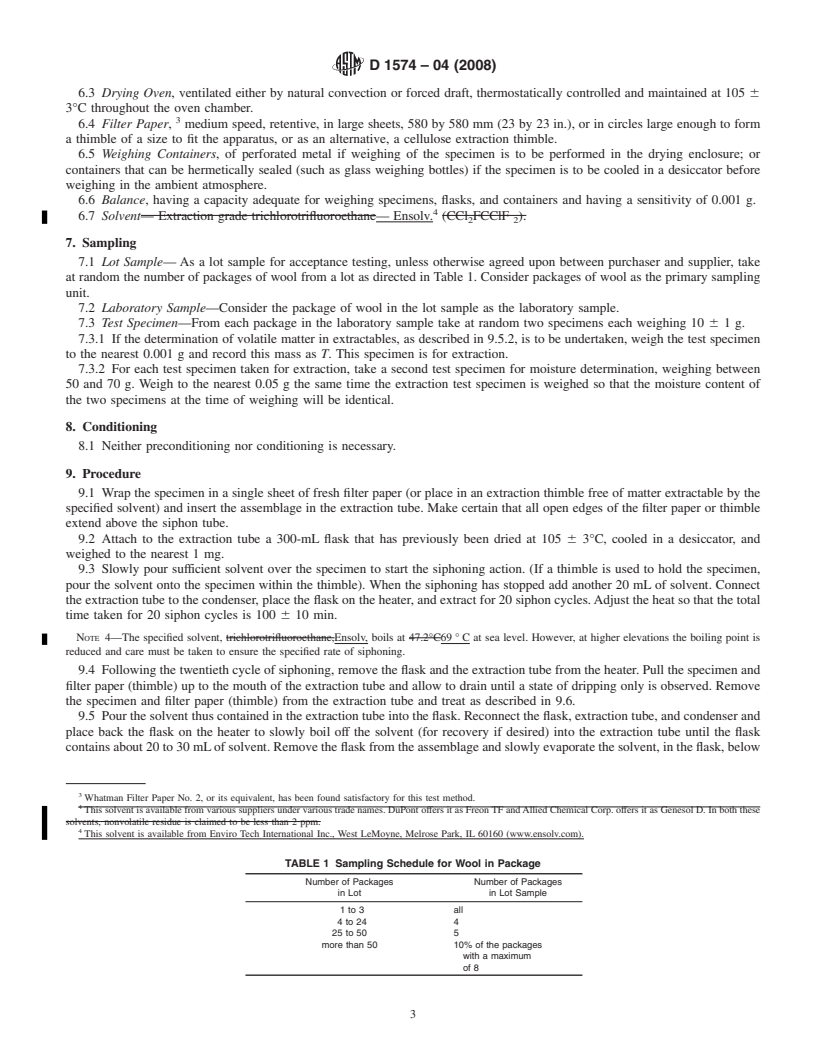

TABLE 1 Sampling Schedule for Wool in Package

formathimbleofasizetofittheapparatus,orasanalternative,

Number of Packages Number of Packages

a cellulose extraction thimble.

in Lot in Lot Sample

6.5 Weighing Containers, of perforated metal if weighing of

1to3 all

4to24 4

the specimen is to be performed in the drying enclosure; or

25 to 50 5

more than 50 10% of the packages

with a maximum

Whatman Filter Paper No. 2, or its equivalent, has been found satisfactory for of 8

this test method.

D1574 − 04 (2008)

the siphoning has stopped add another 20 mL of solvent. (1) Test Method D2462 is not applicable to material known

Connect the extraction tube to the condenser, place the flask on to contain any steam distillable water-soluble matter. If it is

suspected that such matter is present, the method should be

the heater, and extract for 20 siphon cycles.Adjust the heat so

used with caution.

that the total time taken for 20 siphon cycles is 100 6 10 min.

