ASTM D2972-15(2023)

(Test Method)Standard Test Methods for Arsenic in Water

Standard Test Methods for Arsenic in Water

SIGNIFICANCE AND USE

4.1 Herbicides, insecticides, and many industrial effluents contain arsenic and are potential sources of water pollution. Arsenic is significant because of its adverse physiological effects on humans.

SCOPE

1.1 These test methods2 cover the photometric and atomic absorption determination of arsenic in most waters and wastewaters. Three test methods are given as follows:

Concentration

Range

Sections

Test Method A—Silver Diethyldithio-

carbamate Colorimetric

5 μg/L to 250 μg/L

7 to 16

Test Method B—Atomic Absorption,

Hydride Generation

1 μg/L to 20 μg/L

17 to 26

Test Method C—Atomic Absorption,

Graphite Furnace

5 μg/L to 100 μg/L

27 to 36

1.2 The analyst should direct attention to the precision and bias statements for each test method. It is the user's responsibility to ensure the validity of these test methods for waters of untested matrices.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 11.1 and 20.2.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2972 − 15 (Reapproved 2023)

Standard Test Methods for

Arsenic in Water

This standard is issued under the fixed designation D2972; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 These test methods cover the photometric and atomic

D1129 Terminology Relating to Water

absorption determination of arsenic in most waters and waste-

D1193 Specification for Reagent Water

waters. Three test methods are given as follows:

D2777 Practice for Determination of Precision and Bias of

Concentration Sections

Applicable Test Methods of Committee D19 on Water

Range

Test Method A—Silver Diethyldithio- 5 μg ⁄L to 250 μg ⁄L 7 to 16 D3370 Practices for Sampling Water from Flowing Process

carbamate Colorimetric

Streams

Test Method B—Atomic Absorption, 1 μg ⁄L to 20 μg/L 17 to 26

D3919 Practice for Measuring Trace Elements in Water by

Hydride Generation

Test Method C—Atomic Absorption, 5 μg ⁄L to 100 μg/L 27 to 36

Graphite Furnace Atomic Absorption Spectrophotometry

Graphite Furnace

D4841 Practice for Estimation of Holding Time for Water

Samples Containing Organic and Inorganic Constituents

1.2 The analyst should direct attention to the precision and

D5810 Guide for Spiking into Aqueous Samples

bias statements for each test method. It is the user’s responsi-

D5673 Test Method for Elements in Water by Inductively

bility to ensure the validity of these test methods for waters of

Coupled Plasma—Mass Spectrometry

untested matrices.

D5847 Practice for Writing Quality Control Specifications

1.3 The values stated in SI units are to be regarded as

for Standard Test Methods for Water Analysis

standard. The values given in parentheses are mathematical

E60 Practice for Analysis of Metals, Ores, and Related

conversions to inch-pound units that are provided for informa-

Materials by Spectrophotometry

tion only and are not considered standard.

E275 Practice for Describing and Measuring Performance of

Ultraviolet and Visible Spectrophotometers

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions:

priate safety, health, and environmental practices and deter-

3.1.1 For definitions of terms used in these test methods,

mine the applicability of regulatory limitations prior to use.

refer to Terminology D1129.

For specific hazard statements, see 11.1 and 20.2.

3.2 Definitions of Terms Specific to This Standard:

1.5 This international standard was developed in accor-

3.2.1 total recoverable arsenic, n—a descriptive term relat-

dance with internationally recognized principles on standard-

ing to the arsenic forms recovered in the acid-digestion

ization established in the Decision on Principles for the

procedure specified in these test methods.

Development of International Standards, Guides and Recom-

3.2.1.1 Discussion—Some organic-arsenic compounds,

mendations issued by the World Trade Organization Technical

such as phenylarsonic acid, disodium methane arsonate, and

Barriers to Trade (TBT) Committee. dimethylarsonic acid, are not recovered completely during the

digestion step.

4. Significance and Use

These test methods are under the jurisdiction of ASTM Committee D19 on

4.1 Herbicides, insecticides, and many industrial effluents

Water and are the direct responsibility of Subcommittee D19.05 on Inorganic

contain arsenic and are potential sources of water pollution.

Constituents in Water.

Current edition approved Dec. 1, 2023. Published December 2023. Originally

Arsenic is significant because of its adverse physiological

approved in 1993. Last previous edition approved in 2015 as D2972 – 15. DOI:

effects on humans.

