ASTM F2707-10

(Specification)Standard Safety Performance Specification for Safe Design and Installation of Field Fabricated Suction-Limiting Vent Systems for Suction Entrapment Prevention in Swimming Pools, Spas, Hot Tubs, and Wading Pools

Standard Safety Performance Specification for Safe Design and Installation of Field Fabricated Suction-Limiting Vent Systems for Suction Entrapment Prevention in Swimming Pools, Spas, Hot Tubs, and Wading Pools

SCOPE

1.1 This safety performance specification provides requirements for safety in design and installation when using a suction-limiting vent system for suction entrapment prevention in swimming pools, spas, hot tubs, or wading pools.

1.2 The purpose of the vent is to relieve the vacuum at the suction outlet(s) caused by any blockage of the suction outlet(s). The vent is intended to prevent body entrapment at the suction outlet(s) and may also mitigate limb entrapment. It is not intended to prevent other injuries caused by the suction outlet(s) such as hair entrapment, mechanical entrapment, or evisceration.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2707 −10

Standard Safety Performance Specification for

Safe Design and Installation of Field Fabricated Suction-

Limiting Vent Systems for Suction Entrapment Prevention in

1

Swimming Pools, Spas, Hot Tubs, and Wading Pools

This standard is issued under the fixed designation F2707; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 allowable drawdown, n—drawdown depth corre-

sponding to the acceptable removal effort for a particular

1.1 This safety performance specification provides require-

uncovered sump; it is physically built into the system.

ments for safety in design and installation when using a

suction-limiting vent system for suction entrapment prevention

3.1.2 engineer, n—registered professional engineer.

in swimming pools, spas, hot tubs, or wading pools.

3.1.3 field-fabricated vent (FFV), n—open-to-atmosphere

1.2 The purpose of the vent is to relieve the vacuum at the

ventinstalledbetweenthepoolsuctionoutlet(s)andthesuction

suction outlet(s) caused by any blockage of the suction

side of the pump in such a way as to relieve the vacuum caused

outlet(s). The vent is intended to prevent body entrapment at

by a blockage of the suction outlet(s).

the suction outlet(s) and may also mitigate limb entrapment. It

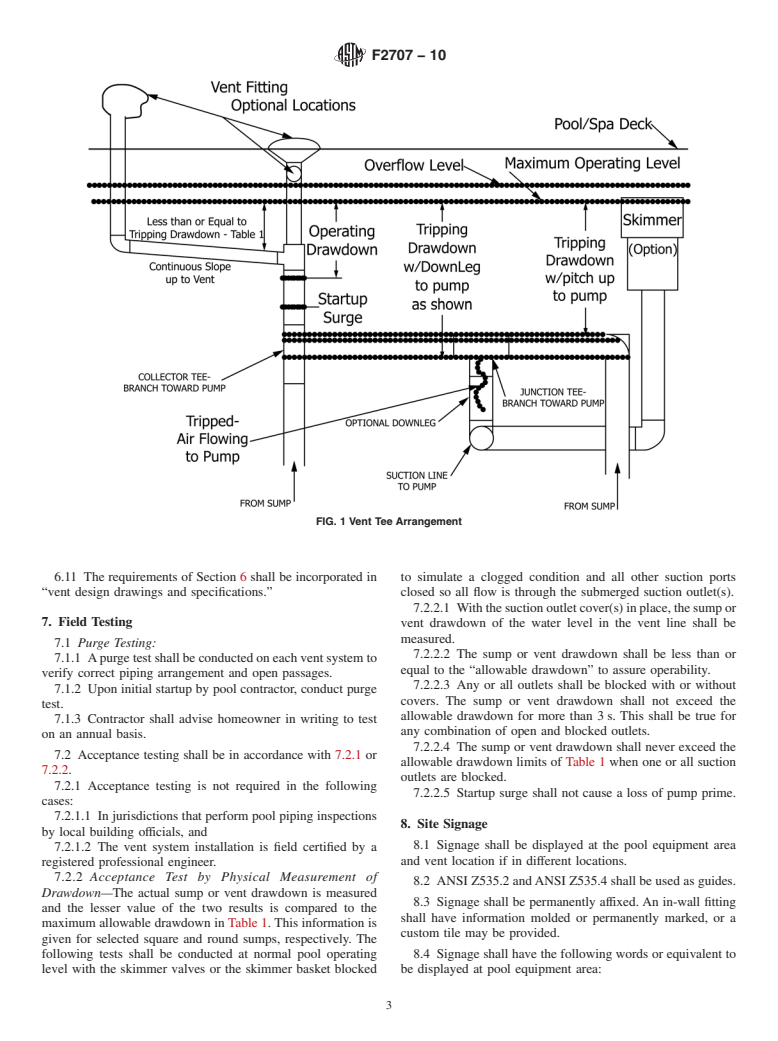

3.1.4 operating drawdown, n—lowering of the water level

is not intended to prevent other injuries caused by the suction

in the vent from the static condition caused by normal

outlet(s) such as hair entrapment, mechanical entrapment, or

operation.

evisceration.

3.1.5 purge test, n—placing a blocking element over the

1.3 The values stated in inch-pound units are to be regarded

sump to ensure that air enters the vent system.

as standard. The values given in parentheses are mathematical

3.1.6 startup surge, n—transient lowering of the water level

conversions to SI units that are provided for information only

in the vent during pump startup.

and are not considered standard.

3.1.6.1 Discussion—If excessive, the pump may lose prime.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.1 This performance specification outlines the require-

bility of regulatory limitations prior to use.

ments needed to design and install a field-fabricated vent for

safety purposes. Vents only address suction outlet body and

2. Referenced Documents

may mitigate limb entrapment. Vents have proven effective

when installed correctly. It is not intended to prevent other

2

2.1 ANSI Standards:

injuries caused by suction outlet(s) such as hair entrapment,

ANSI Z535.2 Environmental and facility safety signs

mechanical entrapment, or evisceration.

ANSI Z535.4 Product safety signs and labels

ASME/ANSI A112.19.8 Suction Fittings for Use in Swim-

5. General Requirements

ming Pools, Wading Pools, Spas, and Hot Tubs

5.1 Design and installation instructions for field-fabricated

vents (FFV) shall be certified only by a registered professional

3. Terminology

engineer. Multiple systems may be built to the same “vent

3.1 Definitions:

design drawings and specifications” with the approval of the

engineer.

5.2 The design and installation of the vent is specific to each

1

This test method is under the jurisdiction of ASTM Committee F15 on

piping system and shall consider all relevant parameters

Consumer Products and is the direct responsibility of Subcommittee F15.51 on

Safety Vacuum Release Systems for Swimming Pools, Spas and Hot Tubs.

includingbutnotlimitedto:elevations,flowrate,startupsurge,

Current edition approved Nov. 1, 2010. Published March 2011. DOI: 10.1520/

minimum and maximum water operating levels, water depth at

F2707-10.

2

the suction outlet(s), pipe fittings, spacing between fittings,

Available fromAvailable from American National Standards Institute (ANSI),

25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org. atmospheric vent fitting, and suction outlet configurations.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2707−10

5.3 The vent shall be tested in place for proper function. See 6.4 Under normal operation, the vent system shall not

Section 7 for details. adversely affect pump suction, system flow, or other equipment

performance.

6. Specific Requirements

6.5 Nocheckvalvesorvalvesshallbeinstalledbetweenany

6.1 Theengineershallspecifyminimumandmaximumflow s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.