ASTM B738-03(2008)

(Specification)Standard Specification for Fine-Wire Bunch-Stranded and Rope-Lay Bunch-Stranded Copper Conductors for Use as Electrical Conductors

Standard Specification for Fine-Wire Bunch-Stranded and Rope-Lay Bunch-Stranded Copper Conductors for Use as Electrical Conductors

ABSTRACT

This specification deals with bare fine-wire bunch-stranded and rope-lay bunch-stranded copper conductors made from round copper wires finer than No. 40 AWG, either coated or uncoated with tin or silver, for use as electrical conductors. The conductor types covered in this specification are designated Type B for bunch-stranded conductors, and Type R for rope-lay bunch-stranded conductors. On the other hand, the wire classifications are assigned as: Class R, stranded conductors using wire 42 AWG; Class S, stranded conductors using wire 44 AWG; Class T, stranded conductors using wire 46 AWG; Class U, stranded conductors using wire 48 AWG; and Class V, stranded conductors using wire 50 AWG. Wires shall undergo tests that shall evaluated their conformance to physical and electrical properties such as wire cross-sectional area and diameter, coating thickness, tensile strength, elongation, and DC resistance.

SCOPE

1.1 This specification covers bare bunch-stranded and rope-lay bunch-stranded conductors made from round copper wires finer than No. 40 AWG with diameters less than 0.0031 in. (.078 mm), either coated or uncoated with tin or silver, for use as electrical conductors. (Explanatory Note 1).

1.2 The values (SI units) for density and temperature are regarded as the standard. For all other properties the inch-pound values are to be regarded as standard, and the SI units may be approximate.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B738 −03(Reapproved 2008)

Standard Specification for

Fine-Wire Bunch-Stranded and Rope-Lay Bunch-Stranded

Copper Conductors for Use as Electrical Conductors

This standard is issued under the fixed designation B738; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Classification

3.1 For the purposes of this specification, the following

1.1 This specification covers bare bunch-stranded and rope-

classifications have been assigned (Explanatory Note 2):

lay bunch-stranded conductors made from round copper wires

3.1.1 Type:

finer than No. 40 AWG with diameters less than 0.0031 in.

(.078 mm), either coated or uncoated with tin or silver, for use 3.1.1.1 Type B—Bunch-stranded conductors.

3.1.1.2 Type R—Rope-lay bunch-stranded conductors.

as electrical conductors. (Explanatory Note 1).

3.1.2 Class:

1.2 The values (SI units) for density and temperature are

3.1.2.1 Class R—Stranded conductors using wire 42 AWG

regarded as the standard. For all other properties the inch-

(0.0025).

pound values are to be regarded as standard, and the SI units

3.1.2.2 Class S—Stranded conductors using wire 44 AWG

may be approximate.

(0.0020).

3.1.2.3 Class T—Stranded conductors using wire 46 AWG

2. Referenced Documents

(0.00157).

2.1 ASTM Standards: 3.1.2.4 Class U—Stranded conductors using wire 48 AWG

B33Specification for Tin-Coated Soft or Annealed Copper (0.00124).

Wire for Electrical Purposes 3.1.2.5 Class V—Stranded conductors using wire 50 AWG

B49Specification for Copper Rod Drawing Stock for Elec-

(0.00099).

trical Purposes

3.2 Detailed information on Type B Conductors is found in

B172Specification for Rope-Lay-Stranded Copper Conduc-

Table 1 and Table 2. Detailed information on Type R Conduc-

torsHavingBunch-StrandedMembers,forElectricalCon-

tors is found in Table 3 and Table 2.

ductors

B174Specification for Bunch-Stranded Copper Conductors

4. Ordering Information

for Electrical Conductors

4.1 Orders for materials under this specification shall in-

B193Test Method for Resistivity of Electrical Conductor

clude the following information:

Materials

4.1.1 Quantity of each size, class, and type,

B258 Specification for Nominal Diameters and Cross-

4.1.2 Conductor size—circular-mil area, dc resistance (7.1)

SectionalAreasofAWGSizesofSolidRoundWiresUsed

or AWG (5.2.1),

as Electrical Conductors

4.1.3 Class and type (Section 3),

B298Specification for Silver-Coated Soft orAnnealed Cop-

4.1.4 Whether coated or uncoated; if coated, designate type

per Wire

of coating (6.1); if silver coated, the minimum thickness of

B354Terminology Relating to Uninsulated Metallic Electri-

silver (6.1.2), and whether tarnish protection is desired (11.3),

cal Conductors

4.1.5 Maximum length of lay (5.2.4), if required,

4.1.6 Temper (6.2),

4.1.7 Separators, if required (5.2.2),

This specification is under the jurisdiction of ASTM Committee B01 on

4.1.8 Package size (11.1),

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

Conductors of Copper and Copper Alloys.

