ASTM D3594-93(2000)

(Test Method)Standard Test Method for Copolymerized Ethyl Acrylate In Ethylene-Ethyl Acrylate Copolymers

Standard Test Method for Copolymerized Ethyl Acrylate In Ethylene-Ethyl Acrylate Copolymers

SCOPE

1.1 This test method covers ethylene-ethyl acrylate copolymers containing from 1 to 25% ethyl acrylate comonomer.

1.2 The values stated in SI units are to be regarded as the standard. (See Practice E380.)

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1--There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3594 – 93 (Reapproved 2000)

Standard Test Method for

Copolymerized Ethyl Acrylate In Ethylene-Ethyl Acrylate

Copolymers

This standard is issued under the fixed designation D3594; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

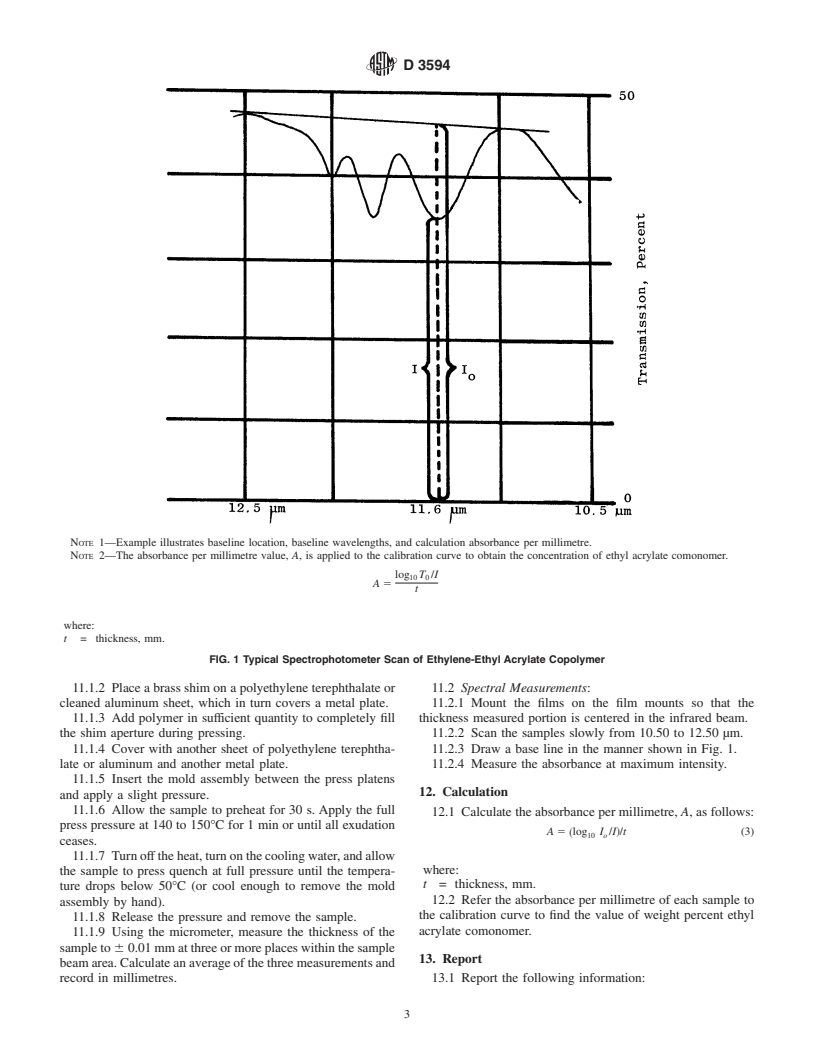

1. Scope wavelengthwhenthereisnocomonomerpresent.Itapparently

is unique and characteristic of the copolymer. There is no

1.1 This test method covers ethylene-ethyl acrylate copoly-

interference from the monomer at this wavelength.

mers containing from 1 to 25% ethyl acrylate comonomer.

4.2 The infrared absorption band at 11.60 µm is of medium

1.2 The values stated in SI units are to be regarded as the

intensity;consequently,fairlythickfilmsareemployed.Thisis

standard. (See Practice E380.)

an advantage in that errors in measurements of the thicknesses

1.3 This standard does not purport to address all of the

of films have minimal influence on the analytical result. Film

safety problems, if any, associated with its use. It is the

thicknessisselectedsothatnotmorethan80%oftheinfrared

responsibility of the user of this standard to establish appro-

energy is absorbed at the analytical wavelength. The approxi-

priate safety and health practices and determine the applica-

mate thicknesses found to be satisfactory for different concen-

bility of regulatory limitations prior to use.

trationsofcomonomerareasfollows:(1)lessthan5weight%

NOTE 1—There is no similar or equivalent ISO standard.

ethyl acrylate=0.5 mm, ( 2) 5 to 15 weight% ethyl acry-

late=0.25 mm, and (3) 15 to 25 weight% ethyl acry-

2. Referenced Documents

late=0.18 mm. It is necessary first to press a film approxi-

2.1 ASTM Standards:

mately 0.25 mm in thickness and scan it to observe the

B883 Terminology Relating to Plastics

absorption intensity unless the approximate ethyl acrylate

D1898 Practice for Sampling of Plastics

content is known.

