ASTM F1958/F1958M-99(2005)

(Test Method)Standard Test Method for Determining the Ignitability of Non-flame-Resistant Materials for Clothing by Electric Arc Exposure Method Using Mannequins

Standard Test Method for Determining the Ignitability of Non-flame-Resistant Materials for Clothing by Electric Arc Exposure Method Using Mannequins

SIGNIFICANCE AND USE

This test method determines the ignitability of materials in single or multiple layers.

5.1.1 Material performance shall be determined from the ignitability of the specimen(s) and shall be reported as a probability of ignition at various incident energy levels.

5.1.2 Materials which meet the flame resistance requirements of Specification F 1506 do not require testing by this test method unless the mechanism of passing Specification F 1506 involves melting and escape from the flame source (for example, coated fabrics, certain rainwear fabrics).

This test method maintains the specimen in a static, vertical position and does not involve movement except that resulting from the exposure.

This test method specifies a standard set of exposure conditions. Different exposure conditions may produce different results. In addition to the standard set of exposure conditions, other conditions representative of the expected hazard may be used.

SCOPE

1.1 This test method is used to identify materials that are ignitable and that can continue to burn when exposed to an electric arc, and determines (a) the incident exposure energy that causes ignition, and (b) the probability of ignition.

1.2 The specimens tested in this test method are materials fabricated in the form of shirts.

1.3 This test method shall be used to measure and describe the properties of materials, products, or assemblies in response to convective and radiant energy generated by an electric arc under controlled laboratory conditions.

1.4 The values stated in either SI units or in other units shall be regarded separately as standard. The values stated in each system may not be exact equivalents, therefore each system must be used independently of the other, without combining values in any way.

1.5 This standard shall not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 For specific precautions, see Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1958/F1958M – 99 (Reapproved 2005)

Standard Test Method for

Determining the Ignitability of Non-flame-Resistant Materials

for Clothing by Electric Arc Exposure Method Using

Mannequins

ThisstandardisissuedunderthefixeddesignationF1958/F1958M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4391 Terminology Relating to The Burning Behavior of

Textiles

1.1 This test method is used to identify materials that are

F1494 Terminology Relating to Protective Clothing

ignitable and that can continue to burn when exposed to an

F1506 Performance Specification for Flame Resistant Tex-

electric arc, and determines (a) the incident exposure energy

tile Materials for Wearing Apparel for Use by Electrical

that causes ignition, and (b) the probability of ignition.

Workers Exposed to Momentary Electric Arc and Related

1.2 The specimens tested in this test method are materials

Thermal Hazards

fabricated in the form of shirts.

F1959/F1959M Test Method for Determining the Arc Rat-

1.3 This test method shall be used to measure and describe

ing of Materials for Clothing

the properties of materials, products, or assemblies in response

2.2 ANSI/IEEE Standards:

to convective and radiant energy generated by an electric arc

Standard Dictionary of Electrical and Electronics Terms

under controlled laboratory conditions.

1.4 The values stated in either SI units or in other units shall

3. Terminology

be regarded separately as standard. The values stated in each

3.1 Definitions:

system may not be exact equivalents, therefore each system

3.1.1 See also Terminology D4391.

must be used independently of the other, without combining

3.1.2 arc duration, n—time duration of the arc, s.

values in any way.

3.1.3 arc energy, vi dt, n—sum of the instantaneous arc

1.5 This standard shall not be used to describe or appraise

voltage values multiplied by the instantaneous arc current

the fire hazard or fire risk of materials, products, or assemblies

values multiplied by the incremental time values during the

under actual fire conditions. However, results of this test may

arc, J.

be used as elements of a fire assessment which takes into

3.1.4 arc gap, n—distance between the arc electrodes, in.

account all of the factors which are pertinent to an assessment

3.1.5 arc voltage, n—voltage across the gap caused by the

of the fire hazard of a particular end use.

current flowing through the resistance created by the arc gap,

1.6 This standard does not purport to address all of the

V.

safety concerns, if any, associated with its use. It is the

3.1.6 asymmetrical arc current, n—the total arc current

responsibility of the user of this standard to establish appro-

produced during closure; it includes a direct component and a

priate safety and health practices and determine the applica-

symmetrical component, A.

bility of regulatory limitations prior to use.

