ASTM D6478-10(2014)

(Test Method)Standard Test Method for Determining Specific Packability of Fabrics Used in Inflatable Restraints

Standard Test Method for Determining Specific Packability of Fabrics Used in Inflatable Restraints

SIGNIFICANCE AND USE

5.1 This test method is useful for determining the specific packability of uncoated and coated airbag fabrics. Fabric packability is an important factor in the design of airbag modules due to their inherent spacial constraints.

5.2 A folded specimen exhibits better specific packability if it occupies a lower total volume at the specified loads compared to another specimen.

5.3 The time required to test one sample (four specimens from the same lot of fabric) is approximately 1.5 h using this test method. Due to the length of time required by this test method to perform a single test, this test method is most suitable for use in design and development analysis or for inclusion in a list of required tests conducted for annual certification of an airbag fabric.

SCOPE

1.1 This test method covers procedures for determining the ability to fold and pack fabrics used for inflatable restraints using an index of specific packability.

1.2 Procedures in this test method describe operator techniques that must be followed closely to obtain repeatable and accurate results. Since these techniques are difficult to convey in writing, supplemental training for operators is required. A training video is available from ASTM (see Adjuncts ADJD6478 and ADJD6478A).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 Procedures and apparatus other than those stated in this practice may be used as agreed upon between the purchaser and the supplier with specific deviations from this practice acknowledged in the report.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6478 −10 (Reapproved 2014)

Standard Test Method for

Determining Specific Packability of Fabrics Used in

Inflatable Restraints

This standard is issued under the fixed designation D6478; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers procedures for determining the

2.2 ASTM Adjuncts:

ability to fold and pack fabrics used for inflatable restraints

ADJD6478 — 17 Detailed Drawings

using an index of specific packability.

ADJD6478A — Videotape-Supplemental Training

1.2 Procedures in this test method describe operator tech-

niques that must be followed closely to obtain repeatable and

3. Terminology

accurate results. Since these techniques are difficult to convey

3.1 For all terminology relating to D13.20, Inflatable

in writing, supplemental training for operators is required. A

restraints, refer to Terminology D6799.

training video is available from ASTM (see Adjuncts

3.1.1 The following terms are relevant to this standard:

ADJD6478 and ADJD6478A).

inflatable restraint, packability, specific packability.

1.3 The values stated in SI units are to be regarded as

3.2 For all other terms related to textiles, see Terminology

standard. No other units of measurement are included in this

D123.

standard.

4. Summary of Test Method

1.4 Procedures and apparatus other than those stated in this

practice may be used as agreed upon between the purchaser

4.1 Afabricspecimenisfoldeduniformlyina“Z”patternin

and the supplier with specific deviations from this practice

the warp and fill directions.

acknowledged in the report.

4.2 The folded specimen is placed into a transparent box

1.5 This standard does not purport to address all of the

that confines the specimen securely during compression.

safety concerns, if any, associated with its use. It is the

4.3 Thefoldedspecimeniscompressedusingatensiletester

responsibility of the user of this standard to establish appro-

outfitted with special hardware, and the resulting volume is

priate safety and health practices, and determine the applica-

recorded at specified loads. The total of all the individual

bility of regulatory limitations prior to use.

volumes recorded at each specified cell is the specific pack-

ability of the fabric.

2. Referenced Documents

2.1 ASTM Standards:

5. Significance and Use

D123Terminology Relating to Textiles

5.1 This test method is useful for determining the specific

D1776Practice for Conditioning and Testing Textiles

packability of uncoated and coated airbag fabrics. Fabric

D2904Practice for Interlaboratory Testing of a Textile Test

packability is an important factor in the design of airbag

Method that Produces Normally Distributed Data (With-

modules due to their inherent spacial constraints.

drawn 2008)

5.2 Afolded specimen exhibits better specific packability if

D6799Terminology Relating to Inflatable Restraints

it occupies a lower total volume at the specified loads com-

pared to another specimen.

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextiles

and is the direct responsibility of Subcommittee D13.20 on Inflatable Restraints.

