ASTM A944-99

(Test Method)Standard Test Method for Comparing Bond Strength of Steel Reinforcing Bars to Concrete Using Beam-End Specimens

Standard Test Method for Comparing Bond Strength of Steel Reinforcing Bars to Concrete Using Beam-End Specimens

SCOPE

1.1 This test method describes procedures to establish the relative bond strength of steel reinforcing bars in concrete.

1.2 This test method is intended to determine the effects of surface preparation or condition (such as bar coatings) on the bond strength of deformed steel reinforcing bars (of sizes ranging from No. 10 to No. 35 [No. 3 to No. 11]) to concrete.

1.3 The values stated in SI units are to be regarded as the standard. The values given in brackets are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 944 – 99

Standard Test Method for

Comparing Bond Strength of Steel Reinforcing Bars to

Concrete Using Beam-End Specimens

This standard is issued under the fixed designation A 944; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.4 embedment length, n—the distance from the surface of

the concrete test specimen to the installed end of the steel

1.1 This test method describes procedures to establish the

reinforcing bar. This equals the sum of the lead length and the

relative bond strength of steel reinforcing bars in concrete.

bonded length.

1.2 This test method is intended to determine the effects of

3.1.5 lead length, n—the length of the test bar that is not in

surface preparation or condition (such as bar coatings) on the

contact with concrete but is between the surface of the concrete

bond strength of deformed steel reinforcing bars (of sizes

test specimen and the bonded length.

ranging from No. 10 to No. 36 [No. 3 to No. 11]) to concrete.

3.1.6 relative rib area, n—ratio of the projected rib area

1.3 The values stated in SI units are to be regarded as the

normal to bar axis to the product of the nominal bar perimeter

standard. The values given in brackets are for information only.

and the center-to-center rib spacing.

1.4 This standard does not purport to address all of the

3.2 Symbols:

safety concerns, if any, associated with its use. It is the

C = Concrete cover, mm [in.].

b

responsibility of the user of this standard to establish appro-

d = Nominal diameter of reinforcing bar, mm [in.].

b

priate safety and health practices and determine the applica-

l = Embedment length, mm [in.].

e

bility of regulatory limitations prior to use.

4. Apparatus

2. Referenced Documents

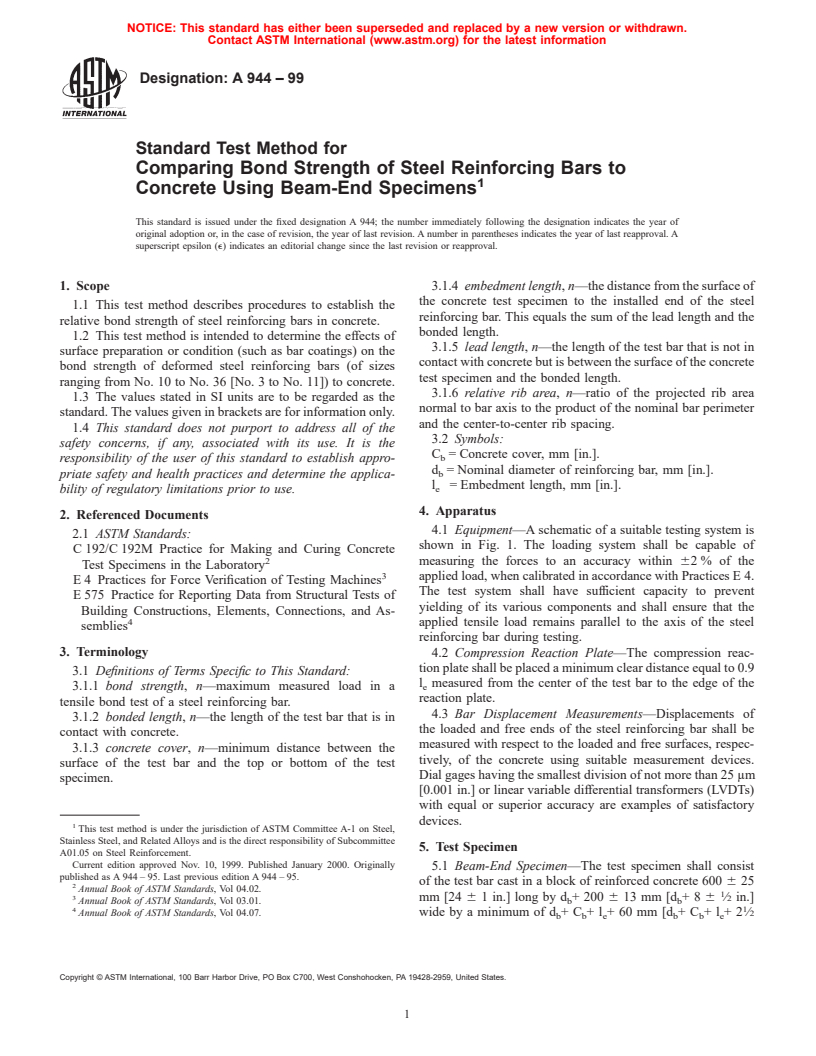

4.1 Equipment—A schematic of a suitable testing system is

2.1 ASTM Standards:

shown in Fig. 1. The loading system shall be capable of

C 192/C 192M Practice for Making and Curing Concrete

measuring the forces to an accuracy within 62 % of the

Test Specimens in the Laboratory

applied load, when calibrated in accordance with Practices E 4.

E 4 Practices for Force Verification of Testing Machines

The test system shall have sufficient capacity to prevent

E 575 Practice for Reporting Data from Structural Tests of

yielding of its various components and shall ensure that the

Building Constructions, Elements, Connections, and As-

applied tensile load remains parallel to the axis of the steel

semblies

reinforcing bar during testing.