4.1.9 Specialpackagemarking,ifrequired(Section10),and

Current edition approved April 1, 2008. Published May 2008. Originally

4.1.10 Place of inspection (Section 9).

approved in 1984. Last previous edition approved in 2003 as B738–03. DOI:

10.1520/B0738-03R08.

4.2 In addition, Supplementary Requirements shall apply

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

onlywhenspecifiedbythepurchaserintheinquiry,contract,or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

purchase order for direct procurement by agencies of the U.S.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Government.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B738−03 (2008)

TABLE 1 Classification of Type B Bunch-Stranded Conductors

6.1.2 Silver coating shall conform to the minimum thick-

A

Class Wire Diameter, in. Conductor Sizes, AWG ness requirements of the purchase document. Minimum thick-

R 0.0025 (No. 42 AWG) 24,26,28,30,32,34 ness shall be determined using the method for determining

S 0.0020 (No. 44 AWG) 26,28,30,32,34,36

plating thickness described in Specification B298.

T 0.00157 (No. 46 AWG) 28,30,32,34,36,38

6.1.3 The finished diameter and mass of the coated wires

U 0.00124 (No. 48 AWG) 30,32,34,36,38,40

V 0.00099 (No. 50 AWG) 32,34,36,38,40 used shall be substantially equal to those of the uncoated wires

A

of the same class.

Sufficientquantitiesofwiresofthesediametersshallbeusedtoformconductors

having cross-sectional areas approximately equal to the AWG conductor sizes

6.2 Temper—Unless otherwise specified, all coated conduc-

listed.

tors shall be furnished in the annealed temper. Uncoated

conductors may be furnished either annealed or unannealed as

ordered (see 4.1.6).

NOTE 1—The term unannealed as used in this specification means

5. Materials and Manufacture

cold-worked conductor as produced on commercial wire-drawing ma-

5.1 The material shall be copper of such quality and purity

chines.

that the finished product shall have the properties and charac-

6.3 Tensile Strength and Elongation—The stranded conduc-

teristics described in this specification. Material meeting the

tor, in its finished form, shall conform to the following:

requirements of Specification B49 is such a material.

Tensile Strength, min. Elongation, min,

5.2 Construction: Finished State psi MPa 10 in. %

Unannealed 40 000 275 .

5.2.1 Cross-SectionalArea—The cross-sectional area, num-

Annealed . . 10

ber, and diameter of wires for a variety of strand constructions

in general use are shown in Table 2.

7. Electrical Properties

5.2.2 Separators—If a separator is required to be furnished

7.1 DC Resistance—The dc resistance in Ω/1000 ft of the

with the conductor, it shall be specified by the purchaser at the

bunch-stranded conductor shall not exceed the appropriate

time of the order as to the requirements for the kind and

values specified in Table 5. The dc resistance inΩ/1000 ft of

thickness of material and its application details.

the rope-lay bunch-stranded conductor shall not exceed the

5.2.3 Joints:

appropriate values specified in Table 6 (Explanatory Note 3

5.2.3.1 Necessary joints in wires shall be made in accor-

and Note 4).

dance with accepted commercial practice.

5.2.3.2 Joints shall be so constructed and so disposed

8. Test Methods

throughout the conductor that the diameter or configuration of

8.1 Coating—Teststodetermineconformanceofthecoating

the completed conductor is not substantially affected, and that

totherequirementsofSpecificationB33orSpecificationB298

the flexibility of the completed conductor is not adversely

shall be performed on the individual wires before stranding

affected.

(see 6.1.1 to 6.1.3).

5.2.4 Lay:

5.2.4.1 Conductors of the same size and description fur- 8.2 Tensile Strength and Elongation:

nished on one order shall have the same lay. 8.2.1 Tests to determine conformance to the tensile strength

5.2.4.2 The direction of the lay of bunch-stranded conduc- and elongation requirements of 6.3 shall be made on the

tors shall be at the option of the manufacturer unless otherwise finished stranded conductor.

specified by the purchaser. 8.2.2 Determine tensile strength, T , expressed in pounds

s

5.2.4.3 Unless otherwise specified by the purchaser, the per square inch as follows:

length of the lay of bare or coated bunch-stranded conductors

L

T 5

shall conform to the requirements of Table 4.

s

A

5.2.4.4 Thedirectionofthelayoftheouterlayerofrope-lay

where:

stranded conductors shall be lefthand, unless otherwise speci-

L = maximum load on the stranded conductor during the

fied by the purchaser.

