ASTM D6317-98

(Test Method)Standard Test Method for Low Level Determination of Total Carbon, Inorganic Carbon and Organic Carbon in Water by Ultraviolet, Persulfate Oxidation, and Membrane Conductivity Detection

Standard Test Method for Low Level Determination of Total Carbon, Inorganic Carbon and Organic Carbon in Water by Ultraviolet, Persulfate Oxidation, and Membrane Conductivity Detection

SCOPE

1.1 This test method covers the determination of total carbon (TC), inorganic carbon (IC), and total organic carbon (TOC) in water in the range from 10 to 1000 ug/L of carbon. This method is for laboratory or grab sample applications and has been subjected to an interlaboratory study under the guidelines of D2777. Test Method D5997 can be used for on-line determinations. The test method utilizes persulfate or ultraviolet oxidation of organic carbon, or both coupled with a CO2 selective membrane to recover the CO2 into deionized water. The change in conductivity of the deionized water is measured and related to carbon concentration in the oxidized sample. Inorganic carbon is determined in a similar manner without the oxidation step. In both cases, the sample is acidified to facilitate CO2 recovery through the membrane. The relationship between the conductivity measurement and the carbon concentration is described by a set of chemometric equations for the chemical equilibrium of CO2, HCO3-, and H, and the relationship between the ionic concentrations and the conductances resulting in linear response of the method over the stated range of TOC. See Test Method D4519 for a discussion of the measurement of CO2 by conductivity.

1.2 This test method has the advantage of a very high sensitivity detector that allows very low detection levels on relatively small volumes of sample. Also, use of two measurement channels allows determination of CO2 in the sample independently of organic carbon. Isolation of the conductivity detector from the sample by the CO2 selective membrane results in a very stable calibration, with minimal interferences.

1.3 This test method was used successfully with reagent water spiked with various organic materials. It is the user's responsibility to ensure the validity of this test method for waters of untested matrices.

1.4 In addition to laboratory analyses, this test method may be adapted to on line monitoring. See Test Method D5997.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 6317 – 98

Standard Test Method for

Low Level Determination of Total Carbon, Inorganic Carbon

and Organic Carbon in Water by Ultraviolet, Persulfate

Oxidation, and Membrane Conductivity Detection

This standard is issued under the fixed designation D 6317; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of total

responsibility of the user of this standard to establish appro-

carbon (TC), inorganic carbon (IC), and total organic carbon

priate safety and health practices and determine the applica-

(TOC) in water in the range from 10 to 1000 μg/L of carbon.

bility of regulatory limitations prior to use.

This method is for laboratory or grab sample applications and

has been subjected to an interlaboratory study under the

2. Referenced Documents

guidelines of D 2777. Test Method D 5997 can be used for

2.1 ASTM Standards:

on-line determinations. The test method utilizes persulfate or

D 1129 Terminology Relating to Water

ultraviolet oxidation of organic carbon, or both coupled with a

D 1192 Specification for Equipment for Sampling Water

CO selective membrane to recover the CO into deionized

2 2

and Steam

water. The change in conductivity of the deionized water is

D 1193 Specification for Reagent Water

measured and related to carbon concentration in the oxidized

D 2777 Practice for Determination of Precision and Bias of

sample. Inorganic carbon is determined in a similar manner

Applicable Methods of Committee D-19 on Water

without the oxidation step. In both cases, the sample is

D 3370 Practices for Sampling Water from Closed Con-

acidified to facilitate CO recovery through the membrane. The

duits

relationship between the conductivity measurement and carbon

D 4210 Practice for Intralaboratory Quality Control Proce-

concentration is described by a set of chemometric equations

– +

dures and a Discussion on Reporting Low-Level Data

for the chemical equilibrium of CO , HCO , and H , and the

2 3

D 5997 Test Method for On-Line Monitoring of Total Car-

relationship between the ionic concentrations and the conduc-

bon, Inorganic Carbon in Water by Ultraviolet, Persulfate

tivity. The chemometric model includes the temperature de-

Oxidation, and Membrane Conductivity Detection

pendence of the equilibrium constants and the specific conduc-

D 4519 Test Method for Determination of Anions and

tances resulting in linear response of the method over the stated

Carbon Dioxide in High Purity Water by Cation Exchange

range of TOC. See Test Method D 4519 for a discussion of the

and Degassed Cation Conductivity

measurement of CO by conductivity.

