ASTM A264-12(2019)

(Specification)Standard Specification for Stainless Chromium-Nickel Steel-Clad Plate

Standard Specification for Stainless Chromium-Nickel Steel-Clad Plate

ABSTRACT

This specification covers the requirements for plate of a carbon steel or low-alloy steel base to which is integrally and continuously bonded on one or both sides a layer of stainless chromium-nickel steel for pressure vessel. The steel shall be made by the open-heart, electric-furnace, or basic-oxygen processes and the alloy-cladding metal shall be metallurgically bonded to the base metal. The steel clad plate shall be heat treated. The steel specimens shall undergo tension test and shall conform to the required values of tensile strength and yield strength. The steel materials shall also undergo bend tests and shall conform to the required values of shear strength and bond strength. Product and chemical analyses shall also be performed on the steel specimens.

SCOPE

1.1 This specification2 covers plate of a carbon steel or low-alloy steel base to which is integrally and continuously bonded on one or both sides a layer of stainless chromium-nickel steel. The material is generally intended for pressure vessel use.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A264 −12 (Reapproved 2019)

Standard Specification for

Stainless Chromium-Nickel Steel-Clad Plate

This standard is issued under the fixed designation A264; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope A578/A578M Specification for Straight-Beam Ultrasonic

2 Examination of Rolled Steel Plates for Special Applica-

1.1 This specification covers plate of a carbon steel or

tions

low-alloy steel base to which is integrally and continuously

A751 Test Methods, Practices, and Terminology for Chemi-

bonded on one or both sides a layer of stainless chromium-

cal Analysis of Steel Products

nickel steel. The material is generally intended for pressure

vessel use. 2.2 Other Standards:

ASME Boiler and Pressure Vessel Code, Section IX

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

3. Terminology

conversions to SI units that are provided for information only

and are not considered standard.

3.1 Definitions of Terms Specific to This Standard:

3.1.1 This material is considered as single-clad or double-

1.3 This international standard was developed in accor-

clad corrosion-resisting chromium-nickel steel plate, depend-

dance with internationally recognized principles on standard-

ing on whether one or both sides are covered.

ization established in the Decision on Principles for the

3.1.2 alloy cladding, n—the stainless chromium-nickel steel

Development of International Standards, Guides and Recom-

component of the composite plate.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3.1.3 base metal (backing steel), n—component to which

the alloy cladding is applied, usually the greater percentage of

2. Referenced Documents

the composite plate and usually consisting of carbon or

2.1 ASTM Standards:

low-alloy steel.

A6/A6M Specification for General Requirements for Rolled

3.1.4 integrally and continuously bonded, n—the process by

Structural Steel Bars, Plates, Shapes, and Sheet Piling

whichthealloycladdingandbasemetalarebroughttogetherto

A20/A20M SpecificationforGeneralRequirementsforSteel

form a metallurgical bond at essentially the entire interface of

Plates for Pressure Vessels

the two metals by means other than those processes that do not

A240/A240M Specification for Chromium and Chromium-

produce a homogeneous composite plate.

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

Vessels and for General Applications

4. Ordering Information

A370 Test Methods and Definitions for Mechanical Testing

4.1 It is the responsibility of the purchaser to specify all

of Steel Products

requirements that are necessary for material ordered under this

A480/A480M Specification for General Requirements for

specification. Such requirements may include, but are not

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

limited to, the following:

Sheet, and Strip

4.1.1 Quantity (weight or number of pieces).

4.1.2 Cladding alloy specification, (UNS or ASTM Specifi-

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

cation A240/A240M and whether cladding is for corrosion

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.11 on Steel Plates for Boilers and Pressure Vessels. allowance only),

Current edition approved March 1, 2019. Published April 2019. Originally

4.1.3 Base metal specification.

approved in 1943. Last previous edition approved in 2012 as A264 – 12. DOI:

4.1.4 Bond integrity Class (1, 3, or 5).

10.1520/A0264-12R19.

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

cation SA-264 in Section II of that Code.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

the ASTM website. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A264 − 12 (2019)

4.1.5 Dimensions including the minimum or nominal thick- case of clad plate manufactured without hot rolling, the base

ness of the cladding alloy, and the backing steel, or of the total metal and alloy cladding components may be heat treated

composite plate and if more or less restrictive thickness separately as appropriate prior to bonding.

tolerances apply. 5.2.2 Duplex stainless steel clad plates shall be provided in

4.1.6 Product analysis, if required (see Section 10). Specify

a heat treated condition as agreed upon between the purchaser

whether applicable to the cladding alloy, backing steel or both. and the manufacturer.