5.2.4.5 The length of the lay of the outer layer of rope-lay tension test (see Explanatory Note 5), lbs, and

A = original cross-sectional area of the stranded conductor,

stranded conductors shall be not less than 8 or more than 16

in. /in. (see 8.2).

times the outside diameter of the completed conductor. The

length of the lay of the wires composing the bunch-stranded

8.2.3 The original cross-sectional area of the stranded con-

members shall be not more than 30 times the diameter of the

ductor shall be considered to be the cross-sectional area of the

member.

individualwirecalculatedfromthenominalwirediameter(see

Table 5) multiplied by the number of wires in the stranded

6. Physical Properties

conductor (Explanatory Note 6).

6.1 WireCoating—When coated, the coating of the wires of 8.2.4 Determine the elongation of the specimen as the

the stranded conductor, before stranding, shall conform to the permanent increase in length, expressed in percent of the

requirements of 6.1.1 or 6.1.2. original length, due to the breaking of the specimen in tension,

6.1.1 Tin coating shall conform to the coating requirements by measurements made between the jaws of testing machine.

of Specification B33. The zero length shall be the distance between the jaws at the

B738−03 (2008)

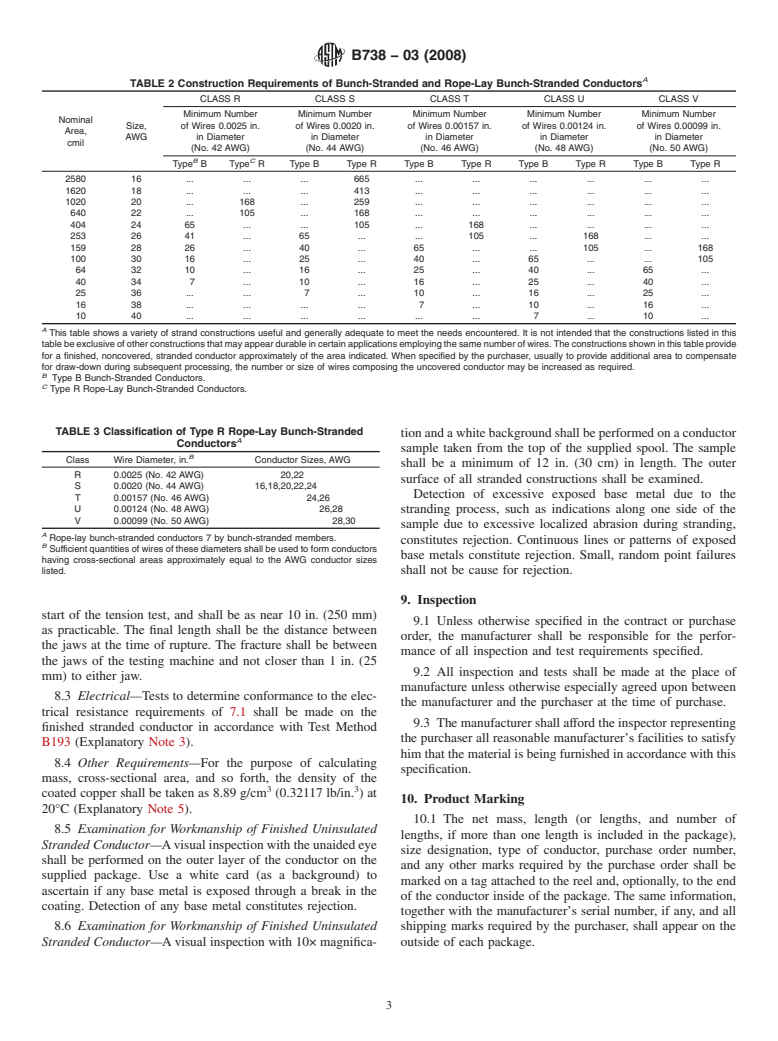

A

TABLE 2 Construction Requirements of Bunch-Stranded and Rope-Lay Bunch-Stranded Conductors

CLASS R CLASS S CLASS T CLASS U CLASS V

Minimum Number Minimum Number Minimum Number Minimum Number Minimum Number

Nominal

Size, of Wires 0.0025 in. of Wires 0.0020 in. of Wires 0.00157 in. of Wires 0.00124 in. of Wires 0.00099 in.

Area,

AWG in Diameter in Diameter in Diameter in Diameter in Diameter

cmil

(No. 42 AWG) (No. 44 AWG) (No. 46 AWG) (No. 48 AWG) (No. 50 AWG)

B C

Type B Type R Type B Type R Type B Type R Type B Type R Type B Type R

2580 16 . . . 665 . . . . . .

1620 18 . . . 413 . . . . . .

1020 20 . 168 . 259 . . . . . .

640 22 . 105 . 168 . . . . . .

404 24 65 . . 105 . 168 . . . .

253 26 41 . 65 . . 105 . 168 . .

