ASTM E883-11(2017)

(Guide)Standard Guide for Reflected–Light Photomicrography

Standard Guide for Reflected–Light Photomicrography

SIGNIFICANCE AND USE

4.1 This guide is useful for the photomicrography and photomacrography of metals and other materials.

4.2 The subsequent processing of the photographic materials is also treated.

SCOPE

1.1 This guide outlines various methods which may be followed in the photography of metals and materials with the reflected-light microscope. Methods are included for preparation of prints and transparencies in black-and-white and in color, using both direct rapid and wet processes.

1.2 Guidelines are suggested to yield photomicrographs of typical subjects and, to the extent possible, of atypical subjects as well. Information is included concerning techniques for the enhanced display of specific material features. Descriptive material is provided where necessary to clarify procedures. References are cited where detailed descriptions may be helpful.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use. Specific precautionary statements are given in X1.7.

1.4 The sections appear in the following order:

Referenced documents

2

Terminology

3

Significance and use

4

Magnification

5

Reproduction of photomicrographs

6

Optical systems

7

Illumination sources

8

Illumination of specimens

9

Focusing

10

Filters for photomicrography

11

Illumination techniques

12

Instant-processing films

13

Photographic materials

14

Photographic exposure

15

Photographic processing

16

Keywords

17

Suggestions for visual use of metallographic microscopes

Appendix X1

Guide for metallographic photomacrography

Appendix X2

Electronic photography

Appendix X3

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:E883 −11 (Reapproved 2017)

Standard Guide for

Reflected–Light Photomicrography

This standard is issued under the fixed designation E883; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

Electronic photography Appendix

X3

1.1 This guide outlines various methods which may be

1.5 This international standard was developed in accor-

followed in the photography of metals and materials with the

dance with internationally recognized principles on standard-

reflected-light microscope. Methods are included for prepara-

ization established in the Decision on Principles for the

tion of prints and transparencies in black-and-white and in

Development of International Standards, Guides and Recom-

color, using both direct rapid and wet processes.

mendations issued by the World Trade Organization Technical

1.2 Guidelines are suggested to yield photomicrographs of

Barriers to Trade (TBT) Committee.

typical subjects and, to the extent possible, of atypical subjects

as well. Information is included concerning techniques for the

2. Referenced Documents

enhanced display of specific material features. Descriptive

2.1 ASTM Standards:

material is provided where necessary to clarify procedures.

E7Terminology Relating to Metallography

References are cited where detailed descriptions may be

E175Terminology of Microscopy

helpful.

E768Guide for Preparing and Evaluating Specimens for

1.3 This standard does not purport to address all of the

Automatic Inclusion Assessment of Steel

safety concerns, if any, associated with its use. It is the

E1951Guide for Calibrating Reticles and Light Microscope

responsibility of the user of this standard to establish appro-

Magnifications

priate safety and health practices and determine the applica- 3

2.2 Other Standard:

bility of regulatory requirements prior to use. Specific precau-

MSDSMercury-Material Safety Data Sheet

tionary statements are given in X1.7.

1.4 The sections appear in the following order:

3. Terminology

Referenced documents 2

3.1 Definitions—For definitions of terms used in this guide,

Terminology 3

see Terminologies E7 and E175.

Significance and use 4

Magnification 5

Reproduction of photomicrographs 6

4. Significance and Use

Optical systems 7

Illumination sources 8

4.1 This guide is useful for the photomicrography and

Illumination of specimens 9

photomacrography of metals and other materials.

Focusing 10

Filters for photomicrography 11

4.2 The subsequent processing of the photographic materi-

Illumination techniques 12

als is also treated.

Instant-processing films 13

Photographic materials 14

Photographic exposure 15

5. Magnification

Photographic processing 16

Keywords 17

5.1 Photomicrographs shall be made at preferred

Suggestions for visual use of metallographic Appendix

magnifications, except in those special cases where details of

microscopes X1

the microstructure are best revealed by unique magnifications.

Guide for metallographic photomacrography Appendix

X2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This guide is under the jurisdiction of ASTM Committee E04 on Metallogra- Standards volume information, refer to the standard’s Document Summary page on

phyand is the direct responsibility of Subcommittee E04.03 on Light Microscopy. the ASTM website.