5.3 The time required to test one sample (four specimens

Current edition approved July 1, 2014. Published August 2014. Originally

from the same lot of fabric) is approximately 1.5 h using this

approved in 1999. Last previous edition approved in 2010 as D6478–10. DOI:

test method. Due to the length of time required by this test

10.1520/D6478-10R14.

method to perform a single test, this test method is most

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Available from ASTM International Headquarters. For 17 Detailed CAD

The last approved version of this historical standard is referenced on Drawings, Order Adjunct No. ADJD6478. For Videotape-Supplemental Training,

www.astm.org. Order ADJD6478A.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6478−10 (2014)

suitable for use in design and development analysis or for 8. Procedure

inclusion in a list of required tests conducted for annual

8.1 Tensile Tester Set-Up and Calibration Check:

certification of an airbag fabric.

(See X1.1.)

8.1.1 Set tensile tester for compression mode, install load

6. Apparatus

cellwithmaximumforceratingof200to1000N,setcrosshead

6.1 Tensile Tester, outfitted with a rigid base to support the

speedto25.0 61.0mm/min,setdataacquisitionequipmentto

specimen box, and a compression foot attached to the load cell

record thickness with an accuracy of 0.1 mm at loads of 20 to

with a coupling having adjustment and locking capability to

180N in 20N increments (nine total points), set sampling

maintain fixed parallel alignment to the base. Tensile tester

frequency at ≥ 25 Hz and set test endpoint at 200N

shouldbecalibratedannuallybyanindependentagencywhose

8.1.2 Mounttherigidbasetothetensiletesterframe,mount

results are traceable to the National Institute of Science and

thecouplingtotheloadcell,andattachthecompressionfootto

Technology (NIST) or other national standards laboratory.

thecoupling,leavingtheadjustmentlockingmechanismloose.

NOTE 1—The frame of the tensile tester can be used as the rigid base if

(See Note 1)

itisasolidmetalsurfacewhichcansupportcompressionloadingof200N

8.1.3 Lower the crosshead slowly until 200 6 50N force is

withoutdeforming,isperfectlyflat,andsupportstheentirefootprintofthe

achieved and lock the compression foot into position. (See

specimen box.

X1.1.1.)

