ASTM E1856-97(2008)

(Guide)Standard Guide for Evaluating Computerized Data Acquisition Systems Used to Acquire Data from Universal Testing Machines

Standard Guide for Evaluating Computerized Data Acquisition Systems Used to Acquire Data from Universal Testing Machines

SIGNIFICANCE AND USE

This guide is recommended to be used by anyone acquiring data from a universal testing machine using a computerized data acquisition system.

SCOPE

1.1 This guide is intended to assist the user in the evaluation and documentation of computerized data acquisition systems used to acquire data from quasi-static tests, performed on universal testing machines. The report produced will aid in the correct use and calibration of the computerized universal testing machine.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1856 − 97(Reapproved 2008)

Standard Guide for

Evaluating Computerized Data Acquisition Systems Used to

Acquire Data from Universal Testing Machines

This standard is issued under the fixed designation E1856; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

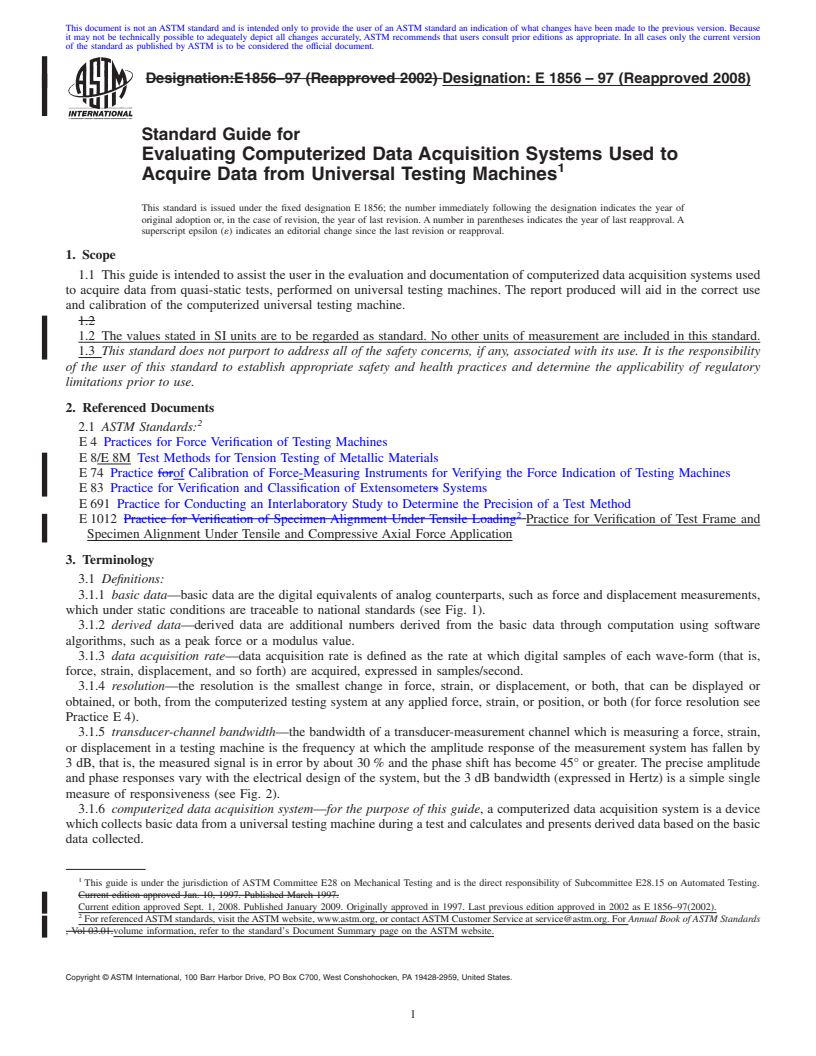

1. Scope 3.1.1 basic data—basic data are the digital equivalents of

analog counterparts, such as force and displacement

1.1 This guide is intended to assist the user in the evaluation

measurements, which under static conditions are traceable to

and documentation of computerized data acquisition systems

national standards (see Fig. 1).

used to acquire data from quasi-static tests, performed on

universal testing machines. The report produced will aid in the

3.1.2 derived data—derived data are additional numbers

correct use and calibration of the computerized universal

derived from the basic data through computation using soft-

testing machine.

ware algorithms, such as a peak force or a modulus value.