9.5.2.2 Extract the first test specimen as described in Sec-

NOTE 4—The specified solvent, Ensolv, boils at 69 ° C at sea level.

tion 9, having determined the mass T of the test specimen

However, at higher elevations the boiling point is reduced and care must

before extraction (see 7.3.1), and the mass W of the oven-dried

be taken to ensure the specified rate of siphoning.

test specimen after extraction.

9.4 Following the twentieth cycle of siphoning, remove the

9.5.2.3 Rationale—Extractable matter, as calculated using

flask and the extraction tube from the heater. Pull the specimen

Eq 4, consists of non-volatile matter only. When the percent of

andfilterpaper(thimble)uptothemouthoftheextractiontube

true-moisture, X, is determined as directed in 9.5.2.1, the

and allow to drain until a state of dripping only is observed.

corresponding mass of moisture, U, can be calculated. When

Remove the specimen and filter paper (thimble) from the the weighed test specimen has been extracted and oven-dried,

extraction tube and treat as described in 9.6. its mass, W, is determined. But W is also equal to T, less the

moisture U, less the non-volatile extractables M, less the

9.5 Pour the solvent thus contained in the extraction tube

volatile extractables N (Eq 7), from the available experimental

into the flask. Reconnect the flask, extraction tube, and

data (T, U, M, and W), the mass of the volatile extractable

condenser and place back the flask on the heater to slowly boil

matter Ncanbecalculated(Eq8)andsubsequently,thepercent

off the solvent (for recovery if desired) into the extraction tube

volatile matter Y, can be obtained (Eq 9).

until the flask contains about 20 to 30 mL of solvent. Remove

9.6 Air-dry the extracted specimen, then place the specimen

the flask from the assemblage and slowly evaporate the

in a suitable container and dry in an oven at 105 6 3°C to

solvent, in the flask, below the boiling point (care should be

constant mass, defined as the absence of any progressive

taken to avoid any loss of solvent and extractable matter by

decrease in mass in excess of 0.10 % of the average, as

overheating and sputtering); then dry to constant mass, by

determined by three successive weighings using the procedure

placing the flask in an oven at 105 6 3°C. Cool in a desiccator

in either 9.6.1 or 9.6.2 to obtain the oven-dry mass of the

and weigh to the nearest 1 mg.

specimen.

9.5.1 Certain oils and finishing agents may contain volatile

9.6.1 If the weighings of the dried specimen are to be

components that may be lost during evaporation of the solvent

obtained with the specimen inside the oven, perform the

and oven-drying. If the identification of the oil or finishing

weighings with any forced-air circulation turned off. Continue

agent is known, a weighed specimen of the material may be

readings of mass until the conditions specified in 9.6 are

dissolved in a fresh portion of the solvent, the solvent then

achieved.

being evaporated as described in 9.5, and the residue weighed

9.6.2 If the weighings of the dried specimen are to be

to determine the volatility of the oil. A correction factor

obtained outside the oven, dry the specimen in a container

specific for the known oil may be calculated using Eq 1 and 2

provided with a tight-fitting cover with this cover removed

and subsequently using the correction factor to determine the

while in the oven. At the end of the drying period, cover the

mass of oven-dried matter corrected for the loss of volatile

container and remove it from the oven. Place the covered

material for use in 10.1, Eq 5:

container in a desiccator, loosen the cover, and cool the

specimen and container to approximately room temperature.

M 5 S 2 V (1)

When cooling is completed, set the cover firmly on the

F 5 S/~S 2 V! 5 S/M (2)

container and weigh the container, cover, and specimen.

C 5 MF (3)

Replace the container and specimen in the oven, remove the

cover, and dry. Repeat the cooling and weighing procedures.

where:

Continuethisprocedureuntiltheconditionsspecifiedin9.6are

M = mass of oven-dried extracted matter,

achieved.

V = mass of original material volatilized,

S = mass of original material dissolved in solvent,

NOTE 5—If matter insoluble in Ensolv is to be d

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D1574–87(Reapproved1995) Designation:D1574–04 (Reapproved 2008)

Standard Test Method for

Extractable Matter in Wool and Other Animal Fibers

This standard is issued under the fixed designation D 1574; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thistestmethodcoversthedeterminationoftheamountofextractablematterinsamplesofallformsofwool,exceptgrease

wool, that is extractable with trichlorotrifluoroethane (CCl -FCClF ). a non-flammable vapor degreasing and cleaning solvent.

