ASTM C1323-96(2001)

(Test Method)Standard Test Method for Ultimate Strength of Advanced Ceramics with Diametrally Compressed C-Ring Specimens at Ambient Temperature

Standard Test Method for Ultimate Strength of Advanced Ceramics with Diametrally Compressed C-Ring Specimens at Ambient Temperature

SCOPE

1.1 This test method covers the determination of ultimate strength under monotonic loading of advanced ceramics in tubular form at ambient temperatures. Note that ultimate strength as used in this test method refers to the strength obtained under monotonic compressive loading of C-ring specimens where monotonic refers to a continuous nonstop test rate with no reversals from test initiation to final fracture.

1.2 Values expressed in this test method are in accordance with the International System of Units (SI) and Practice E380.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: C 1323 – 96 (Reapproved 2001)

Standard Test Method for

Ultimate Strength of Advanced Ceramics with Diametrally

Compressed C-Ring Specimens at Ambient Temperature

This standard is issued under the fixed designation C 1323; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Fracture Origins in Advanced Structural Ceramics

MIL-STD-1942(A) Flexural Strength of High Performance

1.1 This test method covers the determination of ultimate

Ceramics at Ambient Temperature

strength under monotonic loading of advanced ceramics in

tubular form at ambient temperatures. Note that ultimate

3. Terminology

strength as used in this test method refers to the strength

3.1 Definitions:

obtained under monotonic compressive loading of C-ring

3.1.1 advancedceramic—anengineered,high-performance,

specimenswheremonotonicreferstoacontinuousnonstoptest

predominatelynonmetallic,inorganic,ceramicmaterialhaving

rate with no reversals from test initiation to final fracture.

specific functional qualities. (C 1145)

1.2 Values expressed in this test method are in accordance

3.1.2 breaking load—the load at which fracture occurs.

withtheInternationalSystemofUnits(SI)andPracticeE380.

(E 6)

1.3 This standard does not purport to address all of the

3.1.3 C-ring—circular test specimen geometry with the

safety concerns, if any, associated with its use. It is the

mid-section (slot) removed to allow bending displacement

responsibility of the user of this standard to establish appro-

(compression or tension). (E 6)

priate safety and health practices and determine the applica-

3.1.4 flexural strength—a measure of the ultimate strength

bility of regulatory limitations prior to use.

of a specified beam in bending.

2. Referenced Documents 3.1.5 modulus of elasticity—the ratio of stress to corre-

sponding strain below the proportional limit. (E 6)

2.1 ASTM Standards:

3.1.6 slow crack growth—subcritical crack growth (exten-

C1145 Terminology on Advanced Ceramics

sion) which may result from, but is not restricted to, such

C1161 Test Method for Flexural Strength of Advanced

mechanisms as environmentally assisted stress corrosion or

Ceramics at Ambient Temperature

diffusive crack growth.

C1239 Practice for Reporting Uniaxial Strength Data and

Estimating Weibull Distribution Parameters for Advanced

4. Significance and Use

Ceramics

4.1 Thistestmethodmaybeusedformaterialdevelopment,

E4 Practices for Force Verification of Testing Machines

material comparison, quality assurance, and characterization.

E6 Terminology Relating to Methods of Mechanical Test-

Extremecareshouldbeexercisedwhengeneratingdesigndata.

ing

4.2 For a C-ring under diametral compression, the maxi-

E337 TestMethodforMeasuredHumiditywithPsychrom-

mum tensile stress occurs at the outer surface. Hence, the

eter (Measurement of Wet- and Dry-Bulb Temperatures)

C-ring specimen loaded in compression will predominately

E380 PracticeforUseofInternationalSystemofUnits(SI)

evaluate the strength distribution and flaw population(s) on the

(the Modernized Metric System)

3 external surface of a tubular component. Accordingly, the

2.2 Military Standards:

condition of the inner surface may be of lesser consequence in

MIL-HDBK-790 Fractography and Characterization of

specimen preparation and testing.

