ASTM D5462-93(2001)

(Test Method)Standard Test Method for On-Line Measurement of Low-Level Dissolved Oxygen in Water

Standard Test Method for On-Line Measurement of Low-Level Dissolved Oxygen in Water

SCOPE

1.1 This test method covers the on-line determination of dissolved oxygen (DO) in water samples primarily in ranges from 0 to 500 µg/L (ppb), although higher ranges may be used for calibration. On-line instrumentation is used for continuous measurements of DO in samples that are brought through sample lines and conditioned from high-temperature and high-pressure sources when necessary.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards statements, see 6.5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5462 – 93 (Reapproved 2001)

Standard Test Method for

On-Line Measurement of Low-Level Dissolved Oxygen in

Water

This standard is issued under the fixed designation D 5462; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope tration. Oxygen consumption and regeneration balance each

other within the probes under stable conditions, and the net flux

1.1 This test method covers the on-line determination of

through the membrane is insignificant.

dissolved oxygen (DO) in water samples primarily in ranges

3.2.3 galvanic systems—sensing probes and measuring in-

from 0 to 500 μg/L (ppb), although higher ranges may be used

struments that develop an electrical current from two elec-

for calibration. On-line instrumentation is used for continuous

trodes inside the probe from which the final measurement is

measurements of DO in samples that are brought through

derived.

sample lines and conditioned from high-temperature and high-

3.2.4 partial pressure (of oxygen)—the volume fraction of

pressure sources when necessary.

oxygen multiplied by the total pressure. The partial pressure of

1.2 This standard does not purport to address all of the

oxygen is the actual parameter detected by DO probes, whether

safety concerns, if any, associated with its use. It is the

in air or dissolved in water.

responsibility of the user of this standard to establish appro-

3.2.5 polarographic systems—sensing probes and measur-

priate safety and health practices and determine the applica-

ing instruments that include circuitry to control the operating

bility of regulatory limitations prior to use. For specific hazards

voltage of the system, usually using a third (reference) elec-

statements, see 6.5.

trode in the probe.

2. Referenced Documents

4. Summary of Test Method

2.1 ASTM Standards:

4.1 Dissolved oxygen is measured by means of an electro-

D 1066 Practice for Sampling Steam

2 chemical cell separated from the sample by a gas-permeable

D 1129 Terminology Relating to Water

membrane. Behind the membrane and inside the probe, elec-

D 1192 Specification for Equipment for Sampling Water

trodes immersed in an electrolyte develop an electrical current

and Steam in Closed Conduits

proportional to the oxygen partial pressure of the sample.

D 1193 Specification for Reagent Water

4.2 The partial pressure signal is temperature compensated

D 2777 Practice for Determination of Precision and Bias of

automatically to account for variations with temperature of the

Applicable Methods of Committee D-19 on Water

following: oxygen solubility in water; electrochemical cell

D 3370 Practices for Sampling Water from Closed Con-

output; and, when necessary, diffusion rate of oxygen through

duits

the membrane. This yields a direct readout in concentration of

D 3864 Practice for Continual On-Line Monitoring Systems

μg/L (ppb) or mg/L (ppm).

for Water Analysis

4.3 Diffusion-type probes rely on a continuous diffusion of

3. Terminology oxygen through the membrane. Immediately inside the mem-

brane, oxygen is reduced at the noble metal cathode, usually

3.1 Definitions—For definitions of terms used in this test

platinum or gold. An electrical current is developed that is

method, refer to Terminology D 1129.

directly proportional to the arrival rate of oxygen molecules at

3.2 Definitions of Terms Specific to This Standard:

the cathode, which is in turn dependent on the diffusion rate

3.2.1 diffusion-type probes—galvanic or polarographic sen-

through the membrane. The less noble anode, usually silver or

sors that depend on the continuous influx of oxygen through

lead, completes the circuit and is oxidized in proportion to the

the membrane to develop the measurement signal.

current flow. At steady state, the resulting current signal is then

3.2.2 equilibrium-type probes—modified polarographic

proportional to the oxygen partial pressure of the sample.

sensing probes that have a negligible influx of oxygen through

Thorough descriptions of diffusion-type probes are given by

the membrane except during changes of sample DO concen-

Hitchman (1) and Fatt (2).

4.4 Equilibrium-type probes rely on oxygen diffusion

This test method is under the jurisdiction of ASTM Committee D19 on Water

and is the direct responsibility of Subcommittee D19.03 on Sampling of Water and

Water-Formed Deposits, Surveillance of Water, and Flow Measurement of Water.

