ASTM D3545-02

(Test Method)Standard Test Method for Alcohol Content and Purity of Acetate Esters by Gas Chromatography

Standard Test Method for Alcohol Content and Purity of Acetate Esters by Gas Chromatography

SCOPE

1.1 This test method covers the determination by gas chromatography of the ester content and the corresponding alcohol content of acetate esters. This test method has been applied to ethyl, n-propyl, isopropyl, n-butyl, isobutyl, and 2-ethoxyethyl acetates.

1.2 Water, and in some cases acetic acid, cannot be determined by this test method and must be measured by other appropriate ASTM procedures and the results used to normalize the chromatographic value.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 For specific hazard information and guidance, see the supplier's Material Safety Data Sheet for material listed in this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3545–02

Standard Test Method for

Alcohol Content and Purity of Acetate Esters by Gas

1

Chromatography

This standard is issued under the fixed designation D 3545; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

5

1. Scope E 260 Practice for Packed Column Gas Chromatography

1.1 This test method covers the determination by gas

3. Summary of Test Method

chromatography of the ester content and the corresponding

3.1 A representative specimen is introduced into a gas-

alcohol content of acetate esters. This test method has been

liquid partition column. The acetate is separated from impuri-

applied to ethyl, n-propyl, isopropyl, n-butyl, isobutyl, and

ties such as alcohols, other esters, ethers, and several uniden-

2-ethoxyethyl acetates.

tified compounds while the components are transported

1.2 Water, and in some cases acetic acid, cannot be deter-

through the column by an inert carrier gas. The separated

mined by this test method and must be measured by other

components are measured in the effluent by a detector and

appropriate ASTM procedures and the results used to normal-

recorded as a chromatogram. The chromatogram is interpreted

ize the chromatographic value.

by applying component attenuation and detector response

1.3 This standard does not purport to address all of the

factors to the peak areas, and the relative concentrations are

safety concerns, if any, associated with its use. It is the

determined by relating the individual peak responses to the

responsibility of the user of this standard to establish appro-

total peak response. Water and acidity are measured by Test

priate safety and health practices and determine the applica-

Methods D 1364 and D 1613, respectively, and the results are

bility of regulatory limitations prior to use.

used to normalize the values obtained by gas chromatography.

1.4 For specific hazard information and guidance, see the

supplier’s Material Safety Data Sheet for material listed in this

4. Significance and Use

specification.

4.1 This test method is useful for identifying and for

2. Referenced Documents determining the quantity of various impurities in acetate esters.

4.2 Total purity of the acetate esters must be determined by

2.1 ASTM Standards:

use of other appropriate ASTM procedures with this test

D 1364 Test Method for Water in Volatile Solvents (Karl

2 method.

Fischer Reagent Titration Method)

D 1613 Test Method for Acidity in Volatile Solvents and

5. Apparatus

Chemical Intermediates Used in Paint, Varnish, Lacquer,

5.1 Chromatograph—Any gas chromatograph having either

2

and Related Products

a thermal conductivity or flame ionization detector, provided

D 2593 Test Method for Butadiene Purity and Hydrocarbon

the system has sufficient sensitivity and stability to obtain for

3

Impurities by Gas Chromatography

0.01 % of the parent alcohol a recorder deflection of at least 20

E 180 Practice for Determining the Precision of ASTM

4 mm at a signal-to-noise ratio of at least 5 to 1. The specimen

Methods forAnalysis and Testing of Industrial Chemicals

size used in judging the sensitivity must be such that the

column is not overloaded, which would result in peak broad-

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint ening, loss of resolution, shifting retention times and formation

and Related Coatings, Materials, andApplications and is the direct responsibility of

of leading peaks. Volumes of 5 µL with thermal conductivity

Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermediates.

and 1 to 2 µL with flame ionization detectors have been found

Current edition approved Jan. 10, 2002. Published March 2002. Originally

acceptable.

published as D 3545 – 76. Last previous edition D 3545 – 95.

2

Annual Book of ASTM Standards, Vol 06.04.

3

Annual Book of ASTM Standards, Vol 05.01.

4 5

Annual Book of ASTM Standards, Vol 15.05. Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

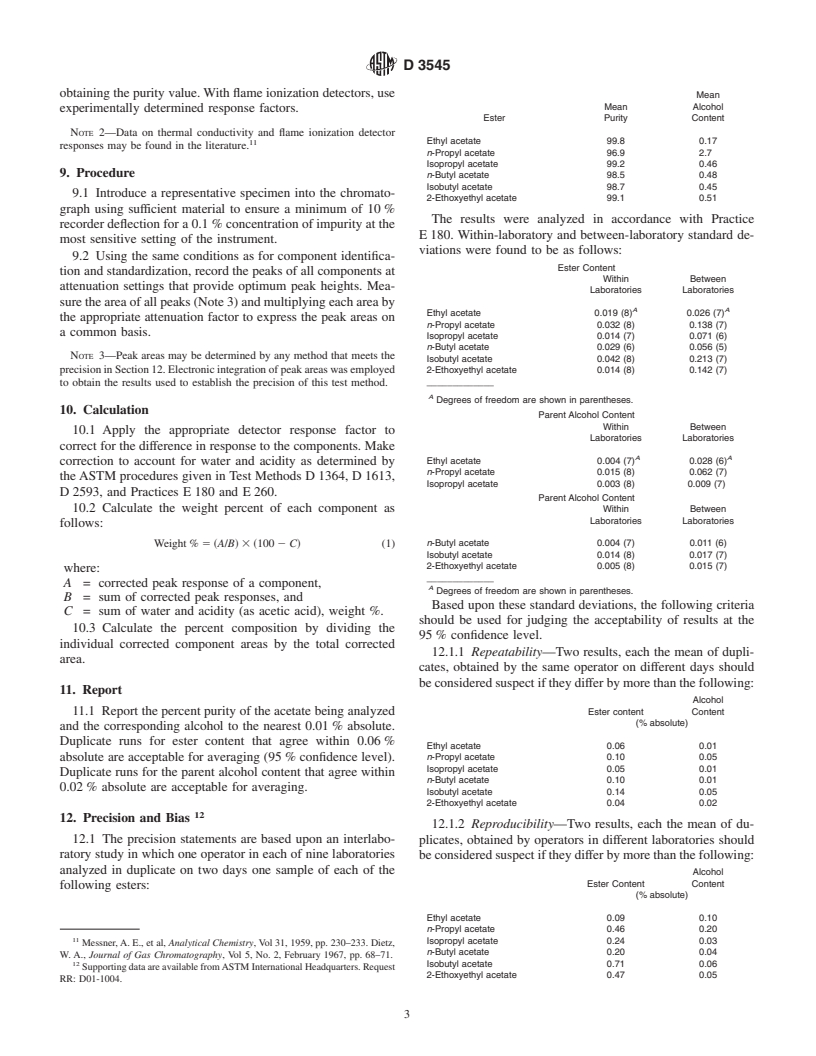

D3545

5.1.1 The injection port of the chromatograph must have a by retention time and for calibration for quantitative measure-

volume of at least 1.2 mLto provide for proper vaporization of ments. Most can be obtained from chemical supply houses.

the material. The use of a smaller injection port or on-column

injection has been found to cause peak broadening and tailing. 7. Preparation of Apparatus

5.2 Column—A 3-m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.