NOTE 1—AC-ring in tension or an O-ring in compression may be used

to evaluate the internal surface.

This test method is under the jurisdiction of ASTM Committee C28 on

Advanced Ceramics and is the direct responsibility of Subcommittee C28.04.08 on

4.3 The flexure stress is computed based on simple curved-

Thermal Systems.

beamtheory(1) withassumptionsthatthematerialisisotropic

Current edition approved Jan. 10, 1996. Published April 1996.

and homogeneous, the moduli of elasticity are identical in

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700 The boldface numbers in parentheses refer to a list of references at the end of

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C 1323 – 96 (2001)

compression or tension, and the material is linearly elastic; all chiningdamageintroducedduringspecimenpreparationcanbe

homogeneityandisotropyassumptionsprecludetheuseofthis either a random interfering factor in the determination of the

standard for continuous fiber reinforced composites. Average maximuminertstrength(strengthpotential)ofpristinematerial

grain size(s) shall be no greater than one fiftieth ( ⁄50)ofthe (that is, increase frequency of surface or edge initiated frac-

C-ring thickness. tures compared to volume initiated fractures), or an inherent

4.4 Because advanced ceramics exhibiting brittle behavior part of the strength characteristics being measured. Universal

generallyfracturecatastrophicallyfromasingledominantflaw or standardized methods of surface/sample preparation do not

for a particular tensile stress field, the surface area and volume exist. Hence, it shall be understood that final machining steps

ofmaterialsubjectedtotensilestressesisasignificantfactorin may or may not negate machining damage introduced during

determining the ultimate strength. Moreover, because of the the initial machining. Thus, specimen fabrication history may

statistical distribution of the flaw population(s) in advanced play an important role in the measured strength distributions

ceramics exhibiting brittle behavior, a sufficient number of and shall be reported.

specimens at each testing condition is required for statistical

analysis and design. This test method provides guidelines for 6. Apparatus

the number of specimens that should be tested for these

6.1 Loading—Specimens shall be loaded in any suitable

purposes (see 8.4).

testing machine provided that uniform rates of direct loading

4.5 Because of a multitude of factors related to materials

can be maintained. The system used to monitor the loading

processing and component fabrication, the results of C-ring

shall be free from any initial lags and will have the capacity to

testsfromaparticularmaterialorselectedportionsofapart,or

record the maximum load applied to the C-ring specimen

both, may not necessarily represent the strength and deforma-

duringthetest.Testingmachineaccuracyshallbewithin1.0%

tion properties of the full-size end product or its in-service

in accordance with PracticesE4.

behavior.

6.1.1 This test method permits the use of either fixed

4.6 The ultimate strength of a ceramic material may be

loading rams or, when necessary (see 9.3), a self-adjusting

influenced by slow crack growth or corrosion, or both, and is

fixture such as a universal joint or spherically seated platen

therefore, sensitive to the testing mode, testing rate, or envi-

may be used in conjunction with the upper loading ram.When

ronmental influences, or a combination thereof. Testing at

fixed loading rams are used, they shall be aligned so that the

sufficiently rapid rates as outlined in this test method may

platensurfaceswhichcomeintocontactwiththespecimensare

minimize the consequences of subcritical (slow) crack growth

parallel to within 0.015 mm. Alignment of the testing system

or stress corrosion.

must be verified at a minimum at the beginning and at the end

4.7 The flexural behavior and strength of an advanced

of a test series. An additional verification of alignment is

monolithic ceramic are dependent on the material’s inherent

recommended, although not required, at the middle of the test

resistance to fracture, the presence of flaws, or damage

series.

accumulation processes, or a combination thereof.Analysis of

NOTE 2—Atestseriesisinterpretedtomeanadiscretegroupoftestson

fracturesurfacesandfractography,thoughbeyondthescopeof

individual specimens conducted within a discrete period of time on a

thistestmethod,ishighlyrecommended(furtherguidancemay

particular material configuration, test specimen geometry, test conditions,

be obtained from MIL HDBK-790 and Ref (2)).

or other uniquely definable qualifier (for example, a test series composed

of Material A comprising ten specimens of Geometry B tested at a fixed

5. Interferences

rate in strain control to final fracture in ambient air).

