ASTM D5163-91(1996)

(Guide)Standard Guide for Establishing Procedures to Monitor the Performance of Safety Related Coatings in an Operating Nuclear Power Plant

Standard Guide for Establishing Procedures to Monitor the Performance of Safety Related Coatings in an Operating Nuclear Power Plant

SCOPE

1.1 This guide covers procedures for establishing a program to monitor Service Level I coating systems in operating nuclear power plants. Monitoring is an on going process of evaluating the condition of the in-service coating systems.

1.2 It is the intent of this guide to provide a recommended basis for establishing a coatings monitoring program, not to mandate a singular basis for all programs. Variations or simplifications of the program described in this guide may be appropriate for each operating nuclear power plant depending on their licensing commitments. Similar guidelines may be applicable for Service Level II and other areas outside containment.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5163 – 91 (Reapproved 1996)

Standard Guide for

Establishing Procedures to Monitor the Performance of

Safety Related Coatings in an Operating Nuclear Power

Plant

This standard is issued under the fixed designation D 5163; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 4541 Test Method for Pull-Off Strength of Coatings

Using Portable Adhesion Testers

1.1 This guide covers procedures for establishing a program

F 1130 Practice for Inspecting the Coating System of a

to monitor Service Level I coating systems in operating nuclear

Ship

power plants. Monitoring is an on going process of evaluating

F 1131 Practice for Inspecting the Coating System of a

the condition of the in-service coating systems.

Ship’s Tanks and Voids

1.2 It is the intent of this guide to provide a recommended

F 1132 Practice for Inspecting the Coating System of a

basis for establishing a coatings monitoring program, not to

Ship’s Decks and Deck Machinery

mandate a singular basis for all programs. Variations or

F 1133 Practice for Inspecting the Coating System of a

simplifications of the program described in this guide may be

Ship’s Underwater Hull and Boottop During Drydocking

appropriate for each operating nuclear power plant depending

2.2 ANSI Standard:

on their licensing commitments. Similar guidelines may be

N45.2.6—Qualification of Inspection, Examination, and

applicable for Service Level II and other areas outside contain-

Testing Personnel for Nuclear Power Plants

ment.

1.3 This standard does not purport to address all of the

2.3 SSPC Standard:

safety concerns, if any, associated with its use. It is the

SSPC-PA2—Measurement of Dry Paint Thickness With

responsibility of the user of this standard to establish appro-

Magnetic Gages

priate safety and health practices and determine the applica-

2.4 NACE Standard:

bility of regulatory limitations prior to use.

RP0188-88—Standard Practice Discontinuity (Holiday)

2. Referenced Documents Testing of Protective Coatings

2.1 ASTM Standards:

3. Significance and Use

D 610 Test Methods for Evaluating Degree of Rusting on

3.1 Establishment of an in-service coatings monitoring pro-

Painted Steel Surfaces

gram permits planning and prioritization of coatings mainte-

D 714 Test Method for Evaluating Degree of Blistering of

nance work as needed to maintain coat integrity and perfor-

Paints

mance in nuclear Service Level I coating systems. For

D 1186 Test Methods for Nondestructive Measurement of

additional information on nuclear maintenance coating work,

Dry Film Thickness of Nonmagnetic Coatings Applied to

3 refer to ASTM Manual on Maintenance Coatings for Nuclear

a Ferrous Base

Power Plants.

D 3359 Test Methods for Measuring Adhesion by Tape

3 3.2 A coatings monitoring program enables early identifica-

Test

tion and detection of potential problems in coating systems.

D 4121 Practice for Photographic Documentation of Coat-

Some Service Level I coating systems may be known in

ing and Lining Failures and Defects

advance to be suspect, deficient, or unqualified. Monitoring

D 4537 Guide for Establishing Procedures to Qualify and

Certify Inspection Personnel for Coating Work in Nuclear

Facilities

Annual Book of ASTM Standards, Vol 01.07.

Available from American National Standards Institute, 11 W. 42nd Street, 13th

This guide is under the jurisdiction of ASTM Committee D33 on Protective Floor, New York, NY 10036.

Coating and Lining Work for Power Generation Facilities and is the direct Available from Steel Structures Painting Council, 4400 Fifth Ave., Pittsburgh,

responsibility of Subcommittee D33.04 on Quality Systems and Inspection. PA 15213.

Current edition approved Oct. 3, 1991. Published December 1991. Available from National Association of Corrosion Engineers, P. O. Box

Annual Book of ASTM Standards, Vol 06.02. 218340, Houston, TX 77218.