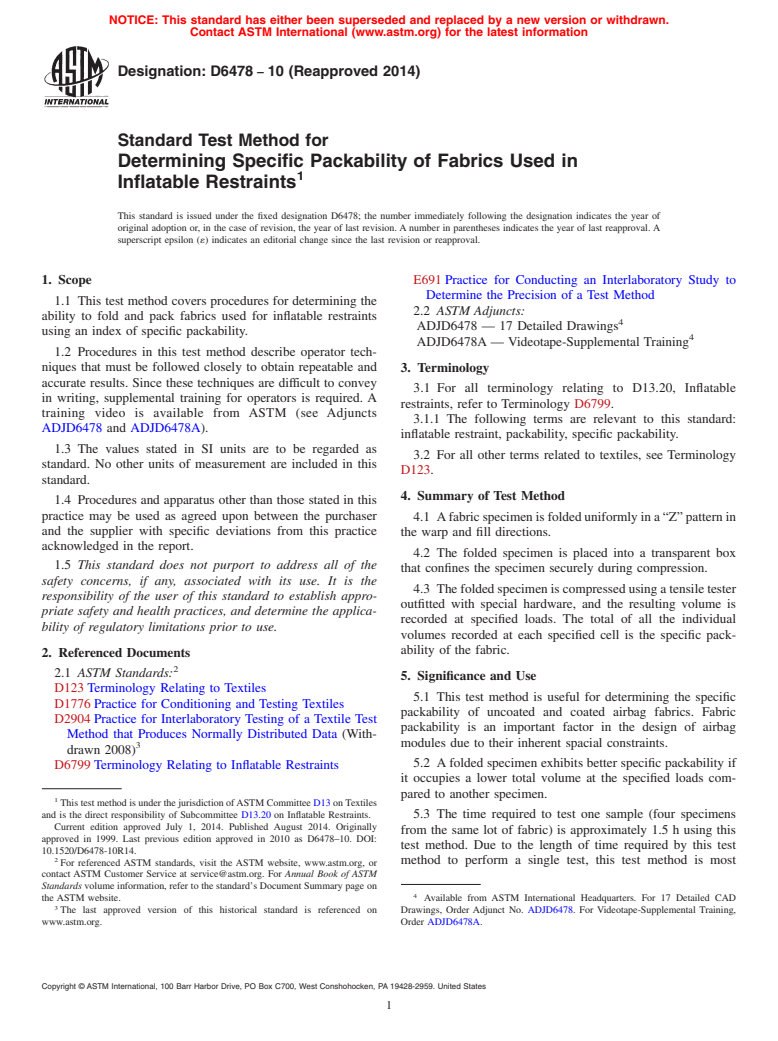

6.2 Apparatus Manufactured in Accordance With Drawings

5 8.1.4 Raise the crosshead until there is a gap of approxi-

(See Fig. 1):

mately 1 mm between the compression foot and the base and

6.2.1 RectangularBox,100by15060.1mmwith99by149

visually check for parallel alignment in both directions. (See

60.1mmcoverplateconstructedoftransparentpolycarbonate

X1.1.2.)

material.

8.1.5 Raise the crosshead, place the specimen box on the

6.2.2 RectangularTemplateandRotaryCuttingPad,750by

tensile tester base, and insert the top cover plate into the box.

800 mm 60.5mm,forcuttingspecimensfromfabricsamples

8.1.6 Raisethespecimenboxbyhanduntilthecompression

(optional).

foot is inside the box, then lower the crosshead and box

6.2.3 Jig, consisting of two sets of slats (wide and narrow)

together until the box rests on the support base and the

formakingthefoldsandaframethatholdstheslatsinposition

compression foot is not touching the cover plate. Position the

during folding.

box so that the compression foot is in the approximate center

6.2.4 Compression Gage Blocks, with thickness of 10, 20,

of the box.

and 30 6 0.1 mm.

6.2.5 All dimensions shall be verified at time of manufac-

NOTE 2—Exercise caution to avoid possible operator injury from the

tureusingmeasuringdevicestraceabletotheNationalInstitute

pinch-point between the compression foot and the specimen box.

of Science and Technology (NIST) or other national standards

8.1.7 Lower the crosshead until a force of 100 6 30N is

laboratory.

achieved and set zero.

6.3 Rotary Razor Cutter.

NOTE 3—An alternate zero can be used to simplify the test. To use the

6.4 Large Paperclips (Three), preferably with a serrated

alternate zero, set the true zero as specified, raise the crosshead to the

surface to improve gripping capability.

desired point, and zero the crosshead position again. The position of the

alternate zero should be selected such that the compression foot does not

6.5 Permanent Marking Pen, pen with fine tip.

touch the cover plate when the fabric specimen is in the box. A position

of +35 mm is suitable for most airbag fabrics.

7. Specimen Preparation

8.1.8 Raise the crosshead, place the specimen box on the

7.1 Condition fabric samples for a minimum of3hinthe

tensile tester base, insert the 10-mm gage block and then the

standard atmosphere for testing textiles in accordance with

cover plate into the box.

Practice D1776.

8.1.9 Raisethespecimenboxbyhanduntilthecompression

7.2 Withoutfrayingorfusingtheedges,cutfour750by800

foot is inside the box, then lower the crosshead and box

6 5-mm specimens from each sample, with the 800-mm

together until the box rests on the support base and the

dimension aligned in the warp direction and the cuts aligned

compression foot is not touching the cover plate. Position the

with the warp and weft yarns in the fabric.

box so that the compression foot is in the approximate center

of the box. (See X1.1.3.)

7.3 Write the fabric sample identification and the specimen

number on the lower right corner of the specimen (warp yarns 8.1.10 Initiate the compression test and record thickness at

running up/down and weft yarns running right/left relative to all specified loads.

the operator) at a location about 50 mm from the bottom edge

8.1.11 Repeat 8.1.8 – 8.1.10 using the 20 and 30-mm gage

and 50 mm from the right edge.

blocks.

