ASTM B814-95

(Specification)Standard Specification for :Nickel-Chromium-Iron-Molybdenum-Tungsten Alloy (UNS N06920) Plate, Sheet, and Strip

Standard Specification for :Nickel-Chromium-Iron-Molybdenum-Tungsten Alloy (UNS N06920) Plate, Sheet, and Strip

SCOPE

1.1 This specification covers nickel-chromium-iron-molybdenum-tungsten alloy UNS N06920 in the form of rolled plate, sheet, and strip for general corrosion service.

1.2 The following products are covered under this specification:

1.2.1 Sheet and Strip -Hot or cold rolled, annealed and descaled unless solution-annealing is performed in an atmosphere yielding a bright finish; and

1.2.2 Plate -Hot rolled, solution-annealed, and descaled.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

Designation: B 814 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Nickel-Chromium-Iron-Molybdenum-Tungsten Alloy

1

(UNS N06920) Plate, Sheet, and Strip

This standard is issued under the fixed designation B 814; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.1.1 Alloy.

4.1.2 Dimensions—Thickness (in decimals of an inch),

1.1 This specification covers nickel-chromium-iron-

width, and length (inch or fraction of an inch).

molybdenum-tungsten alloy UNS N06920 in the form of rolled

4.1.3 Certification—State whether a report of test results is

plate, sheet, and strip for general corrosion service.

required (Section 15).

1.2 The following products are covered under this specifi-

4.1.4 Optional Requirement—Plate; state how the plate is to

cation:

be cut (see 7.8.1 and Table 1).

1.2.1 Sheet and Strip—Hot or cold rolled, annealed and

4.1.5 Purchase Inspection—State which tests or inspections

descaled unless solution-annealing is performed in an atmo-

are to be witnessed (Section 13).

sphere yielding a bright finish; and

4.1.6 Samples for Product (Check) Analysis—State whether

1.2.2 Plate—Hot rolled, solution-annealed, and descaled.

samples shall be furnished (9.2.2).

1.3 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

5. Chemical Composition

information only.

5.1 The material shall conform to the chemical composition

requirements prescribed in Table 2.

2. Referenced Documents

5.2 If a product (check) analysis is made by the purchaser,

2.1 ASTM Standards:

the material shall conform to the requirements specified in

2

E 8 Test Methods for Tension Testing of Metallic Materials

Table 2 subject to the permissible tolerances given in Table 3.

E 29 Practice for Using Significant Digits in Test Data to

3

Determine Conformance with Specifications

6. Mechanical Properties and Other Requirements

E 55 Practice for Sampling Wrought Nonferrous Metals and

6.1 Tensile Properties—The material shall conform to the

4

Alloys for Determination of Chemical Composition

room temperature tensile properties prescribed in Table 4.

E 354 Test Methods for Chemical Analysis of High-

Temperature, Electrical, Magnetic, and Other Similar Iron, 7. Dimensions, Mass, and Permissible Variations

4

Nickel and Cobalt Alloys

7.1 For the purposes of calculating the weight of the

3

material covered by this specification, a density of 0.303 lb/in.

3. Terminology

3

(8.39 g/cm ) shall be used.

3.1 Definitions of Terms Specific to This Standard:

7.2 Thickness:

3

3.1.1 plate—material ⁄16 in. (4.76 mm) and over in thick-

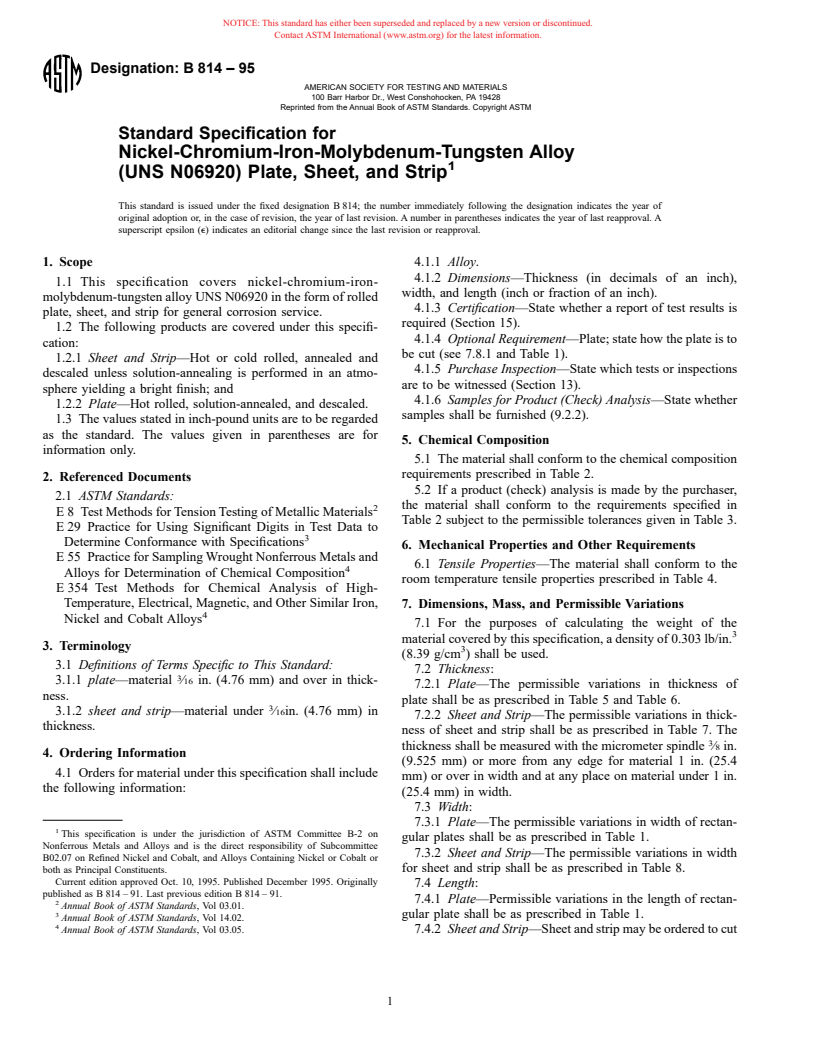

7.2.1 Plate—The permissible variations in thickness of

ness.

plate shall be as prescribed in Table 5 and Table 6.