3.1.7 blowout, n—the extinguishing of the arc caused by a

1.7 For specific precautions, see Section 7.

magnetic field.

2. Referenced Documents 3.1.8 closure, n—point on supply current wave form where

arc is initiated.

2.1 ASTM Standards:

3.1.9 delta peak temperature, n—difference between the

D123 Terminology Relating to Textiles

maximum temperature and the initial temperature of the sensor

during the test, °C.

This test method is under the jurisdiction of ASTM Committee F-18 on

3.1.10 heatflux, n—the thermal intensity indicated by the

Electrical Protective Equipment for Workers and is the direct responsibility of

amount of energy transmitted per unit area and time (cal/

Subcommittee F18.65 on Wearing Apparel.

2 2

cm s)(W/cm ).

Current edition approved March 1, 2005. Published April 2005. Originally

approved in 1997 as PS 57 – 97. Last previous edition approved in 1999 as

F1958/F1958M-99. DOI: 10.1520/F1958_F1958M-99R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from the Institute of Electrical and Electronic Engineers, Inc., 345 E.

the ASTM website. 47th St., New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1958/F1958M – 99 (2005)

3.1.11 i t, n—sum of the instantaneous arc current values 6. Apparatus

squared multiplied by the incremental time values during the

6.1 General Arrangement for Determining Ignitability Us-

arc, A /s.

ing Mannequins and Monitor Sensors—The test apparatus

3.1.12 ignitability, n (ignitable, adj)—in electric arc expo-

shall consist of supply bus, arc controller, recorder, arc

sure,thepropertyofamaterialinvolvingignitionaccompanied

electrodes, mannequins, and incident energy monitoring sen-

by heat and light, and continued burning resulting in consump-

sors. The arc exposure shall be monitored with two incident

tion of at least 25 % of the exposed area of the test specimen.

energy monitoring sensors for each mannequin.

3.1.13 ignition, n—the initiation of combustion.

