ASTM C1373/C1373M-11

(Practice)Standard Practice for Determination of Thermal Resistance of Attic Insulation Systems Under Simulated Winter Conditions

Standard Practice for Determination of Thermal Resistance of Attic Insulation Systems Under Simulated Winter Conditions

SCOPE

1.1 This practice presents a laboratory procedure to determine the thermal resistance of attic insulation systems under simulated steady-state winter conditions. The practice applies only to attic insulation systems that face an open attic air space.

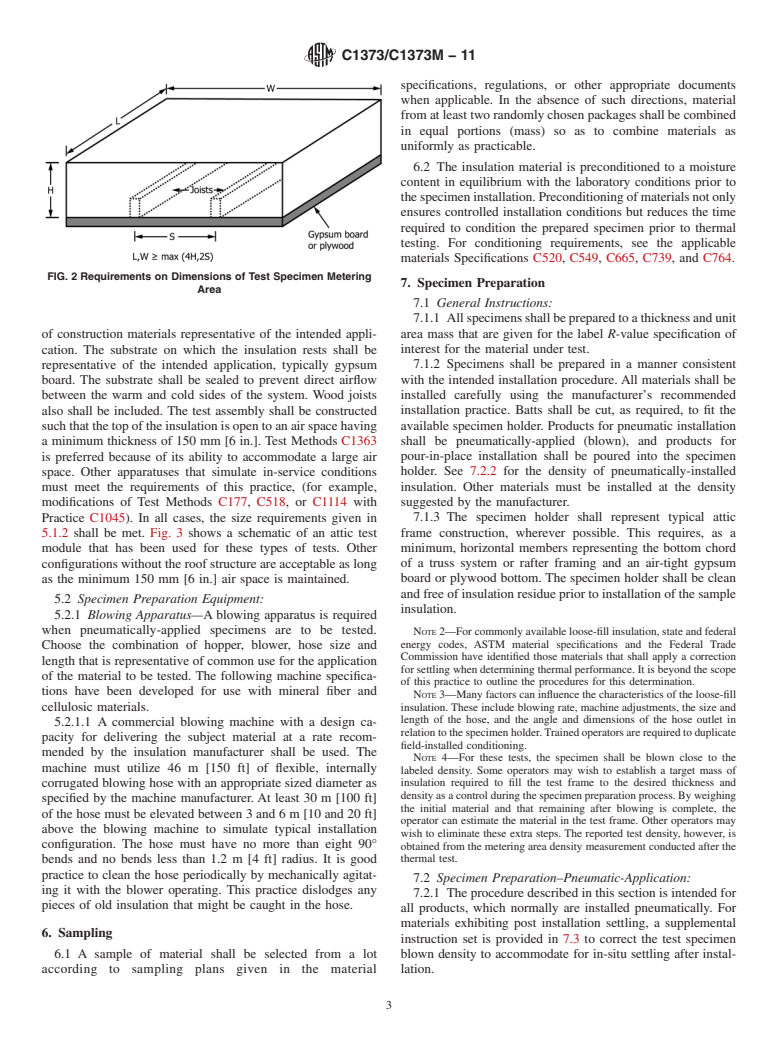

1.2 The thermal resistance of the insulation is inferred from calculations based on measurements on a ceiling system consisting of components consistent with the system being studied. For example, such a system might consist of a gypsum board or plywood ceiling, wood ceiling joists, and attic insulation with its top exposed to an open air space. The temperature applied to the gypsum board or plywood shall be in the range of 18 to 24°C (64 to 75°F). The air temperature above the insulation shall correspond to winter conditions and may range from -46°C to 10°C (-51 to 50°F). The gypsum board or plywood ceiling shall be sealed to prevent direct airflow between the warm and cold sides of the system.

1.3 This practice applies to a wide variety of loose-fill or blanket thermal insulation products including fibrous glass, rock/slag wool, or cellulosic fiber materials; granular types including vermiculite and perlite; pelletized products; and any other insulation material that may be installed pneumatically or poured in place. The practice considers the effects on heat transfer of structures, specifically the ceiling joists, substrate, for example, gypsum board, air films, and possible facings, films, or other materials that may be used in conjunction with the insulation.

1.4 This practice measures the thermal resistance of the attic/ceiling system in which the insulation material has been preconditioned according to the material Specifications C 549, C 665, C 739, and C 764.

1.5 The specimen preparation techniques outlined in this standard do not cover the characterization of loose-fill materials intended for enclosed applications.

1.6 This practice may be used to characterize material behavior under controlled steady-state laboratory conditions intended to simulate actual temperature conditions of use. The practice does not simulate forced air flow conditions.