1.2 The values stated in SI units are to be regarded as

3.1.3 data acquisition rate—data acquisition rate is defined

standard. No other units of measurement are included in this

as the rate at which digital samples of each wave-form (that is,

standard.

force, strain, displacement, and so forth) are acquired, ex-

1.3 This standard does not purport to address all of the

pressed in samples/second.

safety concerns, if any, associated with its use. It is the

3.1.4 resolution—the resolution is the smallest change in

responsibility of the user of this standard to establish appro-

force, strain, or displacement, or both, that can be displayed or

priate safety and health practices and determine the applica-

obtained, or both, from the computerized testing system at any

bility of regulatory limitations prior to use.

applied force, strain, or position, or both (for force resolution

2. Referenced Documents

see Practice E4).

2.1 ASTM Standards:

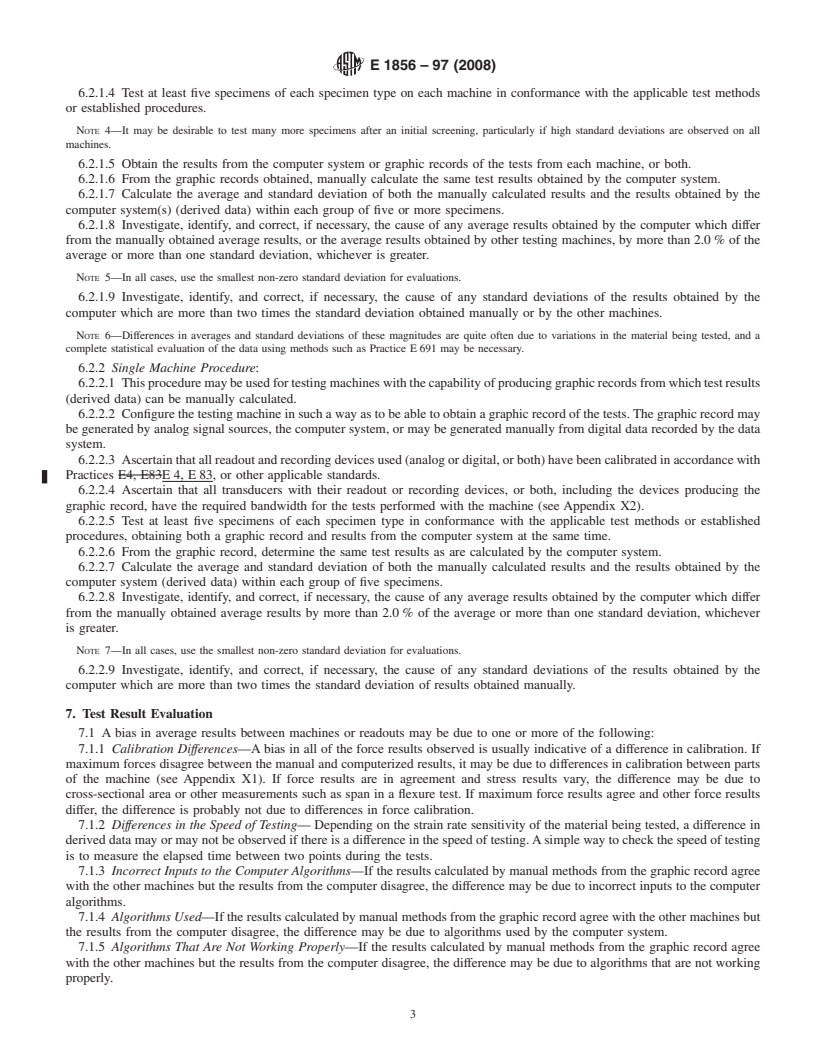

3.1.5 transducer-channel bandwidth—the bandwidth of a

E4 Practices for Force Verification of Testing Machines

transducer-measurement channel which is measuring a force,

E8/E8M Test Methods for Tension Testing of Metallic Ma-

strain, or displacement in a testing machine is the frequency at

terials

which the amplitude response of the measurement system has

E74 Practice of Calibration of Force-Measuring Instruments

fallen by 3 dB, that is, the measured signal is in error by about

for Verifying the Force Indication of Testing Machines

30 % and the phase shift has become 45° or greater. The

E83 Practice for Verification and Classification of Exten-

precise amplitude and phase responses vary with the electrical

someter Systems

design of the system, but the 3 dB bandwidth (expressed in

E691 Practice for Conducting an Interlaboratory Study to

Hertz) is a simple single measure of responsiveness (see Fig.