8.1.12 Ensure that the thickness measured for each gage

block at 100N force is within 65.0% of the actual thickness.

Equipment designed by AlliedSignal Performance Fibers, is manufactured

Excessivevariationindicatestheneedforequipmentservicing.

according to drawing #61-27A-7906-2 and is available from Precision Machine

Company,Inc.,2915WestLehighStreet,Richmond,VA23230.CopyrightforCAD

8.2 Specimen Folding:

drawings held by AlliedSignal and provided to ASTM with full unlimited authori-

zation to distribute copies and/or to designate other parties to distribute copies. (See X1.2.)

D6478−10 (2014)

FIG. 1Apparatus

8.2.1 Placethefoldingjigonatableapproximately0.8min 8.2.3 Place the fabric specimen in the jig with the identifi-

heightwiththe“A”sideofthejigtotheleftoftheoperatorand cation mark up and at the bottom right corner, nearest the

place all slats on the table in ascending numerical order from operator, and align the edges of the specimen with the outer

top to bottom.The “A” and “B” identification marks on the jig guide lines on the jig base.

base and all slats indicate correct orientation for installation 8.2.4 Fold the specimen using the wide slats, #1 to #5,

and numbers on the slats indicate the correct sequence for visually inspecting and adjusting at each step to ensure that all

installation. (See X1.2.1.) folds are straight, are aligned to within 61 mm and that the

8.2.2 Place the base slat in the jig. fabric is tight around the slats.

D6478−10 (2014)

NOTE 4—If slippage or misalignment occurs, the following procedure berepeatedusingthesamespecimenifthereissufficientfabricremaining

can be repeated using the same specimen if there is sufficient fabric for the trimming step at the beginning and end of the folding process.

remaining for the trimming step at the beginning and end of the folding

8.2.13.1 Install slat #1 on top of the fabric specimen. Slide

process.

thespecimenintopositionsothatthefabricprotrudesapproxi-

8.2.4.1 Install slat #1 on top of the fabric specimen. Slide

mately 5 mm under the back edge of the slat.

thespecimenintopositionsothatthefabricprotrudesapproxi-

8.2.13.2 Check and adjust the relative alignment of the

mately 5 mm under the back edge of the slat.

folded edges under slat #1 so that they are directly on top of

8.2.4.2 Run the rotary razor cutter along the back edge of

each other.

slat #1 and remove the trimmed excess fabric. (See X1.2.2.)

8.2.13.3 Use the back edge of slat #1 to hold the folded

8.2.4.3 Pullthefabricfronttobackacrossthetopofslat#1,

specimen in position and remove the paperclip under the slat.

and install slat #2.

8.2.13.4 Run the rotary razor cutter along the back edge of

8.2.4.4 Pull the fabric from back to front across the top of

slat #1 and remove the trimmed excess fabric. (See X1.2.9.)

slat #2, and install slat #3. (See X1.2.3.)

8.2.13.5 Pull the fabric from front to back across the top of

8.2.4.5 Pull the fabric from front to back across the top of

slat #1, and install slat #2.

slat #3, and install slat #4.

8.2.13.6 Pull the fabric from back to front across the top of

8.2.4.6 Pull the fabric from back to front across the top of

slat #2, and install slat #3.

slat #4, and install slat #5.

8.2.13.7 Pull the fabric from front to back across the top of

8.2.4.7 Run the rotary razor cutter along the front edge of

slat #3, and install slat #4.

slat #5 and remove the trimmed excess fabric. (See X1.2.4.)

8.2.13.8 Remove the second paperclip from under slat #4.

8.2.5 Position the jig so that the “B” side faces toward the

8.2.13.9 Pull the fabric from back to front across the top of

operator.

slat #4, and install slat #5.

8.2.6 Usingafine-tippermanentmarker,makethinhorizon-

8.2.13.10 Pullthefabricfromfronttobackacrossthetopof

talmarksonthefabricatthreelocationsalongtherightsideof

slat #5, and install slat #6.

slots #2 and #4 as indicated by guide lines on the jig base.

