ASTM A861-04(2017)

(Specification)Standard Specification for High-Silicon Iron Pipe and Fittings

Standard Specification for High-Silicon Iron Pipe and Fittings

ABSTRACT

This specification covers high-silicon iron pipe and pipe fittings intended for corrosion-resistant service for both above- and below-grade construction. The castings shall be true to pattern, reasonable smooth, and free from defects that would make the castings unfit for the use for which they are intended. The material shall conform to the chemical composition requirements specified. All centrifugally cast high-silicon iron pipe shall be supplied in the as-cast condition. All other pipe and fittings shall be supplied in the stress-relieved condition; the stress relieving procedures are presented. Acid-proof joints for hub/plain-end pipe shall require the use of an acid-proof rope packing. No-hub pipe and fittings shall require a special acid resistant mechanical joint coupling. High-silicon iron pipe can be cut with either manual or hydraulic snap cutters. Hydrostatic testing shall be conducted on all castings.

SCOPE

1.1 This specification covers high-silicon iron pipe and pipe fittings intended for corrosion-resistant service for both above- and below-grade construction.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 Pipe and pipe fittings shall be the no-hub (MJ) or the hub and plain end design.

1.4 Pipe and pipe fittings shall be of the sizes specified in Table 1 and Table 2 and Figs. 1-71 or other sizes that shall be permitted to conform to the requirements given herein.

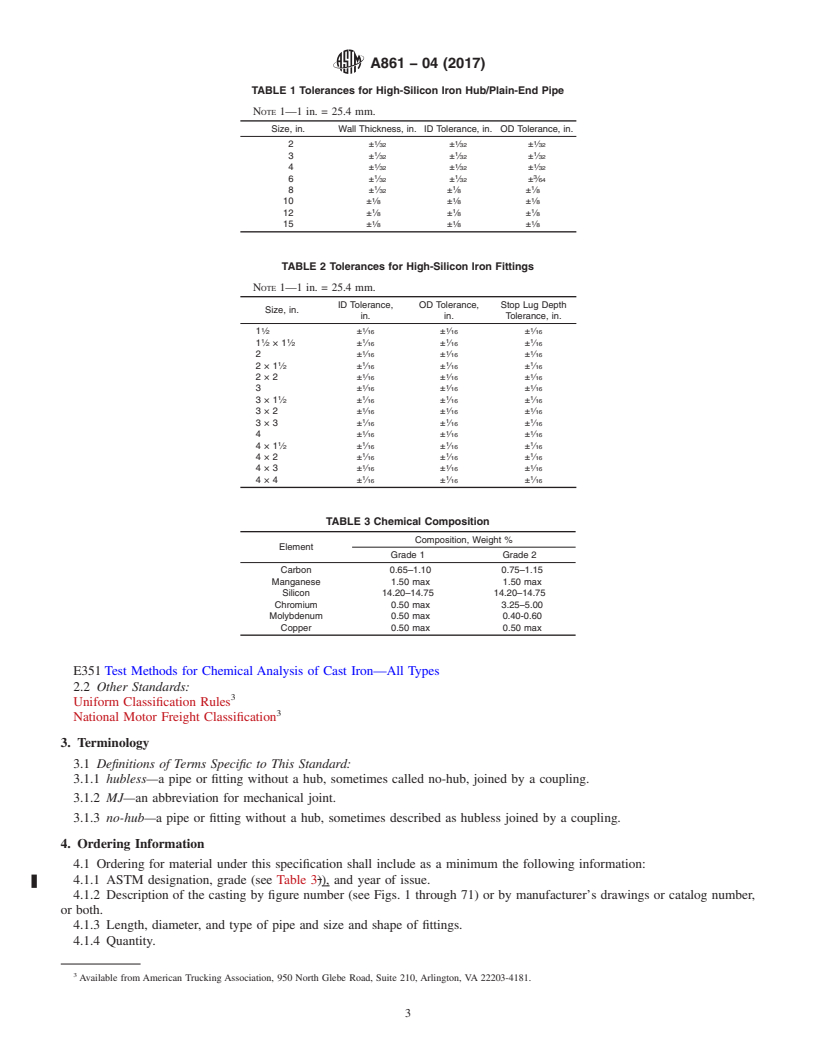

TABLE 1 Tolerances for High-Silicon Iron Hub/Plain-End Pipe

Note 1: 1 in. = 25.4 mm.

