ASTM D5127-13(2018)

(Guide)Standard Guide for Ultra-Pure Water Used in the Electronics and Semiconductor Industries

Standard Guide for Ultra-Pure Water Used in the Electronics and Semiconductor Industries

SIGNIFICANCE AND USE

4.1 This guide recommends the water quality required for the electronics and microelectronics industries. High-purity water is required to prevent contamination of products during manufacture, since contamination can lead to an unacceptable, low yield of electronic devices.

4.2 The range of water purity is defined in accordance with the manufacturing process. The types of ultra-pure water are defined with respect to device line width. In all cases, the water-quality recommendations apply at the point of distribution.

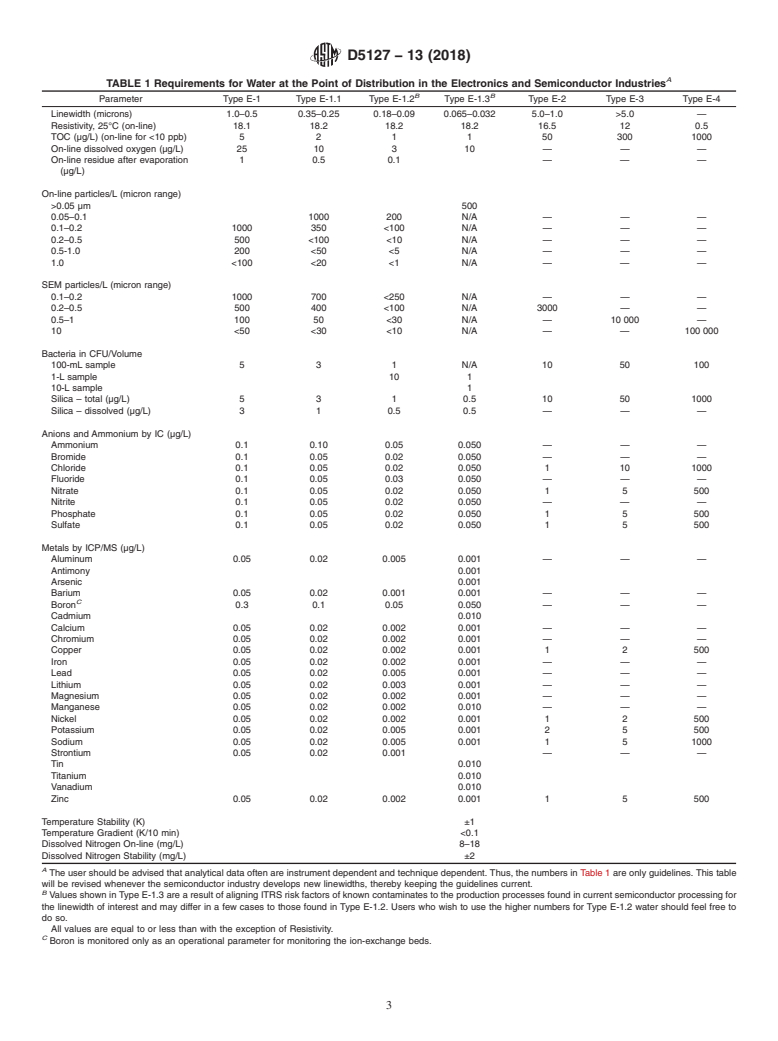

4.3 The limits on the impurities are related to current contamination specifications and to available analytical methods (either performed in a suitable clean laboratory or by on-line instrumentation). On-line and off-line methods are used in accordance with current industry practice. Concentration of the sample may be required to measure the impurities at the levels indicated in Table 1. (A) The user should be advised that analytical data often are instrument dependent and technique dependent. Thus, the numbers in Table 1 are only guidelines. This table will be revised whenever the semiconductor industry develops new linewidths, thereby keeping the guidelines current.(B) Values shown in Type E-1.3 are a result of aligning ITRS risk factors of known contaminates to the production processes found in current semiconductor processing for the linewidth of interest and may differ in a few cases to those found in Type E-1.2. Users who wish to use the higher numbers for Type E-1.2 water should feel free to do so.

All values are equal to or less than with the exception of Resistivity.(C) Boron is monitored only as an operational parameter for monitoring the ion-exchange beds.

SCOPE

1.1 This guide provides recommendations for water quality related to electronics and semiconductor-industry manufacturing. Seven classifications of water are described, including water for line widths as low as 0.032 μm. In all cases, the recommendations are for water at the point of distribution (POD).

1.2 Water is used for washing and rinsing of semiconductor components during manufacture. Water is also used for cleaning and etching operations, making steam for oxidation of silicon surfaces, preparing photomasks, and depositing luminescent materials. Other applications are in the development and fabrication of solid-state devices, thin-film devices, communication lasers, light-emitting diodes, photo-detectors, printed circuits, memory devices, vacuum-tube devices, or electrolytic devices.