2 2

1.2 This test method does not cover the determination of the amounts of different components in the extracted matter nor their

identification.

1.3 This test method is suitable for use with other animal fibers.

NOTE 1—The determination of extractable matter in yarns and in felts is covered in Test Methods D 2257 and D 461. For the determination of

alcohol-extractable matter in oven-dry scoured wool, refer to Test Methods D 584 and D 1334.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations

prior to use. See 5.4 and Note 3.

2. Referenced Documents

2.1 ASTM Standards:

D 123 Terminology Relating to Textiles

D 461 Test Methods for Felt

D 584 Test Method for Wool Content of Raw Wool—Laboratory Scale

D 1334 Test Method for Wool Content of Raw Wool—Commercial Scale

D 1576 Test Method for Moisture in Wool by Oven-Drying

D 2257 Test Method for Extractable Matter in Textiles

D 2462Test Method for Moisture inWool by Distillation withToluene Test Method for Moisture inWool by DistillationWith

Toluene

D 4845 Terminology Relating to Wool

3. Terminology

3.1 Definitions:

3.1.1animal fiber, n—any natural protein-base fiber.

3.1.1.1Discussion—As used in this standard, “animal fiber” refers in particular to those fibers covered by the Wool Products

Labeling Act of 1939 and “recycled wool” as defined in the Act as amended in 1980. It also includes, but is not limited to, those

fibers listed in Table 1 of Terminology D123Definitions:

3.1.1 For definitions of textile terms used in this test method: animal fiber, extractable matter, grease wool, recycled wool, wool

and wool, refer to Terminology D 4845.

3.1.2extractable matter, n—nonfibrous material in or on a textile, not including water, which is removable by a specified solvent

or solvents as directed in a specified procedure.

3.1.2.1Discussion—Forthepurposesofthismethod,extractablematterdoesnotincludemoisturebut(1)isnon-fibrousmaterial,

(2) is usually oily, waxy, or resinous in nature, and (3) may include protein, particularly if the extracting solvent is ethyl alcohol

or contains ethyl alcohol.

3.1.3grease wool, n—wool taken from the living sheep and which has not been commercially scoured.

This test method is under the jursidiction of ASTM Committee D-13 on Textiles and is the direct responsibility of Subcommittee D13.13 on Wool and Wool Felt.

Current edition approved July 31, 1987. Published September 1987. Originally published as D1574–58T. Last previous edition D1574–87.

This test method is under the jursidiction of ASTM Committee Textiles and is the direct responsibility of Subcommittee Wool and Felt on D13.13 .

Current edition approved Aug. 1, 2008. Published September 2008. Originally approved in 1958. Last previous edition approved in 2004 as D 1574 – 04.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 07.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1574–04 (2008)

3.1.4recycled wool, n— as defined in the Wool Products Labeling Act as amended in 1980, “the resulting fiber when wool has

been woven or felted into a wool product which, without ever having been utilized in any way by the ultimate consumer,

subsequently has been made into a fibrous state, or the resulting fiber when wool or reprocessed wool has been spun, woven,

knitted, or felted into a wool product which, after having been used in any way by the ultimate consumer, subsequently has been

made into a fibrous state.”

3.1.4.1Discussion—In the amended Act of 1980, the term “recycled wool” replaced the terms “reprocessed wool” and “reused

wool.”

3.1.5wool, n—the fibrous covering of sheep, Ovis species.

3.1.5.1Discussion—For the purposes of this method, the word wool is used in the generic sense, and includes both wool as

defined in the Wool Products Labeling Act of 1939 as well as recycled wool as defined in the amended Act of 1980.

3.1.6wool, n—as defined in the Wool Products LabelingAct of 1939, “the fiber from the fleece of the sheep or lamb, or hair of

the Angora goat or Cashmere goat (and may include the so called specialty fibers from the hair of the camel, alpaca, llama, and

vicuna) which has never been reclaimed from any woven or felted wool product.”

