ASTM D4047-00(2005)

(Test Method)Standard Test Method for Phosphorus in Lubricating Oils and Additives by Quinoline Phosphomolybdate Method

Standard Test Method for Phosphorus in Lubricating Oils and Additives by Quinoline Phosphomolybdate Method

SIGNIFICANCE AND USE

Knowledge of the phosphorus content, and thus the phosphorus-containing additives, in a lubricating oil or additive can be used to predict performance characteristics.

SCOPE

1.1 This test method covers the determination of 0.005 to 10.0 mass % phosphorus in unused lubricating oil and additive concentrates. There is no reason to doubt its applicability to filtered, used lubricating oils, but no systematic study of this application has been made.

1.2 The test method is applicable to samples containing any of the phosphorus compounds in normal use.

Note 1—This test method extends the scope of the previous version of IP 149 and replaces IP 148 and the previous version of IP 149 as a referee method.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 6.9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4047–00 (Reapproved 2005)

Designation: 149/93

Standard Test Method for

Phosphorus in Lubricating Oils and Additives by Quinoline

Phosphomolybdate Method

This standard is issued under the fixed designation D4047; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D6299 Practice for Applying Statistical Quality Assurance

and Control Charting Techniques to Evaluate Analytical

1.1 This test method covers the determination of 0.005 to

Measurement System Performance

10.0 mass % phosphorus in unused lubricating oil and additive

2.2 IP Standard:

concentrates. There is no reason to doubt its applicability to

IP 148 Test Method for Phosphorous in Lubricating Oils

filtered, used lubricating oils, but no systematic study of this

and Additives

application has been made.

1.2 The test method is applicable to samples containing any

3. Summary of Test Method

of the phosphorus compounds in normal use.

3.1 Additive concentrates are diluted with phosphorus-free

NOTE 1—This test method extends the scope of the previous version of

white oil to produce a working blend.

IP149 and replaces IP148 and the previous version of IP149 as a referee

3.2 Thesampleisignitedwithexcessofzincoxidewhereby

method.

phosphorus is converted to phosphate.The residue is dissolved

1.3 The values stated in SI units are to be regarded as the

in hydrochloric acid and any sulfide formed is oxidized with

standard.

potassium bromate. Phosphorus is then precipitated as quino-

1.4 This standard does not purport to address all of the

line phosphomolybdate and determined volumetrically by

safety concerns, if any, associated with its use. It is the

addition of excess standard alkali and back titration with

responsibility of the user of this standard to establish appro-

standard acid.

priate safety and health practices and determine the applica-

4. Significance and Use

bility of regulatory limitations prior to use. For specific hazard

statements, see 6.9.

4.1 Knowledge of the phosphorus content, and thus the

phosphorus-containing additives, in a lubricating oil or addi-

2. Referenced Documents

tive can be used to predict performance characteristics.

2.1 ASTM Standards:

5. Apparatus

D1193 Specification for Reagent Water

5.1 Silica Crucibles, 40-mm internal diameter at the top and

40 mm in height. The internal surface should be smooth and

free from pitting.

This test method is under the jurisdiction of ASTM Committee D02 on

5.2 Muffle Furnace,capableofmaintainingatemperatureof

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

approximately 700°C, and fitted with ports to allow air

Current edition approved May 1, 2005. Published May 2005. Originally

circulation.

approved in 1981. Last previous edition approved in 2000 as D4047 – 00. DOI:

5.3 Beakers, 25-mL capacity.

10.1520/D4047-00R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

the ASTM website. U.K.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4047–00 (2005)

6. Reagents and Materials

P = approximate percent phosphorus in the sample, and

A = grams of sample required for a 10-g blend.