E131 Terminology Relating to Molecular Spectroscopy

4.3 For the highest precision, the test method requires that

E168 Practices for General Techniques of Infrared Quanti-

the thickness of the sample film be determined accurately.

tative Analysis

4.4 The general procedure is to scan the absorption band

E177 Practice for Use of the Terms Precision and Bias in

from 10.50 to 12.50 µm, although a single-point measurement

ASTM Test Methods

may also be used.This test method describes the use of a scan

E275 Practice for Describing and Measuring Performance

and employs the base-line method as outlined in 7.2 and the

of Ultraviolet, Visible, and Near Infrared Spectrophotom-

figure illustrating the Base-Line Method for MeasuringAbsor-

eters

bance of Practices E168. A calibration curve is prepared by

E380 Practice for Use of the International System of Units

plotting absorbance per millimetre values versus weight per-

(SI)

cent ethyl acrylate for several copolymers which have had

ethyl acrylate contents established by a fast neutron activation

3. Terminology

analysis of oxygen content. The ethyl acrylate content of an

3.1 See Terminology D883.

unknown sample is then obtained by referring the absorbance

per millimetre value to the calibration curve.

4. Summary of Test Method

4.1 The infrared absorption band at 11.60 µm responds to

5. Significance and Use

increases in comonomer content.There is no absorption at this

5.1 Ethyl acrylate is copolymerized with ethylene to pro-

duce film, molding, and wire coating resins with improved

1 physical properties. Ethyl acrylate comonomer increases flex-

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods ibility, stress cracking resistance, toughness, and clarity. A

(Section D20.70.08).

rapid quantitative technique is needed for the evaluation of the

Current edition approved Feb. 15, 1993. Published April 1993. Originally

amount of ethyl acrylate in a resin for specification purposes

published as D3594–77. Last previous edition D3594–77 (1987).

because physical properties change rapidly with increasing

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 08.02. comonomer content.

Annual Book of ASTM Standards, Vol 14.01.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3594

5.2 Infrared spectrophotometric analysis, when suitably oxygen content is fast neutron activation analysis. The ethyl

calibrated, can be used for the measurement of the concentra- acrylate comonomer content, E, is calculated from the oxygen

tion of comonomer present. Calibration is performed with analysis, assuming that all oxygen present is due to ethyl

samples that have been analyzed for oxygen content by fast acrylate, as follows:

neutron activation analysis. Oxygen content is converted to

100 3 X

E, wt% 5 (1)

ethyl acrylate comonomer content by a simple calculation.

31.5

5.3 A purpose of the infrared method of analysis is to

where:

provide a procedure for use in quality control analysis. It is a

X = oxygen content of unknown copolymers, weight%.

rapid, secondary method of analysis as contrasted with the

10.2 Set the controls of the infrared spectrometer for quan-

more expensive and time-consuming fast neutron activation

titative conditions with a good signal-to-noise ratio and satis-

analysis which is the primary, calibrating method.

factory reproducibility. Use a sufficiently expanded chart scale

such that line width can be measured accurately. Use a

6. Apparatus

scanningspeedsufficientlyslowtogivegoodreproducibilityof

6.1 Infrared Spectrophotometer, capable of spectral resolu-

band shape. Set the slit width narrow enough that there is little

tion equivalenttothatdefinedbyPracticeE275andexhibited

distortion of the true band shape. Record the instrument

in Fig. 7 of that practice. The instrument should be capable of

conditions used.

scale expansion along the wavelength (or wave number) axis.

NOTE 2—For the Perkin-Elmer Model 221 Spectrophotometer the

6.1.1 Fourier Transform Infrared Spectrophotometer (FT-

−1

followingsettingsaresatisfactory:PrismNaCl,slits2X,slitprogram927,

IR), with nominal 4 cm resolution.

attenuator speed 600, amplifier gain adjusted to give good response, chart

6.2 Compression-Molding Press, small, with platens ca-

scale 0.01 µm/mm, chart speed 0.5 µm/min, electrical balance and

pable of being heated to 150°C.

suppression adjusted to specifications in instrument manual. Comparable

6.3 Metal Plates, two, 150 by 150 mm or larger, of 0.5-mm

operating conditions should be used when other instruments are em-

thickness with smooth surfaces, chromium plated preferably.

ployed.

6.4 Brass Shims, three, approximately 75 by 75 mm and

10.3 Scan the films from 10.50 to 12.50 µm.

thicknesses of 0.50 mm, 0.25 mm, and 0.18 mm, with an

NOTE 3—Films having high gloss may exhibit interference fringes in

apert

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.