10.1520/D2972-15R23.

Similar to that appearing in Standard Methods for the Examination of Water

and Wastewater, 12th edition, APHA, Inc., New York, NY, 1965; and identical with For referenced ASTM standards, visit the ASTM website, www.astm.org, or

that in Brown, E., Skougstad, M. W., and Fishman, M. J., “Methods for Collection contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and Analysis of Water Samples for Dissolved Minerals and Gases,” Techniques of Standards volume information, refer to the standard’s Document Summary page on

Water-Resources Investigations of the U.S. Geological Survey, Book 5, 1970, p. 46. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2972 − 15 (2023)

5. Purity of Reagents stannous chloride, and finally to gaseous arsine by zinc in

hydrochloric acid solution. The resulting mixture of gases is

5.1 Reagent grade chemicals shall be used in all tests.

passed through a scrubber containing borosilicate wool im-

Unless otherwise indicated, it is intended that all reagents shall

pregnated with lead acetate solution and then into an absorp-

conform to the specifications of the Committee on Analytical

tion tube containing a solution of silver diethyldithiocarbamate

Reagents of the American Chemical Society, where such

in pyridine. Arsine reacts with this reagent to form a red-

specifications are available. Other grades may be used, pro-

colored silver sol having maximum absorbance at about

vided it is first ascertained that the reagent is of sufficiently

540 nm. The absorbance of the solution is measured photo-

high purity to permit its use without lessening the accuracy of

metrically and the arsenic determined by reference to an

the determination.

analytical curve prepared from standards.

5.2 Purity of Water—Unless otherwise indicated, references

to water shall be understood to mean reagent water conforming

9. Interferences

to Specification D1193, Type I. Other reagent water types may

9.1 Although many samples are relatively free of

be used provided it is first ascertained that the water is of

interferences, several metals, notably cobalt, nickel, mercury,

sufficiently high purity to permit its use without adversely

silver, platinum, copper, chromium, and molybdenum, may

affecting the bias and precision of the test method. Type II

interfere with the evolution of arsine and with the recovery of

water was specified at the time of round robin testing of these

arsenic. The presence of any or all of these metals in a sample

test methods.

being analyzed must be considered as a potential source of

interference, and the analyst must fully determine the extent of

6. Sampling

actual interference, if any. This could be accomplished by

6.1 Collect the sample in accordance with Practices D3370.

spiking.

6.2 Preserve the samples with HNO (sp gr 1.42) to a pH of

9.2 Hydrogen sulfide and other sulfides interfere, but com-

2 or less immediately at the time of collection; normally about

monly encountered quantities are effectively removed by the

2 mL/L is required. If only dissolved arsenic is to be

lead acetate scrubber and the digestion.

determined, filter the sample through a 0.45 μm membrane

9.3 Antimony interferes by forming stibine, which distills

filter before acidification. The holding times for the samples

along with the arsine. Stibine reacts with the color-forming

may be calculated in accordance with Practice D4841.

reagent to form a somewhat similar red sol having maximum

NOTE 1—Alternatively, the pH may be adjusted in the laboratory if the

absorbance near 510 nm. The sensitivity for antimony at

sample is returned within 14 days. However, acid must be added at least

540 nm is only about 8 % that of arsenic (1 mg/L of antimony

24 h before analysis to dissolve any metals that adsorb to the container

will show an apparent presence of 0.08 mg/L of arsenic).

walls. This could reduce hazards of working with acids in the field when

appropriate.

9.4 Nitric acid interferes with the test and must be com-

pletely eliminated during the digestion.

