ASTM F1913-04(2014)

(Specification)Standard Specification for Vinyl Sheet Floor Covering Without Backing

Standard Specification for Vinyl Sheet Floor Covering Without Backing

ABSTRACT

This specification covers sheet floor covering having a vinyl wear layer without backing. Products also may contain a clear specialty performance top layers. This type of floor covering is intended for use in commercial and light commercial buildings. The wear layer shall have a vinyl plastic binder and may include pigments, fillers, extenders, and other ingredients. This layer shall be stabilized against heat and light deterioration. The binder content of the PVC-pattern portion of the wear layer such as vinyl resins, plasticizers, and stabilizers shall be a minimum of 50 %.

SCOPE

1.1 This specification covers sheet floor covering having a vinyl wear layer without backing. Products also may contain a clear specialty performance top layer(s).

1.2 This type of floor covering is intended for use in commercial and light commercial buildings. General information and performance characteristics, which determine serviceability and recommended use, are included in this specification.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1913 −04 (Reapproved 2014)

Standard Specification for

Vinyl Sheet Floor Covering Without Backing

This standard is issued under the fixed designation F1913; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ient Flooring by Color Change

F1914 Test Methods for Short-Term Indentation and Re-

1.1 This specification covers sheet floor covering having a

sidual Indentation of Resilient Floor Covering

vinyl wear layer without backing. Products also may contain a

2.2 ANSI/ASQC Standard:

clear specialty performance top layer(s).

ANS/ASQC Z1.4 Sampling Procedures and Tables for In-

1.2 This type of floor covering is intended for use in

spection by Attributes

commercial and light commercial buildings. General informa-

tion and performance characteristics, which determine service-

3. Terminology

abilityandrecommendeduse,areincludedinthisspecification.

3.1 Definitions— Terms used in this specification are de-

1.3 The values stated in inch-pound units are to be regarded

fined in accordance with Terminology F141.

as standard. The values given in parentheses are mathematical

3.2 Definitions of Terms Specific to This Standard:

conversions to SI units that are provided for information only

3.2.1 wear layer, n—the portion of a resilient floor covering

and are not considered standard.

that contains the pattern effect.

1.4 This standard does not purport to address all of the

3.2.1.1 Discussion—The wear layer thickness and total

safety concerns, if any, associated with its use. It is the

thickness of through pattern unbacked sheet vinyl flooring are

responsibility of the user of this standard to establish appro-

the same.Aclear specialty performance top layer may be used

priate safety and health practices and determine the applica-

to enhance specific properties and to protect the pattern effect

bility of regulatory limitations prior to use.

and shall be counted as part of the wear layer. The wear layer

does not include temporary finishes or maintenance coatings.

2. Referenced Documents

2.1 ASTM Standards:

4. Significance and Use

F137 Test Method for Flexibility of Resilient Flooring Ma-

4.1 The information in this specification is for use by

terials with Cylindrical Mandrel Apparatus

specifiers as a reference when selecting unbacked resilient

F141 Terminology Relating to Resilient Floor Coverings

sheet vinyl flooring for areas within commercial and light

F386 Test Method for Thickness of Resilient Flooring Ma-

commercial buildings.

terials Having Flat Surfaces

F410 Test Method for Wear Layer Thickness of Resilient

5. Classification

Floor Coverings by Optical Measurement

5.1 Sheet Vinyl floor covering shall conform to the follow-

F925 Test Method for Resistance to Chemicals of Resilient

ing.

Flooring

5.1.1 The binder content of the PVC-pattern portion of the

F970 Test Method for Static Load Limit

wear layer (vinyl resins, plasticizers, and stabilizers) shall be a

F1514 TestMethodforMeasuringHeatStabilityofResilient

minimum of 50 %.Aclear specialty performance layer(s) used

Flooring by Color Change

as the top layer is not described by binder limits.

F1515 Test Method for Measuring Light Stability of Resil-

PVC Binder Content

Minimum % PVC Wear Layer Description

50 % The material shall be a vinyl compound consisting

This specification is under the jurisdiction of ASTM Committee F06 on

of a blended composition of pigments stabilized

Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80

against heat and light deterioration. The design,

on Specifications.

color and pattern extends throughout the thickness

Current edition approved Nov. 1, 2014. Published December 2014. Originally

of the wear layer.

approved in 1998. Last previous edition approved in 2010 as F1913 - 04(2010).

