ASTM B805-23

(Specification)Standard Specification for Precipitation Hardening Nickel Alloys Bar and Wire

Standard Specification for Precipitation Hardening Nickel Alloys Bar and Wire

ABSTRACT

This specification covers UNS N07716, N07725, N07773, N07776, N09777, and N09925 nickel alloy hot or cold finished rounds, squares, hexagons, rectangles, and cold finished wires. Bars should be supplied in solution treated conditions while wires should be in both solution-treated and cold-finished conditions. The recommended solution treatment should consist of heating the material to a certain temperature followed by rapid cooling. Solution-treated materials should at least conform to the minimum room temperature mechanical properties and should be suitable for subsequent age hardening.

SCOPE

1.1 This specification covers nickel alloys UNS N07716, N07725, N07773, N07776, N09777, and N09925 in the form of hot or cold finished rounds, squares, hexagons, rectangles, and cold finished wire.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following precautionary caveat pertains only to the test methods, portion, Section 13, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B805 − 23

Standard Specification for

1

Precipitation Hardening Nickel Alloys Bar and Wire

This standard is issued under the fixed designation B805; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E8/E8M Test Methods for Tension Testing of Metallic Ma-

terials

1.1 This specification covers nickel alloys UNS N07716,

E29 Practice for Using Significant Digits in Test Data to

N07725, N07773, N07776, N09777, and N09925 in the form

Determine Conformance with Specifications

of hot or cold finished rounds, squares, hexagons, rectangles,

E1473 Test Methods for Chemical Analysis of Nickel,

and cold finished wire.

Cobalt, and High-Temperature Alloys

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

3. Terminology

conversions to SI units that are provided for information only

3.1 Definitions—Definitions for terms defined in Terminol-

and are not considered standard.

ogy B899 shall apply unless otherwise defined by the require-

1.3 The following precautionary caveat pertains only to the

ments of this document.

test methods, portion, Section 13, of this specification: This

3.2 Definitions of Terms Specific to This Standard:

standard does not purport to address all of the safety concerns,

3.2.1 bar, n—material of round, rectangular (flats),

if any, associated with its use. It is the responsibility of the user

hexagonal, square, or other solid section up to and including

of this standard to become familiar with all hazards including

1

10 in. (254 mm) in width and ⁄8 in. (3.2 mm) or over in

those identified in the appropriate Safety Data Sheet (SDS) for

thickness in straight lengths.

this product/material as provided by the manufacturer, to

establish appropriate safety, health, and environmental prac- 3.2.2 wire, n—a cold-worked solid product of uniform cross

tices and determine the applicability of regulatory limitations

section along its whole length, usually supplied in coil form.

prior to use.

1.4 This international standard was developed in accor-

4. Ordering Information

dance with internationally recognized principles on standard-

4.1 It is the responsibility of the purchaser to specify all

ization established in the Decision on Principles for the

requirements that are necessary for material ordered under this

Development of International Standards, Guides and Recom-

specification. Examples of such requirements include, but are

mendations issued by the World Trade Organization Technical

not limited to the following:

Barriers to Trade (TBT) Committee.

4.1.1 Alloy name or UNS number,

4.1.2 ASTM designation and date of issue,

2. Referenced Documents

4.1.3 Quantity,

2

2.1 ASTM Standards:

4.1.4 Form (bar or wire),

B880 Specification for General Requirements for Chemical

4.1.5 Dimensions,

Check Analysis Limits for Nickel, Nickel Alloys and

4.1.6 Condition,

Cobalt Alloys

4.1.7 Finish,

B899 Terminology Relating to Non-ferrous Metals and Al-

4.1.8 Certification—State if certification is required,

loys

4.1.9 Samples for Product Analysis—State if samples for

product analysis are to be furnished, and

4.1.10 Purchaser Inspection—State if purchaser inspection

1

This specification is under the jurisdiction of ASTM Committee B02 on

is required and which tests or inspections are to be witnessed.

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.07 on Refined Nickel and Cobalt and Their Alloys.

Current edition approved April 1, 2023. Published May 2023. Originally 5. Chemical Composition

ɛ1

approved in 1990. Last previous edition approved in 2017 as B805 – 06 (2017) .