Current edition approved Sept. 15, 1993. Published November 1993. The boldface numbers in parentheses refer to the list of references at the end of

Annual Book of ASTM Standards, Vol 11.01. this test method.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5462

through the membrane only until equilibrium between the spheric conditions that deviate from a nominal range of 745 to

inside and outside is achieved. Oxygen is reduced at the noble 775 mmHg. See Table 1 for altitude corrections. Calibration

metal cathode, as with diffusion-type probes. However, the under low-pressure conditions without compensation would

measuring circuit forces electrical current to flow through the result in positive measurement errors.

noble metal anode equal and opposite to that at the cathode, 6.5 The growth of bacteria in sample lines and flow cham-

and the resulting oxidation reaction produces bers and on probe membranes can consume oxygen and cause

oxygen. This is the exact reverse of the reaction at the cathode, negative errors. Chemical sterilization with hydrochloric acid

so there is no net consumption of oxygen by the probe. It (1 + 44) or sodium hypochlorite solution (10 mg/L) should be

reaches equilibrium in constant DO samples, and no net performed if errors from bacteria growth are suspected.

oxygen diffuses through the membrane. Accuracy is not

NOTE 1—Warning: Do not mix hydrochloric acid and sodium hy-

dependent on membrane surface condition or sample flow-

pochlorite since hazardous chlorine gas would be released rapidly.

rate.

6.6 The passage of high-temperature samples containing

both DO and an oxygen scavenger through hot sample lines

5. Significance and Use

can allow continued reaction of the two. With long sample

5.1 DO may be either a corrosive or passivating agent in

lines, the DO measured at the probe may be significantly below

boiler/steam cycles and is therefore controlled to specific

that at the sample point. Short sample lines and cooling near

concentrations that are low relative to environmental and

the source are recommended.

wastewater treatment samples. Out-of-specification DO con-

6.7 Volatile oxygen scavengers or suppressants, such as

centrations may cause corrosion in boiler systems, which leads

hydrazine, amines, and hydrogen, that pass through the probe

to corrosion fatigue and corrosion products—all detrimental to

membrane may cause unwanted reactions at the electrodes and

the life and efficient operation of a power unit. The efficiency

negative errors. The magnitude of errors depends on the

of DO removal from boiler feedwater by mechanical or

relative concentrations of DO and the oxygen scavenger or

chemical means, or both, may be monitored by continuously

suppressant as well as the type of electrochemical cell used.

measuring the DO concentration before and after the removal

The probe manufacturer’s cautions and limitations should be

process with on-line instrumentation. DO measurement is also

considered.

a check for air leakage into the boiler water cycle.

6.8 New sample lines require conditioning to achieve equi-

5.2 Guidelines for feedwater to high-pressure boilers with

librium conditions. See Practices D 3370 to avoid sampling

all volatile treatment generally require a feedwater DO con-

interferences.

centration below 5 μg/L (3).

6.9 Iron oxides and other deposits accumulate in slow-

5.3 Boiler feedwater with oxygenated treatment is main-

flowing horizontal sample lines and can develop

tained in a range of 50 to 300 μg/L DO (4).

chromatograph-like retention of dissolved species, resulting in

5.4 In microelectronics production, DO can be detrimental

very long delay times. Precautions are described in Section 9.

in some manufacturing processes, for example, causing unde-

6.10 The response time can be slow for large decreases in

sirable oxidation on silicon wafers.