3 9

Annual Book of ASTM Standards, Vol 06.01. Available from ASTM Headquarters, 100 Barr Harbor Dr., West Consho-

Discontinued; see 1992 Annual Book of ASTM Standards, Vol 06.01. hocken, PA 19428-2959.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5163

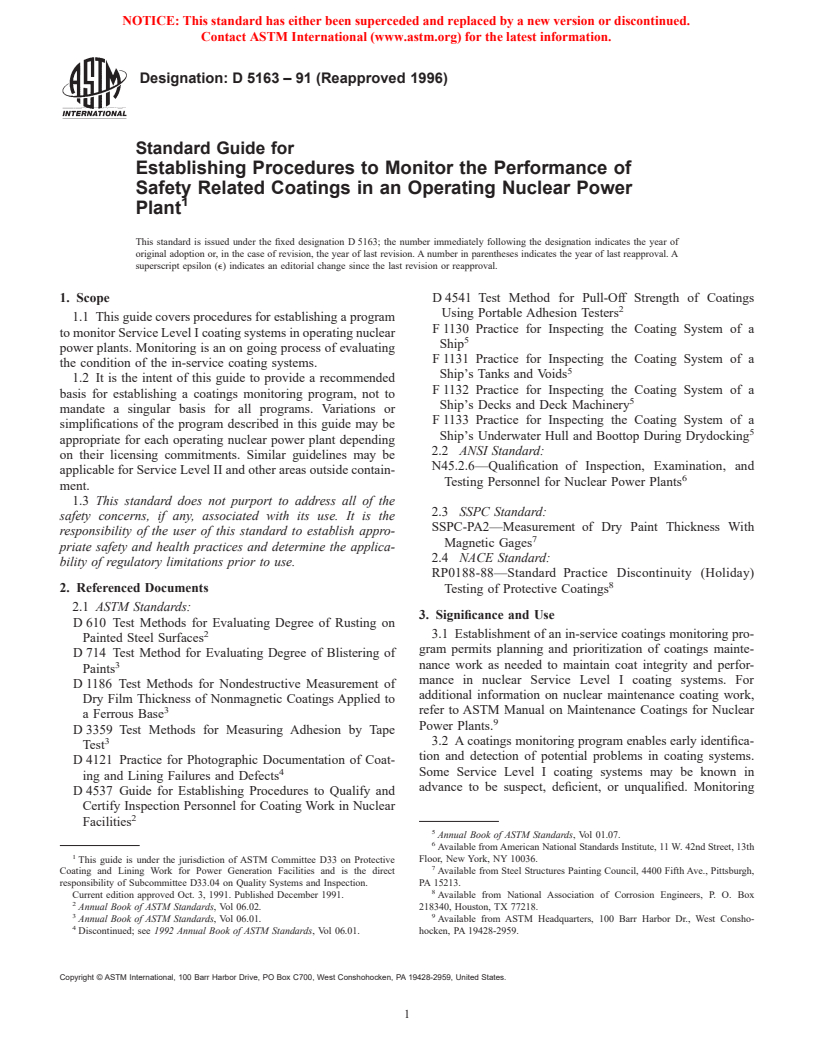

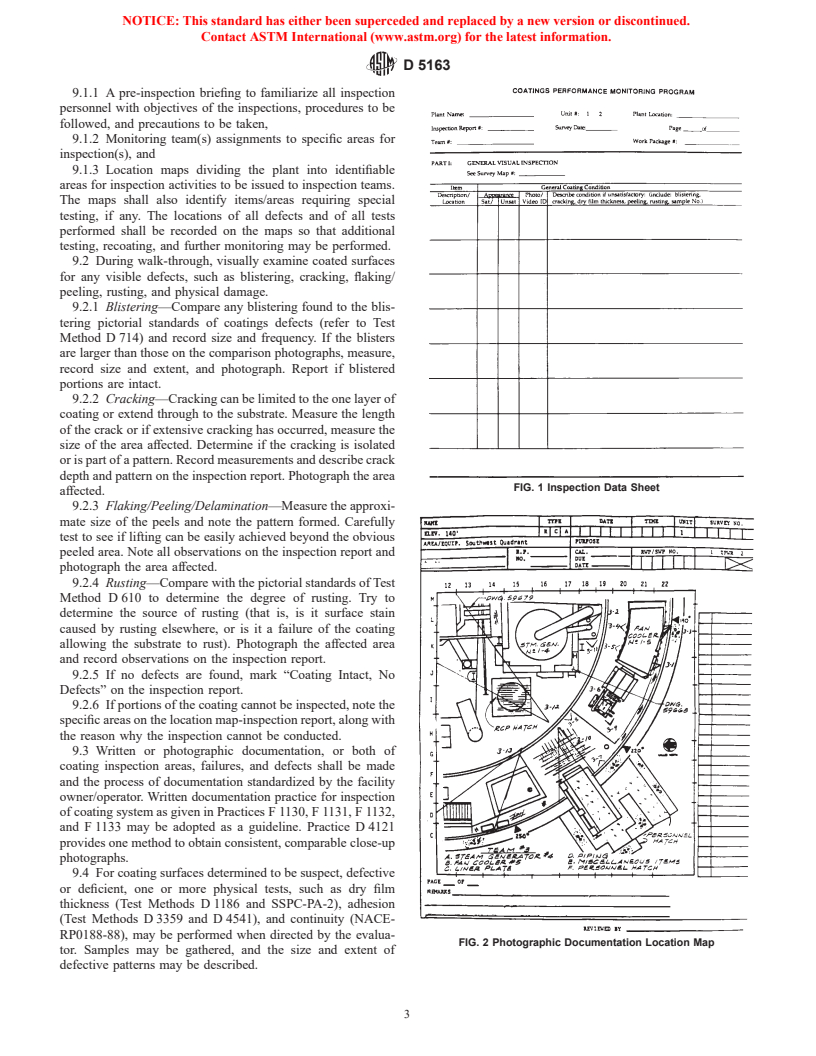

coating performance will assist in developing follow-up pro- 6.2.3 Copies of previous inspection or monitoring reports.

cedures to resolve any significant deficiency relative to coating

6.2.4 Documentation pertaining to any maintenance work

work.

performed on existing coating systems.

3.3 Degraded coatings may generate debris under design

basis accident conditions that could adversely affect the per-

7. Premonitoring Procedure

formance of the post-accident safety systems. A coatings

7.1 Prior to conducting an inspection of the coating systems,

monitoring program may be required to fulfill safety analysis

the responsible organization shall ensure that the necessary

report commitments for Service Level I coating work in a

services and equipment required for inspection are provided.

nuclear power plant facility.

Factors that must be considered while planning the inspection

activities include, but are not limited to, lighting, access to

4. Responsibility

coated surfaces, cleaning surfaces of any deposit or build up,

4.1 The owner/operator shall identify the department or

ventilation and, where necessary, special underwater inspection

group within the organization to be responsible for establishing

requirements.

the applicable requirements for activities or procedures cov-

7.2 Station access procedures for Service Level I coating

ered by this guide and shall document the scope of their

systems monitoring shall be followed. While access procedures

responsibility. Owner/operator delegation of this responsibility

may vary from plant to plant, specific station access procedures

to other outside qualified organizations is permitted and shall

may include:

be documented.

7.2.1 Security clearance for protected, radiation controlled,

4.2 It is the responsibility of the owner/operator or his