1.3 Users needing water qualities different from those described here should consult other water standards, such as Specification D1193 and Guide D5196.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5127 − 13 (Reapproved 2018)

Standard Guide for

Ultra-Pure Water Used in the Electronics and

Semiconductor Industries

This standard is issued under the fixed designation D5127; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This guide provides recommendations for water quality

D1129Terminology Relating to Water

related to electronics and semiconductor-industry manufactur-

D1193Specification for Reagent Water

ing. Seven classifications of water are described, including

D1976Test Method for Elements in Water by Inductively-

water for line widths as low as 0.032 µm. In all cases, the

Coupled Plasma Atomic Emission Spectroscopy

recommendations are for water at the point of distribution

D2791TestMethodforOn-lineDeterminationofSodiumin

(POD).

Water

1.2 Water is used for washing and rinsing of semiconductor

D3919Practice for Measuring Trace Elements in Water by

components during manufacture. Water is also used for clean-

Graphite Furnace Atomic Absorption Spectrophotometry

ing and etching operations, making steam for oxidation of

D4191TestMethodforSodiuminWaterbyAtomicAbsorp-

silicon surfaces, preparing photomasks, and depositing lumi-

tion Spectrophotometry

nescent materials. Other applications are in the development

D4192Test Method for Potassium in Water by Atomic

and fabrication of solid-state devices, thin-film devices, com-

Absorption Spectrophotometry

munication lasers, light-emitting diodes, photo-detectors,

D4327Test Method forAnions in Water by Suppressed Ion

printed circuits, memory devices, vacuum-tube devices, or

Chromatography

electrolytic devices.

D4453Practice for Handling of High Purity Water Samples

1.3 Users needing water qualities different from those de- D4517Test Method for Low-Level Total Silica in High-

scribed here should consult other water standards, such as

Purity Water by Flameless Atomic Absorption Spectros-

Specification D1193 and Guide D5196.

copy

D5173Guide for On-Line Monitoring of Total Organic

1.4 This standard does not purport to address all of the

Carbon inWater by Oxidation and Detection of Resulting

safety concerns, if any, associated with its use. It is the

Carbon Dioxide

responsibility of the user of this standard to establish appro-

D5196Guide for Bio-Applications Grade Water

priate safety, health, and environmental practices and deter-

D5391Test Method for Electrical Conductivity and Resis-

mine the applicability of regulatory limitations prior to use.

tivity of a Flowing High Purity Water Sample

1.5 This international standard was developed in accor-

D5462Test Method for On-Line Measurement of Low-

dance with internationally recognized principles on standard-

Level Dissolved Oxygen in Water

ization established in the Decision on Principles for the

D5542Test Methods for TraceAnions in High Purity Water

Development of International Standards, Guides and Recom-

by Ion Chromatography

mendations issued by the World Trade Organization Technical

D5544Test Method for On-Line Measurement of Residue

Barriers to Trade (TBT) Committee.

After Evaporation of High-Purity Water

D5673Test Method for Elements in Water by Inductively

Coupled Plasma—Mass Spectrometry

This guide is under the jurisdiction ofASTM Committee D19 on Water and is

thedirectresponsibilityofSubcommitteeD19.02onQualitySystems,Specification,

and Statistics. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 15, 2018. Published November 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1990. Last previous edition approved in 2013 as D5127–13. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D5127-13R18. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5127 − 13 (2018)

D5996Test Method for MeasuringAnionic Contaminants in widths between 0.065 and 0.032 µm. This type is the water of

High-Purity Water by On-Line Ion Chromatography ultimate practical purity produced in large volumes, and is

D5997 Test Method for On-Line Monitoring of Total intended for the most critical microelectronic uses. ASTM

Carbon,InorganicCarboninWaterbyUltraviolet,Persul- Type E-1.3 is also identical to the SEMI (Semiconductor

fate Oxidation, and Membrane Conductivity Detection Equipment and Materials International) Guide for Ultrapure

F1094Test Methods for Microbiological Monitoring of Water Used in Semiconductor Processing (F063), 2010 ver-

Water Used for Processing Electron and Microelectronic sion.

Devices by Direct Pressure Tap Sampling Valve and by 5.1.5 Type E-2—This water is classified as microelectronic

the Presterilized Plastic Bag Method

water to be used in the production of devices that have

dimensions between 1 and 5 µm.

3. Terminology

5.1.6 Type E-3—This grade of water is classified as macro-

electronicwatertobeusedintheproductionofdeviceshaving

3.1 Definitions:

3.1.1 For definitions of terms used in this standard, refer to dimensions larger than 5 µm. This grade may be used to

Terminology D1129. produce larger components and some small components not

affected by trace amounts of impurities.