3.1.7For definitions of other textile terms used in this test method, refer to Terminology D123

3.2 For definitions of other textile terms used in this test method, refer to Terminology D 123.

4. Summary of Test Method

4.1 The specimen is extracted in a Soxhlet apparatus with a specified halogenated hydrocarbon solvent. The extract is filtered,

thesolventisevaporated,andboththeresidueandtheextractedspecimenaredriedandweighed.Theamountofextractablematter

is calculated and reported as a percentage of the oven-dry mass of the wool specimen, that is, the mass of the oven-dried extracted

specimen plus the mass of the oven-dried extracted material.

4.2 Special procedures are provided to correct for errors in determining the amount of extractable matter as summarized in 4.1

if it is known or thought to contain volatile components.

5. Significance and Use

5.1 TestMethodD 1574isconsideredsatisfactoryforacceptancetestingsincethemethodhasbeenusedextensivelyinthetrade

for acceptance testing.

5.1.1 In case of a dispute arising from differences in reported test results when usingTest Method D 1574 for acceptance testing

of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias

between their laboratories. Competent statistical assistance is recommended for the investigation of bias.As a minimum, the two

parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type

in question. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average

results from the two laboratories should be compared using Student’s t-test for unpaired data and an acceptable probability level

chosenbythetwopartiesbeforethetestingisbegun.Ifabiasisfound,eitheritscausemustbefoundandcorrectedorthepurchaser

and the supplier must agree to interpret future test results in the light of the known bias.

5.2 This test method may be used to estimate the quantity of oil, grease, and waxy materials remaining on or in wool fibers after

scouring, or the quantity of lubricant added before carding or remaining after carding, or the quantity of such materials added or

removed in subsequent processing operations.

5.3 The residues obtained in this test may be subjected to chemical analysis for identification and assay of the component

materials, if desired.

5.4 The specified solvent in this test method does not remove some materials, such as soaps, that may be present in wool and

hence in some cases may reflect more closely the added content of some extractables in wool such as oils. When such materials

are present and an estimate of their quantity is desired, some other solvent or combination of solvents should be used as specified

in a material specification or by agreement. The information in the Annex of this test method may be useful for this purpose.

Various solvents have been used in the past, and are still used to some extent. Many of these solvents are undesirable, however,

because of flammability, toxic or anesthetic effects, or unpleasant odors. Trichlorotrifluoroethane is nonflammable, has a very low

leveloftoxicity,andahighdegreeofstabilityandisagoodsolventformostfattyormineraloils,greases,andwaxes.Thespecified

solvent, under conditions of the test, was found in interlaboratory test not to extract wool protein.

NOTE 2—Since the specified solvent is primarily a solvent for oils rather than soap, the extractable matter obtained in this procedure may be considered

a measure of commercial oil content.

NOTE 3—Due to the hazardous nature of some of the solvents listed in Table A1.1, the user should refer to the manufacturer’s recommendations for

use before using under the conditions of this test method.

6. Apparatus and Reagents

6.1 Soxhlet Extraction Apparatus , including an extraction tube, condenser, and flask. A large extraction tube having a

standard-taper joints T55/50 and 24/40 and a 300-mL flask are recommended, but any size capable of holding at least a 10-g

specimen is satisfactory.

6.2 Heater for Extraction Apparatus , preferably electric, thermostatically controlled, and of a design that avoids direct heating

of the flask above the lowest solution level.

D1574–04 (2008)

6.3 Drying Oven, ventilated either by natural convection or forced draft, thermostatically controlled and maintained at 105 6

3°C throughout the oven chamber.

6.4 Filter Paper, medium speed, retentive, in large sheets, 580 by 580 mm (23 by 23 in.), or in circles large enough to form

a thimble of a size to fit the apparatus, or as an alternative, a cellulose extraction thimble.