159 28 26 . 40 . 65 . . 105 . 168

100 30 16 . 25 . 40 . 65 . . 105

64 32 10 . 16 . 25 . 40 . 65 .

40 34 7 . 10 . 16 . 25 . 40 .

25 36 . . 7 . 10 . 16 . 25 .

16 38 . . . . 7 . 10 . 16 .

10 40 . . . . . . 7 . 10 .

A

This table shows a variety of strand constructions useful and generally adequate to meet the needs encountered. It is not intended that the constructions listed in this

tablebeexclusiveofotherconstructionsthatmayappeardurableincertainapplicationsemployingthesamenumberofwires.Theconstructionsshowninthistableprovide

for a finished, noncovered, stranded conductor approximately of the area indicated. When specified by the purchaser, usually to provide additional area to compensate

for draw-down during subsequent processing, the number or size of wires composing the uncovered conductor may be increased as required.

B

Type B Bunch-Stranded Conductors.

C

Type R Rope-Lay Bunch-Stranded Conductors.

TABLE 3 Classification of Type R Rope-Lay Bunch-Stranded

tionandawhitebackgroundshallbeperformedonaconductor

A

Conductors

sample taken from the top of the supplied spool. The sample

B

Class Wire Diameter, in. Conductor Sizes, AWG

shall be a minimum of 12 in. (30 cm) in length. The outer

R 0.0025 (No. 42 AWG) 20,22

surface of all stranded constructions shall be examined.

S 0.0020 (No. 44 AWG) 16,18,20,22,24

Detection of excessive exposed base metal due to the

T 0.00157 (No. 46 AWG) 24,26

U 0.00124 (No. 48 AWG) 26,28

stranding process, such as indications along one side of the

V 0.00099 (No. 50 AWG) 28,30

sample due to excessive localized abrasion during stranding,

A

Rope-lay bunch-stranded conductors 7 by bunch-stranded members.

constitutes rejection. Continuous lines or patterns of exposed

B

Sufficientquantitiesofwiresofthesediametersshallbeusedtoformconductors

base metals constitute rejection. Small, random point failures

having cross-sectional areas approximately equal to the AWG conductor sizes

listed. shall not be cause for rejection.

9. Inspection

start of the tension test, and shall be as near 10 in. (250 mm)

9.1 Unless otherwise specified in the contract or purchase

as practicable. The final length shall be the distance between

order, the manufacturer shall be responsible for the perfor-

the jaws at the time of rupture. The fracture shall be between

mance of all inspection and test requirements specified.

the jaws of the testing machine and not closer than 1 in. (25

9.2 All inspection and tests shall be made at the place of

mm) to either jaw.

manufacture unless otherwise especially agreed upon between

8.3 Electrical—Tests to determine conformance to the elec-

the manufacturer and the purchaser at the time of purchase.

trical resistance requirements of 7.1 shall be made on the

9.3 Themanufacturershallaffordtheinspectorrepresenting

finished stranded conductor in accordance with Test Method

the purchaser all reasonable manufacturer’s facilities to satisfy

B193 (Explanatory Note 3).

himthatthematerialisbeingfurnishedinaccordancewiththis

8.4 Other Requirements—For the purpose of calculating

specification.

mass, cross-sectional area, and so forth, the density of the

3 3

coated copper shall be taken as 8.89 g/cm (0.32117 lb/in.)at

10. Product Marking

20°C (Explanatory Note 5).

10.1 The net mass, length (or lengths, and number of

8.5 Examination for Workmanship of Finished Uninsulated

lengths, if more than one length is included in the package),

StrandedConductor—Avisualinspectionwiththeunaidedeye

size designation, type of conductor, purchase order number,

shall be performed on the outer layer of the conductor on the

and any other marks required by the purchase order shall be

supplied package. Use a white card (as a background) to

marked on a tag attached to the reel and, optionally, to the end

ascertain if any base metal is exposed through a break in the

of the conductor inside of the package. The same information,

coating. Detection of any base metal constitutes rejection.

together with the manufacturer’s serial number, if any, and all

8.6 Examination for Workmanship of Finished Uninsulated shipping marks required by the purchaser, shall appear on the

outside of each package.

Stranded Conductor—Avisual inspection with 10× magnifica-

B738−03 (2008)

TABLE 4 Maximum Length of Lay for Bunch-Stranded Conductors

Nominal Diameter Nominal Area Maximum Length of Lay

Size, AWG

in. (mm) cmil (mm ) in. (mm)

24 0.024 (0.61) 404 (0.20) 0.70 (18)

26 0.019 (0.48) 253 (0.13) 0.60 (15)

28 0.015 (0.38) 159 (0.081) 0.50 (13)

30 0.012 (0.30) 100 (0.051) 0.40 (10)

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B 738–98 Designation: B 738 – 03 (Reapproved 2008)

Standard Specification for

Fine-Wire Bunch-Stranded and Rope-Lay Bunch-Stranded

Copper Conductors for Use as Electrical Conductors

This standard is issued under the fixed designation B 738; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers bare bunch-stranded and rope-lay bunch-stranded conductors made from round copper wires finer

than No. 40AWG with diameters less than 0.0031 in. (.078 mm), either coated or uncoated with tin or silver, for use as electrical

conductors. (Explanatory Note 1).

