ASTM A701-96(2000)

(Specification)Standard Specification for Ferromanganese-Silicon

Standard Specification for Ferromanganese-Silicon

SCOPE

1.1 This specification covers a manganese-silicon alloy designated as ferromanganese-silicon.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 701 – 96 (Reapproved 2000)

Standard Specification for

Ferromanganese-Silicon

This standard is issued under the fixed designation A 701; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

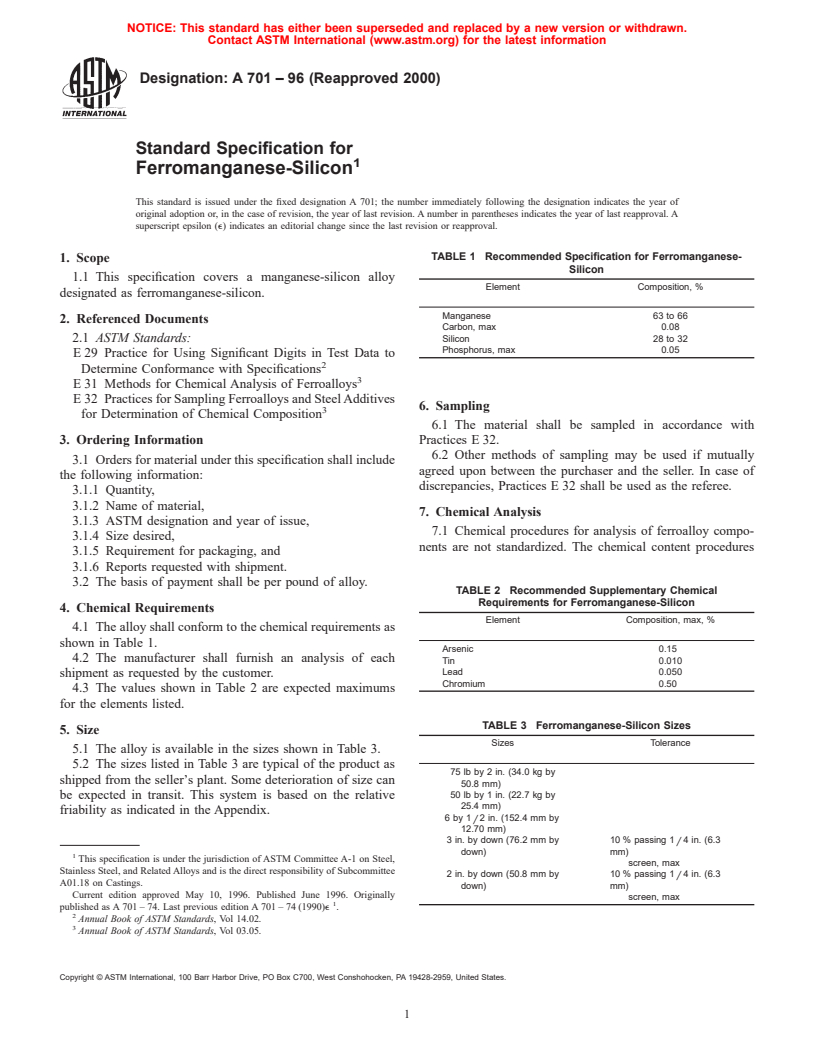

TABLE 1 Recommended Specification for Ferromanganese-

1. Scope

Silicon

1.1 This specification covers a manganese-silicon alloy

Element Composition, %

designated as ferromanganese-silicon.

Manganese 63 to 66

2. Referenced Documents

Carbon, max 0.08

2.1 ASTM Standards: Silicon 28 to 32

Phosphorus, max 0.05

E 29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

E 31 Methods for Chemical Analysis of Ferroalloys

E 32 Practices for Sampling Ferroalloys and Steel Additives

6. Sampling

for Determination of Chemical Composition

6.1 The material shall be sampled in accordance with

3. Ordering Information Practices E 32.

6.2 Other methods of sampling may be used if mutually

3.1 Orders for material under this specification shall include

agreed upon between the purchaser and the seller. In case of

the following information:

discrepancies, Practices E 32 shall be used as the referee.

3.1.1 Quantity,

3.1.2 Name of material,

7. Chemical Analysis

3.1.3 ASTM designation and year of issue,

7.1 Chemical procedures for analysis of ferroalloy compo-

3.1.4 Size desired,

nents are not standardized. The chemical content procedures

3.1.5 Requirement for packaging, and

3.1.6 Reports requested with shipment.

3.2 The basis of payment shall be per pound of alloy.

TABLE 2 Recommended Supplementary Chemical

Requirements for Ferromanganese-Silicon

4. Chemical Requirements

Element Composition, max, %

4.1 The alloy shall conform to the chemical requirements as

shown in Table 1.

Arsenic 0.15

4.2 The manufacturer shall furnish an analysis of each

Tin 0.010

Lead 0.050

shipment as requested by the customer.

Chromium 0.50

4.3 The values shown in Table 2 are expected maximums

for the elements listed.

TABLE 3 Ferromanganese-Silicon Sizes

5. Size

Sizes Tolerance

5.1 The alloy is available in the sizes shown in Table 3.

5.2 The sizes listed in Table 3 are typical of the product as

75 lb by 2 in. (34.0 kg by

shipped from the seller’s plant. Some deterioration of size can

50.8 mm)

50 lb by 1 in. (22.7 kg by

be expected in transit. This system is based on the relative

25.4 mm)

friability as indicated in the Appendix.

6by1 2 in. (152.4 mm by

/

12.70 mm)

3 in. by down (76.2 mm by 10 % passing 1 4 in. (6.3

/

down) mm)

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

screen, max

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

2 in. by down (50.8 mm by 10 % passing 1 4 in. (6.3

/

A01.18 on Castings.

down) mm)

Current edition approved May 10, 1996. Published June 1996. Originally

screen, max

published as A 701 – 74. Last previous edition A 701 – 74 (1990)e .

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 03.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 701 – 96 (2000)

must be mutually agreed upon between the purchaser and th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.