4.1.7 Mechanicalproperties,includingsheartestifrequired.

5.2.3 When plates are to be cold formed, or when otherwise

4.1.8 Finish (see Section 12). required by the base metal specification, the purchaser may

4.1.9 Restrictions, if required, on repair by welding (see

specify that such plates, following solution annealing, be heat

Section 14). treated for grain refinement of the base metal by normalizing

4.1.10 Additionstothespecificationorspecialrequirements

and either air cooled or water quenched as appropriate.

such as any applicable construction code rules.

4.1.11 Corrosion testing if applicable.

6. Chemical Composition

4.1.12 Notification when the cladding alloy is to be used for

6.1 The composite plate may conform to any desired com-

inclusion in the design strength calculations for an applicable

bination of alloy-cladding metal and base metal as described in

construction code.

6.2 and 6.3 and as agreed upon between the purchaser and the

NOTE 1—Construction codes may dictate certain fabrication require-

manufacturer.

ments when the cladding is used in the design calculations that may be

6.2 Alloy Cladding Metal—The alloy-cladding metal speci-

different than if the cladding is used for corrosion resistance only. This

may be particularly important when the alloy cladding involves the use of fied shall conform to the requirements as to chemical compo-

welded components in the explosion bonded clad manufacturing process.

sition prescribed for the respective chromium-nickel or duplex

It is incumbent on the purchaser to make the clad manufacturer aware of

steel in Specification A240/A240M.

any such restrictions or applications at time of order.

6.3 Base Metal—The base metal shall be carbon steel or

4.2 Inadditiontothebasicrequirementsofthisspecification

low-alloy steel conforming to the ASTM specifications for

and the backing steel specification, certain supplementary

steel for pressure vessels, or other, as agreed by the purchaser

requirements are available when additional control, testing, or

and the manufacturer. The base metal shall conform to the

examination is required to meet end use requirements. The

chemical requirements of the specification to which it is

purchaser is referred to the listed supplementary requirements

ordered.

in this specification and to the detailed requirements in

Specification A20/A20M.

7. Mechanical Properties

4.3 If the requirements of this specification are in conflict

7.1 Tensile Requirements:

with the requirements of SpecificationA20/A20M, the require-

7.1.1 The tensile properties shall be determined by a

ments of this specification shall prevail.

tension test of the composite plate for clad plates that meet all

4.4 Special tests.

of the following conditions.

(1) The composite gage is less than or equal to 1 ⁄2 in. (38

5. Materials and Manufacture

mm).

5.1 Process:

(2) The specified minimum tensile strength of the base

5.1.1 The steel shall be made by the open-hearth, electric-

steel is less than or equal to 70 000 psi (485 MPa)

furnace, or basic-oxygen processes, or by secondary processes

(3) The specified minimum yield strength of the base steel

whereby steel made from these primary processes is remelted

is less than or equal to 40 000 psi (275 MPa).

using, but not limited to electroslag remelting or vacuum-arc

(4) The tensile properties thus determined shall be not less

remelting processes.

than the minimum and not more than 5000 psi (35 MPa) over

5.1.2 The alloy-cladding metal may be metallurgically

the maximum prescribed in the specification for the base steel

bonded to the base metal by any method that will produce a

used.All other tensile test requirements of the specification for

clad steel that will conform to the requirements of this

the base steel shall be met.

specification.

7.1.2 The tensile properties shall be determined by a

5.1.3 For explosively bonded products, the alloy cladding

tension test of the base steel only for clad plates that meet one

metal may be comprised of two or more separate alloy plates

of the following conditions. The properties thus determined

or sheets completely welded together to form a single fabri-

shall meet all of the tensile test requirements for the base steel.

cated component.

(1) The composite gage is greater than 1 ⁄2 in. (38 mm).

(2) The specified minimum tensile strength of the base

5.2 Heat Treatment:

5.2.1 Unless otherwise specified or agreed upon between steel is greater than 70 000 psi (485 MPa).

(3) The specified minimum yield strength of the base steel

thepurchaserandthemanufacturer,allausteniticstainlesssteel

clad plates shall be given a heat treatment consisting of heating is greater than 40 000 psi (275 MPa).

to the proper temperature for the solution of the chromium 7.1.3 If the cladding is for corrosion allowance only, the

carbidesinthecladdingfollowedbyindividualaircooling.For cladding need not be included in the tensile test. The tensile

base metals of air-hardening low-alloy steels the above heat properties thus determined shall meet the base steel require-

treatment shall be followed by a tempering treatment. In the ments.