3

3.1.2 sheet and strip—material under ⁄16in. (4.76 mm) in

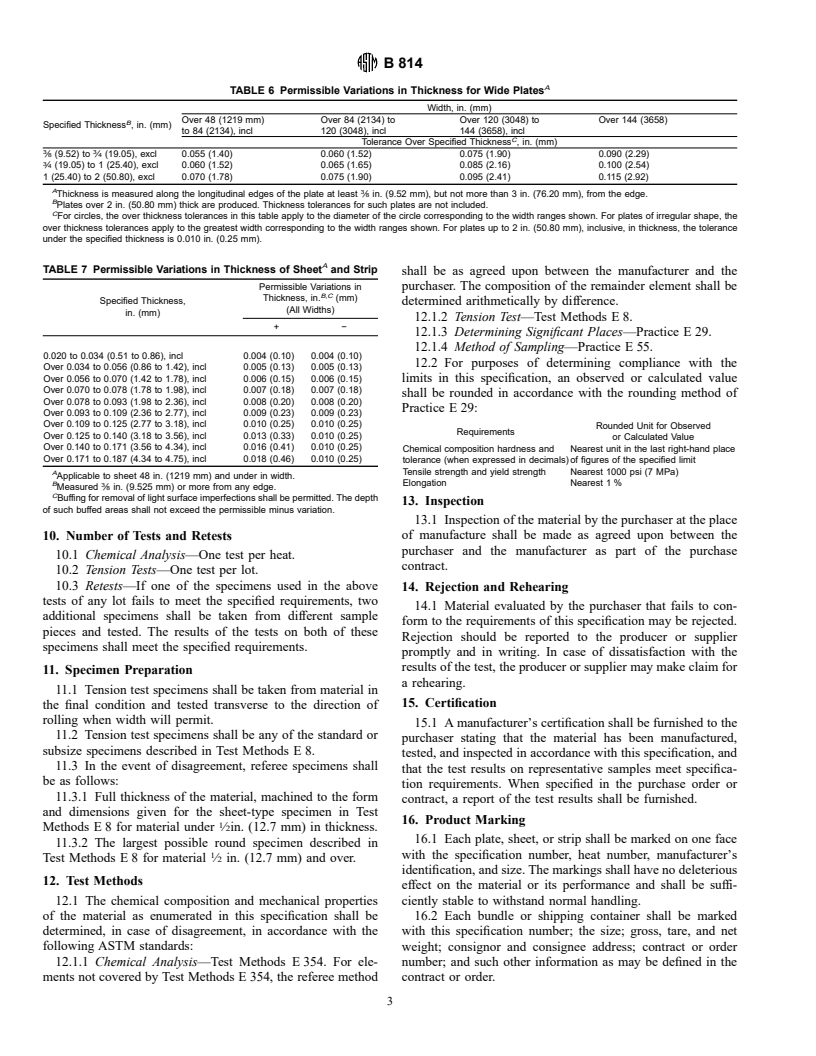

7.2.2 Sheet and Strip—The permissible variations in thick-

thickness.

ness of sheet and strip shall be as prescribed in Table 7. The

3

thickness shall be measured with the micrometer spindle ⁄8 in.

4. Ordering Information

(9.525 mm) or more from any edge for material 1 in. (25.4

4.1 Orders for material under this specification shall include

mm) or over in width and at any place on material under 1 in.

the following information:

(25.4 mm) in width.

7.3 Width:

7.3.1 Plate—The permissible variations in width of rectan-

1

This specification is under the jurisdiction of ASTM Committee B-2 on

gular plates shall be as prescribed in Table 1.

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

7.3.2 Sheet and Strip—The permissible variations in width

B02.07 on Refined Nickel and Cobalt, and Alloys Containing Nickel or Cobalt or

both as Principal Constituents. for sheet and strip shall be as prescribed in Table 8.

Current edition approved Oct. 10, 1995. Published December 1995. Originally

7.4 Length:

published as B 814 – 91. Last previous edition B 814 – 91.

7.4.1 Plate—Permissible variations in the length of rectan-

2

Annual Book of ASTM Standards, Vol 03.01.

3

gular plate shall be as prescribed in Table 1.

Annual Book of ASTM Standards, Vol 14.02.

4

Annual Book of ASTM Standards, Vol 03.05. 7.4.2 Sheet and Strip—Sheet and strip may be ordered to cut

1

---------------------- Page: 1 ----------------------

B 814

TABLE 1 Permissible Variations in Width and Length of Sheared, TABLE 3 Product (Check) Analysis Tolerances

Plasma-Torch-Cut, or Abrasive Cut Rectangular Plate

Element Tolerance Over the Max or

Under the Min Limit, %

Permissible Variations in Widths

and Lengths for Dimensions

Given, in. (mm)

Chromium 0.25

Specified Thickness

Iron 0.30

Up to 30 (760), Over 30 (760)

incl Molybdenum 0.15

Tungsten: Under m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.