1.2 This test method has the advantage of a very high

3. Terminology

sensitivity detector that allows very low detection levels on

3.1 Definitions— For definitions of terms used in this test

relatively small volumes of sample. Also, use of two measure-

method, refer to Terminology D 1129.

ment channels allows determination of CO in the sample

3.2 Definitions of Terms Specific to This Standard:

independently of organic carbon. Isolation of the conductivity

3.2.1 inorganic carbon (IC)—carbon in the form of carbon

detector from the sample by the CO selective membrane

dioxide, carbonate ion, or bicarbonate ion.

results in a very stable calibration, with minimal interferences.

3.2.2 refractory material—that which cannot be oxidized

1.3 This test method was used successfully with reagent

completely under the test method conditions.

water spiked with various organic materials. It is the user’s

3.2.3 total carbon (TC)—the sum of IC and TOC.

responsibility to ensure the validity of this test method for

3.2.4 total organic carbon (TOC)—carbon in the form of

waters of untested matrices.

organic compounds.

1.4 In addition to laboratory analyses, this test method may

be adapted to on line monitoring. See Test Method D 5997.

4. Summary of Test Method

4.1 Carbon can occur in water as inorganic and organic

compounds. This test method can be used to make independent

This test method is under the jurisdiction of ASTM Committee D19 on Water

and is the direct responsibility of Subcommittee D19.03 on Sampling of Water and

Water-Formed Deposits, Surveillance of Water, and Flow Measurement of Water.

Current edition approved Sept. 10, 1998. Published November 1998. Annual Book of ASTM Standards, Vol. 11.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6317–98

FIG. 1 Schematic Diagram of TOC Analyzer System

measurements of IC and TC and can also determine TOC as the membranes that allow the specific passage of CO to high

difference of TC and IC. If IC is high relative to TOC it is purity water where change in conductivity is measured and;

desirable to use a vacuum degassing unit to reduce the IC (4) Conversion of the conductivity detector signal to a

concentration as part of the measurement. Alternatively, the IC display of carbon concentration in parts per million

can be removed by acidifying and sparging the sample prior to (ppm=mg/L) or parts per billion (ppb=μg/L). The IC channel

injection into the instrument. The basic steps of the procedure reading is subtracted from the TC channel to give a TOC

are as follows: reading. A diagram of suitable apparatus is given in Fig. 1.

(1) Removal of IC, if desired, by vacuum degassing; References 1-5 provide additional information on the method.

(2) Conversion of remaining inorganic carbon to CO by

5. Significance and Use

action of acid in both channels and oxidation of total carbon to

5.1 This test method is used for determination of the carbon

CO by action of ultraviolet (UV) radiation in the TC channel.

content of water from a variety of natural, domestic, and

(Acid-persulfate can be added but is usually not required at

TOC levels below 1 ppm).

(3) Detection of CO that is swept out of the U.V. reactor

2 The boldface numbers in parentheses refer to the list of references found at the

and delay coil by the liquid stream and passed through end of this Test Method.