A264 − 12 (2019)

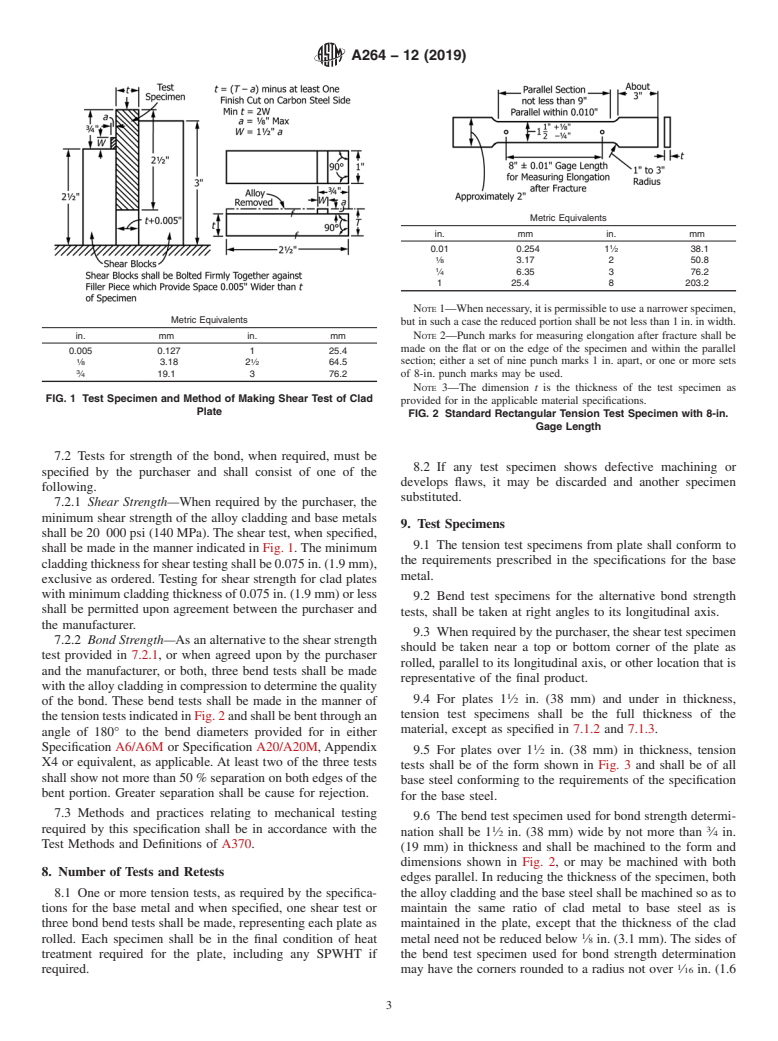

Metric Equivalents

in. mm in. mm

0.01 0.254 1 ⁄2 38.1

⁄8 3.17 2 50.8

⁄4 6.35 3 76.2

1 25.4 8 203.2

NOTE 1—When necessary, it is permissible to use a narrower specimen,

Metric Equivalents

but in such a case the reduced portion shall be not less than 1 in. in width.