DOI: 10.1520/F1913-04R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1913−04 (2014)

5.1.1.1 All flooring may have a clear specialty performance up to a maximum 0.005 in. and is not removable by normal

toplayer(s)withanaverageminimumtotalthicknessof0.0004 maintenance procedures.

in. The specialty performance top layer(s) may consist of a

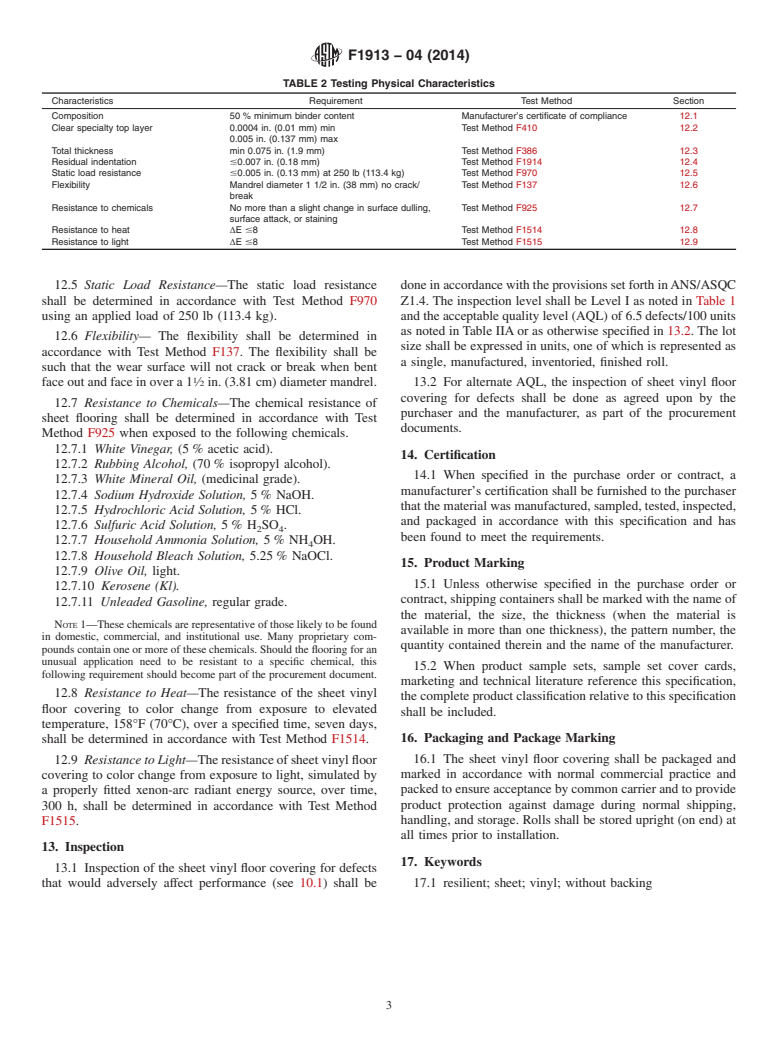

8. Physical Requirements

single layer or multiple layers, which do not delaminate under

normal use. Top layer(s) thinner than 0.0004 in. may be used

8.1 Sheetvinylfloorcoveringshallmeettherequirementsin

but cannot be counted as part of the clear specialty perfor-

Table 2.

mance top layer.

9. Dimensions

5.1.2 The total thickness is the sum of the PVC wear layer

and the clear specialty top layer(s).The total thickness average

9.1 Common roll widths are 49-in. (1.25-m), 59-in. (1.5-m),

minimum is 0.075 in. (1.9 mm).

72-in. (1.83-m), and 78-in. (2-m) widths (minus 0 in.). Other

widths may be available.

6. Ordering Information

9.2 The floor covering shall be furnished in a minimum

6.1 Sheet vinyl floor covering without backing shall be

average overall thickness of 0.075 in. (1.9 mm).

ordered according to characteristics important to the purchaser

for the intended use as indicated by Table 1.