DO. This is especially true of measurements below 10 μg/L

following air calibration, which corresponds to a concentration

6. Interferences

6.1 The leakage of atmospheric air into samples is some-

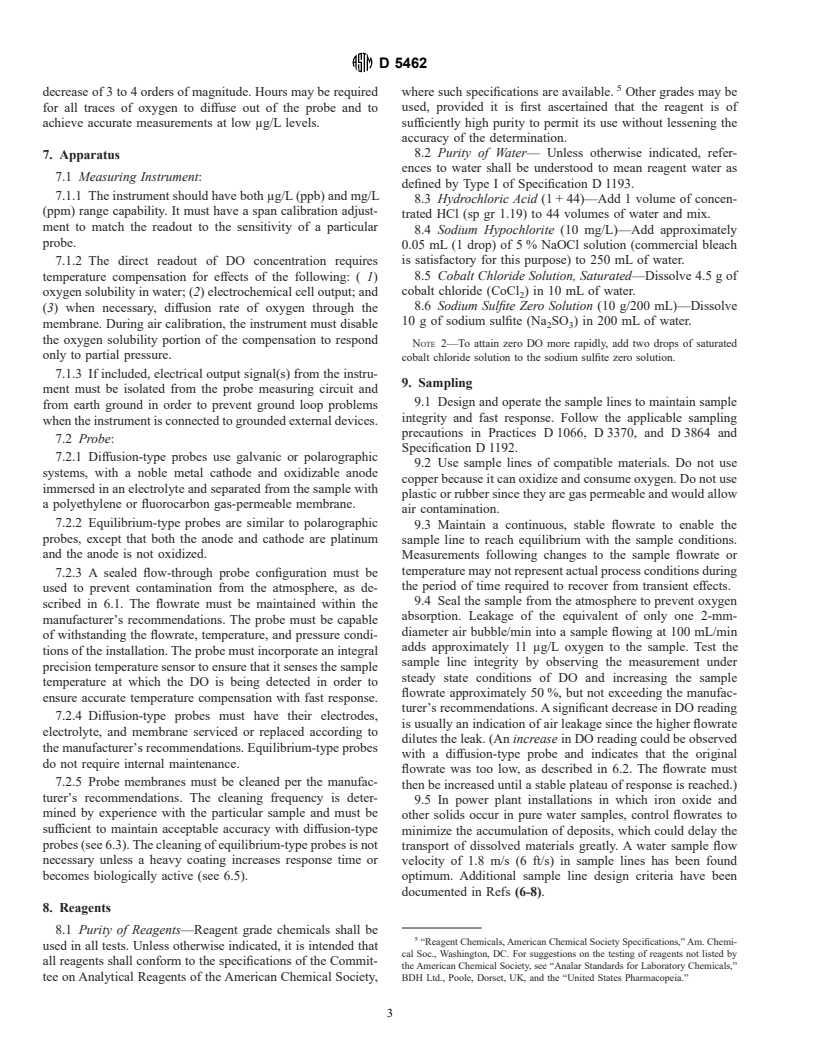

TABLE 1 Solubility of Oxygen (mg/L) at Various Temperatures

times difficult to avoid and detect. Although sample line fittings

and Elevations (Based on Sea Level Barometric Pressure of

and connections to flow chambers may be water tight, it is still

760 mmHg) (5)

possible for air to diffuse through the water film of a joint to

Temperature, Elevation, ft above Sea Level

contaminate a low-μg/L sample. Section 9 provides further

°C

0 1000 2000 3000 4000 5000 6000

details on this non-obvious interference.

6.2 Diffusion-type probes consume oxygen and will deplete 0 14.6 14.1 13.6 13.2 12.7 12.3 11.8

2 13.8 13.3 12.9 12.4 12.0 11.6 11.2

it from the sample in immediate contact with the membrane

4 13.1 12.7 12.2 11.9 11.4 11.0 10.6

surface unless an adequate, turbulent sample flow is main-

6 12.4 12.0 11.6 11.2 10.8 10.4 10.1

tained. The manufacturer’s minimum flowrate recommenda- 8 11.8 11.4 11.0 10.6 10.3 9.9 9.6

10 11.3 10.9 10.5 10.2 9.8 9.5 9.2

tions must be met or exceeded in order to prevent erroneously

12 10.8 10.4 10.1 9.7 9.4 9.1 8.8

low readings.

14 10.3 9.9 9.6 9.3 9.0 8.7 8.3

6.3 Diffusion-type probes are subject to negative errors 16 9.9 9.7 9.2 8.9 8.6 8.3 8.0

18 9.5 9.2 8.7 8.6 8.3 8.0 7.7

from the buildup of coatings such as iron oxides, which impede

20 9.1 8.8 8.5 8.2 7.9 7.7 7.4

the diffusion rate of oxygen. (Equilibrium-type probes are not

22 8.7 8.4 8.1 7.8 7.7 7.3 7.1

24 8.4 8.1 7.8 7.6 7.3 7.1 6.8

subject to errors from flowrate or coating.)