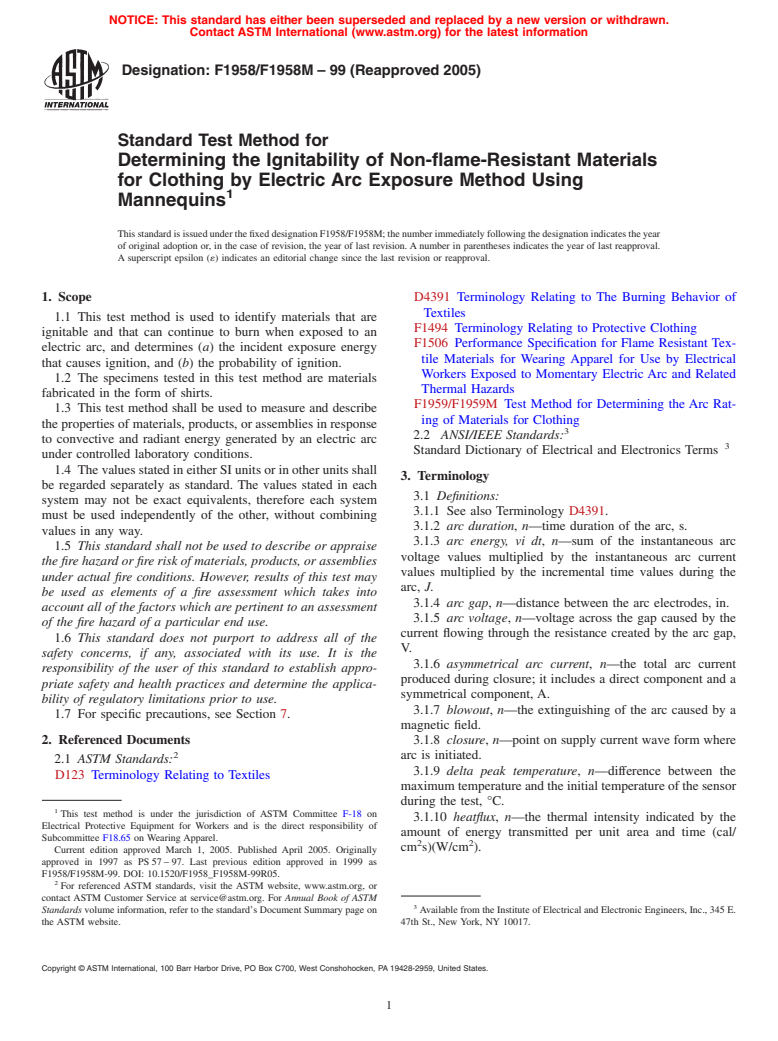

6.1.1 Arrangement of the Mannequins—Aminimum of two

3.1.14 incident energy (E), n—the amount of energy (total

i

mannequinswithtwomonitoringsensorseachshallbeusedfor

heat, cal/cm ) received at a surface as a direct result of an

each test. Position monitor sensors on each side of the

electrical arc discharge as measured by temperature rise on

mannequins as shown in Fig. 1.An additional mannequin with

copper calorimeters.

monitoring sensors may be placed around the arc as shown in

3.1.15 incident energy monitoring sensors—sensors

Fig. 2 to evaluate multiple samples of the same materials at the

mounted on each side of the mannequins.

same distance from the arc. Each mannequin shall be visually

3.1.15.1 Discussion—Sensors use the calorimeters de-

observed for ignition.

scribed in Test Method F1959/F1959M.

6.1.2 Specimen Holder—Use a male mannequin torso, size

3.1.16 peak arc current, n—maximum value of the AC arc

large, made from non-conductive fiberglass construction. (A

current, A.

mannequin, such as Model 7001 D, Morgese Soriano or

3.1.17 RMS arc current, n—root mean square of theAC arc

equivalent is acceptable). The mannequin shall be constructed

current, A.

in an erect posture. The mannequin head may be removable.

3.1.18 time to delta peak temperature, n—the time from

The mannequins shall have detachable arms that are straight

beginning of the initiation of the arc to the time the delta peak

and mount in a vertical position to allow the test specimen at

temperature is reached, s.

the chest to be the closest point to the centerline of the arc.The

3.1.19 X/R ratio, n—the ratio of system inductive reactance

arms of the mannequins may be shortened to 4 in. [102 mm] to

toresistance.ItisproportionaltotheL/Rratiooftimeconstant,

permit ease of specimen mounting. The position of the man-

and is, therefore, indicative of the rate of decay of any DC

nequins from the centerline of the arc electrodes shall be

offset. A large X/R ratio corresponds to a large time constant

adjustable from 8 in. [203 mm] to 24 in. [610 mm] as shown

and a slow rate of decay.

in Figs. 1 and 3.

3.2 For definitions of other textile terms used in this test

6.1.3 The mannequins may be instrumented. Refer to Ap-

method, refer to Terminologies D123 and F1494.

pendix X1.