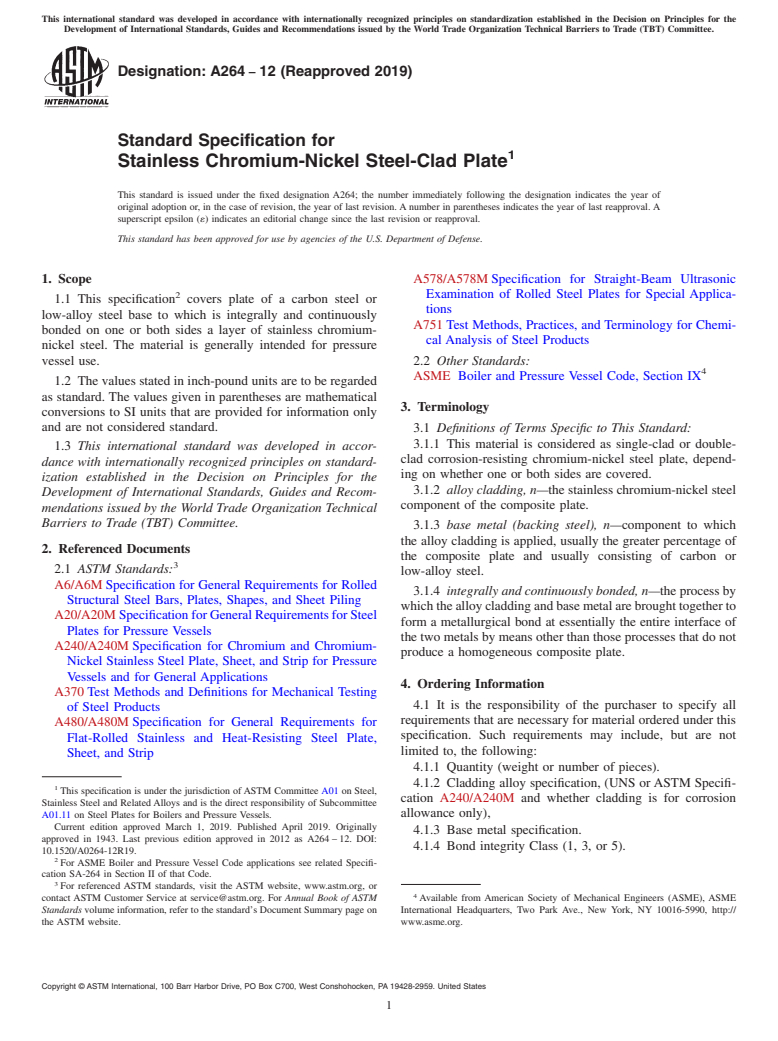

in. mm in. mm NOTE 2—Punch marks for measuring elongation after fracture shall be

made on the flat or on the edge of the specimen and within the parallel

0.005 0.127 1 25.4

1 1

section; either a set of nine punch marks 1 in. apart, or one or more sets

⁄8 3.18 2 ⁄2 64.5

⁄4 19.1 3 76.2

of 8-in. punch marks may be used.

NOTE 3—The dimension t is the thickness of the test specimen as

FIG. 1 Test Specimen and Method of Making Shear Test of Clad

provided for in the applicable material specifications.

Plate

FIG. 2 Standard Rectangular Tension Test Specimen with 8-in.

Gage Length

7.2 Tests for strength of the bond, when required, must be

8.2 If any test specimen shows defective machining or

specified by the purchaser and shall consist of one of the

develops flaws, it may be discarded and another specimen

following.

substituted.

7.2.1 Shear Strength—When required by the purchaser, the

minimum shear strength of the alloy cladding and base metals

9. Test Specimens

shall be 20 000 psi (140 MPa). The shear test, when specified,

9.1 The tension test specimens from plate shall conform to

shall be made in the manner indicated in Fig. 1. The minimum

the requirements prescribed in the specifications for the base

claddingthicknessforsheartestingshallbe0.075in.(1.9mm),

metal.

exclusive as ordered. Testing for shear strength for clad plates

with minimum cladding thickness of 0.075 in. (1.9 mm) or less

9.2 Bend test specimens for the alternative bond strength

shall be permitted upon agreement between the purchaser and

tests, shall be taken at right angles to its longitudinal axis.

the manufacturer.

9.3 When required by the purchaser, the shear test specimen

7.2.2 Bond Strength—As an alternative to the shear strength

should be taken near a top or bottom corner of the plate as

test provided in 7.2.1, or when agreed upon by the purchaser

rolled, parallel to its longitudinal axis, or other location that is

and the manufacturer, or both, three bend tests shall be made

representative of the final product.

withthealloycladdingincompressiontodeterminethequality

9.4 For plates 1 ⁄2 in. (38 mm) and under in thickness,

of the bond. These bend tests shall be made in the manner of

tension test specimens shall be the full thickness of the

thetensiontestsindicatedinFig.2andshallbebentthroughan

material, except as specified in 7.1.2 and 7.1.3.

angle of 180° to the bend diameters provided for in either

Specification A6/A6M or Specification A20/A20M, Appendix 1

9.5 For plates over 1 ⁄2 in. (38 mm) in thickness, tension

X4 or equivalent, as applicable. At least two of the three tests

tests shall be of the form shown in Fig. 3 and shall be of all

shall show not more than 50 % separation on both edges of the

base steel conforming to the requirements of the specification

bent portion. Greater separation shall be cause for rejection.

for the base steel.

7.3 Methods and practices relating to mechanical testing

9.6 The bend test specimen used for bond strength determi-

1 3

required by this specification shall be in accordance with the

nation shall be 1 ⁄2 in. (38 mm) wide by not more than ⁄4 in.

Test Methods and Definitions of A370.

(19 mm) in thickness and shall be machined to the form and

dimensions shown in Fig. 2, or may be machined with both

8. Number of Tests and Retests

edges parallel. In reducing the thickness of the specimen, both

8.1 One or more tension tests, as required by the specifica- the alloy cladding and the base steel shall be machined so as to

tions for the base metal and when specified, one shear test or maintain the same ratio of clad metal to base steel as is

three bond bend tests shall be made, representing each plate as maintained in the plate, except that the thickness of the clad

rolled. Each specimen shall be in the final condition of heat metal need not be reduced below ⁄8 in. (3.1 mm). The sides of

treatment required for the plate, including any SPWHT if the bend test specimen used for bond strength determination

required. may have the corners

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.