ASTM C846-94(2009)

(Practice)Standard Practice for Application of Cellulosic Fiber Insulating Board for Wall Sheathing

Standard Practice for Application of Cellulosic Fiber Insulating Board for Wall Sheathing

SIGNIFICANCE AND USE

This standard provides recommendations for the installation in a safe and effective manner. Actual conditions may vary greatly, and additional care should be taken to ensure a safe and effective installation.

This standard presents requirements that are general in nature and considered practical. They are not intended as specific recommendations. The user should consult the manufacturer for recommended application methods and procedures.

This standard does not address the applicability of regulatory limitations. This is the responsibility of the user.

SCOPE

1.1 This practice covers the requirements for storing, handling, and application of cellulosic fiber insulating board products.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C846 − 94(Reapproved 2009)

Standard Practice for

Application of Cellulosic Fiber Insulating Board for Wall

Sheathing

This standard is issued under the fixed designation C846; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 exterior finish—the shingle, lap, or panel siding

material, masonry veneer, or stucco applied over the sheathing

1.1 This practice covers the requirements for storing,

as a protective, decorative exterior finish of the building.

handling, and application of cellulosic fiber insulating board

3.1.2 fasteners—nails, staples, or screws used for applica-

products.

tion of the sheathing.

1.2 The values stated in inch-pound units are to be regarded

3.1.3 framing members—those portions of the studs,

as standard. The values given in parentheses are mathematical

headers, bracing, and blocking which serve to receive the

conversions to SI units that are provided for information only

sheathing. Framing members can be wood or metal.

and are not considered standard.

3.1.4 regular wall sheathing—described in Definitions

1.3 This standard does not purport to address all of the

D1554 and Specification C208. It is 4 ft (1.22 m) wide with

safety concerns, if any, associated with its use. It is the

square-cut edges on all sides and ⁄2 in. (12.7 mm) in thickness.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3.1.5 structural wall sheathing—described in Definitions

bility of regulatory limitations prior to use.

D1554 and Specification C208. When installed in accordance

with Section 7, it is considered a structural sheathing providing

2. Referenced Documents

adequate racking resistance. It is 4 ft (1.22 m) wide and ⁄2 in.

2.1 ASTM Standards:

(12.7 mm) or ⁄32 in. (19.8 mm) in thickness with square-cut

C208 Specification for Cellulosic Fiber Insulating Board

edges on all sides.

D1554 Terminology Relating to Wood-Base Fiber and Par-

3.1.6 vertical application—sheathing applied with the long

ticle Panel Materials

edges parallel to the studs.

2.2 Voluntary Product Standard:

ANSI/AHAA194.1 Cellulosic Fiberboard

4. Significance and Use

2.3 Federal Specifications:

4.1 This standard provides recommendations for the instal-

FF-N-105-B with Interim Amendment 4 Nails, Brads,

lation in a safe and effective manner. Actual conditions may

Staples and Spikes: Wire Cut and Wrought

vary greatly, and additional care should be taken to ensure a

UU-B-790-A Building Paper, Vegetable Fiber: (Kraft,

safe and effective installation.

Waterproofed, Water Repellent and Fire Resistant)

4.2 This standard presents requirements that are general in

3. Terminology

nature and considered practical. They are not intended as

specific recommendations. The user should consult the manu-

3.1 Definitions of Terms Specific to This Standard:

facturerforrecommendedapplicationmethodsandprocedures.

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

4.3 This standard does not address the applicability of

Insulation and is the direct responsibility of Subcommittee C16.40 on Insulation

regulatory limitations. This is the responsibility of the user.

Systems.

Current edition approved April 1, 2009. Published August 2009. Originally

5. Materials

approved in 1976. Last previous edition approved in 2003 as C846 – 94 (2003).

DOI: 10.1520/C0846-94R09.

5.1 Sheathing shall conform to ANSI/AHA A194.1 and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Specification C208.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

5.2 Nails for application of sheathing to wood framing shall

the ASTM website.

3 conform to Federal Specification FF-N-105-B, including In-

Available from American Hardboard Assoc., 1210 W. Northwest Highway,

Palatine, IL. terim Amendment 4, and shall be in accordance with Table 1.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

1 25

5.3 Staples for application of ⁄2-in. and ⁄32-in. sheathing to

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

www.dodssp.daps.mil. wood framing shall meet the following requirements:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C846 − 94 (2009)

TABLE 1 Nail Dimensions

Sheathing Thickness, Galvanized Steel Common

in. (mm) Roofing Nails Nails

Gage 11 11 ⁄2 (6d)

Length, min, in. (mm) 1 ⁄2 (38.1) 2 (50.8)

1 7 17

⁄2 (12.7) Head diameter, min, in. (mm) ⁄16 (11.1) ⁄64 (6.75)

A

Wire diameter, min, in. (mm) 0.120 (3.06) 0.1130 (2.87)

Gage 11 10 ⁄4 (8d)

3 1

Length, min, in. (mm) 1 ⁄4 (44.5) 2 ⁄2 (63.5)

25 7 9

⁄32 (19.8) Head diameter, min, in. (mm) ⁄16 (11.1) ⁄32 (7.14)

A

Wire diameter, min, in. (mm) 0.120 (3.06) 0.131 (3.33)

A

Prior to galvanizing.