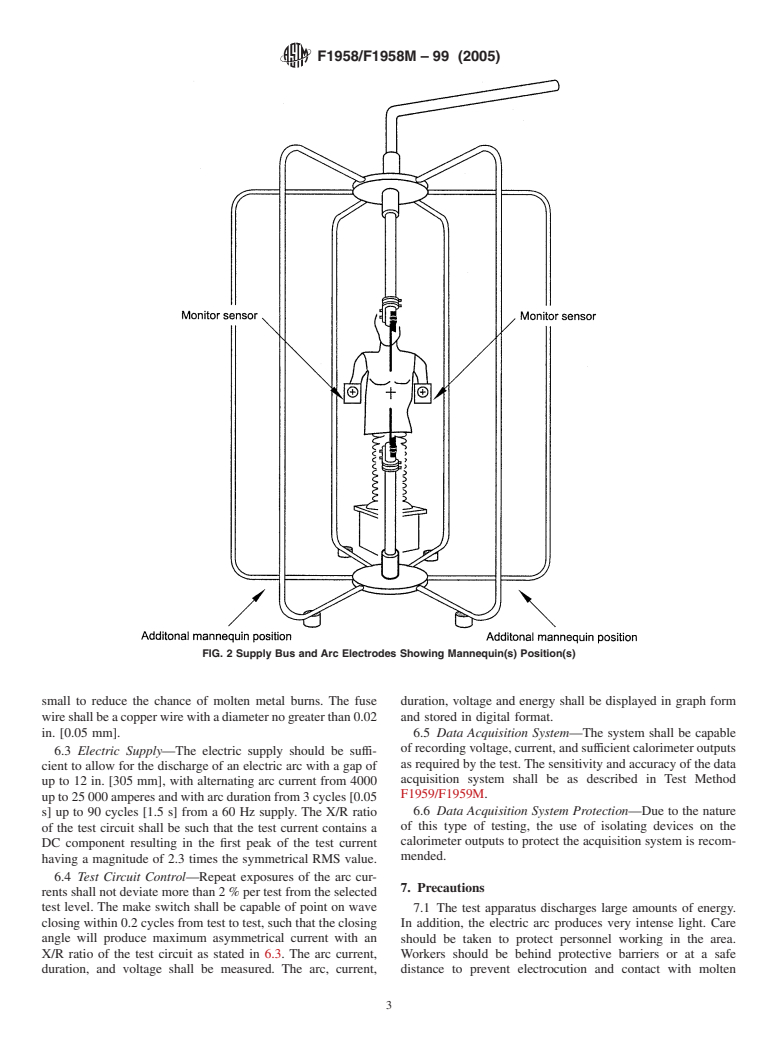

4. Summary of Test Method 6.2 Supply Bus and Electrodes—A typical arrangement of

the supply bus and arc electrodes is shown in Fig. 2. The arc

4.1 This test method exposes a material to heat energy from

shall be in a vertical position as shown.

anelectricarc,anddetermines(a)theincidentexposureenergy

6.2.1 Electrodes—Make the electrodes from stainless steel

that causes ignition, and (b) the probability of ignition.

(Alloy Type 303 or Type 304) rod of a nominal ⁄4 –in. [19–

4.1.1 During this procedure, a material is observed for

mm] diameter. Lengths of 18 in. [450 mm] long initially have

ignitability during and after exposure to an electric arc.

been found to be adequate.

4.2 Materialperformanceisdeterminedfromtheignitability

6.2.2 Fuse Wire—A fuse wire, connecting the ends of

of the specimen(s).

opposing electrodes tips, is used to initiate the arc. This wire is

5. Significance and Use

consumed during the test; therefore, its mass shall be very

5.1 This test method determines the ignitability of materials

in single or multiple layers.

5.1.1 Material performance shall be determined from the

ignitability of the specimen(s) and shall be reported as a

probability of ignition at various incident energy levels.

5.1.2 Materials which meet the flame resistance require-

ments of Specification F1506 do not require testing by this test

method unless the mechanism of passing Specification F1506

involves melting and escape from the flame source (for

example, coated fabrics, certain rainwear fabrics).

5.2 This test method maintains the specimen in a static,

vertical position and does not involve movement except that

resulting from the exposure.

5.3 This test method specifies a standard set of exposure

conditions. Different exposure conditions may produce differ-

ent results. In addition to the standard set of exposure condi-

tions, other conditions representative of the expected hazard

may be used. FIG. 1 Mannequin With Monitor Sensors

F1958/F1958M – 99 (2005)

FIG. 2 Supply Bus and Arc Electrodes Showing Mannequin(s) Position(s)

small to reduce the chance of molten metal burns. The fuse duration, voltage and energy shall be displayed in graph form

wireshallbeacopperwirewithadiameternogreaterthan0.02 and stored in digital format.

in. [0.05 mm]. 6.5 Data Acquisition System—The system shall be capable

of recording voltage, current, and sufficient calorimeter outputs

6.3 Electric Supply—The electric supply should be suffi-

as required by the test. The sensitivity and accuracy of the data

cient to allow for the discharge of an electric arc with a gap of

acquisition system shall be as described in Test Method

up to 12 in. [305 mm], with alternating arc current from 4000

F1959/F1959M.

upto25000amperesandwitharcdurationfrom3cycles[0.05

6.6 Data Acquisition System Protection—Due to the nature

s] up to 90 cycles [1.5 s] from a 60 Hz supply. The X/R ratio

of this type of testing, the use of isolating devices on the

of the test circuit shall be such that the test current contains a

calorimeter outputs to protect the acquisition system is recom-

DC component resulting in the first peak of the test current

mended.

having a magnitude of 2.3 times the symmetrical RMS value.