1.2 Thevalues(SIunits)fordensityandtemperatureareregardedasthestandard.Forallotherpropertiestheinch-poundvalues

are to be regarded as standard, and the SI units may be approximate.

2. Referenced Documents

2.1 ASTM Standards:

B 33 Specification for Tinned Soft or Annealed Copper Wire for Electrical Purposes

B 49 Specification for Copper Redraw Rod Drawing Stock for Electrical Purposes

B 172 Specification for Rope-Lay-Stranded Copper Conductors Having Bunch-Stranded Members, for Electrical Conductors

B 174 Specification for Bunch-Stranded Copper Conductors for Electrical Conductors

B 193 Test Method for Resistivity of Electrical Conductor Materials

B 258 Specification for Standard Nominal Diameters and Cross-SectionalAreas ofAWG Sizes of Solid Round Wires Used as

Electrical Conductors

B 298 Specification for Silver-Coated Soft or Annealed Copper Wire

B 354 Terminology Relating to Uninsulated Metallic Electrical Conductors

3. Classification

3.1 For the purposes of this specification, the following classifications have been assigned (Explanatory Note 2):

3.1.1 Type:

3.1.1.1 Type B—Bunch-stranded conductors.

3.1.1.2 Type R—Rope-lay bunch-stranded conductors.

3.1.2 Class:

3.1.2.1 Class R—Stranded conductors using wire 42 AWG (0.0025).

3.1.2.2 Class S—Stranded conductors using wire 44 AWG (0.0020).

3.1.2.3 Class T—Stranded conductors using wire 46 AWG (0.00157).

3.1.2.4 Class U—Stranded conductors using wire 48 AWG (0.00124).

3.1.2.5 Class V—Stranded conductors using wire 50 AWG (0.00099).

3.2 Detailed information on Type B Conductors is found in Table 1 and Table 2. Detailed information on Type R Conductors

is found in Table 3 and Table 2.

4. Ordering Information

4.1 Orders for materials under this specification shall include the following information:

4.1.1 Quantity of each size, class, and type,

4.1.2 Conductor size—circular-mil area, d-cdc resistance (7.1) or AWG (5.2.1),

4.1.3 Class and type (Section 3),

This specification is under the jurisdiction ofASTM Committee B-1B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on Conductors

of Copper and Copper Alloys.

Current edition approved March 10, 1998.April 1, 2008. Published September 1998.May 2008. Originally published as B738–84.approved in 1984. Last previous edition

approved in 2003 as B 738 – 903.

Annual Book of ASTM Standards, Vol 02.03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 738 – 03 (2008)

TABLE 1 Classification of Type B Bunch-Stranded Conductors

A

Class Wire Diameter, in. Conductor Sizes, AWG

R 0.0025 (No. 42 AWG) 24,26,28,30,32,34

S 0.0020 (No. 44 AWG) 26,28,30,32,34,36

T 0.00157 (No. 46 AWG) 28,30,32,34,36,38

U 0.00124 (No. 48 AWG) 30,32,34,36,38,40

V 0.00099 (No. 50 AWG) 32,34,36,38,40

A

Sufficient quantities of wires of these diameters shall be used to form

conductors having cross-sectional areas approximately equal to theAWG conduc-

tor sizes listed.

A

TABLE 2 Construction Requirements of Bunch-Stranded and Rope-Lay Bunch-Stranded Conductors

CLASS R CLASS S CLASS T CLASS U CLASS V

Minimum Number Minimum Number Minimum Number Minimum Number Minimum Number

Nominal

Size, of Wires 0.0025 in. of Wires 0.0020 in. of Wires 0.00157 in. of Wires 0.00124 in. of Wires 0.00099 in.

Area,

AWG in Diameter in Diameter in Diameter in Diameter in Diameter

cmil

(No. 42 AWG) (No. 44 AWG) (No. 46 AWG) (No. 48 AWG) (No. 50 AWG)

B C

Type B Type R Type B Type R Type B Type R Type B Type R Type B Type R

2580 16 . . . 665 . . . . . .

1620 18 . . . 413 . . . . . .

1020 20 . 168 . 259 . . . . . .

640 22 . 105 . 168 . . . . . .