and vital areas, and escorted or unescorted clearance as

designee performing these activities to specify the detailed

required,

methods and procedures for meeting the applicable require-

7.2.2 Radiological history including prior radiation expo-

ments of this guide.

sure for all personnel involved,

4.3 The owner/operator or his designee shall assign a

7.2.3 Health physics classroom training in the use of radia-

coordinator to be responsible for supervising coating inspec-

tion detection and monitoring devices and procedures for

tion activities, data collection and documentation, and for

wearing anticontamination clothing,

ensuring that inspection personnel are adequately trained and

7.2.4 A radiation work permit based on health physics

qualified.

radiological survey of the work location,

4.4 The owner/operator shall assign responsibility for evalu-

7.2.5 Compliance with radiation work permit requirements

ating the results of inspection activities carried out under the

and other special radiation controls unique to each work

coatings performance monitoring program.

location, and

7.2.6 Issuance of dosimetry.

5. Frequency

7.3 The safety requirements of the facility owner/operator

5.1 Frequency of in-service coating inspection monitoring

must be met when performing all inspection operations.

shall be determined by the owner/operator. In operating nuclear

power plants certain monitoring activities may be restricted to

8. Personnel Requirements, Qualifications, and Training

major maintenance outages or refueling outages. It is a good

8.1 The facility owner/operator shall specify the require-

practice to perform inspections during each refueling outage or

ments and guidelines for qualification and training of inspec-

during other major maintenance outages as needed.

tion personnel involved in the program. However, inspectors

and the coordinator shall be knowledgeable coatings personnel

6. Records and Past History

meeting the requirements of ASTM Guide D 4537 or ANSI

6.1 Coating performance will depend on the operating

N45.2.6. The coordinator shall, as a minimum, be a Level II

conditions experienced b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.