Determine the Precision of a Test Method

2).

E1012 Practice for Verification of Testing Frame and Speci-

men Alignment Under Tensile and Compressive Axial

3.1.6 computerized data acquisition system—for the pur-

Force Application

pose of this guide, a computerized data acquisition system is a

device which collects basic data from a universal testing

3. Terminology

machine during a test and calculates and presents derived data

3.1 Definitions:

based on the basic data collected.

This guide is under the jurisdiction of ASTM Committee E28 on Mechanical

4. Summary of Guide

Testing and is the direct responsibility of Subcommittee E28.15 on Automated

Testing.

4.1 Comparative tests are performed to determine if the

Current edition approved Sept. 1, 2008. Published January 2009. Originally

derived data acquired with a computerized universal testing

approvedin1997.Lastpreviouseditionapprovedin2002asE1856–97(2002).DOI:

10.1520/E1856-97R08.

machine agree with results acquired on the same machine from

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

graphical records or with results acquired on other testing

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

machines to ensure that the materials being tested are correctly

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. characterized.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1856 − 97 (2008)

computer system, or may be generated manually from digital

data recorded by the data system.

6.2.1.3 Ascertain that all readout and recording devices

have been calibrated in accordance with Practices E4, E83,or

other applicable standards.

6.2.1.4 Test at least five specimens of each specimen type

on each machine in conformance with the applicable test

methods or established procedures.

NOTE 4—It may be desirable to test many more specimens after an

initial screening, particularly if high standard deviations are observed on

all machines.

6.2.1.5 Obtain the results from the computer system or

graphic records of the tests from each machine, or both.

6.2.1.6 From the graphic records obtained, manually calcu-

late the same test results obtained by the computer system.

6.2.1.7 Calculate the average and standard deviation of both

the manually calculated results and the results obtained by the

FIG. 1 Basic Data and Derived Data

computer system(s) (derived data) within each group of five or

more specimens.

6.2.1.8 Investigate, identify, and correct, if necessary, the

cause of any average results obtained by the computer which

differ from the manually obtained average results, or the

average results obtained by other testing machines, by more

than 2.0 % of the average or more than one standard deviation,

whichever is greater.

NOTE 5—In all cases, use the smallest non-zero standard deviation for

evaluations.

6.2.1.9 Investigate, identify, and correct, if necessary, the

cause of any standard deviations of the results obtained by the

FIG. 2 Bandwidth

computerwhicharemorethantwotimesthestandarddeviation

obtained manually or by the other machines.

NOTE 6—Differences in averages and standard deviations of these

5. Significance and Use

magnitudes are quite often due to variations in the material being tested,

and a complete statistical evaluation of the data using methods such as

5.1 This guide is recommended to be used by anyone

Practice E691 may be necessary.

acquiring data from a universal testing machine using a

6.2.2 Single Machine Procedure:

computerized data acquisition system.

6.2.2.1 This procedure may be used for testing machines

with the capability of producing graphic records from which

6. Procedure

test results (derived data) can be manually calculated.

6.1 Choose at least five different test specimen types which

6.2.2.2 Configure the testing machine in such a way as to be

are representative of the specimens commonly tested on the

able to obtain a graphic record of the tests. The graphic record

testing machine.

may be generated by analog signal sources, the computer

NOTE 1—If the testing machine is used to test less than five different

system, or may be generated manually from digital data

specimen types, choose all those tested.

recorded by the data system.

NOTE 2—Specimen types can be differentiated by material (strength

6.2.2.3 Ascertainthatallreadoutandrecordingdevicesused

level), size, shape, or test performed, or both.

(analog or digital, or both) have been calibrated in accordance

6.2 Use one of the following procedures to evaluate and

with Practices E4, E83, or other applicable standards.

document the conformity of the computerized test results.