404 24 65 . . 105 . 168 . . . .

253 26 41 . 65 . . 105 . 168 . .

159 28 26 . 40 . 65 . . 105 . 168

100 30 16 . 25 . 40 . 65 . . 105

64 32 10 . 16 . 25 . 40 . 65 .

40 34 7 . 10 . 16 . 25 . 40 .

25 36 . . 7 . 10 . 16 . 25 .

16 38 . . . . 7 . 10 . 16 .

10 40 . . . . . . 7 . 10 .

A

This table shows a variety of strand constructions useful and generally adequate to meet the needs encountered. It is not intended that the constructions listed in this

tablebeexclusiveofotherconstructionsthatmayappeardurableincertainapplicationsemployingthesamenumberofwires.Theconstructionsshowninthistableprovide

for a finished, noncovered, stranded conductor approximately of the area indicated. When specified by the purchaser, usually to provide additional area to compensate

for draw-down during subsequent processing, the number or size of wires composing the uncovered conductor may be increased as required.

B

Type B Bunch-Stranded Conductors.

C

Type R Rope-Lay Bunch-Stranded Conductors.

TABLE 3 Classification of Type R Rope-Lay Bunch-Stranded

A

Conductors

B

Class Wire Diameter, in. Conductor Sizes, AWG

R 0.0025 (No. 42 AWG) 20,22

S 0.0020 (No. 44 AWG) 16,18,20,22,24

T 0.00157 (No. 46 AWG) 24,26

U 0.00124 (No. 48 AWG) 26,28

V 0.00099 (No. 50 AWG) 28,30

A

Rope-lay bunch-stranded conductors 7 by bunch-stranded members.

B

Sufficient quantities of wires of these diameters shall be used to form

conductors having cross-sectional areas approximately equal to theAWG conduc-

tor sizes listed.

4.1.4 Whether coated or uncoated; if coated, designate type of coating (6.1); if silver coated, the minimum thickness of silver

(6.1.2), and whether tarnish protection is desired (11.3),

4.1.5 Maximum length of lay (5.2.4), if required,

4.1.6 Temper (6.2),

4.1.7 Separators, if required (5.2.2),

4.1.8 Package size (11.1),

4.1.9 Special package marking, if required (Section 10), and

4.1.10 Place of inspection (Section 9).

4.2 In addition, Supplementary Requirements shall apply only when specified by the purchaser in the inquiry, contract, or

purchase order for direct procurement by agencies of the U.S. Government.

5. Materials and Manufacture

5.1 The material shall be copper of such quality and purity that the finished product shall have the properties and characteristics

described in this specification. Material meeting the requirements of Specification B 49 is such a material.

5.2 Construction:

B 738 – 03 (2008)

5.2.1 Cross-Sectional Area—The cross-sectional area, number, and diameter of wires for a variety of strand constructions in

general use are shown in Table 2.

5.2.2 Separators—If a separator is required to be furnished with the conductor, it shall be specified by the purchaser at the time

of the order as to the requirements for the kind and thickness of material and its application details.

5.2.3 Joints:

5.2.3.1 Necessary joints in wires shall be made in accordance with accepted commercial practice.

5.2.3.2 Joints shall be so constructed and so disposed throughout the conductor that the diameter or configuration of the

completed conductor is not substantially affected, and that the flexibility of the completed conductor is not adversely affected.

5.2.4 Lay:

5.2.4.1 Conductors of the same size and description furnished on one order shall have the same lay.

5.2.4.2 The direction of the lay of bunch-stranded conductors shall be at the option of the manufacturer unless otherwise

specified by the purchaser.

5.2.4.3 Unless otherwise specified by the purchaser, the length of the lay of bare or coated bunch-stranded conductors shall

conform to the requirements of Table 4.

5.2.4.4 The direction of the lay of the outer layer of rope-lay stranded conductors shall be lefthand, unless otherwise specified

by the purchaser.

5.2.4.5 The length of the lay of the outer layer of rope-lay stranded conductors shall be not less than 8 or more than 16 times

the outside diameter of the completed conductor. The length of the lay of the wires composing the bunch-stranded members shall

be not more than 30 times the diameter of the member.

