ASTM D3951-18(2023)

(Practice)Standard Practice for Commercial Packaging

Standard Practice for Commercial Packaging

SIGNIFICANCE AND USE

4.1 This practice covers the requirements for the commercial preservation, packaging, packing (exterior container), unitization, and marking for supplies and equipment. It provides for multiple handling and shipment by any mode, and storage periods of a minimum of one year in enclosed facilities without degradation or damage to the product within the container. It also provides for package quantities suitable for redistribution without additional repackaging or marking. Planned storage that exceeds one year requires more than minimum requirements for physical and mechanical protection.

4.2 This practice is applicable to Department of Defense shipments for:

4.2.1 Items intended for immediate use;

4.2.2 Items for not-mission-capable supply;

4.2.3 Items intended for depot operational consumption;

4.2.4 Small parcel shipments (CONUS), not-for-stock; and

4.2.5 Direct vendor deliveries (CONUS ONLY).

4.3 All other Department of Defense shipments shall be in accordance with MIL-STD-2073–1.

SCOPE

1.1 This practice establishes minimum requirements for packaging of supplies and equipment, exclusive of ammunition, explosives, or hazardous materials, as covered in Title 49 of the Code of Federal Regulations.

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3951 − 18 (Reapproved 2023)

Standard Practice for

Commercial Packaging

This standard is issued under the fixed designation D3951; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D5168 Practice for Fabrication and Closure of Triple-Wall

Corrugated Fiberboard Containers

1.1 This practice establishes minimum requirements for

D5445 Practice for Pictorial Markings for Handling of

packaging of supplies and equipment, exclusive of

Goods

ammunition, explosives, or hazardous materials, as covered in

D6039/D6039M Specification for Open and Covered Wood

Title 49 of the Code of Federal Regulations.

Crates

1.2 The values stated in inch-pound units are to be regarded

D6251/D6251M Specification for Wood-Cleated Panelboard

as standard. No other units of measurement are included in this

Shipping Boxes

standard.

D6254/D6254M Specification for Wirebound Pallet-Type

1.3 This standard does not purport to address all of the Wood Boxes

safety concerns, if any, associated with its use. It is the

D6255/D6255M Specification for Steel or Aluminum Slot-

responsibility of the user of this standard to establish appro- ted Angle Crates

priate safety, health, and environmental practices and deter-

D6256/D6256M Specification for Wood-Cleated Shipping

mine the applicability of regulatory limitations prior to use. Boxes with Skidded, Load-Bearing Bases

1.4 This international standard was developed in accor-

D6880/D6880M Specification for Wood Boxes

dance with internationally recognized principles on standard- D7478/D7478M Specification for Heavy Duty Sheathed

ization established in the Decision on Principles for the

Wood Crates

Development of International Standards, Guides and Recom-

2.2 Code of Federal Regulations:

mendations issued by the World Trade Organization Technical

Title 49 Transportation (Parts 100 to 199)

Barriers to Trade (TBT) Committee.

2.3 Military and Federal Standards:

MIL-STD-129 Military Marking for Shipment and Storage

2. Referenced Documents

MIL-STD-147 Palletized Unit Loads

2.1 ASTM Standards:

MIL-STD-2073–1 Standard Practice for Military Packaging

D996 Terminology of Packaging and Distribution Environ-

FED-STD-123 Marking for Shipment (Civil Agencies)

ments

2.4 International Standards:

D1974/D1974M Practice for Methods of Closing, Sealing,

ISPM Publication No. 15 Regulation of Wood Packaging

and Reinforcing Fiberboard Boxes

Material in International Trade (International Standards

D4169 Practice for Performance Testing of Shipping Con-

for Phytosanitary Measures (ISPM))

tainers and Systems

D4727/D4727M Specification for Corrugated and Solid Fi-

3. Terminology

berboard Sheet Stock (Container Grade) and Cut Shapes

3.1 Terminology found in Terminology D996 shall apply.

D5118/D5118M Practice for Fabrication of Fiberboard Ship-

ping Boxes

3.2 Definitions of Terms Specific to This Standard:

3.2.1 CONUS—Continental United States (excluding Ha-

waii and Alaska).