Size, in.

Wall Thickness, in.

ID Tolerance, in.

OD Tolerance, in.

2

±1/32

±1/32

±1/32

3

±1/32

±1/32

±1/32

4

±1/32

±1/32

±1/32

6

±1/32

±1/32

±3/64

8

±1/32

±1/8

±1/8

10

±1/8

±1/8

±1/8

12

±1/8

±1/8

±1/8

15

±1/8

±1/8

±1/8

TABLE 2 Tolerances for High-Silicon Iron Fittings

Note 1: 1 in. = 25.4 mm.

Size, in.

ID Tolerance,

in.

OD Tolerance,

in.

Stop Lug Depth

Tolerance, in.

11/2

±1/16

±1/16

±1/16

11/2 × 11/2

±1/16

±1/16

±1/16

2

±1/16

±1/16

±1/16

2 × 11/2

±1/16

±1/16

±1/16

2 × 2

±1/16

±1/16

±1/16

3

±1/16

±1/16

±1/16

3 × 11/2

±1/16

±1/16

±1/16

3 × 2

±1/16

±1/16

±1/16

3 × 3

±1/16

±1/16

±1/16

4

±1/16

±1/16

±1/16

4 × 11/2

±1/16

±1/16

±1/16

4 × 2

±1/16

±1/16

±1/16

4 × 3

±1/16

±1/16

±1/16

4 × 4

±1/16

±1/16

±1/16

TABLE 3 Chemical Composition

Element

Composition, Weight %

Grade 1

Grade 2

Carbon

0.65–1.10

0.75–1.15

Manganese

1.50 max

1.50 max

Silicon

14.20–14.75

14.20–14.75

Chromium

0.50 max

3.25–5.00

Molybdenum

0.50 max

0.40-0.60

Copper

0.50 max

0.50 max

FIG. 1 No-Hub Pipe (MJ)

Size, in.

J, in.

F, in.

t, in.

11/2

23/16 (2.19)

84

5/16

2

211/16 (2.69)

84

5/16

3

349/64 (3.77)

84

5/16

4

449/64 (4.77)

84

5/16

Note 1: 1 in. = 25.4 mm.