6.5 Weighing Containers, of perforated metal if weighing of the specimen is to be performed in the drying enclosure; or

containers that can be hermetically sealed (such as glass weighing bottles) if the specimen is to be cooled in a desiccator before

weighing in the ambient atmosphere.

6.6 Balance, having a capacity adequate for weighing specimens, flasks, and containers and having a sensitivity of 0.001 g.

6.7 Solvent— Extraction grade trichlorotrifluoroethane— Ensolv. (CCl FCClF ).

2 2

7. Sampling

7.1 Lot Sample— As a lot sample for acceptance testing, unless otherwise agreed upon between purchaser and supplier, take

at random the number of packages of wool from a lot as directed in Table 1. Consider packages of wool as the primary sampling

unit.

7.2 Laboratory Sample—Consider the package of wool in the lot sample as the laboratory sample.

7.3 Test Specimen—From each package in the laboratory sample take at random two specimens each weighing 10 61g.

7.3.1 If the determination of volatile matter in extractables, as described in 9.5.2, is to be undertaken, weigh the test specimen

to the nearest 0.001 g and record this mass as T. This specimen is for extraction.

7.3.2 For each test specimen taken for extraction, take a second test specimen for moisture determination, weighing between

50 and 70 g. Weigh to the nearest 0.05 g the same time the extraction test specimen is weighed so that the moisture content of

the two specimens at the time of weighing will be identical.

8. Conditioning

8.1 Neither preconditioning nor conditioning is necessary.

9. Procedure

9.1 Wrap the specimen in a single sheet of fresh filter paper (or place in an extraction thimble free of matter extractable by the

specified solvent) and insert the assemblage in the extraction tube. Make certain that all open edges of the filter paper or thimble

extend above the siphon tube.

9.2 Attach to the extraction tube a 300-mL flask that has previously been dried at 105 6 3°C, cooled in a desiccator, and

weighed to the nearest 1 mg.

9.3 Slowly pour sufficient solvent over the specimen to start the siphoning action. (If a thimble is used to hold the specimen,

pour the solvent onto the specimen within the thimble). When the siphoning has stopped add another 20 mL of solvent. Connect

the extraction tube to the condenser, place the flask on the heater, and extract for 20 siphon cycles.Adjust the heat so that the total

time taken for 20 siphon cycles is 100 6 10 min.

NOTE 4—The specified solvent, trichlorotrifluoroethane,Ensolv, boils at 47.2°C69 ° C at sea level. However, at higher elevations the boiling point is

reduced and care must be taken to ensure the specified rate of siphoning.

9.4 Following the twentieth cycle of siphoning, remove the flask and the extraction tube from the heater. Pull the specimen and

filter paper (thimble) up to the mouth of the extraction tube and allow to drain until a state of dripping only is observed. Remove

the specimen and filter paper (thimble) from the extraction tube and treat as described in 9.6.

9.5 Pour the solvent thus contained in the extraction tube into the flask. Reconnect the flask, extraction tube, and condenser and

place back the flask on the heater to slowly boil off the solvent (for recovery if desired) into the extraction tube until the flask

contains about 20 to 30 mLof solvent. Remove the flask from the assemblage and slowly evaporate the solvent, in the flask, below

Whatman Filter Paper No. 2, or its equivalent, has been found satisfactory for this test method.

This solvent is available from various suppliers under various trade names. DuPont offers it as Freon TF andAllied Chemical Corp. offers it as Genesol D. In both these

solvents, nonvolatile residue is claimed to be less than 2 ppm.

This solvent is available from Enviro Tech International Inc., West LeMoyne, Melrose Park, IL 60160 (www.ensolv.com).

TABLE 1 Sampling Schedule for Wool in Package

Number of Packages Number of Packages

in Lot in Lot Sample

1to3 all

4to24 4

25 to 50 5

more than 50 10% of the packages

with a maximum

of 8

D1574–04 (2008)

the boiling point (care should be taken to avoid any loss of solvent and extractable matter by overheating and sputtering); then dry

to constant mass, by placing the flask in an oven at 105 6 3°C. Cool in a desicca

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.