This practice is under the jurisdiction of ASTM Committee D10 on Packaging

and is the direct responsibility of Subcommittee D10.27 on Fiberboard Shipping

Containers, Containerboard and Related Structures and Materials.

Current edition approved Oct. 1, 2023. Published October 2023. Originally Available from Superintendent of Documents, U.S. Government Printing

approved in 1980. Last previous edition approved in 2018 as D3951 – 18. DOI: Office, Washington, DC 20402.

10.1520/D3951-18R23. Available from Document Automation and Production Service, Building 4/D,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 700 Robbins Avenue, Philadelphia, PA 19111-5094,. http://assist.daps.dla.mil/

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM quicksearch.

Standards volume information, refer to the standard’s Document Summary page on Available from the International Plant Protection Convention at http://

the ASTM website. www.aphis.usda.gov/import_export/plants/plant_exports/wpm/index.shtml.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3951 − 18 (2023)

3.2.2 immediate use—used or consumed within seven days coatings, barrier protection, volatile corrosion inhibitors, or

of receipt. desiccated unit packs.

5.1.1.3 Cushioning—Items requiring protection from physi-

3.2.3 safe delivery—in packaging—delivery of a shipment

cal and mechanical damage or which are fragile shall be

to its destination with minimal damage to the package and no

protected by wrapping, cushioning, pack compartmentization,

damage to the contents.

cartonizing, or other means to mitigate shock and vibration to

prevent damage during handling and shipment.

4. Significance and Use

5.1.1.4 Loose-fill Cushioning/Dunnage —Loose-fill mate-

4.1 This practice covers the requirements for the commer-

rial shall be prohibited for all Department of Defense (DoD)

cial preservation, packaging, packing (exterior container),

and/or General Services Administration (GSA) shipments and

unitization, and marking for supplies and equipment. It pro-

shipments to aerospace facilities.

vides for multiple handling and shipment by any mode, and

5.1.2 Unit Package:

storage periods of a minimum of one year in enclosed facilities

5.1.2.1 Unit Package— A unit package shall be so designed

without degradation or damage to the product within the

and constructed that it will contain the contents with no

container. It also provides for package quantities suitable for

damage to them, and with minimal damage to the unit pack

redistribution without additional repackaging or marking.

during shipment and storage in the shipping container

Planned storage that exceeds one year requires more than

configuration, and shall allow subsequent handling.

minimum requirements for physical and mechanical protec-

5.1.2.2 Unit Package Quantity—Unless otherwise specified

tion.

in the contract or purchase order, the unit package quantity

4.2 This practice is applicable to Department of Defense

shall be one each part, set, or assembly, except for small

shipments for:

lightweight items, for example, industrial hardware, which will

4.2.1 Items intended for immediate use;

be unit packaged in quantities that are standard in the trade and

4.2.2 Items for not-mission-capable supply;

suitable for retail sales. Single items weighing over 5 lb shall

4.2.3 Items intended for depot operational consumption;

be individually packaged.

4.2.4 Small parcel shipments (CONUS), not-for-stock; and

5.1.2.3 Bulk packaging shall be specifically excluded unless

4.2.5 Direct vendor deliveries (CONUS ONLY).

specified in the contract or purchase order.

4.3 All other Department of Defense shipments shall be in

5.1.3 Intermediate Package:

accordance with MIL-STD-2073–1.

5.1.3.1 The use of intermediate packaging is encouraged

particularly when such use enhances handling and storage.

5. Requirements

5.1.4 Packing:

5.1 General—The following requirements, unless specifi- 5.1.4.1 Unit packages and intermediate packages not meet-

ing the requirements for a shipping container shall be packed in

cally changed by the contract or order, shall apply. Suppliers

are encouraged to use advanced packaging technology. shipping containers.

5.1.1 Packaging—Preservation, packaging, packing, and 5.1.4.2 Shipping Containers—The shipping container (in-

marking furnished by the suppliers shall meet or exceed the cluding any necessary blocking, bracing, cushioning, or water

following minimum requirements: resistance) shall comply with the regulations of the carrier used

5.1.1.1 Cleanliness—Items shall be free of dirt and other and shall provide safe delivery to the destination. The shipping

contaminants which would contribute to deterioration of the container shall be capable of multiple handling and storage

item or which would require cleaning by the customer prior to periods at a minimum of one year in enclosed facilities without

use. Coatings and preservatives applied to the item for protec- degradation or damage to the product. Table 1 provides

tion are not considered contaminants. suggested size and weight limits for shipping containers and

5.1.1.2 Preservation—Items susceptible to corrosion or de- may be used for unit and intermediate packages when speci-

terioration shall be provided protection such as preservative fying a fiberboard container, wood box, or crate.