5.1 Test environment (vacuum, inert gas, ambient air, etc.)

6.1.2 Materialssuchasfoilorthinrubbersheetshallbeused

including moisture content (that is, relative humidity) may

between the loading rams and the specimen for ambient

have an influence on the measured ultimate strength. In

temperature tests to reduce the effects of friction and to

particular, the behavior of materials susceptible to slow crack-

redistribute the load. Aluminum oxide (alumina) felt or other

growthfracturewillbestronglyinfluencedbytestenvironment

high-temperature “cloth” with a high-temperature capability

andtestingrate.Testingtoevaluatethemaximuminertstrength

may also be used. The use of a material with a high-

(strength potential) of a material shall therefore be conducted

temperature capability is recommended to ensure consistency

in inert environments or at sufficiently rapid testing rates, or

with elevated temperature tests (if planned), provided the

both, so as to minimize slow crack-growth effects. Conversely,

high-temperature “cloth” is chemically compatible with the

testing can be conducted in environments and testing modes

specimen at all testing temperatures.

and rates representative of service conditions to evaluate

6.2 The fixture used during the tests shall be stiffer than the

material performance under use conditions. When testing in

uncontrolled ambient air for the purpose of evaluating maxi- specimen to ensure that a majority of the crosshead travel (at

least 80%) is imposed on the C-ring specimen.

mum inert strength (strength potential), relative humidity and

temperature must be monitored and reported. Testing at hu- 6.3 Data Acquisition—At the minimum, an autographic

midity levels >65% RH is not recommended and any devia- record of applied load shall be obtained. Either analog chart

tions from this recommendation must be reported. recorders or digital data acquisition systems can be used for

5.2 C-ring specimens are useful for the determination of this purpose. Ideally, an analog chart recorder or plotter shall

ultimate strength of tubular components in the as-received/as- beusedinconjunctionwithadigitaldataacquisitionsystemto

used condition without surface preparations that may distort provide an immediate record of the test as a supplement to the

the strength controlling flaw population(s). Nonetheless, ma- digital record. Recording devices shall be accurate to 0.1% of

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C 1323 – 96 (2001)