8.2.13.11 Pullthefabricfrombacktofrontacrossthetopof

Makethinverticalmarksonthefabricspecimenadjacenttothe

slat #6, and install slat #7.

horizontalmarksusingaverticaledgeofthe30mmgageblock

8.2.13.12 Remove the third paperclip from under slat #7.

as a guide. When making the vertical marks, insert the pen tip

8.2.13.13 Runtherotaryrazorcutteralongthefrontedgeof

slightly under slat #1 so that the bottom single layer of fabric

slat #7 and remove the trimmed excess fabric.

also will be marked. (See X1.2.5.)

8.2.14 Position the jig so that the “B” side faces toward the

8.2.7 Remove the slat bracket on the “B” side.

operator.

8.2.8 Remove the wide slats one at a time from top to

8.2.15 Remove the slat bracket for the “B” side.

bottom.

8.2.16 Remove the narrow slats one at a time from top to

8.2.8.1 Slide slat #5 out and slightly left.

bottom.

8.2.8.2 Slide slat #4 out and slightly left.

8.2.16.1 Slide slat #7 out and slightly left, and slide the

8.2.8.3 Slide slat #3 out and slightly right. (See X1.2.6.)

specimen box cover plate on top of the folded specimen as the

8.2.8.4 Slide slat #2 out and slightly left.

slat is moved away to prevent the specimen from unfolding.

8.2.8.5 Slide slat #1 out and slightly right.

Thecoverplateshouldbeorientedwith“front”totherightside

8.2.9 Pinch the fabric folds and the single layer of fabric

and facing upward.

together using the horizontal and vertical marks to align the

8.2.16.2 Slide slat #6 out and slightly lef

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6478 − 10 D6478 − 10 (Reapproved 2014)

Standard Test Method for

Determining Specific Packability of Fabrics Used in

Inflatable Restraints

This standard is issued under the fixed designation D6478; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers procedures for determining the ability to fold and pack fabrics used for inflatable restraints using

an index of specific packability.

1.2 Procedures in this test method describe operator techniques that must be followed closely to obtain repeatable and accurate

results. Since these techniques are difficult to convey in writing, supplemental training for operators is required. A training video

is available from ASTM (see Adjuncts ADJD6478 and ADJD6478A).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 Procedures and apparatus other than those stated in this practice may be used as agreed upon between the purchaser and

the supplier with specific deviations from this practice acknowledged in the report.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices, and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning and Testing Textiles

D2904 Practice for Interlaboratory Testing of a Textile Test Method that Produces Normally Distributed Data (Withdrawn 2008)

D6799 Terminology Relating to Inflatable Restraints

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 ASTM Adjuncts:

ADJD6478 — 17 Detailed Drawings

ADJD6478A — Videotape-Supplemental Training

3. Terminology

3.1 For all terminology relating to D13.20, Inflatable restraints, refer to Terminology D6799.

3.1.1 The following terms are relevant to this standard: inflatable restraint, packability, specific packability.

3.2 For all other terms related to textiles, see Terminology D123.

4. Summary of Test Method

4.1 A fabric specimen is folded uniformly in a “Z” pattern in the warp and fill directions.

4.2 The folded specimen is placed into a transparent box that confines the specimen securely during compression.

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.20 on Inflatable Restraints.

Current edition approved June 1, 2010July 1, 2014. Published August 2010August 2014. Originally approved in 1999. Last previous edition approved in 20092010 as

D6478–09.–10. DOI: 10.1520/D6478-10.10.1520/D6478-10R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Available from ASTM International Headquarters. For 17 Detailed CAD Drawings, Order Adjunct No. ADJD6478. For Videotape-Supplemental Training, Order

ADJD6478A.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6478 − 10 (2014)

4.3 The folded specimen is compressed using a tensile tester outfitted with special hardware, and the resulting volume is

recorded at specified loads. The total of all the individual volumes recorded at each specified cell is the specific packability of the

fabric.

5. Significance and Use

5.1 This test method is useful for determining the specific packability of uncoated and coated airbag fabrics. Fabric packability

is an important factor in the design of airbag modules due to their inherent spacial constraints.