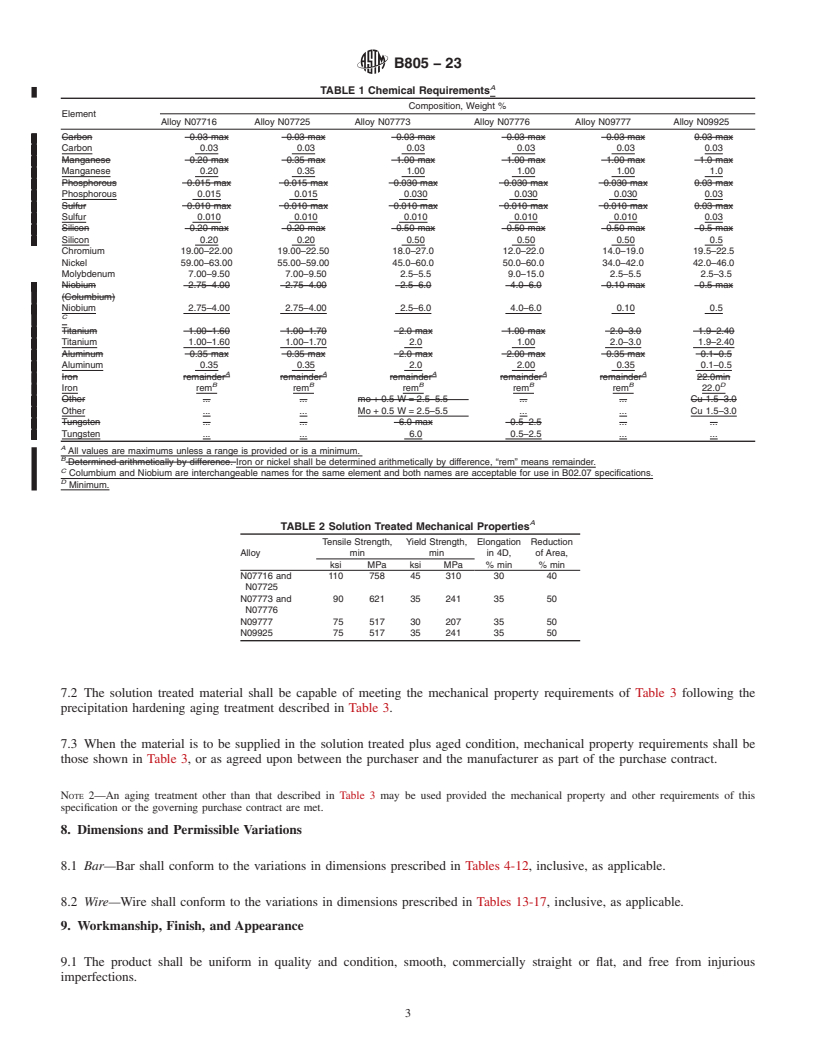

5.1 The material shall conform to the composition limits

DOI: 10.1520/B0805-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or specified in Table 1.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 If a product (check) analysis is performed, the material

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. shall conform to the tolerances provided in Specification B880.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B805 − 23

A

TABLE 1 Chemical Requirements

Composition, Weight %

Element

Alloy N07716 Alloy N07725 Alloy

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: B805 − 06 (Reapproved 2017) B805 − 23

Standard Specification for

1

Precipitation Hardening Nickel Alloys Bar and Wire

This standard is issued under the fixed designation B805; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorial changes were made throughout in April 2017.

1. Scope*

1.1 This specification covers nickel alloys UNS N07716, N07725, N07773, N07776, N09777, and N09925 in the form of hot or

cold finished rounds, squares, hexagons, rectangles, and cold finished wire.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The following precautionary caveat pertains only to the test methods, portion, Section 13, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this

product/material as provided by the manufacturer, to establish appropriate safety and health practices,safety, health, and

environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B880 Specification for General Requirements for Chemical Check Analysis Limits for Nickel, Nickel Alloys and Cobalt Alloys

B899 Terminology Relating to Non-ferrous Metals and Alloys

E8/E8M Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E1473 Test Methods for Chemical Analysis of Nickel, Cobalt, and High-Temperature Alloys

3. Terminology

3.1 Definitions—Definitions for terms defined in Terminology B899 shall apply unless otherwise defined by the requirements of

this document.

3.2 Definitions of Terms Specific to This Standard:

1

This specification is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.07 on Refined

Nickel and Cobalt and Their Alloys.

Current edition approved April 1, 2017April 1, 2023. Published April 2017May 2023. Originally approved in 1990. Last previous edition approved in 20112017 as

ɛ1

B805 – 06 (2011).(2017) . DOI: 10.1520/B0805-06R17E01.10.1520/B0805-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B805 − 23

3.2.1 bar, n—material of round, rectangular (flats), hexagonal, square, or other solid section up to and including 10 in. (254 mm)

1

10 in. (254 mm) in width and ⁄8 in. (3.2 mm) or over in thickness in straight lengths.

3.2.2 wire, n—a cold-worked solid product of uniform cross section along its whole length, usually supplied in coil form.

4. Ordering Information

4.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material ordered under this

specification. Examples of such requirements include, but are not limited to the following:

4.1.1 Alloy name or UNS number,

4.1.2 ASTM designation and date of issue,

4.1.3 Quantity,

4.1.4 Form (bar or wire),

4.1.5 Dimensions,

4.1.6 Condition,

4.1.7 Finish,

4.1.8 Certification—State if certification is required,

4.1.9 Samples for Product Analysis—State if samples for product analysis are to be furnished, and

4.1.10 Purchaser Inspection—State if purchaser inspection is required and which tests or inspections are to be witnessed.

5. Chemical Compos

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.