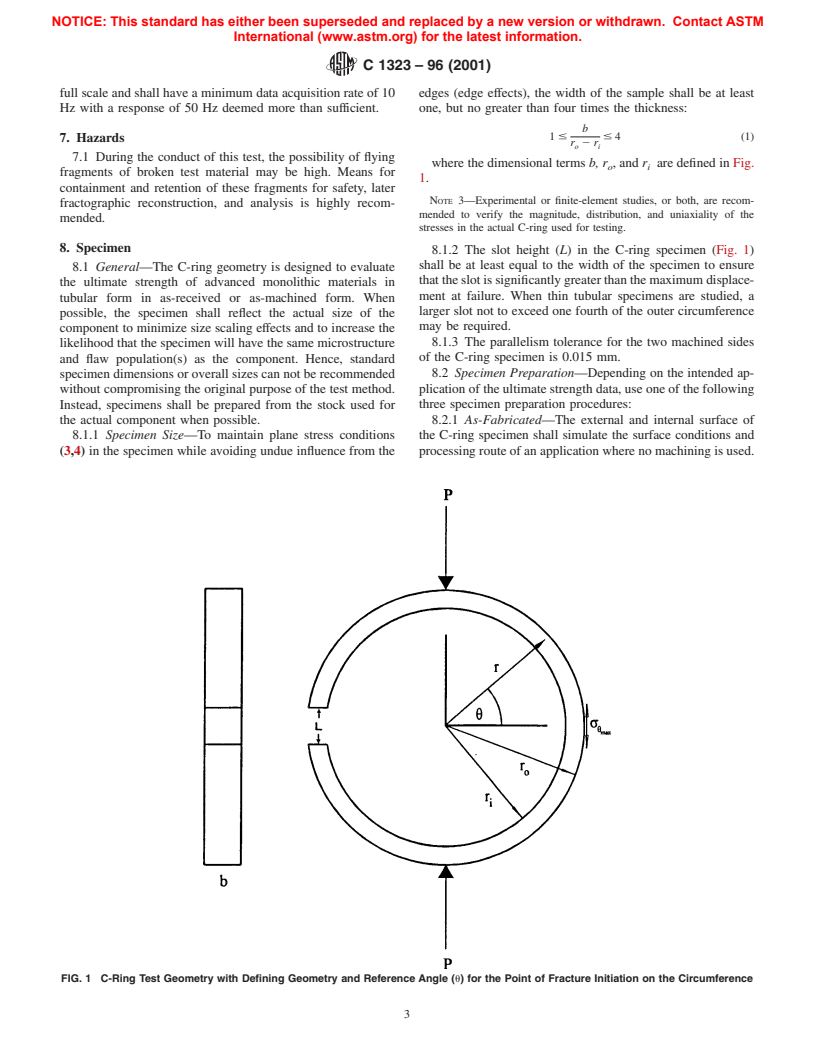

full scale and shall have a minimum data acquisition rate of 10 edges (edge effects), the width of the sample shall be at least

Hz with a response of 50 Hz deemed more than sufficient. one, but no greater than four times the thickness:

b

1# #4 (1)

7. Hazards

r 2 r

o i

7.1 During the conduct of this test, the possibility of flying

where the dimensional terms b, r , and r are defined in Fig.

o i

fragments of broken test material may be high. Means for

1.

containment and retention of these fragments for safety, later

NOTE 3—Experimental or finite-element studies, or both, are recom-

fractographic reconstruction, and analysis is highly recom-

mended to verify the magnitude, distribution, and uniaxiality of the

mended.

stresses in the actual C-ring used for testing.

8. Specimen

8.1.2 The slot height (L) in the C-ring specimen (Fig. 1)

shall be at least equal to the width of the specimen to ensure

8.1 General—The C-ring geometry is designed to evaluate

thattheslotissignificantlygreaterthanthemaximumdisplace-

the ultimate strength of advanced monolithic materials in

ment at failure. When thin tubular specimens are studied, a

tubular form in as-received or as-machined form. When

larger slot not to exceed one fourth of the outer circumference

possible, the specimen shall reflect the actual size of the

may be required.

component to minimize size scaling effects and to increase the

8.1.3 The parallelism tolerance for the two machined sides

likelihood that the specimen will have the same microstructure

of the C-ring specimen is 0.015 mm.

and flaw population(s) as the component. Hence, standard

specimendimensionsoroverallsizescannotberecommended 8.2 Specimen Preparation—Depending on the intended ap-

plicationoftheultimatestrengthdata,useoneofthefollowing

without compromising the original purpose of the test method.

three specimen preparation procedures:

Instead, specimens shall be prepared from the stock used for

the actual component when possible. 8.2.1 As-Fabricated—The external and internal surface of

8.1.1 Specimen Size—To maintain plane stress conditions the C-ring specimen shall simulate the surface conditions and

(3,4) in the specimen while avoiding undue influence from the processingrouteofanapplicationwherenomachiningisused.

FIG. 1 C-Ring Test Geometry with Defining Geometry and Reference Angle (u) for the Point of Fracture Initiation on the Circumference

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C 1323 – 96 (2001)

No additional machining specifications for these surfaces are formofthestrengthdistributionandWeibull(5)parametersare

relevant. Each side section shall be machined from the tubular desired within the confidence bounds established by Practice

stock and lap finished with 15 µm media to remove any large C1239.

machining defects.All edges shall then be either chamfered at

45° to a distance of 0.15 6 0.05 mm or rounded to a radius of

9. Procedure

0.15 6 0.05 mm to avoid edge dominated failures (“edge-

9.1 Specimen Dimensions—After machining the C-ring and

checking”).

slot, measure the outer diameter, inner diameter, wall thick-

ness, and wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.