10. Workmanship, Finish, and Appearance

6.2 Intended Use— The following is a partial list providing

10.1 Materials furnished under this specification shall be an

generic guidance on typical applications of product use. For

acceptable match to an approved sample(s) in pattern, color,

specific applications, refer to the manufacturers product rec-

and surface appearance. The product shall be free of defects,

ommendations.

which would adversely affect performance or appearance.

6.2.1 LC (Light Commercial):

6.2.1.1 Multi-family Dwelling—Common Areas.

11. Sampling

6.2.1.2 Hotel/Motel Guest Rooms.

11.1 Sampling for testing physical characteristics listed in

6.2.2 C (Commercial):

Table 2 shall be done in accordance with the provisions set

6.2.2.1 Educational/Institutional.

forth in ANSI/ASQC Z1.4. The inspection level shall be

6.2.2.2 Hospital/Health Care.

special inspection level S-1 as noted in Table 1 and the

6.2.2.3 Retail/Mercantile.

acceptablequalitylevel(AQL)shallbe6.5defects/100unitsas

6.2.2.4 Office

noted in Table II-A or as otherwise specified in 11.3. The lot

6.2.2.5 Hospitality.

size shall be expressed in units. A unit represents a single,

6.3 The purchaser may wish to specify the following items: manufactured, inventoried, finished roll.

6.3.1 Manufacturer,

11.2 Samples shall be obtained in the required length from

6.3.2 Style name and number,

the outside end of the roll and shall encompass the total width

6.3.3 Minimum roll width (see 9.1),

of the material.

6.3.4 Surface texture (see 7.1.3), and

11.3 Sampling for testing physical characteristics listed in

6.3.5 Variation in list of chemicals used to demonstrate

Table 2 shall be agreed upon by the purchaser and the

chemical resistance (see 12.7).

manufacturer as part of the procurement documents.

7. Material

12. Test Methods

7.1 Wear Layer:

12.1 Wear Layer Binder Content—The wear layer binder

7.1.1 The wear layer shall have a vinyl plastic binder and

content shall be determined by statement of formula (manu-

may include pigments, fillers, extenders, and other ingredients;

facturer’s certificate of compliance).

and shall be stabilized against heat and light deterioration (see

12.8 and 12.9).

12.2 Clear Specialty Performance Top Layer Thickness—

7.1.2 The binder of the wear layer shall consist of one or

The specialty performance top layer thickness shall be deter-

more vinyl resins, platicizers, and stabilizers. Each resin shall

mined in accordance with Test Method F410 except the

be polyvinyl chloride or a copolymer of vinyl chloride not less

thickness of the sample shall be the average

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1913 − 04 (Reapproved 2010) F1913 − 04 (Reapproved 2014)

Standard Specification for

Vinyl Sheet Floor Covering Without Backing

This standard is issued under the fixed designation F1913; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers sheet floor covering having a vinyl wear layer without backing. Products also may contain a clear

specialty performance top layer(s).

1.2 This type of floor covering is intended for use in commercial and light commercial buildings. General information and

performance characteristics, which determine serviceability and recommended use, are included in this specification.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

F137 Test Method for Flexibility of Resilient Flooring Materials with Cylindrical Mandrel Apparatus

F141 Terminology Relating to Resilient Floor Coverings

F386 Test Method for Thickness of Resilient Flooring Materials Having Flat Surfaces

F410 Test Method for Wear Layer Thickness of Resilient Floor Coverings by Optical Measurement

F925 Test Method for Resistance to Chemicals of Resilient Flooring

F970 Test Method for Static Load Limit

F1514 Test Method for Measuring Heat Stability of Resilient Flooring by Color Change

F1515 Test Method for Measuring Light Stability of Resilient Flooring by Color Change

F1914 Test Methods for Short-Term Indentation and Residual Indentation of Resilient Floor Covering

2.2 ANSI/ASQC Standard:

ANS/ASQC Z1.4 Sampling Procedures and Tables for Inspection by Attributes

3. Terminology

3.1 Definitions— Terms used in this specification are defined in accordance with Terminology F141.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 wear layer, n—the portion of a resilient floor covering that contains the pattern effect.