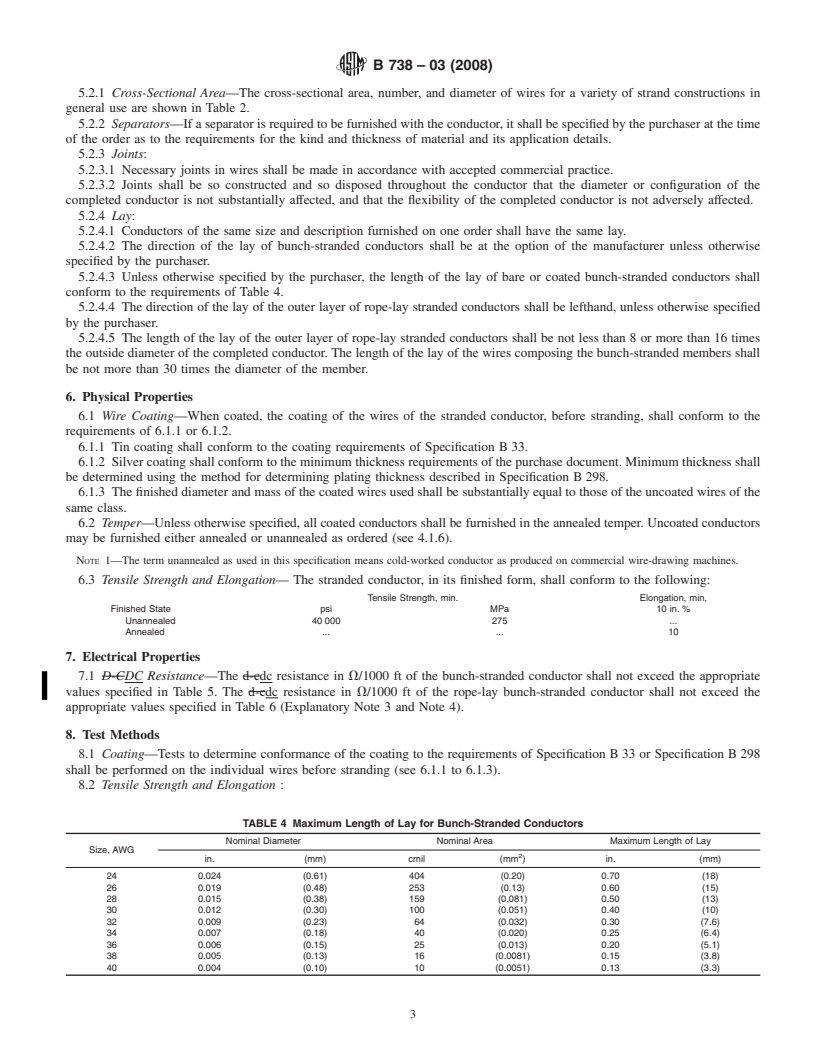

6. Physical Properties

6.1 Wire Coating—When coated, the coating of the wires of the stranded conductor, before stranding, shall conform to the

requirements of 6.1.1 or 6.1.2.

6.1.1 Tin coating shall conform to the coating requirements of Specification B 33.

6.1.2 Silver coating shall conform to the minimum thickness requirements of the purchase document. Minimum thickness shall

be determined using the method for determining plating thickness described in Specification B 298.

6.1.3 The finished diameter and mass of the coated wires used shall be substantially equal to those of the uncoated wires of the

same class.

6.2 Temper—Unless otherwise specified, all coated conductors shall be furnished in the annealed temper. Uncoated conductors

may be furnished either annealed or unannealed as ordered (see 4.1.6).

NOTE 1—The term unannealed as used in this specification means cold-worked conductor as produced on commercial wire-drawing machines.

6.3 Tensile Strength and Elongation— The stranded conductor, in its finished form, shall conform to the following:

Tensile Strength, min. Elongation, min,

Finished State psi MPa 10 in. %

Unannealed 40 000 275 .

Annealed . . 10

7. Electrical Properties

7.1 D-CDC Resistance—The d-cdc resistance in V/1000 ft of the bunch-stranded conductor shall not exceed the appropriate

values specified in Table 5. The d-cdc resistance in V/1000 ft of the rope-lay bunch-stranded conductor shall not exceed the

appropriate values specified in Table 6 (Explanatory Note 3 and Note 4).

8. Test Methods

8.1 Coating—Tests to determine conformance of the coating to the requirements of Specification B 33 or Specification B 298

shall be performed on the individual wires before stranding (see 6.1.1 to 6.1.3).

8.2 Tensile Strength and Elongation :

TABLE 4 Maximum Length of Lay for Bunch-Stranded Conductors

Nominal Diameter Nominal Area Maximum Length of Lay

Size, AWG

in. (mm) cmil (mm ) in. (mm)

24 0.024 (0.61) 404 (0.20) 0.70 (18)

26 0.019 (0.48) 253 (0.13) 0.60 (15)

28 0.015 (0.38) 159 (0.081) 0.50 (13)

30 0.012 (0.30) 100 (0.051) 0.40 (10)

32 0.009 (0.23) 64 (0.032) 0.30 (7.6)

34 0.007 (0.18) 40 (0.020) 0.25 (6.4)

36 0.006 (0.15) 25 (0.013) 0.20 (5.1)

38 0.005 (0.13) 16 (0.0081) 0.15 (3.8)

40 0.004 (0.10) 10 (0.0051) 0.13 (3.3)

B 738 – 03 (2008)

TABLE 5 D-C Ohmic Resistance Per 1000 Ft. of Type B Bunch-Stranded Conductors

A B

Conductor Construction D-C Resistance at 20°C, V/1000 ft, max.