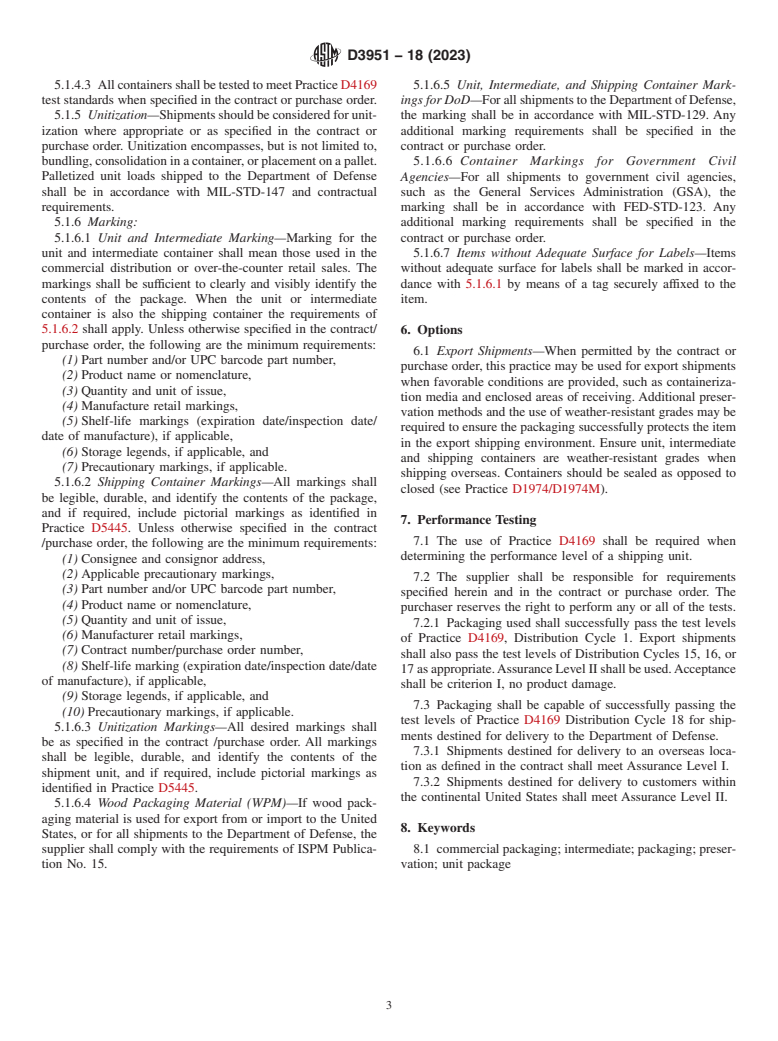

TABLE 1 Weight and Size Limits of Shipping Containers

Container Standard Maximum Outside Dimensions, Maximum Weight of

length + width + depth Boxes and Contents (lb)

Practice D5118/D5118M SW Corrugated $40 and #105 in. #120

DW Corrugated $85 and #120 in. #180

Practice D5168 TW Corrugated $110 and #125 in. #300

A

Specification D6251/D6251M As required #1000

A

Specification D6880/D6880M As required #1000

A

Specification D6256/D6256M #16 ft #2500

A

Specification D6254/D6254M As required #2500

A

Specification D6255/D6255M As required #3000

A

Specification D6039/D6039M As required #4000

A

Specification D7478/D7478M 30 ft L × 9 ft W × 10 ft H #30 000

A

Containers with length and width greater than 48 in. shall be designed with four-way entry lift capability. Containers with gross weight over 100 lb shall have 2-way forklift

entry at a minimum.