5.2 A folded specimen exhibits better specific packability if it occupies a lower total volume at the specified loads compared

to another specimen.

5.3 The time required to test one sample (four specimens from the same lot of fabric) is approximately 1.5 h using this test

method. Due to the length of time required by this test method to perform a single test, this test method is most suitable for use

in design and development analysis or for inclusion in a list of required tests conducted for annual certification of an airbag fabric.

6. Apparatus

6.1 Tensile Tester, outfitted with a rigid base to support the specimen box, and a compression foot attached to the load cell with

a coupling having adjustment and locking capability to maintain fixed parallel alignment to the base. Tensile tester should be

calibrated annually by an independent agency whose results are traceable to the National Institute of Science and Technology

(NIST) or other national standards laboratory.

NOTE 1—The frame of the tensile tester can be used as the rigid base if it is a solid metal surface which can support compression loading of 200N

without deforming, is perfectly flat, and supports the entire footprint of the specimen box.

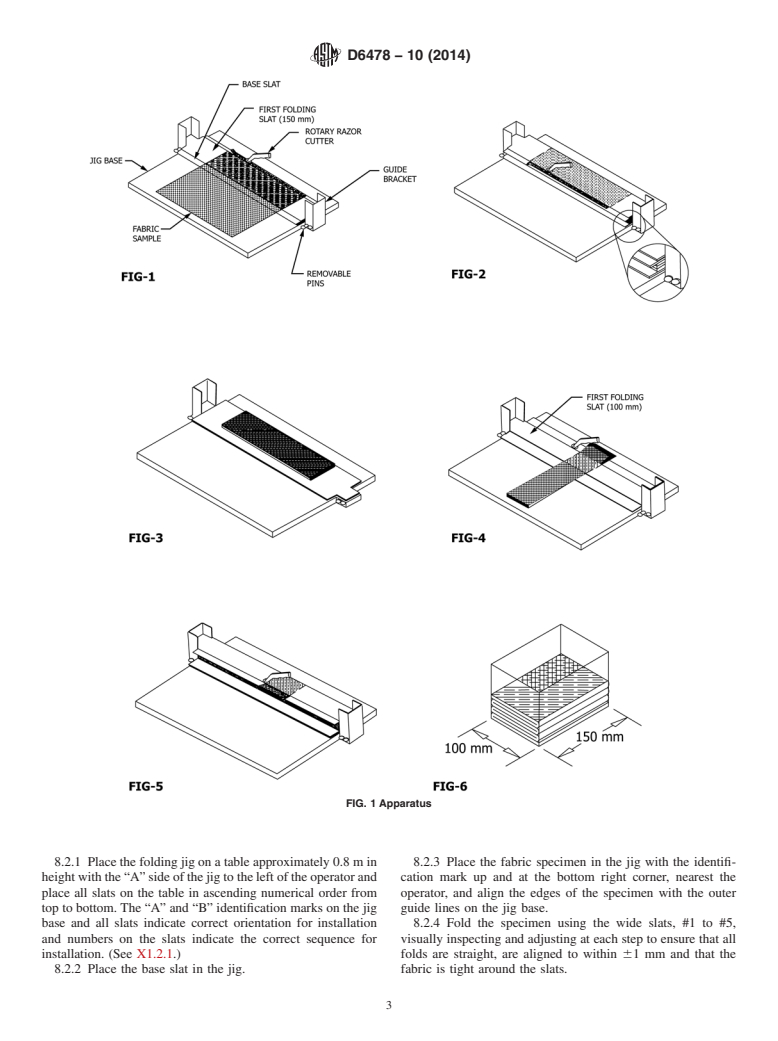

6.2 Apparatus Manufactured in Accordance With Drawings (See Fig. 1):

6.2.1 Rectangular Box, 100 by 1506 0.1mmwith 99 by 149 6 0.1 mm cover plate constructed of transparent polycarbonate

material.

6.2.2 Rectangular Template and Rotary Cutting Pad, 750 by 800 mm 6 0.5 mm , for cutting specimens from fabric samples

(optional).