6.2.2.4 Ascertain that all transducers with their readout or

6.2.1 Round Robin Procedure:

recording devices, or both, including the devices producing the

6.2.1.1 Perform a round robin involving at least two other

graphic record, have the required bandwidth for the tests

testing machines. The other testing machines need not neces-

performed with the machine (see Appendix X2).

sarily be computerized.

6.2.2.5 Test at least five specimens of each specimen type in

NOTE3—Itispreferabletousetestingmachinesofvaryingtypessothat

conformance with the applicable test methods or established

systemic problems are not masked.

procedures, obtaining both a graphic record and results from

6.2.1.2 If possible, configure the testing machines in such a the computer system at the same time.

way as to be able to obtain a graphic record of the tests. The 6.2.2.6 From the graphic record, determine the same test

graphic record may be generated by analog signal sources, the results as are calculated by the computer system.

E1856 − 97 (2008)

6.2.2.7 Calculate the average and standard deviation of both 7.1.8 Alignment of the Test Piece—Poor alignment can

the manually calculated results and the results obtained by the cause lower than normal test results or poorly formed stress-

computer system (derived data) within each group of five strain curves, or both, in the elastic region of the curve (see

specimens. Practice E1012).

6.2.2.8 Investigate, identify, and correct, if necessary, the 7.1.9 Insufficient bandwidth in one or more of the trans-

ducer channels (see Appendix X2).

cause of any average results obtained by the computer which

differ from the manually obtained average results by more than

NOTE 8—Differences are just as likely to be due to problems with the

2.0 % of the average or more than one standard deviation,

manually calculated results as they are to problems with the computer

whichever is greater.

generated results.

NOTE 9—For additional information, see the appendix on Factors

NOTE 7—In all cases, use the smallest non-zero standard deviation for

Affecting Tension Test Results in Test Methods E8/E8M.

evaluations.

7.2 Adifferenceinthestandarddeviationbetweenmachines

6.2.2.9 Investigate, identify, and correct, if necessary, the

may be due to one or more of the following:

cause of any standard deviations of the results obtained by the

7.2.1 Differences in Resolution—Poor resolution can show

computerwhicharemorethantwotimesthestandarddeviation

up in two forms. A standard deviation of zero may indicate

of results obtained manually.

poor resolution.Alternatively, if two or more discrete numeric

results (derived data) occur with a difference between them

7. Test Result Evaluation

which is large relative to the result being measured, poor

resolution may be the cause. Example: 206, 206, 210, 206, 210

7.1 A bias in average results between machines or readouts

(see Appendix X3).

may be due to one or more of the following:

7.2.2 Specimen Dimension Precision—If derived-data force

7.1.1 Calibration Differences—A bias in all of the force

standard deviations agree and derived-data stress standard

results observed is usually indicative of a difference in calibra-

deviations differ, the difference is probably due to imprecise

tion. If maximum forces disagree between the manual and

measurements of cross sectional area.

computerizedresults,itmaybeduetodifferencesincalibration

7.2.3 Differences in the Speed of Testing—Testing at speeds

between parts of the machine (see Appendix X1). If force

thataretoofastmaygiveeitherhighorlowstandarddeviations

results are in agreement and stress results vary, the difference

due to one or more of the transducer-channel bandwidths (see

may be due to cross-sectional area or other measurements such

Appendix X2).

as span in a flexure test. If maximum force results agree and

7.2.4 Unstable Control of Test Speed— Unstable control of

other force results differ, the difference is probably not due to

the testing machine speed may increase the standard deviation

differences in force calibration.

of derived data in strain-rate sensitive materials and cause

7.1.2 Differences in the Speed of Testing—Depending on the

poorly formed stress-strain curves and measurement errors in

strain rate sensitivity of the material being tested, a difference

extreme cases.

in derived data may or may not be observed if there is a

7.2.5 Electrical Noise Being Picked Up By One or More of

difference in the speed of testing. A simple way to check the

the Transducer Channels—Electrical noise can cause computer

speed of testing is to measure the elapsed time between two

algorithms to perform poorly. This may be observed in the

points during the tests.

graphic record or in the basic data. This problem may be

7.1.3 Incorrect Inputs to the Computer Algorithms—If the

detected by capturing data at a fixed force or strain. The

results calculated by manual methods from the graphic record

standard deviation of this data should be comparable to the

agree with the other machines but the results from the

resolution.