D3951 − 18 (2023)

5.1.4.3 All containers shall be tested to meet Practice D4169 5.1.6.5 Unit, Intermediate, and Shipping Container Mark-

test standards when specified in the contract or purchase order. ings for DoD—For all shipments to the Department of Defense,

5.1.5 Unitization—Shipments should be considered for unit- the marking shall be in accordance with MIL-STD-129. Any

ization where appropriate or as specified in the contract or additional marking requirements shall be specified in the

purchase order. Unitization encompasses, but is not limited to, contract or purchase order.

bundling, consolidation in a container, or placement on a pallet. 5.1.6.6 Container Markings for Government Civil

Palletized unit loads shipped to the Department of Defense Agencies—For all shipments to government civil agencies,

shall be in accordance with MIL-STD-147 and contractual such as the General Services Administration (GSA), the

requirements. marking shall be in accordance with FED-STD-123. Any

5.1.6 Marking: additional marking requirements shall be specified in the

5.1.6.1 Unit and Intermediate Marking—Marking for the contract or purchase order.

unit and intermediate container shall mean those used in the 5.1.6.7 Items without Adequate Surface for Labels—Items

commercial distribution or over-the-counter retail sales. The without adequate surface for labels shall be marked in accor-

markings shall be sufficient to clearly and visibly identify the dance with 5.1.6.1 by means of a tag securely affixed to the

contents of the package. When the unit or intermediate item.

container is also the shipping container the requirements of

5.1.6.2 shall apply. Unless otherwise specified in the contract/

6. Options

purchase order, the following are the minimum requirements:

6.1 Export Shipments—When permitted by the contract or

(1) Part number and/or UPC barcode part number,

purchase order, this practice may be used for export shipments

(2) Product name or nomenclature,

when favorable conditions are provided, such as containeriza-

(3) Quantity and unit of issue,

tion media and enclosed areas of receiving. Additional preser-

(4) Manufacture retail markings,

vation methods and the use of weather-resistant grades may be

(5) Shelf-life markings (expiration date/inspection date/

required to ensure the packaging successfully protects the item

date of manufacture), if applicable,

in the export shipping environment. Ensure unit, intermediate

(6) Storage legends, if applicable, and

and shipping containers are weather-resistant grades when

(7) Precautionary markings, if applicable.

shipping overseas. Containers should be sealed as opposed to

5.1.6.2 Shipping Container Markings—All markings shall

closed (see Practice D1974/D1974M).

be legible, durable, and identify the contents of the package,

and if required, include pictorial markings as identified in

7. Performance Testing

Practice D5445. Unless otherwise specified in the contract

7.1 The use of Practice D4169 shall be required when

/purchase order, the following are the minimum requirements:

determining the performance level of a shipping unit.

(1) Consignee and consignor address,

(2) Applicable precautionary markings,

7.2 The supplier shall be responsible for requirements

(3) Part number and/or UPC barcode part number,

specified herein and in the contract or purchase order. The

(4) Product name or nomenclature,

purchaser reserves the right to perform any or all of the tests.

(5) Quantity and unit of issue,

7.2.1 Packaging used shall successfully pass the test levels

(6) Manufacturer retail markings,

of Practice D4169, Distribution Cycle 1. Export shipments

(7) Contract number/purchase order number,

shall also pass the test levels of Distribution Cycles 15, 16, or

(8) Shelf-life marking (expiration date/inspection date/date

17 as appropriate. Assurance Level II shall be used. Acceptance

of manufacture), if applicable,

shall be criterion I, no product damage.

(9) Storage legends, if applicable, and

7.3 Packaging shall be capable of successfully passing the

(10) Precautionary markings, if applicable.

test levels of Practice D4169 Distribution Cycle 18 for ship-

5.1.6.3 Unitization Markings—All desired markings shall

ments destined for delivery to the Department of Defense.

be as specified in the contract /purchase order. All markings

7.3.1 Shipments destined for delivery to an overseas loca-

shall be legible, durable, and identify the contents of the

tion as defined in the contract shall meet Assurance Level I.

shipment unit, and if required, include pictorial markings as

7.3.2 Shipments destined for delivery to customers within

identified in Practice D5445.

the continental United States shall meet Assurance Level II.

5.1.6.4 Wood Packaging Material (WPM)—If wood pack-

aging material is used for export from or import to the United

8. Keywords

States, or for all shipments to the Department of Defense, the

supplier shall comply with the requirements of ISPM Publica- 8.1 commercial packaging; intermediate; packaging; preser-

vation

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.