TEST METHOD A—SILVER

DIETHYLDITHIOCARBAMATE COLORIMETRIC

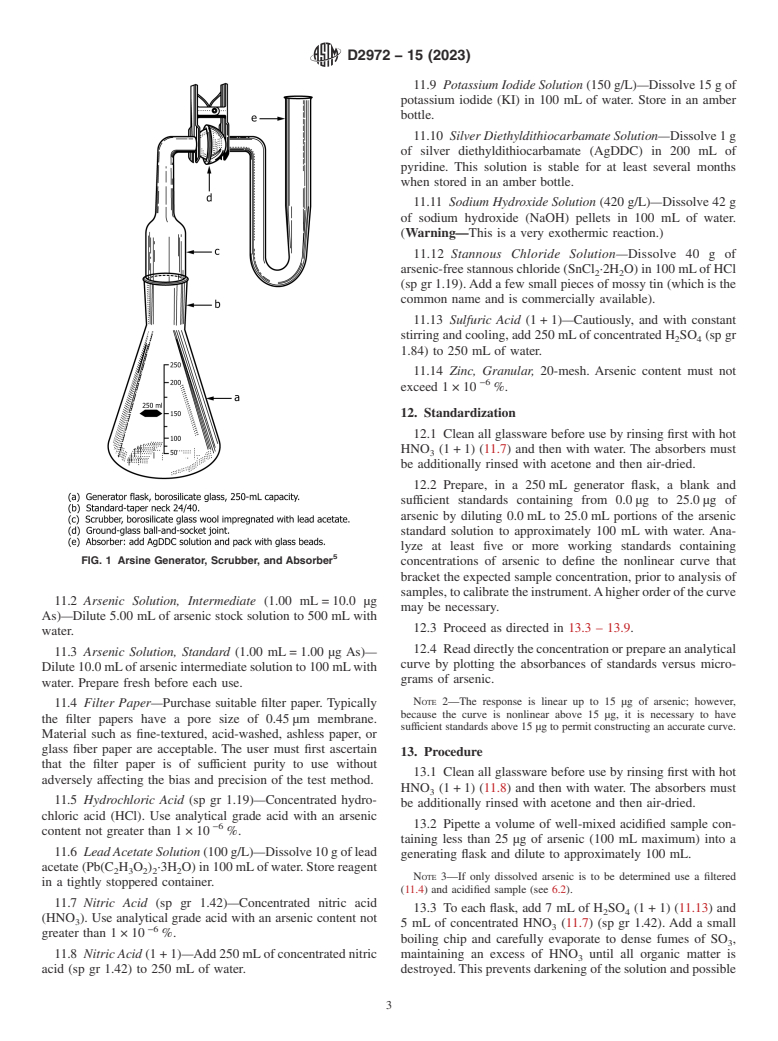

10. Apparatus

7. Scope

10.1 Arsine Generator, Scrubber, and Absorber, assembled

7.1 This test method covers the determination of dissolved

as shown in Fig. 1.

and total recoverable arsenic in most waters and waste waters

10.2 Spectrophotometer or Filter Photometer, suitable for

in the range from 5 μg ⁄L to 250 μg ⁄L of arsenic.

use at 540 nm and providing a light path of at least 10 mm. The

7.2 The precision and bias data were obtained on reagent

filter photometer and photometric practice prescribed in this

water, river water, and process water. The information on

method shall conform to Practice E60. The spectrophotometer

precision and bias may not apply to other waters. It is the user’s

shall conform to Practice E275.

responsibility to ensure the validity of this test method for

waters of untested matrices.

11. Reagents and Materials

11.1 Arsenic Solution, Stock (1.00 mL = 1.00 mg As)—

8. Summary of Test Method

Commercially purchase or dissolve 1.320 g of arsenic trioxide

8.1 Organic arsenic-containing compounds are decomposed

(As O ) (Warning—Arsenic trioxide is extremely toxic. Avoid

2 3

by adding sulfuric and nitric acids and repeatedly evaporating

ingestion or inhalation of dry powder during standard prepa-

the sample to fumes of sulfur trioxide. The arsenic (V) so

ration. Wash hands thoroughly immediately after handling

produced, together with inorganic arsenic originally present, is

arsenic trioxide. Under no circumstances pipette any arsenic

subsequently reduced to arsenic (III) by potassium iodide and

solutions by mouth.), dried for at least 1 h at 110 °C, in 10 mL

of NaOH solution (420 g/L) and dilute to 1 L with water. This

solution is stable. A purchased arsenic stock solution of

ACS Reagent Chemicals, Specifications and Procedures for Reagents and

appropriate known purity is acceptable.

Standard-Grade Reference Materials, American Chemical Society, Washington,

DC. For suggestions on the testing of reagents not listed by the American Chemical

Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

copeial Convention, Inc. (USPC), Rockville, MD. Available commercially.

D2972 − 15 (2023)

11.9 Potassium Iodide Solution (150 g/L)—Dissolve 15 g of

potassium iodide (KI) in 100 mL of water. Store in an amber

bottle.