computer disagree, the difference may be due to incorrect

7.2.6 Differences in Gripping and Other Apparatus in Con-

inputs to the computer algorithms.

tact with the Specimen—Some devices in contact with the

7.1.4 Algorithms Used—If the results calculated by manual

specimenmayonlycauseanoccasionalprematurefailure.This

methodsfromthegraphicrecordagreewiththeothermachines

will show up as a high standard deviation.

but the results from the computer disagree, the difference may

7.2.7 Alignment of the Test Piece—Poor alignment is often

be due to algorithms used by the computer system.

not repeatable and leads to high standard deviations (see

7.1.5 Algorithms That Are Not Working Properly—If the

Practice E1012).

results calculated by manual methods from the graphic record

7.2.8 Insufficient band width in one or more of the trans-

agree with the other machines but the results from the

ducer channels (see Appendix X2).

computer disagree, the difference may be due to algorithms

that are not working properly.

8. Report

7.1.6 Ambiguity in the Interpretation of the Test Method—

The writer(s) of the algorithms used, or the user, or both, may 8.1 Foreachtestingmachineevaluated,reportthefollowing

be interpreting the test method differently or incorrectly. information:

8.1.1 Name of reporting agency,

7.1.7 Differences in Gripping and Other Apparatus in Con-

8.1.2 Date of report,

tact with the Specimen—Differences in gripping and other

apparatus in contact with the specimen may cause premature 8.1.3 Complete testing machine description(s) including the

failure of the specimen or act as a heat sink and cause serialnumber(s)ofthemachine(s),andallinstrumentation,and

differences in elongation related results. the location(s),

E1856 − 97 (2008)

8.1.4 Software version(s) identificati

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E1856–97 (Reapproved 2002) Designation:E1856–97 (Reapproved 2008)

Standard Guide for

Evaluating Computerized Data Acquisition Systems Used to

Acquire Data from Universal Testing Machines

This standard is issued under the fixed designation E 1856; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide is intended to assist the user in the evaluation and documentation of computerized data acquisition systems used

to acquire data from quasi-static tests, performed on universal testing machines. The report produced will aid in the correct use

and calibration of the computerized universal testing machine.

1.2

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

E 8/E 8M Test Methods for Tension Testing of Metallic Materials

E74 Practice forof Calibration of Force-Measuring Instruments for Verifying the Force Indication of Testing Machines

E83 Practice for Verification and Classification of Extensometers Systems

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E 1012 Practice for Verification of Specimen Alignment Under Tensile Loading Practice for Verification of Test Frame and

Specimen Alignment Under Tensile and Compressive Axial Force Application

3. Terminology

3.1 Definitions:

3.1.1 basic data—basic data are the digital equivalents of analog counterparts, such as force and displacement measurements,

which under static conditions are traceable to national standards (see Fig. 1).

3.1.2 derived data—derived data are additional numbers derived from the basic data through computation using software

algorithms, such as a peak force or a modulus value.

3.1.3 data acquisition rate—data acquisition rate is defined as the rate at which digital samples of each wave-form (that is,

force, strain, displacement, and so forth) are acquired, expressed in samples/second.

3.1.4 resolution—the resolution is the smallest change in force, strain, or displacement, or both, that can be displayed or

obtained, or both, from the computerized testing system at any applied force, strain, or position, or both (for force resolution see

Practice E 4).

3.1.5 transducer-channel bandwidth—the bandwidth of a transducer-measurement channel which is measuring a force, strain,

or displacement in a testing machine is the frequency at which the amplitude response of the measurement system has fallen by

3 dB, that is, the measured signal is in error by about 30 % and the phase shift has become 45° or greater. The precise amplitude

and phase responses vary with the electrical design of the system, but the 3 dB bandwidth (expressed in Hertz) is a simple single

measure of responsiveness (see Fig. 2).

3.1.6 computerized data acquisition system—for the purpose of this guide, a computerized data acquisition system is a device

which collects basic data from a universal testing machine during a test and calculates and presents derived data based on the basic

data collected.

This guide is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.15 on Automated Testing.

Current edition approved Jan. 10, 1997. Published March 1997.