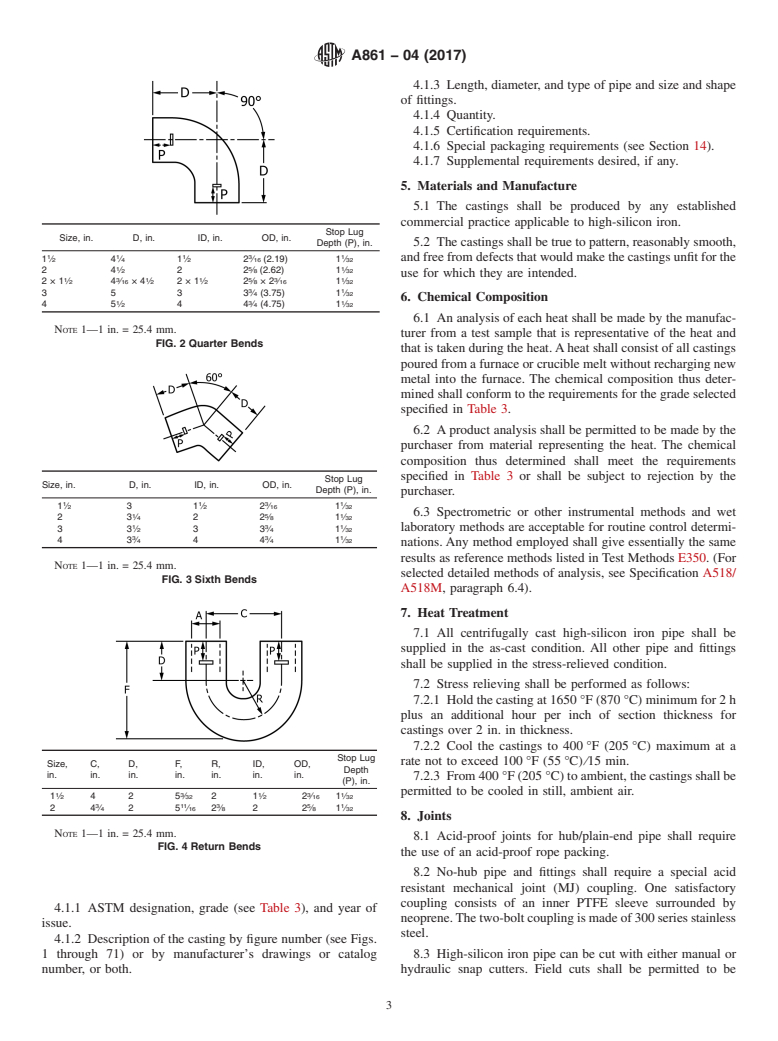

FIG. 2 Quarter Bends

Size, in.

D, in.

ID, in.

OD, in.

Stop Lug

Depth (P), in.

11/2

41/4

11/2

23/16 (2.19)

11/32

2

41/2

2

25/8 (2.62)

11/32

2 × 11/2

43/16 × 41/2

2 × 11/2

25/8 × 23/16

11/32

3

5

3

33/4 (3.75)

11/32

4

51/2

4

43/4 (4.75)

11/32

Note 1: 1 in. = 25.4 mm.

FIG. 3 Sixth Bends

Size, in.

D, in.

ID, in.

OD, in.

Stop Lug

Depth (P), in.

11/2

3

11/2

23/16

11/32

2

...

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A861 − 04 (Reapproved 2017)

Standard Specification for

1

High-Silicon Iron Pipe and Fittings

This standard is issued under the fixed designation A861; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

Figs.

Quarter Bends 2

1.1 This specification covers high-silicon iron pipe and pipe

Sixth Bends 3

fittings intended for corrosion-resistant service for both above- Return Bends 4

Double-Branch Quarter Bend 5

and below-grade construction.

Eighth Bends 6

Sixteenth Bends 7

1.2 The values stated in inch-pound units are to be regarded

Long-Sweep Quarter Bends 8

as standard. The values given in parentheses are mathematical

Sanitary Y Branches 9

conversions to SI units that are provided for information only

Double-Branch Sanitary Y 10

1

Sanitary Combination Y and ⁄8 Bend 11

and are not considered standard.

1

Double-Branch Sanitary Combination Y and ⁄8 Bend 12

1.3 Pipe and pipe fittings shall be the no-hub (MJ) or the Sanitary T Branches 13

Double Branch Sanitary T 14

hub and plain end design.

Sanitary Running Traps 15

Sanitary P Traps 16

1.4 Pipe and pipe fittings shall be of the sizes specified in

Swivel Trap P-Style, Short 17

Table 1 and Table 2 and Figs. 1-71 or other sizes that shall be

Swivel Trap P-Style, Long 18

permitted to conform to the requirements given herein.

Swivel Trap S-Style, Long 19

Centrifugal Drum Trap P Swivel Type 20

1.4.1 Pipe:

Centrifugal Drum Trap S Swivel Type 21

1.4.1.1 No-Hub (MJ) (Fig. 1):

Combination Cleanout and Test Tees 22

Coupling 23

Size (in.) Length (ft)

1

Pipe Plugs 24

1 ⁄2 7

Cleanout Plugs 25

2 7

3 7 No-Hub (MJ) Adapter 26

Reducers-Increasers 27

4 7

Sink Outlet 28

1.4.1.2 Hub/Plain End (Fig.35):

Sink Overflows 29

Threaded Adapters 30

Size (in.) Length (ft)

Trap Cleanout Details 31

2 7

No-Hub (MJ) Adapter 32

3 7

(MJ) (No-Hub) to Lead Adapter 33

4 7

Floor Drains 34

6 7

8 7

1.4.3 Fitting (Hub/Plain End):

10 5

Figs.

12 5

15 5 Hub Plain End Pipe 35

Straight Tees 36

1.4.2 Fitting (No-Hub) (MJ):

Sanitary T Branches 37

Sanitary Y Branches 38

Double-Branch Sanitary Tee 39

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron Double-Branch Sanitary Y 40

1

Double-Branch Sanitary Combination Y and ⁄8 Bend (T-Y) 41

Castings and is the direct responsibility of Subcommittee A04.12 on Pipes and

Short-Sweep Quarter Bends 42

Tubes.