3.2 Definitions of Terms Specific to This Standard:

5.1.7 Type E-4—This grade may be classified as water used

3.2.1 total bacterial counts, n—total number of cultureable

in preparation of plating solutions and for other applications

microorganisms present in the named sample, excluding obli-

where the water being used can be of lesser quality.

gate anaerobic organisms, determined in accordance with Test

Methods F1094.

5.2 Components of the water system for producing

electronic-grade water shall be grouped into five general

3.2.2 total organic carbon (TOC), n—carbonmeasuredafter

processsectionsforthepurposeofsimplifyingtheorganization

inorganic-carbon response has been eliminated by one of the

of the components of the systems. These processes are de-

prescribed ASTM test methods.

scribed in 5.2.1 – 5.2.5.

4. Significance and Use

5.2.1 Pretreatment—The processes in this category include

the addition of various types of coagulants, precipitating

4.1 This guide recommends the water quality required for

agents,clarifiers,sedimentationtanks,andparticulate-filtration

the electronics and microelectronics industries. High-purity

systems (including sand filters, disposable filter elements,

water is required to prevent contamination of products during

ultrafilter membranes, and other particle-removing systems).

manufacture, since contamination can lead to an unacceptable,

Adsorbent or entrapment beds may include greensand, acti-

low yield of electronic devices.

vated carbon, and various synthetic materials specific for

4.2 The range of water purity is defined in accordance with

certain organic and inorganic impurities.

the manufacturing process. The types of ultra-pure water are

5.2.2 Desalination—This process is fundamental to the

defined with respect to device line width. In all cases, the

production of ultra-pure water of all grades, and may include

water-quality recommendations apply at the point of distribu-

more than one of the processes of ion exchange, reverse

tion.

osmosis, electrodialysis, continuous electrodeionization, or all

4.3 The limits on the impurities are related to current

of the above. The size of the system governs the choice of the

contamination specifications and to available analytical meth-

combination of desalination processes. Various configurations

ods (either performed in a suitable clean laboratory or by

of the different processes should be considered, including

on-lineinstrumentation).On-lineandoff-linemethodsareused

two-bed and mixed-bed demineralization, multi-stage reverse

in accordance with current industry practice. Concentration of

osmosis employing various types of membranes,

the sample may be required to measure the impurities at the

electrodeionization, and electrodialysis.

levels indicated in Table 1.

5.2.3 Organic and Biological Removal Systems—Removal

of biological and organic contaminants is an important adjunct

5. Classification

to any system used to prepare ultra-pure water. Dissolved

5.1 Seven types of electronic-grade water are described in organic compounds can accumulate in the system during the

this guide. In all cases, the water-quality recommendations process as well as being present in the original water. Methods

apply at the point of distribution. ofminimizingbiologicalcontaminationincludetheadditionof

5.1.1 Type E-1—This water is classified as microelectronic hydrogenperoxideandozone.Ultravioletirradiationatthe185

water to be used in the production of devices having line nm wavelength provides intense energy for breaking chemical

widths between 0.5 and 1.0 µm. bonds and produces traces of ozone. The 185 nm light lyses

5.1.2 Type E-1.1—This water is classified as microelec- bacteria and breaks down organic compounds to organic acids

tronicwatertobeusedintheproductionofdeviceshavingline and carbon dioxide. Also formed are active intermediate

widths between 0.25 and 0.35 µm. reactants;themainsuchreactantisthehydroxylradical,which

5.1.3 Type E-1.2—This water is classified as microelec- inactivatesbacteria.Variablessuchaswaterflowanddegreeof

tronicwatertobeusedintheproductionofdeviceshavingline certain contaminants like turbidity, iron, and humic and fluvic

widths between 0.09 and 0.18 µm. acidshouldbeconsideredtoachievethemaximumeffectfrom

5.1.4 Type E-1.3—This water is classified as microelec- the irradiation. With the destruction of organics, TOC will be

tronic water to be used in production of devices having line reduced.Therefore,185nmlightshouldonlybeusedupstream

D5127 − 13 (2018)

A

TABLE 1 Requirements for Water at the Point of Distribution in the Electronics and Semiconductor Industries

B B

Parameter Type E-1 Type E-1.1 Type E-1.2 Type E-1.3 Type E-2 Type E-3 Type E-4

Linewidth (microns) 1.0–0.5 0.35–0.25 0.18–0.09 0.065–0.032 5.0–1.0 >5.0 —

Resistivity, 25°C (on-line) 18.1 18.2 18.2 18.2 16.5 12 0.5

TOC (µg/L) (on-line for <10 ppb) 5 2 1 1 50 300 1000

On-line dissolved oxygen (µg/L) 25 10 3 10 — — —

On-line residue after evaporation 10.5 0.1 — — —

(µg/L)

On-line particles/L (micron range)