Current edition approved Sept. 1, 2008. Published January 2009. Originally approved in 1997. Last previous edition approved in 2002 as E 1856–97(2002).

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 03.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1856–97 (2008)

FIG. 1 Basic Data and Derived Data

FIG. 2 Bandwidth

4. Summary of Guide

4.1 Comparative tests are performed to determine if the derived data acquired with a computerized universal testing machine

agree with results acquired on the same machine from graphical records or with results acquired on other testing machines to

ensure that the materials being tested are correctly characterized.

5. Significance and Use

5.1 Thisguideisrecommendedtobeusedbyanyoneacquiringdatafromauniversaltestingmachineusingacomputerizeddata

acquisition system.

6. Procedure

6.1 Choose at least five different test specimen types which are representative of the specimens commonly tested on the testing

machine.

NOTE 1—If the testing machine is used to test less than five different specimen types, choose all those tested.

NOTE 2—Specimen types can be differentiated by material (strength level), size, shape, or test performed, or both.

6.2 Use one of the following procedures to evaluate and document the conformity of the computerized test results.

6.2.1 Round Robin Procedure:

6.2.1.1 Perform a round robin involving at least two other testing machines. The other testing machines need not necessarily

be computerized.

NOTE 3—It is preferable to use testing machines of varying types so that systemic problems are not masked.

6.2.1.2 If possible, configure the testing machines in such a way as to be able to obtain a graphic record of the tests.The graphic

record may be generated by analog signal sources, the computer system, or may be generated manually from digital data recorded

by the data system.

6.2.1.3 Ascertain that all readout and recording devices have been calibrated in accordance with Practices E 4, E 83, or other

applicable standards.

E1856–97 (2008)

6.2.1.4 Test at least five specimens of each specimen type on each machine in conformance with the applicable test methods

or established procedures.

NOTE 4—It may be desirable to test many more specimens after an initial screening, particularly if high standard deviations are observed on all

machines.

6.2.1.5 Obtain the results from the computer system or graphic records of the tests from each machine, or both.

6.2.1.6 From the graphic records obtained, manually calculate the same test results obtained by the computer system.

6.2.1.7 Calculate the average and standard deviation of both the manually calculated results and the results obtained by the

computer system(s) (derived data) within each group of five or more specimens.

6.2.1.8 Investigate, identify, and correct, if necessary, the cause of any average results obtained by the computer which differ

from the manually obtained average results, or the average results obtained by other testing machines, by more than 2.0 % of the

average or more than one standard deviation, whichever is greater.

NOTE 5—In all cases, use the smallest non-zero standard deviation for evaluations.

6.2.1.9 Investigate, identify, and correct, if necessary, the cause of any standard deviations of the results obtained by the

computer which are more than two times the standard deviation obtained manually or by the other machines.

NOTE 6—Differences in averages and standard deviations of these magnitudes are quite often due to variations in the material being tested, and a

complete statistical evaluation of the data using methods such as Practice E 691 may be necessary.

6.2.2 Single Machine Procedure:

6.2.2.1 Thisproceduremaybeusedfortestingmachineswiththecapabilityofproducinggraphicrecordsfromwhichtestresults

(derived data) can be manually calculated.

6.2.2.2 Configure the testing machine in such a way as to be able to obtain a graphic record of the tests.The graphic record may

be generated by analog signal sources, the computer system, or may be generated manually from digital data recorded by the data

system.

6.2.2.3 Ascertainthatallreadoutandrecordingdevicesused(analogordigital,orboth)havebeencalibratedinaccordancewith

Practices E4, E83E 4, E 83, or other applicable standards.

6.2.2.4 Ascertain that all transducers with their readout or recording devices, or both, including the devices producing the

graphic record, have the required bandwidth for the tests performed with the machine (see Appendix X2).

6.2.2.5 Test at least five specimens of each specimen type in conformance with the applicable test methods or established

procedures, obtaining both a graphic record and results from the computer system at the same time.

6.2.2.6 From the graphic record, determine the same test results as are calculated by the computer system.

6.2.2.7 Calculate the average and standard deviation of both the manually calculated results and the results obtained by the

computer system (derived data) within each group of five specimens.

6.2.2.8 Investigate, identify, and correct, if necessary, the cause of any average results obtained by the computer which differ

from the manually obtained average results by more than 2.0 % of the average or more than one standard deviation, whichever

is greater.