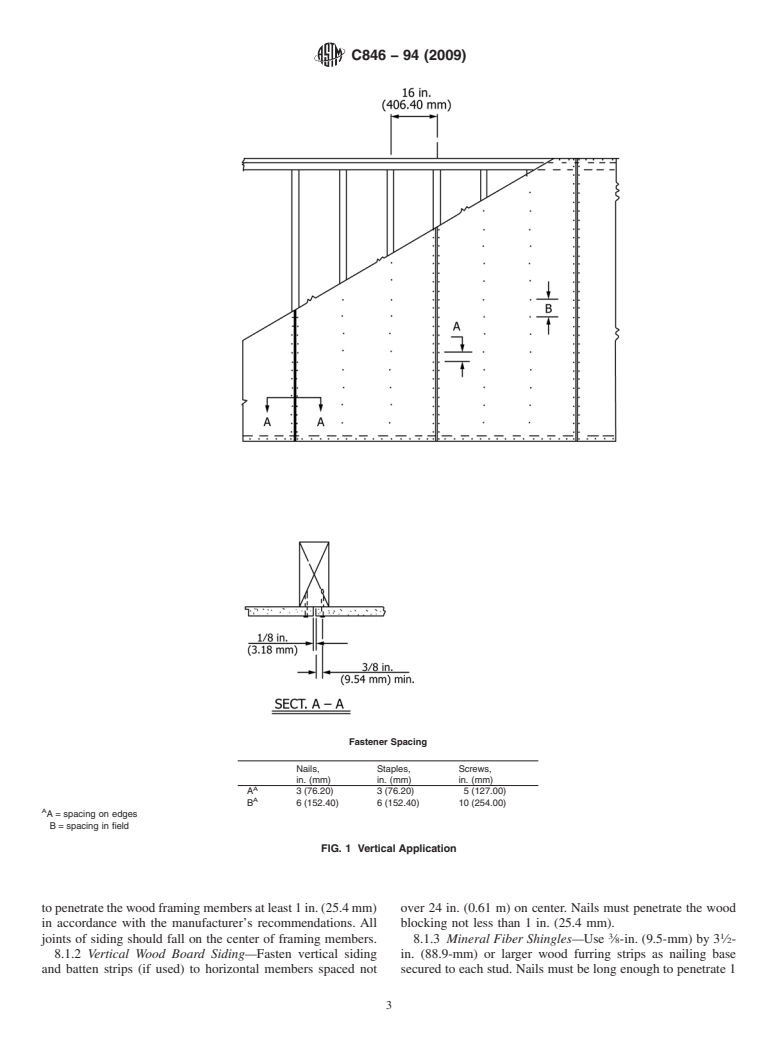

7.1 Vertical Application (see Fig. 1)—Apply 4-ft (1.22-m)

Gage 16

1 25

Thickness, min, in. (mm) 0.057 (1.45)

wide by ⁄2-in. (12.7-mm) or by ⁄32-in. (19.8-mm) sheathing

Width, min, in. (mm) 0.063 (1.59)

vertically with long edges parallel to the vertical studs. Center

Length, min, in. (mm) 1 ⁄2 (38.1)

all joints over the framing members with a ⁄8-in. (3.18-mm)

Crown, min, in. (mm) ⁄16 (11.1)

Points chisel point 1

gap between edges. Leave a ⁄8-in. gap at doors, windows, and

divergent point

horizontal joints. Sheathing should extend from sill to plate. If

divergent chisel point

not, headers for adequate nailing should be provided at all

1 25

5.4 Screwsforapplicationof ⁄2-in.and ⁄32-in.sheathingon

1 25

horizontal joints.Apply fasteners for ⁄2-in. or ⁄32-in. material

14-gage (0.075-in.) (1.90-mm) to 20-gage (0.036-in.)

using roofing nails, common nails (5.2) or staples (5.3) for

(0.91mm) steel studs shall meet the following requirements:

wood framing and screws (5.4) for metal framing. Apply

Head type bugle head

fasteners to intermediate framing members first. For wood

Head diameter, min, in. (mm) ⁄16 (7.94)

1 framing, space fasteners 6 in. (152 mm) (Note 1) on center.

Length, min, in. (mm) 1 ⁄4 (31.8)

Major diameter, in. (mm) ⁄64 (3.57)

Applyperimeterfastene

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.