This specification is under the jurisdiction of ASTM Committee F06 on Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80 on

Specifications.

Current edition approved May 1, 2010Nov. 1, 2014. Published May 2010December 2014. Originally approved in 1998. Last previous edition approved in 20042010 as

F1913 - 04.04(2010). DOI: 10.1520/F1913-04R10.10.1520/F1913-04R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

3.2.1.1 Discussion—

The wear layer thickness and total thickness of through pattern unbacked sheet vinyl flooring are the same. A clear specialty

performance top layer may be used to enhance specific properties and to protect the pattern effect and shall be counted as part of

the wear layer. The wear layer does not include temporary finishes or maintenance coatings.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1913 − 04 (2014)

4. Significance and Use

4.1 The information in this specification is for use by specifiers as a reference when selecting unbacked resilient sheet vinyl

flooring for areas within commercial and light commercial buildings.

5. Classification

5.1 Sheet Vinyl floor covering shall conform to the following.

5.1.1 The binder content of the PVC-pattern portion of the wear layer (vinyl resins, plasticizers, and stabilizers) shall be a

minimum of 50 %. A clear specialty performance layer(s) used as the top layer is not described by binder limits.

PVC Binder Content

Minimum % PVC Wear Layer Description

50 % The material shall be a vinyl compound consisting

of a blended composition of pigments stabilized

against heat and light deterioration. The design,

color and pattern extends throughout the thickness

of the wear layer.

PVC Binder Content

Minimum % PVC Wear Layer Description

50 % The material shall be a vinyl compound consisting

of a blended composition of pigments stabilized

against heat and light deterioration. The design,

color and pattern extends throughout the thickness

of the wear layer.

5.1.1.1 All flooring may have a clear specialty performance top layer(s) with an average minimum total thickness of 0.0004 in.

The specialty performance top layer(s) may consist of a single layer or multiple layers, which do not delaminate under normal use.

Top layer(s) thinner than 0.0004 in. may be used but cannot be counted as part of the clear specialty performance top layer.

5.1.2 The total thickness is the sum of the PVC wear layer and the clear specialty top layer(s). The total thickness average

minimum is 0.075 in. (1.9 mm).

6. Ordering Information

6.1 Sheet vinyl floor covering without backing shall be ordered according to characteristics important to the purchaser for the

intended use as indicated by Table 1.

6.2 Intended Use— The following is a partial list providing generic guidance on typical applications of product use. For specific

applications, refer to the manufacturers product recommendations.