6.2.3 Jig, consisting of two sets of slats (wide and narrow) for making the folds and a frame that holds the slats in position

during folding.

6.2.4 Compression Gage Blocks, with thickness of 10, 20, and 30 6 0.1 mm.

6.2.5 All dimensions shall be verified at time of manufacture using measuring devices traceable to the National Institute of

Science and Technology (NIST) or other national standards laboratory.

6.3 Rotary Razor Cutter.

6.4 Large Paperclips (Three), preferably with a serrated surface to improve gripping capability.

6.5 Permanent Marking Pen, pen with fine tip.

7. Specimen Preparation

7.1 Condition fabric samples for a minimum of 3 h in the standard atmosphere for testing textiles in accordance with Practice

D1776.

7.2 Without fraying or fusing the edges, cut four 750 by 800 6 5-mm specimens from each sample, with the 800-mm dimension

aligned in the warp direction and the cuts aligned with the warp and weft yarns in the fabric.

7.3 Write the fabric sample identification and the specimen number on the lower right corner of the specimen (warp yarns

running up/down and weft yarns running right/left relative to the operator) at a location about 50 mm from the bottom edge and

50 mm from the right edge.

8. Procedure

8.1 Tensile Tester Set-Up and Calibration Check:

(See X1.1.)

8.1.1 Set tensile tester for compression mode, install load cell with maximum force rating of 200 to 1000N, set crosshead speed

to 25.0 6 1.0 mm/min, set data acquisition equipment to record thickness with an accuracy of 0.1 mm at loads of 20 to 180N in

20N increments (nine total points), set sampling frequency at ≥ 25 Hz and set test endpoint at 200N

8.1.2 Mount the rigid base to the tensile tester frame, mount the coupling to the load cell, and attach the compression foot to

the coupling, leaving the adjustment locking mechanism loose. (See Note 1)

Equipment designed by AlliedSignal Performance Fibers, is manufactured according to drawing #61-27A-7906-2 and is available from Precision Machine Company, Inc.,

2915 West Lehigh Street, Richmond, VA 23230. Copyright for CAD drawings held by AlliedSignal and provided to ASTM with full unlimited authorization to distribute

copies and/or to designate other parties to distribute copies.

D6478 − 10 (2014)

FIG. 1 Apparatus

8.1.3 Lower the crosshead slowly until 200 6 50N force is achieved and lock the compression foot into position. (See X1.1.1.)

8.1.4 Raise the crosshead until there is a gap of approximately 1 mm between the compression foot and the base and visually

check for parallel alignment in both directions. (See X1.1.2.)

8.1.5 Raise the crosshead, place the specimen box on the tensile tester base, and insert the top cover plate into the box.

8.1.6 Raise the specimen box by hand until the compression foot is inside the box, then lower the crosshead and box together

until the box rests on the support base and the compression foot is not touching the cover plate. Position the box so that the

compression foot is in the approximate center of the box.

NOTE 2—Exercise caution to avoid possible operator injury from the pinch-point between the compression foot and the specimen box.

8.1.7 Lower the crosshead until a force of 100 6 30N is achieved and set zero.

D6478 − 10 (2014)

NOTE 3—An alternate zero can be used to simplify the test. To use the alternate zero, set the true zero as specified, raise the crosshead to the desired

point, and zero the crosshead position again. The position of the alternate zero should be selected such that the compression foot does not touch the cover

plate when the fabric specimen is in the box. A position of +35 mm is suitable for most airbag fabrics.

8.1.8 Raise the crosshead, place the specimen box on the tensile tester base, insert the 10-mm gage block and then the cover

plate into the box.

8.1.9 Raise the specimen box by hand until the compression foot is inside the box, then lower the crosshead and box together

until the box rests on the support base and the compression foot is not touching the cover plate. Position the box so that the

compression foot is in the approximate center of the box. (See X1.1.3.)

8.1.10 Initiate the compression test and record thickness at all specified loads.

8.1.11 Repeat 8.1.8 – 8.1.10 using the 20 and 30-mm gage blocks.

8.1.12 Ensure that the thickness measured for each gage block at 100N force is within 65.0 % of the actual thickness. Excessive

variation indicates the need for equipment servicing.