>0.05 µm 500

0.05–0.1 1000 200 N/A — — —

0.1–0.2 1000 350 <100 N/A — — —

0.2–0.5 500 <100 <10 N/A — — —

0.5-1.0 200 <50 <5 N/A — — —

1.0 <100 <20 <1 N/A — — —

SEM particles/L (micron range)

0.1–0.2 1000 700 <250 N/A — — —

0.2–0.5 500 400 <100 N/A 3000 — —

0.5–1 100 50 <30 N/A — 10 000 —

10 <50 <30 <10 N/A — — 100 000

Bacteria in CFU/Volume

100-mL sample 5 3 1 N/A 10 50 100

1-L sample 10 1

10-L sample 1

Silica – total (µg/L) 5 3 1 0.5 10 50 1000

Silica – dissolved (µg/L) 3 1 0.5 0.5 — — —

Anions and Ammonium by IC (µg/L)

Ammonium 0.1 0.10 0.05 0.050 — — —

Bromide 0.1 0.05 0.02 0.050 — — —

Chloride 0.1 0.05 0.02 0.050 1 10 1000

Fluoride 0.1 0.05 0.03 0.050 — — —

Nitrate 0.1 0.05 0.02 0.050 1 5 500

Nitrite 0.1 0.05 0.02 0.050 — — —

Phosphate 0.1 0.05 0.02 0.050 1 5 500

Sulfate 0.1 0.05 0.02 0.050 1 5 500

Metals by ICP/MS (µg/L)

Aluminum 0.05 0.02 0.005 0.001 — — —

Antimony 0.001

Arsenic 0.001

Barium 0.05 0.02 0.001 0.001 — — —

C

Boron 0.3 0.1 0.05 0.050 — — —

Cadmium 0.010

Calcium 0.05 0.02 0.002 0.001 — — —

Chromium 0.05 0.02 0.002 0.001 — — —

Copper 0.05 0.02 0.002 0.001 1 2 500

Iron 0.05 0.02 0.002 0.001 — — —

Lead 0.05 0.02 0.005 0.001 — — —

Lithium 0.05 0.02 0.003 0.001 — — —

Magnesium 0.05 0.02 0.002 0.001 — — —

Manganese 0.05 0.02 0.002 0.010 — — —

Nickel 0.05 0.02 0.002 0.001 1 2 500

Potassium 0.05 0.02 0.005 0.001 2 5 500

Sodium 0.05 0.02 0.005 0.001 1 5 1000

Strontium 0.05 0.02 0.001 — — —

Tin 0.010

Titanium 0.010

Vanadium 0.010

Zinc 0.05 0.02 0.002 0.001 1 5 500

Temperature Stability (K) ±1

Temperature Gradient (K/10 min) <0.1

Dissolved Nitrogen On-line (mg/L) 8–18

Dissolved Nitrogen Stability (mg/L) ±2

A

The user should be advised that analytical data often are instrument dependent and technique dependent.Thus, the numbers in Table 1 are only guidelines.This table

will be revised whenever the semiconductor industry develops new linewidths, thereby keeping the guidelines current.

B

Values shown inType E-1.3 are a result of aligning ITRS risk factors of known contaminates to the production processes found in current semiconductor processing for

the linewidth of interest and may differ in a few cases to those found in Type E-1.2. Users who wish to use the higher numbers for Type E-1.2 water should feel free to

do so.

All values are equal to or less than with the exception of Resistivity.

C

Boron is monitored only as an operational parameter for monitoring the ion-exchange beds.

D5127 − 13 (2018)

of the final ion-exchange component. Ultraviolet irradiation at water. If the system has been idle for a period of time or was

254 nm significantly reduces the growth of organisms by not clean when installed, a system sanitization using hydrogen

dislocating the DNA base pairs. This process prevents the peroxide or ozone might be required. The distribution outlets

bacteria from replicating. Membrane filters (including reverse must also be of non-contaminating design and materials;

particular care must be given to minimizing the possibility of

osmosisandultrafilters)mayalsoremovebiologicalimpurities

as well as organic molecules. Synthetic adsorbent columns back contamination of the system from the faucet or valve

outlet.

ranging from porous resins to activated carbon may be effec-

tive in removing organics.

5.3 Component Sections:

5.2.4 Particulate Removal—Particulate removal in the pro-

5.3.1 Primary Section—This section of the water system

duction of ultra-pure water is differentiated from pretreatment

performs the primary purification of the input water. The

that removes gross suspended substances. Particles of all types

primary section should utilize one or more of the pretreatment

(biological, organic, or inorganic) significantly interfere with

anddesalinationprocessesnotedin5.2.Thewaterproducedin

the production of electronic components. Processes used to

the primary section should have a purity equivalent to Type

remove particulate matter generally consist of the use of a

E-4, and may or may not be stored prio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.