6.2.1 LC (Light Commercial):

6.2.1.1 Multi-family Dwelling—Common Areas.

6.2.1.2 Hotel/Motel Guest Rooms.

6.2.2 C (Commercial):

6.2.2.1 Educational/Institutional.

6.2.2.2 Hospital/Health Care.

6.2.2.3 Retail/Mercantile.

6.2.2.4 Office

6.2.2.5 Hospitality.

6.3 The purchaser may wish to specify the following items:

6.3.1 Manufacturer,

6.3.2 Style name and number,

6.3.3 Minimum roll width (see 9.1),

6.3.4 Surface texture (see 7.1.3), and

6.3.5 Variation in list of chemicals used to demonstrate chemical resistance (see 12.7).

7. Material

7.1 Wear Layer:

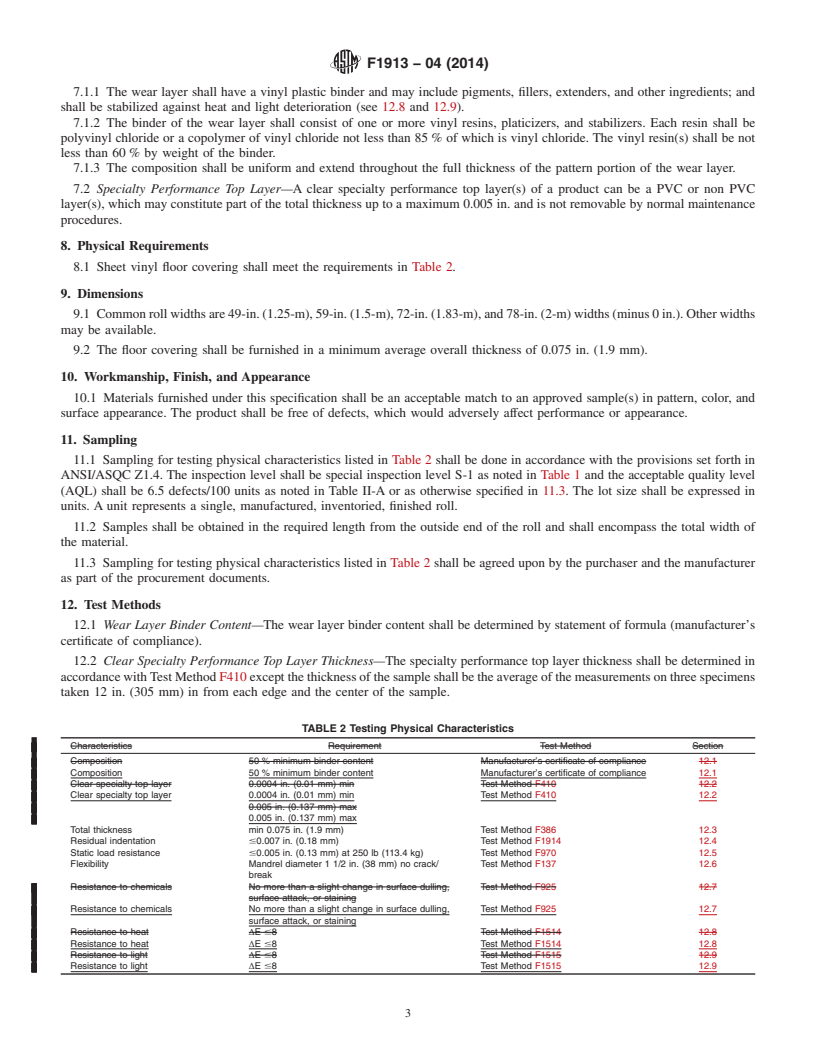

TABLE 1 Total Thickness

Average Minimum in. (mm) Intended Use

0.075 (1.9) LC/C

TABLE 1 Total Thickness

Average Minimum in. (mm) Intended Use

0.075 (1.9) LC/C

F1913 − 04 (2014)

7.1.1 The wear layer shall have a vinyl plastic binder and may include pigments, fillers, extenders, and other ingredients; and

shall be stabilized against heat and light deterioration (see 12.8 and 12.9).

7.1.2 The binder of the wear layer shall consist of one or more vinyl resins, platicizers, and stabilizers. Each resin shall be

polyvinyl chloride or a copolymer of vinyl chloride not less than 85 % of which is vinyl chloride. The vinyl resin(s) shall be not

less than 60 % by weight of the binder.

7.1.3 The composition shall be uniform and extend throughout the full thickness of the pattern portion of the wear layer.

7.2 Specialty Performance Top Layer—A clear specialty performance top layer(s) of a product can be a PVC or non PVC

layer(s), which may constitute part of the total thickness up to a maximum 0.005 in. and is not removable by normal maintenance

procedures.

8. Physical Requirements

8.1 Sheet vinyl floor covering shall meet the requirements in Table 2.

9. Dimensions

9.1 Common roll widths are 49-in. (1.25-m), 59-in. (1.5-m), 72-in. (1.83-m), and 78-in. (2-m) widths (minus 0 in.). Other widths

may be available.

9.2 The floor covering shall be furnished in a minimum average overall thickness of 0.075 in. (1.9 mm).

10. Workmanship, Finish, and Appearance

10.1 Materials furnished under this specification shall be an acceptable match to an approved sample(s) in pattern, color, and

surface appearance. The product shall be free of defects, which would adversely affect performance or appearance.

11. Sampling

11.1 Sampling for testing physical characteristics listed in Table 2 shall be done in accordance with the provisions set forth in

ANSI/ASQC Z1.4. The inspection level shall be special inspection level S-1 as noted in Table 1 and the acceptable quality level

(AQL) shall be 6.5 defects/100 units as noted in Table II-A or as otherwise specified in 11.3. The lot size shall be expressed in

units. A unit represents a single, manufactured, inventoried, finished roll.

11.2 Samples shall be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.