D6317–98

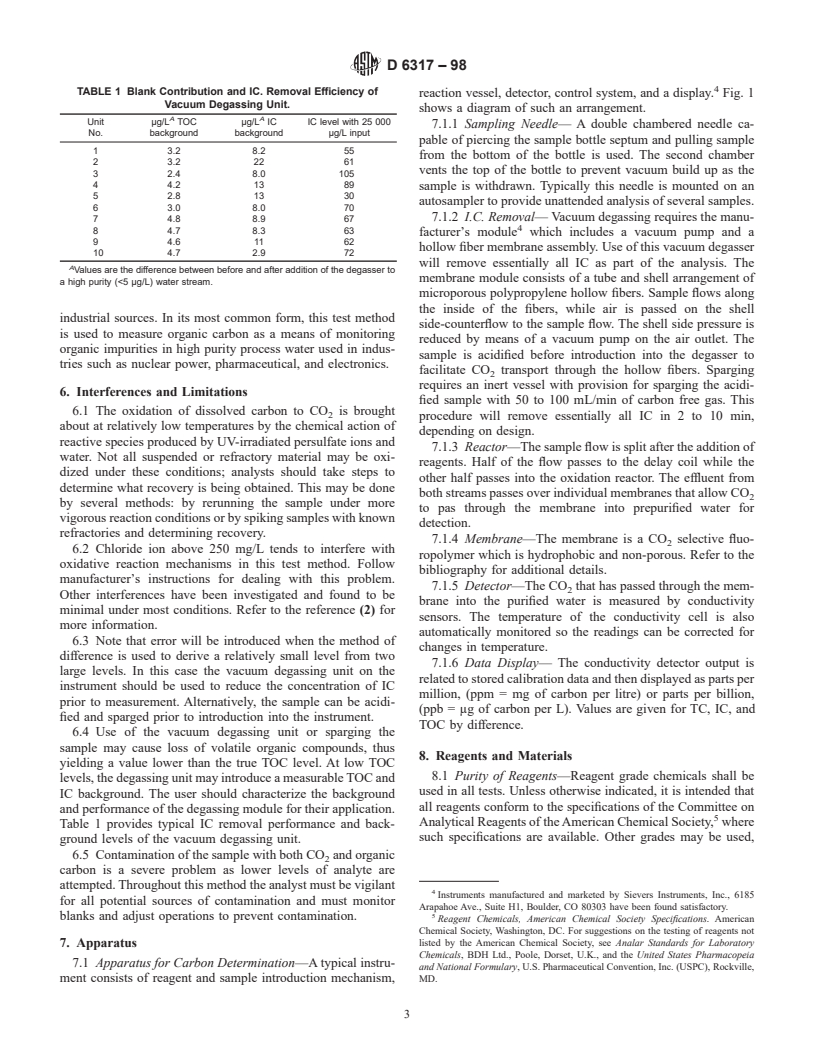

TABLE 1 Blank Contribution and IC. Removal Efficiency of

reaction vessel, detector, control system, and a display. Fig. 1

Vacuum Degassing Unit.

shows a diagram of such an arrangement.

A A

Unit μg/L TOC μg/L IC IC level with 25 000

7.1.1 Sampling Needle— A double chambered needle ca-

No. background background μg/L input

pable of piercing the sample bottle septum and pulling sample

1 3.2 8.2 55

from the bottom of the bottle is used. The second chamber

2 3.2 22 61

vents the top of the bottle to prevent vacuum build up as the

3 2.4 8.0 105

4 4.2 13 89

sample is withdrawn. Typically this needle is mounted on an

5 2.8 13 30

autosampler to provide unattended analysis of several samples.

6 3.0 8.0 70

7.1.2 I.C. Removal— Vacuum degassing requires the manu-

7 4.8 8.9 67

8 4.7 8.3 63

facturer’s module which includes a vacuum pump and a

9 4.6 11 62

hollow fiber membrane assembly. Use of this vacuum degasser

10 4.7 2.9 72

will remove essentially all IC as part of the analysis. The

A

Values are the difference between before and after addition of the degasser to

membrane module consists of a tube and shell arrangement of

a high purity (<5 μg/L) water stream.

microporous polypropylene hollow fibers. Sample flows along

the inside of the fibers, while air is passed on the shell

industrial sources. In its most common form, this test method

side-counterflow to the sample flow. The shell side pressure is

is used to measure organic carbon as a means of monitoring

reduced by means of a vacuum pump on the air outlet. The

organic impurities in high purity process water used in indus-

sample is acidified before introduction into the degasser to

tries such as nuclear power, pharmaceutical, and electronics.

facilitate CO transport through the hollow fibers. Sparging

requires an inert vessel with provision for sparging the acidi-

6. Interferences and Limitations

fied sample with 50 to 100 mL/min of carbon free gas. This

6.1 The oxidation of dissolved carbon to CO is brought

procedure will remove essentially all IC in 2 to 10 min,

about at relatively low temperatures by the chemical action of

depending on design.

reactive species produced by UV-irradiated persulfate ions and

7.1.3 Reactor—The sample flow is split after the addition of

water. Not all suspended or refractory material may be oxi-

reagents. Half of the flow passes to the delay coil while the

dized under these conditions; analysts should take steps to

other half passes into the oxidation reactor. The effluent from

determine what recovery is being obtained. This may be done

both streams passes over individual membranes that allow CO

by several methods: by rerunning the sample under more

to pas through the membrane into prepurified water for

vigorous reaction conditions or by spiking samples with known

detection.

refractories and determining recovery.