Calculated Total

Size Designations Cross-Sectional

Number of Nominal Diameter Annealed Bare or Annealed Tin Unannealed

C Area cmil D E

Wires of Each Wire, in. Silver Coated Coated Bare

24-65 65 0.0025 406 28.3 30.4 29.4

26-41 41 0.0025 256 44.9 48.2 46.7

26-65 65 0.0020 260 45.2 48.5 47.0

28-26 26 0.0025 163 70.8 76.0 73.6

28-40 40 0.0020 160 73.5 78.9 76.4

28-65 65 0.00157 160 71.8 . 74.6

30-16 16 0.0025 100 115.0 123.4 119.6

30-25 25 0.0020 100 117.5 126.2 122.2

30-40 40 0.00157 98.6 116.6 . 121.3

30-65 65 0.00124 99.9 115.0 . 119.6

C C

32-10 10 0.0025 62.5 184.0 197.5 191.3

32-16 16 0.0020 64 183.7 197.2 191.0

C C

32-25 25 0.00157 61.6 186.6 . 194.0

C C

32-40 40 0.00124 61.5 187.0 . 194.4

32-65 65 0.00099 63.7 180.5 . 187.7

34-7 7 0.0025 43.8 262.8 281.8 273.3

34-10 10 0.0020 40 293.8 315.5 305.6

34-16 16 0.00157 39.4 291.6 . 303.2

C C

34-25 25 0.00124 38.4 299.1 . 311.1

34-40 40 0.00099 39.2 293.3 . 305.0

36-7 7 0.0020 28 419.8 450.6 436.5

36-10 10 0.00157 24.6 466.5 . 485.1

36-16 16 0.00124 24.6 467.4 . 486.0

36-25 25 0.00099 24.5 469.3 . 488.0

38-7 7 0.00157 17.3 666.4 . 693.0

C C

38-10 10 0.00124 15.4 747.8 . 777.7

38-16 16 0.00099 15.7 733.2 . 762.5

40-7 7 0.00124 10.8 1068.3 . 1111.0

40-10 10 0.00099 9.8 1173.2 . 1220.0

A

See Table 2 for construction requirements or bunch-stranded conductors.

B

See Explanatory Note 4.

C

Bunch.

D

Thecross-sectionalareasoftheseconductor-sizedesignationsdeviatebymorethan2 %fromthenominalareasofthestandardAWGsizesasdefinedinSpecification

B 258.

E

Tin-coated wire is not available at this time on wire diameters smaller than .0020 (44 AWG).

TABLE 6 D-C Ohmic Resistance Per 1000 Ft. of Type R Rope-Lay Bunch-Stranded Conductor

A B

Conductor Construction D-C Resistance of 20°C, Ohms/1000 ft. max.

Calculated Total

Size Designation Cross-Sectional

Number of Nominal Diameter Annealed Bare or Annealed Tin Unannealed

C B D

Area cmil

Wires of Each Wire, in. Silver Coated Coated Bare

16-665 665 0.0020 2660 4.51 4.84 4.69

18-413 413 0.0020 1652 7.25 7.79 7.54

20-168 168 0.0025 1050 11.2 12.0 11.6

20-259 259 0.0020 1036 11.6 12.4 12.0

22-105 105 0.0025 656 17.9 19.2 18.6

22-168 168 0.0020 672 17.8 19.1 18.5

24-105 105 0.0020 420 28.5 30.6 29.7

24-168 168 0.00157 414 28.3 . 29.4

26-105 105 0.00157 259 45.3 . 47.1

26-168 168 0.00124 258 45.4 . 47.2

28-105 105 0.00124 161 72.6 . 75.5

28-168 168 0.00099 165 71.2 . 74.0

30-105 105 0.00099 103 113.9 . 118.5

A

See Table 2 Construction Requirements of Rope-Lay Bunch-Stranded Conductors.

B

See Explanatory Note 3.

C

Seven Member Ropes.

D

Tin coated wire is not available at this time on wire diameters smaller than .0020 (44 AWG).

8.2.1 Tests to determine conformance to the tensile strength and elongation requirements of 6.3 shall be made on the finished

stranded conductor.

8.2.2 Determine tensile strength, T , expressed in pounds per square inch as follows:

s

L

T 5

s

A

where:

L = maximum load on the stranded conductor during the tension test (see Exp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.