3. Terminology

4.2 Compression Reaction Plate—The compression reac-

tion plate shall be placed a minimum clear distance equal to 0.9

3.1 Definitions of Terms Specific to This Standard:

l measured from the center of the test bar to the edge of the

3.1.1 bond strength, n—maximum measured load in a e

reaction plate.

tensile bond test of a steel reinforcing bar.

4.3 Bar Displacement Measurements—Displacements of

3.1.2 bonded length, n—the length of the test bar that is in

the loaded and free ends of the steel reinforcing bar shall be

contact with concrete.

measured with respect to the loaded and free surfaces, respec-

3.1.3 concrete cover, n—minimum distance between the

tively, of the concrete using suitable measurement devices.

surface of the test bar and the top or bottom of the test

Dial gages having the smallest division of not more than 25 μm

specimen.

[0.001 in.] or linear variable differential transformers (LVDTs)

with equal or superior accuracy are examples of satisfactory

devices.

This test method is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

5. Test Specimen

A01.05 on Steel Reinforcement.

Current edition approved Nov. 10, 1999. Published January 2000. Originally

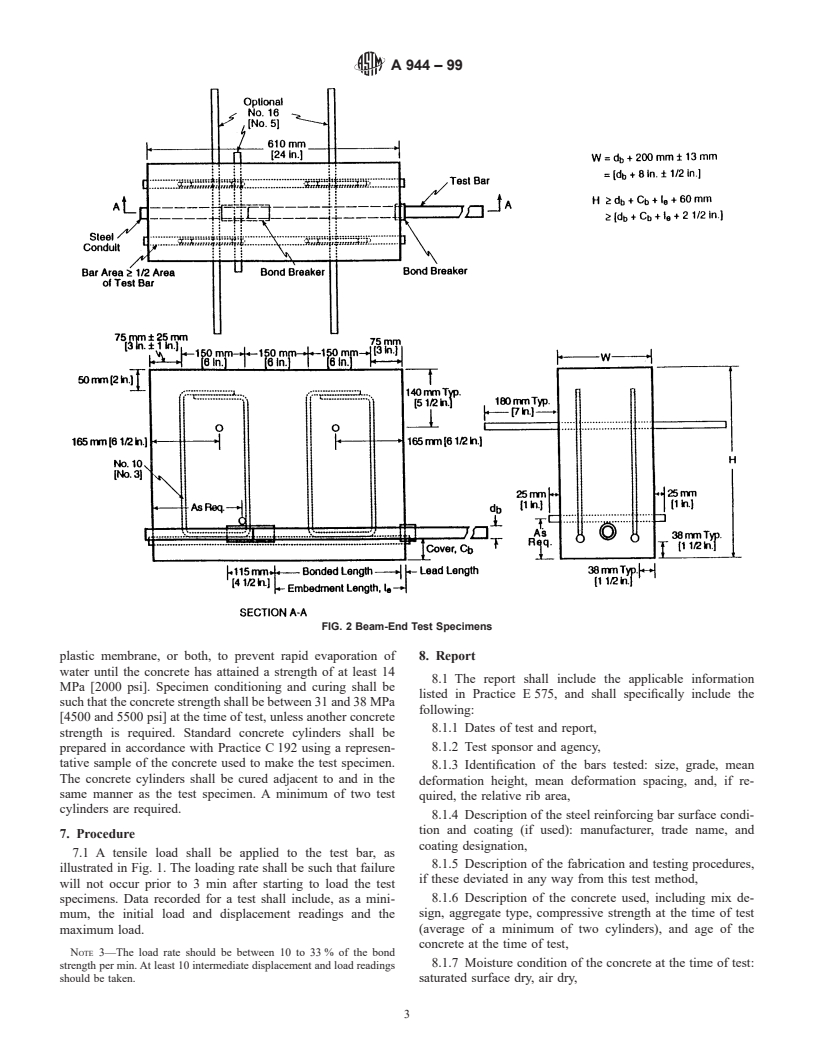

5.1 Beam-End Specimen—The test specimen shall consist

published as A 944 – 95. Last previous edition A 944 – 95.

of the test bar cast in a block of reinforced concrete 600 6 25

Annual Book of ASTM Standards, Vol 04.02.

mm [24 6 1 in.] long by d + 200 6 13 mm [d +8 6 ⁄2 in.]

Annual Book of ASTM Standards, Vol 03.01. b b

Annual Book of ASTM Standards, Vol 04.07. wide by a minimum of d +C +l +60mm[d +C +l +2 ⁄2

b b e b b e

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 944–99

FIG. 1 Schematic of Test Apparatus

NOTE 1—The lead length, shown in Fig. 2, is typically between 13 and

in.] high. A typical test specimen is illustrated in Fig. 2. The

100 mm [0.5 and 4 in.]. This unbonded region is used to prevent a

specimen shall be reinforced by four closed stirrups oriented

cone-type pullout failure at the surface of the concrete. Increases in lead

parallel to the sides of the specimen and two flexural steel

length generally result in an increase in bond strength.

reinforcing bars parallel to the test bar, as shown in Fig. 2.

Transverse steel reinforcing bars similar to those illustrated in 5.2 Fabrication—The concrete block shall be fabricated

using concrete designed to produce a strength at the time of test

Fig. 2 may be used to aid in fabrication and testing. The test bar

shall extend from the front surface a distance that is compatible between 31 and 38 MPa [4500 and 5500 psi]. The specimen

shall be cast in approximately equal layers not exceeding 250

with the test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.