8.2 Specimen Folding:

(See X1.2.)

8.2.1 Place the folding jig on a table approximately 0.8 m in height with the “A” side of the jig to the left of the operator and

place all slats on the table in ascending numerical order from top to bottom. The “A” and “B” identification marks on the jig base

and all slats indicate correct orientation for installation and numbers on the slats indicate the correct sequence for installation. (See

X1.2.1.)

8.2.2 Place the base slat in the jig.

8.2.3 Place the fabric specimen in the jig with the identification mark up and at the bottom right corner, nearest the operator,

and align the edges of the specimen with the outer guide lines on the jig base.

8.2.4 Fold the specimen using the wide slats, #1 to #5, visually inspecting and adjusting at each step to ensure that all folds are

straight, are aligned to within 61 mm and that the fabric is tight around the slats.

NOTE 4—If slippage or misalignment occurs, the following procedure can be repeated using the same specimen if there is sufficient fabric remaining

for the trimming step at the beginning and end of the folding process.

8.2.4.1 Install slat #1 on top of the fabric specimen. Slide the specimen into position so that the fabric protrudes approximately

5 mm under the back edge of the slat.

8.2.4.2 Run the rotary razor cutter along the back edge of slat #1 and remove the trimmed excess fabric. (See X1.2.2.)

8.2.4.3 Pull the fabric front to back across the top of slat #1, and install slat #2.

8.2.4.4 Pull the fabric from back to front across the top of slat #2, and install slat #3. (See X1.2.3.)

8.2.4.5 Pull the fabric from front to back across the top of slat #3, and install slat #4.

8.2.4.6 Pull the fabric from back to front across the top of slat #4, and install slat #5.

8.2.4.7 Run the rotary razor cutter along the front edge of slat #5 and remove the trimmed excess fabric. (See X1.2.4.)

8.2.5 Position the jig so that the “B” side faces toward the operator.

8.2.6 Using a fine-tip permanent marker, make thin horizontal marks on the fabric at three locations along the right side of slots

#2 and #4 as indicated by guide lines on the jig base. Make thin vertical marks on the fabric specimen adjacent to the horizontal

marks using a vertical edge of the 30 mm gage block as a guide. When making the vertical marks, insert the pen tip slightly under

slat #1 so that the bottom single layer of fabric also will be marked. (See X1.2.5.)

8.2.7 Remove the slat bracket on the “B” side.

8.2.8 Remove the wide slats one at a time from top to bottom.

8.2.8.1 Slide slat #5 out and slightly left.

8.2.8.2 Slide slat #4 out and slightly left.

8.2.8.3 Slide slat #3 out and slightly right. (See X1.2.6.)

8.2.8.4 Slide slat #2 out and slightly left.

8.2.8.5 Slide slat #1 out and slightly right.

8.2.9 Pinch the fabric folds and the single layer of fabric together using the horizontal and vertical marks to align the edges

directly on top of each other. Insert a large paperclip halfway over the tow folds and the edge of the single layer of fabric at each

of the three locations marked.

8.2.10 Invert the folded stack and adjust the individual folds and the edge of the single fabric layer so that the alignment is exact

at each of the three locations clipped. Carefully revert the folded stack so that the specimen identification mark is on the top.

8.2.11 Reinstall the slat bracket on the “B” side.

8.2.12 Position the jig with the “A” side left of the operator, position the folded stack so the specimen identification mark is

at the front edge of the jig facing the operator, and align the edges of the folded stack with the inner guidelines on the jig base.

(See X1.2.7.)

8.2.13 Fold the specimen using the narrow slats #1 to #7, visually inspecting and adjusting at each step to insure that all folds

are straight, are aligned to within 61 mm and that the fabric is tight around the slats. (See X1.2.8.)

NOTE 5—If slippage or misalignment occurs, the procedure below can be repeated using the same specimen if there is sufficient fabric remaining for

D6478 − 10 (2014)

the trimming step at the beginning and end of the folding

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.