Long-Sweep Quarter Bends 43

Current edition approved Oct. 1, 2017. Published October 2017. Originally

1

Sanitary Combination Y and ⁄8 Bend (T-Y) 44

approved in 1986. Last previous edition approved in 2013 as A861 – 04 (2013).

Quarter Bends 45

DOI: 10.1520/A0861-04R17.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A861 − 04 (2017)

TABLE 2 Tolerances for High-Silicon Iron Fittings

Sixth Bends 46

Eighth Bends 47

NOTE 1—1 in. = 25.4 mm.

Sixteenth Bends 48

Sanitary Increasers 49 ID Tolerance, OD Tolerance, Stop Lug Depth

Size, in.

Hub Strainers 50 in. in. Tolerance, in.

Sanitary Reducers 51

1 1 1 1

1 ⁄2 ± ⁄16 ± ⁄16 ± ⁄16

Double Hubs 52

1 1 1 1 1

1 ⁄2 × 1 ⁄2 ± ⁄16 ± ⁄16 ± ⁄16

Pipe Plugs 53

1 1 1

2 ± ⁄16 ± ⁄16 ± ⁄16

Cleanout Plugs 54

1 1 1 1

2 × 1 ⁄2 ± ⁄16 ± ⁄16 ± ⁄16

Adapter – Plain end to Split Flange 55

1 1 1

2 × 2 ± ⁄16 ± ⁄16 ± ⁄16

Adapter – Hub to-Split Flange 56

1 1 1

3 ± ⁄16 ± ⁄16 ± ⁄16

Combination Cleanout and Test Tees 57

1 1 1 1

3 × 1 ⁄2 ± ⁄16 ± ⁄16 ± ⁄16

Insertable Joints 58

1 1 1

3 × 2 ± ⁄16 ± ⁄16 ± ⁄16

Backwater Valves 59

1 1 1

3 × 3 ± ⁄16 ± ⁄16 ± ⁄16

Sanitary P Traps 60

1 1 1

4 ± ⁄16 ± ⁄16 ± ⁄16

Sanitary S Traps 61

1 1 1 1

4 × 1 ⁄2 ± ⁄16 ± ⁄16 ± ⁄16

Sanitary Running Traps 62

1 1 1

4 × 2 ± ⁄16 ± ⁄16 ± ⁄16

Floor Drains 63, 64, 65

1 1 1

4 × 3 ± ⁄16 ± ⁄16 ± ⁄16

Floor Drains 66

1 1 1

4 × 4 ± ⁄16 ± ⁄16 ± ⁄16

Floor Drains/Installation – Funnel Attachment 67, 68

Overflow 69

Sink Outlet 70

Detailed Cross Section of Cleanout 71

TABLE 3 Chemical Composition

Chemical Composition Table 3

Composition, Weight %

Transverse Bend Test Minimum Requirements Table S1.1

Element

Grade 1 Grade 2

1.5 This international standard was developed in accor-

Carbon 0.65–1.10 0.75–1.15

dance with internationally recognized principles on standard-

Manganese 1.50 max 1.50 max

ization established in the Decision on Principles for the

Silicon 14.20–14.75 14.20–14.75

Chromium 0.50 max 3.25–5.00

Development of International Standards, Guides and Recom-

Molybdenum 0.50 max 0.40-0.60

mendations issued by the World Trade Organization Technical

Copper 0.50 max 0.50 max

Barriers to Trade (TBT) Committee.

2. Referenced Documen

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A861 − 04 (Reapproved 2013) A861 − 04 (Reapproved 2017)

Standard Specification for

1

High-Silicon Iron Pipe and Fittings

This standard is issued under the fixed designation A861; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers high-silicon iron pipe and pipe fittings intended for corrosion-resistant service for both above- and

below-grade construction.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 Pipe and pipe fittings shall be the no-hub (MJ) or the hub and plain end design.