6.4 Test Circuit Control—Repeat exposures of the arc cur-

7. Precautions

rents shall not deviate more than 2 % per test from the selected

test level. The make switch shall be capable of point on wave 7.1 The test apparatus discharges large amounts of energy.

closing within 0.2 cycles from test to test, such that the closing

In addition, the electric arc produces very intense light. Care

angle will produce maximum asymmetrical current with an should be taken to protect personnel working in the area.

X/R ratio of the test circuit as stated in 6.3. The arc current, Workers should be behind protective barriers or at a safe

duration, and voltage shall be measured. The arc, current, distance to prevent electrocution and contact with molten

F1958/F1958M – 99 (2005)

8.2 Conditioning of Test Specimens:

8.2.1 Launder the required number of test specimens.

8.2.1.1 Launder three times in a washing machine using

commercially available detergent without chlorine bleach and

with a warm 120°F (50°C) water setting.

NOTE 1—Drying is not required following the first two launderings.

8.2.1.2 Following the three laundering cycles, tumble dry in

a dryer on a setting appropriate for the fabric. Remove

specimens when dry.

8.2.1.3 Samples may be restored to a flat condition by

pressing.

8.2.2 For those materials that require cleaning other than

laundering, follow the manufacturer’s recommended practice

and note the procedure used in the test reports.

9. Calibration and Standardization

9.1 Data Collection System Precalibration—The data col-

lection system shall be calibrated by using a thermocouple

calibrator/simulator. This will allow calibrations to be made at

FIG. 3 Arrangement of Mannequin(s)

multiple points and at levels above 100°C. Due to the nature of

the tests frequent calibration checks are recommended.

metal. Workers wishing to directly view the test should use

9.2 Calorimeter Calibration Check—Calorimeters shall be

very heavily tinted glasses such asANSI/ASC Filter Shade 12

checked to verify proper operation. Measure and graph the

welding glasses. If the test is conducted indoors, there shall be

temperature rise of each calorimeter and system response. At

a means to ventilate the area to carry away combustion

30 s no one calorimeter response shall vary by more than 4°C

products, smoke, and fumes. Air currents can disturb the arc,

from the average of all calorimeters. Any calorimeter not

reducing the heatflux at the surface of any of the calorimeters.

meeting this requirement shall be suspected of faulty connec-

The test apparatus should be shielded by non-combustible

tions and shall be replaced or repaired.

materials suitable for the test area. Outdoor tests shall be

NOTE 2—One acceptable method is to expose each calorimeter to a

conducted in a manner appropriate to prevent exposure of the

fixed radiant energy source for 30s. For example, place the front surface

testspecimentomoistureandwind(theelements).Theleadsto

of a 500 W spot light 10.5 in. from the calorimeter. The spot shall be

the test apparatus should be positioned to prevent blowout of

centered on and perpendicular to the calorimeter.

the electric arc. The test apparatus should be insulated from

9.3 Arc Exposure Calibration—Prior to each calibration,

ground for the appropriate test voltage.

position the electrodes of the test apparatus to produce a 12–in.

7.2 The test apparatus, electrodes and calorimeter assem-

[305–mm] gap. The face of the monitor sensors shall be

blies become hot during testing. Use protective gloves when

parallel and normal to the centerline of the electrodes. The

handling these hot objects.

midpoint of the electrode gap shall be at the same elevation as

7.3 Use care when the specimen ignites or releases combus-

thecenterpointofthemonitorsensors(seeFig.1).Connectthe

tible gases. An appropriate fire extinguisher should be readil

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.