6.1 Purity of Reagents—Reagent grade chemicals shall be

7.3 Calculate the mass of white oil for a 10-g blend as

used in all tests. Unless otherwise indicated, it is intended that

follows:

all reagents shall conform to the specifications of the Commit-

tee onAnalytical Reagents of theAmerican Chemical Society,

B 5 10 2 A (2)

where such specifications are available. Other grades may be

where:

used, provided it is first ascertained that the reagent is of

B = mass of white oil, g.

sufficiently high purity to permit its use without lessening the

7.4 Weigh a quantity of sample A 6 0.01 g into a 25-mL

accuracy of the determination.

beaker.

6.2 Purity of Water—Unless otherwise indicated, references

7.5 Weigh into the same beaker B g of white oil.

to water shall be understood to mean reagent water as defined

7.6 Mix the sample and white oil thoroughly by stirring and

by Type II or Type III of Specification D1193.

warming to approximately 50°C.

6.3 Hydrochloric Acid, approximately 1 N reagent solution.

6.4 Hydrochloric Acid (36 mass %)—Concentrated hydro-

8. Procedure

chloric acid (HCl).

8.1 For additive concentrates, weigh into a crucible1gof

6.5 Hydrochloride Acid, (0.1 N)—Hydrochloric acid (HCl)

the homogenized blend prepared in 7.6.

accurately standardized.

8.2 For lubricating oils, weigh into a crucible3gof sample

6.6 Mixed Indicator—Mix 2 volumes of phenolphthalein

or smaller amount estimated to contain not more than3gof

solution with 3 volumes of thymol blue solution.

phosphorus. The amount of sample to be taken is indicated in

6.7 Phenolphthalein Solution, (1 g/L in 95 % volume

Table 1.

ethanol).

8.3 Cover the sample with8gof zinc oxide and level the

6.8 Potassium Bromate (KBrO ), solid.

surface. Apply heat from a Meker burner to the surface until

6.9 Quinoline (Warning—Quinoline has a high toxic acute

the zinc oxide becomes red hot; then gently heat the crucible

systemic rating.)—Redistilled synthetic or, if this is unobtain-

from below with a small bunsen flame so that the oil burns off

able, quinoline freshly distilled from the technical product.

very gently. Finally, when no more vapor is evolved, ignite

Collect the colorless distillate in the boiling range from 232 to

strongly and transfer to a muffle furnace at 700°C to burn off

238°C. Store the quinoline in an amber bottle in the dark.

residual carbon.

6.10 QuinolineHydrochlorideSolution—Dissolve20mLof

8.4 Allow the crucible to cool and carefully transfer its

quinoline in 800 mL of hot water acidified with 25 mL of

contents to a 600-mL beaker (Note 3), completing the transfer

concentrated HCl; add a little paper pulp, cool, filter, and make

with a jet of water from a wash bottle. Add about 50 mL of

up to 1 Lwith water. This solution is stable for about 1 month.

water to the contents of the beaker and rinse the crucible with

6.11 Sodium Hydroxide Solution (0.1 M)—Sodium hydrox-

a few millilitres of concentrated HCl. Add the acid rinsing to

ide (NaOH) accurately standardized.

the beaker and then sufficient concentrated HCl to bring the

6.12 Sodium Molybdate Solution—Dissolve 10 g of sodium

total volume of acid added to 23 mL.

hydroxide (NaOH) and 18 g of ammonia-free molybdenum

8.5 Heat the contents of the beaker until all the ZnO is

trioxide in 200 mL of water and filter the solution.

dissolved,thenboiluntilallhydrogensulfidehasbeenexpelled

NOTE 2—To avoid high blanks caused by silicate interference with

from the solution (test with lead acetate paper). Allow to cool

alkalinereagents,includingsodiummolybdatesolution,storeinpolythene

slightly, add 30 to 50 mg of KBrO , and boil until all free

containers.

bromine has been expelled from the solution (test with fluo-

6.13 Thymol Blue Solution (1 g/L) in 95 % volume ethanol.

rescein paper).

6.14 Zinc Oxide (ZnO), finely divided.

NOTE 3—Glass apparatus should have good resistance to alkali. Do not

use scratched or etched beakers for the precipitation of quinoline

7. Blending Procedure

phosphomolybdate.