1.4 Pipe and pipe fittings shall be of the sizes specified in Table 1 and Table 2 and Figs. 1-71 or other sizes that shall be permitted

to conform to the requirements given herein.

1.4.1 Pipe:

1.4.1.1 No-hubNo-Hub (MJ) (Fig. 1):

Size (in.) Length (ft)

1

1 ⁄2 7

2 7

3 7

4 7

1.4.1.2 Hub/Plain End (Fig.35):

Size (in.) Length (ft)

2 7

3 7

4 7

6 7

8 7

10 5

12 5

15 5

1.4.2 Fitting (No-hub)(No-Hub) (MJ):

Figs.

Quarter Bends 2

Sixth Bends 3

Return Bends 4

Double-Branch Quarter Bend 5

Eighth Bends 6

Sixteenth Bends 7

Long-Sweep Quarter Bends 8

Sanitary Y Branches 9

Double-Branch Sanitary Y 10

1

Sanitary Combination Y and ⁄8 Bend 11

1

Double-Branch Sanitary Combination Y and ⁄8 Bend 12

Sanitary T Branches 13

Double Branch Sanitary T 14

Sanitary Running Traps 15

Sanitary P Traps 16

Swivel Trap P-Style Short 17

Swivel Trap P-Style, Short 17

Swivel Trap P-Style Long 18

Swivel Trap P-Style, Long 18

Swivel Trap S-Style Long 19

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron Castings and is the direct responsibility of Subcommittee A04.12 on Pipes and Tubes.

Current edition approved May 1, 2013Oct. 1, 2017. Published July 2013October 2017. Originally approved in 1986. Last previous edition approved in 20082013 as

A861 – 04 (2008).(2013). DOI: 10.1520/A0861-04R13.10.1520/A0861-04R17.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A861 − 04 (2017)

Swivel Trap S-Style, Long 19

Centrifugal Drum Trap P Swivel Type 20

Centrifugal Drum Trap S Swivel Type 21

Combination Cleanout and Test Tees 22

Coupling 23

Pipe Plugs 24

Cleanout Plugs 25

No-hub (MJ) Adapter 26

No-Hub (MJ) Adapter 26

Reducers—Increasers 27

Reducers-Increasers 27

Sink Outlet 28

Sink Overflows 29

Threaded Adapters 30

Trap Cleanout Details 31

No-hub (MJ) Adapter 32

No-Hub (MJ) Adapter 32

(MJ) (No-hub) to Lead Adapter 33

(MJ) (No-Hub) to Lead Adapter 33

Floor Drains 34

1.4.3 Fitting (Hub/Plain End):

Figs.

Hub Plain End Pipe 35

Straight Tees 36

Sanitary T Branches 37

Sanitary Y Branches 38

Double-Branch Sanitary Tee 39

Double-Branch Sanitary Y 40

1

Double-Branch Sanitary Combination Y and ⁄8 Bend (T-Y) 41

Short-Sweep Quarter Bends 42

Long-Sweep Quarter Bends 43

1

Sanitary Combination Y and ⁄8 Bend (T-Y) 44

Quarter Bends 45

Sixth Bends 46

Eighth Bends 47

Sixteenth Bends 48

Sanitary Increasers 49

Hub Strainers 50

Sanitary Reducers 51

Double Hubs 52

Pipe Plugs 53

Cleanout Plugs 54

Adapter—Plain end to Split Flange 55

Adapter – Plain end to Split Flange 55

Adapter—Hub to-Split Flange 56

Adapter – Hub to-Split Flange 56

Combination Cleanout and Test Tees 57

Insertable Joints 58

Backwater Valves 59

Sanitary P Traps 60

Sanitary S Traps 61

Sanitary Running Traps 62

Floor Drains 63, 64, 65

Floor Drains 66

Floor Drains/Installation—Funnel Attachment 67, 68

Floor Drains/Installation – Funnel Attachment 67, 68

Overflow 69

Sink Outlet 70

Detailed Cross Section of Cleanout 71

Chemical Composition Table 3

Transverse Bend Test Minimum Requirements Table S1.1

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A518/A518M Specification for Corrosion-Resistant High-Silicon Iron Castings

E350 Test Methods for Chemical Analysis of Carbon Steel, Low-Alloy

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.