NOTE 7—In all cases, use the smallest non-zero standard deviation for evaluations.

6.2.2.9 Investigate, identify, and correct, if necessary, the cause of any standard deviations of the results obtained by the

computer which are more than two times the standard deviation of results obtained manually.

7. Test Result Evaluation

7.1 A bias in average results between machines or readouts may be due to one or more of the following:

7.1.1 Calibration Differences—A bias in all of the force results observed is usually indicative of a difference in calibration. If

maximum forces disagree between the manual and computerized results, it may be due to differences in calibration between parts

of the machine (see Appendix X1). If force results are in agreement and stress results vary, the difference may be due to

cross-sectional area or other measurements such as span in a flexure test. If maximum force results agree and other force results

differ, the difference is probably not due to differences in force calibration.

7.1.2 Differences in the Speed of Testing— Depending on the strain rate sensitivity of the material being tested, a difference in

derived data may or may not be observed if there is a difference in the speed of testing.Asimple way to check the speed of testing

is to measure the elapsed time between two points during the tests.

7.1.3 Incorrect Inputs to the Computer Algorithms—If the results calculated by manual methods from the graphic record agree

with the other machines but the results from the computer disagree, the difference may be due to incorrect inputs to the computer

algorithms.

7.1.4 Algorithms Used—If the results calculated by manual methods from the graphic record agree with the other machines but

the results from the computer disagree, the difference may be due to algorithms used by the computer system.

7.1.5 Algorithms That Are Not Working Properly—If the results calculated by manual methods from the graphic record agree

with the other machines but the results from the computer disagree, the difference may be due to algorithms that are not working

properly.

E1856–97 (2008)

7.1.6 Ambiguity in the Interpretation of the Test Method —The writer(s) of the algorithms used, or the user, or both, may be

interpreting the test method differently or incorrectly.

7.1.7 Differences in Gripping and Other Apparatus in Contact with the Specimen—Differences in gripping and other apparatus

in contact with the specimen may cause premature failure of the specimen or act as a heat sink and cause differences in elongation

related results.

7.1.8 Alignment of the Test Piece—Poor alignment can cause lower than normal test results or poorly formed stress-strain

curves, or both, in the elastic region of the curve (see Practice E 1012).

7.1.9 Insufficient bandwidth in one or more of the transducer channels (see Appendix X2).

NOTE 8—Differences are just as likely to be due to problems with the manually calculated results as they are to problems with the computer generated

results.

NOTE 9—For additional information, see the appendix on Factors Affecting Tension Test Results in Test Methods E 8/E 8M.

7.2 A difference in the standard deviation between machines may be due to one or more of the following:

7.2.1 Differences in Resolution—Poor resolution can show up in two forms. A standard deviation of zero may indicate poor

resolution.Alternatively,iftwoormorediscretenumericresults(deriveddata)occurwithadifferencebetweenthemwhichislarge

relative to the result being measured, poor resolution may be the cause. Example: 206, 206, 210, 206, 210 (see Appendix X3).

7.2.2 Specimen Dimension Precision—If derived-data force standard deviations agree and derived-data stress standard

deviations differ, the difference is probably due to imprecise measurements of cross sectional area.

7.2.3 Differences in the Speed of Testing— Testing at speeds that are too fast may give either high or low standard deviations

due to one or more of the transducer-channel bandwidths (see Appendix X2).

7.2.4 Unstable Control of Test Speed— Unstable control of the testing machine speed may increase the standard deviation of

derived data in strain-rate sensitive materials and cause poorly formed stress-strain curves and measurement errors in extreme

cases.

7.2.5 Electrical Noise Being Picked Up By One or More of the Transducer Channels—Electrical noise can cause computer

algorithms to perform poorly. This may be observed in the graphic record or in the basic data. This problem may be detected by

capturing data at a fixed force or strain. The standard deviation of this data should be comparable to the resolution.

7.2.6 Differences in Gripping and Other Apparatus in Contact with the Specimen—Some devices in contact with the specimen

may only cause an occasional premature failure. This will show up as a high standard deviation.

7.2.7 Alignment of the Test Piece—Poor alignment is often not repeatable and leads to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.