1.7 All values shall be reported in both SI and inch-pound units unless specified otherwise by the client.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1373/C1373M − 11

Standard Practice for

Determination of Thermal Resistance of Attic Insulation

1

Systems Under Simulated Winter Conditions

This standard is issued under the fixed designation C1373/C1373M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This practice is be used to characterize material behav-

iorundercontrolledsteady-statelaboratoryconditionsintended

1.1 This practice presents a laboratory procedure to deter-

to simulate actual temperature conditions of use. The practice

mine the thermal resistance of attic insulation systems under

does not simulate forced air flow conditions.

simulated steady-state winter conditions. The practice applies

onlytoatticinsulationsystemsthatfaceanopenatticairspace. 1.7 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

1.2 The thermal resistance of the insulation is inferred from

each system may not be exact equivalents; therefore, each

calculations based on measurements on a ceiling system

system shall be used independently of the other. Combining

consisting of components consistent with the system being

values from the two systems may result in non-conformance

studied. For example, such a system might consist of a gypsum

with the standard.

board or plywood ceiling, wood ceiling joists, and attic

1.7.1 All values shall be reported in both SI and inch-pound

insulation with its top exposed to an open air space. The

units unless specified otherwise by the client.

temperature applied to the gypsum board or plywood shall be

1.8 This standard does not purport to address all of the

in the range of 18 to 24°C [64 to 75°F]. The air temperature

safety concerns, if any, associated with its use. It is the

above the insulation shall correspond to winter conditions and

responsibility of the user of this standard to establish appro-

ranges from –46°C to 10°C [–51 to 50°F]. The gypsum board

priate safety and health practices and determine the applica-

or plywood ceiling shall be sealed to prevent direct airflow

bility of regulatory limitations prior to use.

between the warm and cold sides of the system.

1.3 This practice applies to a wide variety of loose-fill or

2. Referenced Documents

blanket thermal insulation products including fibrous glass,

2

2.1 ASTM Standards:

rock/slag wool, or cellulosic fiber materials; granular types

C167 Test Methods for Thickness and Density of Blanket or

including vermiculite and perlite; pelletized products; and any

Batt Thermal Insulations

other insulation material that is installed pneumatically or

C168 Terminology Relating to Thermal Insulation

poured in place. The practice considers the effects on heat

C177 Test Method for Steady-State Heat Flux Measure-

transfer of structures, specifically the ceiling joists, substrate,

ments and Thermal Transmission Properties by Means of

for example, gypsum board, air films, and possible facings,

the Guarded-Hot-Plate Apparatus

films, or other materials that are used in conjunction with the

C518 Test Method for Steady-State Thermal Transmission

insulation.

Properties by Means of the Heat Flow Meter Apparatus

1.4 This practice measures the thermal resistance of the

C520 Test Methods for Density of Granular Loose Fill

attic/ceiling system in which the insulation material has been

Insulations

preconditioned according to the material Specifications C549,

C549 Specification for Perlite Loose Fill Insulation

C665, C739, and C764.

C665 Specification for Mineral-Fiber Blanket Thermal Insu-

lation for Light Frame Construction and Manufactured

1.5 The specimen preparation techniques outlined in this

Housing

standard do not cover the characterization of loose-fill materi-

C687 Practice for Determination of Thermal Resistance of

als intended for enclosed applications.

Loose-Fill Building Insulation

C739 Specification for Cellulosic Fiber Loose-Fill Thermal

Insulation

1

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

2

Measurement. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2011. Published December 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1998. Last previous edition approved in 2003 as C1373–03. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C1373_C1373M-11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocke

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1373–03 Designation:C1373/C1373M–11

Standard Practice for

Determination of Thermal Resistance of Attic Insulation

1

Systems Under Simulated Winter Conditions

This standard is issued under the fixed designation C1373/C1373M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice presents a laboratory procedure to determine the thermal resistance of attic insulation systems under simulated

steady-state winter conditions. The practice applies only to attic insulation systems that face an open attic air space.