7.1 Samples having a phosphorus content greater than 0.3

8.6 Dilute the liquid to a volume of about 150 mL with

mass % should be blended in white oil to give a phosphorus

water, add 30 mL of concentrated HCl and 30 mL of sodium

content in the range of 0.1 to 0.3 mass %.

molybdate solution, rinsing the sides of the beaker with a little

7.2 Calculate the mass of sample for a 10-g blend as

follows:

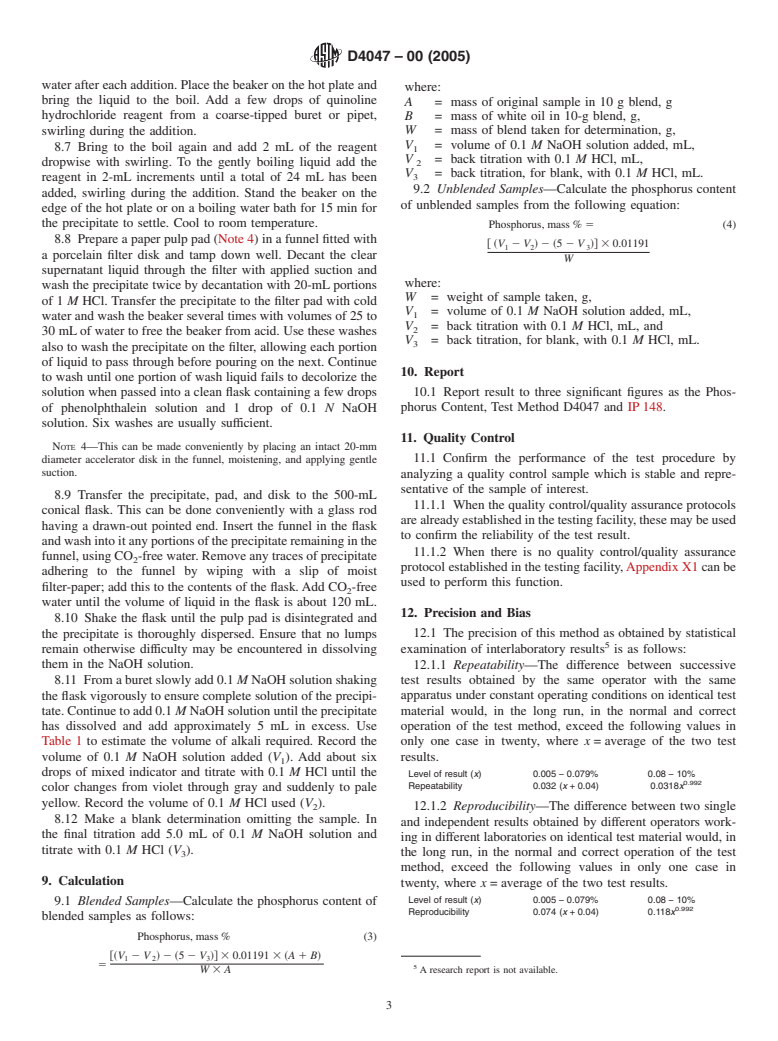

TABLE 1 Amount of Sample

A 5 2/P (1)

Approximate Volume

Phosphorus Content, Approximate Mass of 0.1 M NaOH

where:

mass % of Sample, g solution required

P%m mL

0.005 to 0.10 3 0.005 1.3

0.010 2.5

Reagent Chemicals, American Chemical Society Specifications, American

0.05 13

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

0.10 25

listed by the American Chemical Society, see Analar Standards for Laboratory

Above 0.10 to 0.30 0.10 8

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

0.20 17

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, 0.30 25

MD.

D4047–00 (2005)

water after each addition. Place the beaker on the hot plate and

where:

bring the liquid to the boil. Add a few drops of quinoline

A = mass of original sample i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.