26 8.1 7.8 7.6 7.3 7.0 6.8 6.6

6.4 Calibration must be corrected for barometric pressure

28 7.8 7.5 7.3 7.0 6.8 6.6 6.3

according to the manufacturer’s recommendations at atmo-

30 7.5 7.2 7.0 6.8 6.5 6.3 6.1

32 7.3 7.1 6.8 6.6 6.4 6.1 5.9

34 7.1 6.9 6.6 6.4 6.2 6.0 5.8

36 6.8 6.6 6.3 6.1 5.9 5.7 5.5

Leeds & Northrup, North Wales, PA, Model 7931 dissolved oxygen analyzer

38 6.6 6.4 6.2 5.9 5.7 5.6 5.4

and probe have been found to provide satisfactory equilibrium-type probe perfor-

40 6.4 6.2 6.0 5.8 5.6 5.4 5.2

mance.

D 5462

decrease of 3 to 4 orders of magnitude. Hours may be required where such specifications are available. Other grades may be

for all traces of oxygen to diffuse out of the probe and to used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

achieve accurate measurements at low μg/L levels.

accuracy of the determination.

8.2 Purity of Water— Unless otherwise indicated, refer-

7. Apparatus

ences to water shall be understood to mean reagent water as

7.1 Measuring Instrument:

defined by Type I of Specification D 1193.

7.1.1 The instrument should have both μg/L (ppb) and mg/L

8.3 Hydrochloric Acid (1 + 44)—Add 1 volume of concen-

(ppm) range capability. It must have a span calibration adjust-

trated HCl (sp gr 1.19) to 44 volumes of water and mix.

ment to match the readout to the sensitivity of a particular

8.4 Sodium Hypochlorite (10 mg/L)—Add approximately

probe.

0.05 mL (1 drop) of 5 % NaOCl solution (commercial bleach

7.1.2 The direct readout of DO concentration requires is satisfactory for this purpose) to 250 mL of water.

8.5 Cobalt Chloride Solution, Saturated—Dissolve 4.5 g of

temperature compensation for effects of the following: ( 1)

cobalt chloride (CoCl ) in 10 mL of water.

oxygen solubility in water; (2) electrochemical cell output; and

8.6 Sodium Sulfite Zero Solution (10 g/200 mL)—Dissolve

(3) when necessary, diffusion rate of oxygen through the

10 g of sodium sulfite (Na SO ) in 200 mL of water.

membrane. During air calibration, the instrument must disable

2 3

the oxygen solubility portion of the compensation to respond

NOTE 2—To attain zero DO more rapidly, add two drops of saturated

only to partial pressure.

cobalt chloride solution to the sodium sulfite zero solution.

7.1.3 If included, electrical output signal(s) from the instru-

9. Sampling

ment must be isolated from the probe measuring circuit and

9.1 Design and operate the sample lines to maintain sample

from earth ground in order to prevent ground loop problems

integrity and fast response. Follow the applicable sampling

when the instrument is connected to grounded external devices.

precautions in Practices D 1066, D 3370, and D 3864 and

7.2 Probe:

Specification D 1192.

7.2.1 Diffusion-type probes use galvanic or polarographic

9.2 Use sample lines of compatible materials. Do not use

systems, with a noble metal cathode and oxidizable anode

copper because it can oxidize and consume oxygen. Do not use

immersed in an electrolyte and separated from the sample with

plastic or rubber since they are gas permeable and would allow

a polyethylene or fluorocarbon gas-permeable membrane.

air contamination.

7.2.2 Equilibrium-type probes are similar to polarographic

9.3 Maintain a continuous, stable flowrate to enable the

probes, except that both the anode and cathode are platinum

sample line to reach equilibrium with the sample conditions.

and the anode is not oxidized.

Measurements following changes to the sample flowrate or

temperature may not represent actual process conditions during

7.2.3 A sealed flow-through probe configuration must be

the period of time required to recover from transient effects.

used to prevent contamination from the atmosphere, as de-

9.4 Seal the sample from the atmosphere to prevent oxygen

scribed in 6.1. The flowrate must be maintained within the

absorption. Leakage of the equivalent of only one 2-mm-

manufacturer’s recommendations. The probe must be capable

diameter air bubble/min into a sample flowing at 100 mL/min

of withstanding the flowrate, temperature, and pressure condi-

adds approximately 11 μg/L oxygen to the sample. Test the

tions of the installation. The probe must incorporate an integral

sample line integrity by observing the measurement under

precision temperature sensor to ensure that it senses the sample

steady state conditions of DO and increasing the sample

temperature at which the DO is being detected in order to

flowrate approximately 50 %, but not exceeding the m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.