7.1.4 Membrane—The membrane is a CO selective fluo-

6.2 Chloride ion above 250 mg/L tends to interfere with

ropolymer which is hydrophobic and non-porous. Refer to the

oxidative reaction mechanisms in this test method. Follow

bibliography for additional details.

manufacturer’s instructions for dealing with this problem.

7.1.5 Detector—The CO that has passed through the mem-

Other interferences have been investigated and found to be

brane into the purified water is measured by conductivity

minimal under most conditions. Refer to the reference (2) for

sensors. The temperature of the conductivity cell is also

more information.

automatically monitored so the readings can be corrected for

6.3 Note that error will be introduced when the method of

changes in temperature.

difference is used to derive a relatively small level from two

7.1.6 Data Display— The conductivity detector output is

large levels. In this case the vacuum degassing unit on the

related to stored calibration data and then displayed as parts per

instrument should be used to reduce the concentration of IC

million, (ppm = mg of carbon per litre) or parts per billion,

prior to measurement. Alternatively, the sample can be acidi-

(ppb = μg of carbon per L). Values are given for TC, IC, and

fied and sparged prior to introduction into the instrument.

TOC by difference.

6.4 Use of the vacuum degassing unit or sparging the

sample may cause loss of volatile organic compounds, thus

8. Reagents and Materials

yielding a value lower than the true TOC level. At low TOC

8.1 Purity of Reagents—Reagent grade chemicals shall be

levels, the degassing unit may introduce a measurable TOC and

used in all tests. Unless otherwise indicated, it is intended that

IC background. The user should characterize the background

all reagents conform to the specifications of the Committee on

and performance of the degassing module for their application.

Analytical Reagents of the American Chemical Society, where

Table 1 provides typical IC removal performance and back-

such specifications are available. Other grades may be used,

ground levels of the vacuum degassing unit.

6.5 Contamination of the sample with both CO and organic

carbon is a severe problem as lower levels of analyte are

attempted. Throughout this method the analyst must be vigilant

Instruments manufactured and marketed by Sievers Instruments, Inc., 6185

for all potential sources of contamination and must monitor

Arapahoe Ave., Suite H1, Boulder, CO 80303 have been found satisfactory.

blanks and adjust operations to prevent contamination.

Reagent Chemicals, American Chemical Society Specifications. American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

7. Apparatus

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

7.1 Apparatus for Carbon Determination—A typical instru-

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

ment consists of reagent and sample introduction mechanism, MD.

D6317–98

provided it is first ascertained that the reagent is of sufficient 9.3 To preserve samples for this analysis, store samples in

purity to permit its use without lessening the accuracy of the glass at 4 °C. To aid preservation, acidify the samples to a pH

determination. of 2. It should be noted that acidification will enhance loss of

8.2 Purity of Water— Unless otherwise indicated, refer- inorganic carbon. If the purgeable organic fraction is important,

ences to water shall be understood to mean reagent water fill the sample bottles to overflowing with a minimum of

conforming to Type I or Type II in Specification D 1193. The turbulence and cap them using a fluoropolymer-lined cap,

indicated specification does not actually specify inorganic without headspace.

carbon or organic carbon levels. These levels can affect the 9.4 For water samples where carbon concentrations are

results of this test method, especially at progressively lower greater than the desired range of instrument operation, dilute

levels of the carbon content in the samples to be measured. the samples as necessary.

Where inorganic carbon in reagent water is significant, CO - 9.5 For accurate measurements of samples containing < 0.5

free water may be prepared from reagent water by acidifying to mg/L stringent measures must be taken to minimize contami-

pH 2, then sparging with fritted-glass sparger using CO -free nation. Low level samples exposed to ambient air will gener-

gas (time will depend on volume and gas flow rate, and should ally increase in both inorganic and organic carbon. Sample

be determined by test). The carbon contribution of the reagent container and all sampling devices must be clean and exposure

water should be determined and its effect allowed for in of the sample to the atmosphere must be minimized. Blanks

preparation of standards and other solutions. CO -free water should be carried through all steps of the sampling and analysis

should be protected from atmospheric contamination. Glass procedure to check for contamination.

containers are required for storage of water and standard

solutions. Continuous U.V. treatment of water with recycling

10. Instrument Operation

through appropriate mixed bed ion exchange resins

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.