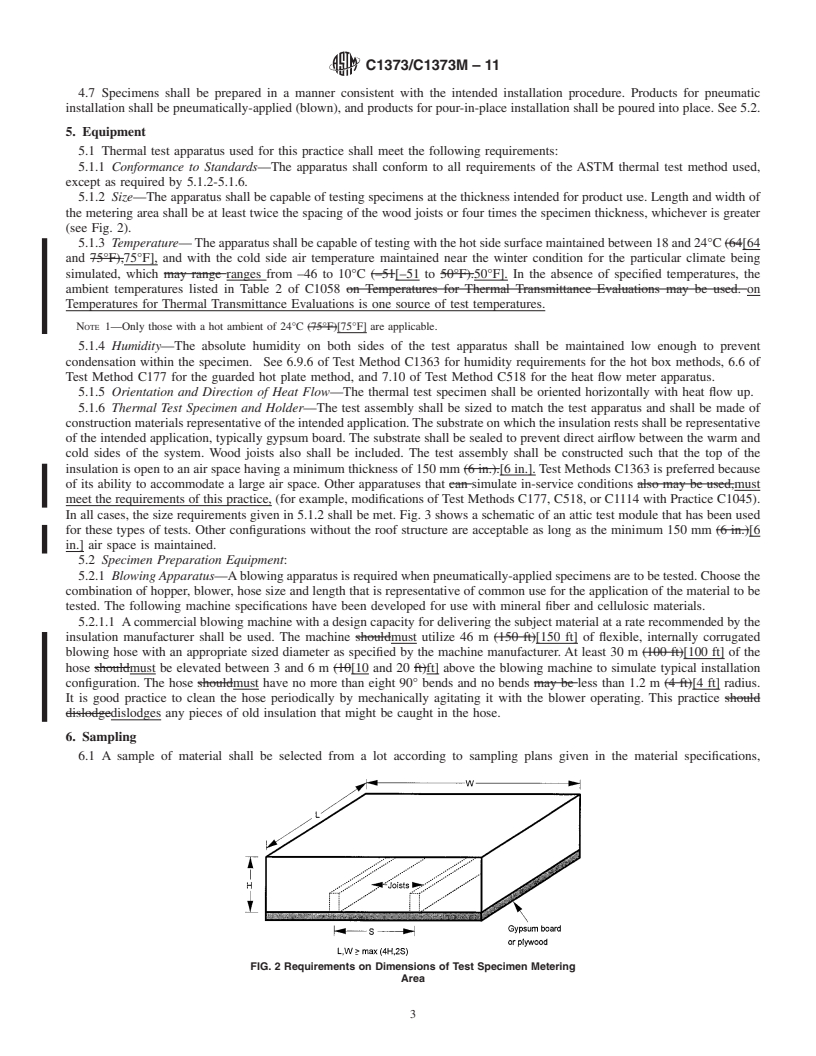

1.2 The thermal resistance of the insulation is inferred from calculations based on measurements on a ceiling system consisting

of components consistent with the system being studied. For example, such a system might consist of a gypsum board or plywood

ceiling, wood ceiling joists, and attic insulation with its top exposed to an open air space. The temperature applied to the gypsum

board or plywood shall be in the range of 18 to 24°C (64[64 to 75°F).75°F]. The air temperature above the insulation shall

correspond to winter conditions and may range ranges from –46°C to 10°C (–51[–51 to 50°F).50°F]. The gypsum board or

plywood ceiling shall be sealed to prevent direct airflow between the warm and cold sides of the system.

1.3 This practice applies to a wide variety of loose-fill or blanket thermal insulation products including fibrous glass, rock/slag

wool, or cellulosic fiber materials; granular types including vermiculite and perlite; pelletized products; and any other insulation

material that may be is installed pneumatically or poured in place. The practice considers the effects on heat transfer of structures,

specifically the ceiling joists, substrate, for example, gypsum board, air films, and possible facings, films, or other materials that

may beare used in conjunction with the insulation.

1.4 This practice measures the thermal resistance of the attic/ceiling system in which the insulation material has been

preconditioned according to the material Specifications C549, C665, C739, and C764.

1.5 The specimen preparation techniques outlined in this standard do not cover the characterization of loose-fill materials

intended for enclosed applications.

1.6This practice may be used to characterize material behavior under controlled steady-state laboratory conditions intended to

simulate actual temperature conditions of use. The practice does not simulate forced air flow conditions.

1.7All values shall be reported in both SI and inch-pound units unless specified otherwise by the client.

1.6 This practice is be used to characterize material behavior under controlled steady-state laboratory conditions intended to

simulate actual temperature conditions of use. The practice does not simulate forced air flow conditions.

1.7 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.7.1 All values shall be reported in both SI and inch-pound units unless specified otherwise by the client.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C167 Test Methods for Thickness and Density of Blanket or Batt Thermal Insulations

C168 Terminology Relating to Thermal Insulation

C177 Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the

Guarded-Hot-Plate Apparatus

1

This practice is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

Measurements.

Current edition approved April 10, 2003. Published May 2003. Originally approved in 1998. Last previous edition approved in 2001 as C1373–01. DOI:

10.1520/C1373-03.on Thermal Measurement.

Current edition approved Nov. 1, 2011. Published December 2011. Originally approved in 1998. Last previous edition approved in 2003 as C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.