11.10 Silver Diethyldithiocarbamate Solution—Dissolve 1 g

of silver diethyldithiocarbamate (AgDDC) in 200 mL of

pyridine. This solution is stable for at least several months

when stored in an amber bottle.

11.11 Sodium Hydroxide Solution (420 g/L)—Dissolve 42 g

of sodium hydroxide (NaOH) pellets in 100 mL of water.

(Warning—This is a very exothermic reaction.)

11.12 Stannous Chloride Solution—Dissolve 40 g of

arsenic-free stannous chloride (SnCl ·2H O) in 100 mL of HCl

2 2

(sp gr 1.19). Add a few small pieces of mossy tin (which is the

common name and is commercially available).

11.13 Sulfuric Acid (1 + 1)—Cautiously, and with constant

stirring and cooling, add 250 mL of concentrated H SO (sp gr

2 4

1.84) to 250 mL of water.

11.14 Zinc, Granular, 20-mesh. Arsenic content must not

−6

exceed 1 × 10 %.

12. Standardization

12.1 Clean all glassware before use by rinsing first with hot

HNO (1 + 1) (11.7) and then with water. The absorbers must

be additionally rinsed with acetone and then air-dried.

12.2 Prepare, in a 250 mL generator flask, a blank and

sufficient standards containing from 0.0 μg to 25.0 μg of

arsenic by diluting 0.0 mL to 25.0 mL portions of the arsenic

standard solution to approximately 100 mL with water. Ana-

lyze at least five or more working standards containing

FIG. 1 Arsine Generator, Scrubber, and Absorber

concentrations of arsenic to define the nonlinear curve that

bracket the expected sample concentration, prior to analysis of

samples, to calibrate the instrument. A higher order of the curve

11.2 Arsenic Solution, Intermediate (1.00 mL = 10.0 μg

may be necessary.

As)—Dilute 5.00 mL of arsenic stock solution to 500 mL with

12.3 Proceed as directed in 13.3 – 13.9.

water.

12.4 Read directly the concentration or prepare an analytical

11.3 Arsenic Solution, Standard (1.00 mL = 1.00 μg As)—

curve by plotting the absorbances of standards versus micro-

Dilute 10.0 mL of arsenic intermediate solution to 100 mL with

grams of arsenic.

water. Prepare fresh before each use.

NOTE 2—The response is linear up to 15 μg of arsenic; however,

11.4 Filter Paper—Purchase suitable filter paper. Typically

because the curve is nonlinear above 15 μg, it is necessary to have

the filter papers have a pore size of 0.45 μm membrane.

sufficient standards above 15 μg to permit constructing an accurate curve.

Material such as fine-textured, acid-washed, ashless paper, or

glass fiber paper are acceptable. The user must first ascertain

13. Procedure

that the filter paper is of sufficient purity to use without

13.1 Clean all glassware before use by rinsing first with hot

adversely affecting the bias and precision of the test method.

HNO (1 + 1) (11.8) and then with water. The absorbers must

11.5 Hydrochloric Acid (sp gr 1.19)—Concentrated hydro-

be additionally rinsed with acetone and then air-dried.

chloric acid (HCl). Use analytical grade acid with an arsenic

13.2 Pipette a volume of well-mixed acidified sample con-

−6

content not greater than 1 × 10 %.

taining less than 25 μg of arsenic (100 mL maximum) into a

11.6 Lead Acetate Solution (100 g/L)—Dissolve 10 g of lead

generating flask and dilute to approximately 100 mL.

acetate (Pb(C H O ) ·3H O) in 100 mL of water. Store reagent

2 3 2 2 2

NOTE 3—If only dissolved arsenic is to be determined use a filtered

in a tightly stoppered container.

(11.4) and acidified sample (see 6.2).

11.7 Nitric Acid (sp gr 1.42)—Concentrated nitric acid

13.3 To each flask, add 7 mL of H SO (1 + 1) (11.13) and

2 4

(HNO ). Use analytical grade acid with an arsenic content not

5 mL of concentrated HNO (11.7) (sp gr 1.42). Add a small

−6

greater than 1 × 10 %.

boiling chip and carefully evaporate to dense fumes of SO ,

11.8 Nitric Acid (1 + 1)—Add 250 mL of concentrated nitric maintaining an excess of HNO until all organic matter is

acid (sp gr 1.42) to 250 mL of water. destroyed. This prevents darkening of the solution and possible

D2972 − 15 (2023)

T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.