Current edition approved June 1, 2017. Published June 2017. Originally AvailablefromUnitedStatesEnvironmentalProtectionAgency(EPA),William

approved in 1982. Last previous edition approved in 2011 as E883–11. DOI: Jefferson Clinton Bldg., 1200 Pennsylvania Ave., NW, Washington, DC 20460,

10.1520/E0883-11R17. http://www.epa.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E883−11 (2017)

5.2 Thepreferredmagnificationsforphotomicrographs,are: 7.5 The resolution of the microscope depends primarily on

25×, 50×, 75×, 100×, 200×, 250×, 400×, 500×, 750×, 800×, the numerical aperture of the objective in use (1) . The term

and 1000×. empty magnification is used to describe high magnifications

(above approximately 1100 times the numerical aperture of an

5.3 Magnifications are normally calibrated using a stage

objective), which have been shown to offer no increase in

micrometer. Calibration procedures in Guide E1951 should be

image resolution. Nevertheless, some types of information,

followed.

such as the distance between two constituents, may be more

easily obtained from microstructures examined at moderate

6. Reproduction of Photomicrographs

empty magnifications.

6.1 Photomicrographs should be at one of the preferred

8. Illumination Sources

magnifications. A milli- or micrometre marker shall be super-

imposed on the photomicrograph to indicate magnification, in

8.1 MetallographicphotomicrographytypicallyusesKöhler

a contrasting tone. The published magnification, if known,

illumination. To obtain Köhler illumination, an image of the

should be stated in the caption.

fielddiaphragmisfocusedinthespecimenplane,andanimage

of the lamp filament or arc is focused in the plane of the

6.2 Photomicrograph captions should include basic back-

aperture diaphragm. Specific steps to obtain Köhler illumina-

ground information (for example, material identification,

tion vary with the microscope used. The manufacturer’s

etchant, mechanical or thermal treatment details) and should

instructions should be followed closely.

briefly describe what is illustrated so that the photomicrograph

can stand independent of the text. 8.2 For incandescent lamps, the applied voltage determines

the unit brightness and the color temperature of the source.

6.3 Arrowsorothermarkings,inacontrastingtone,shallbe

Evaporatedtungstenblackenstheenvelope,resultingindimin-

used to designate specific features in a photomicrograph. Any

ished brightness and color temperature as the lamp ages.

marking used shall be referenced in the caption.

Tungsten-halogenlampsminimizeenvelopeblackening,main-

taining constant brightness and color temperature for most of

7. Optical Systems

theirlife.Thehighbrightnessand3200Kcolortemperatureof

7.1 Microscope objectives are available in increasing order

these lamps makes them especially suitable for color photomi-

of correction as achromats, semiapochromats (fluorites) and

crography.

apochromats(seeTerminologiesE7andE175).Planobjectives

8.3 With arc sources, brightness per unit area is substan-

are recommended for photographic purposes because their

tially higher than that from any incandescent source. Their

correctionprovidesaflatterimage.Theobjectivelensformsan

spectral output contains high energy spikes superimposed on a

image of the specimen in a specific plane behind the objective

white-lightcontinuum.Theyalsocontainsignificantultraviolet

calledthebackfocalplane.(Thisisoneofseveralpossiblereal

(UV) and infrared (IR) emissions that should be removed for

image planes, called intermediary planes, where reticles may

eye safety (and for photographic consistency, with UV); see

be inserted as optical overlays on the image.)

8.4, 11.3.1, and 11.5.2.

7.2 The eyepiece magnifies the back focal plane (or other) 8.3.1 Xenonarcsproduceaspectralqualityclosetodaylight

intermediaryimageforobservationorphotomicrography.Eye- (5600K), with a strong spike at 462 nm. Strong emissions in

pieces are sometimes also used to accomplish the full correc- the IR should be removed. Xenon arcs that do not produce

tion of the objective’s spherical aberration and to improve the ozone are recommended.

flatness of field. 8.3.2 Carbon arcs have a continuous output in the visible

portion of the spectrum, with a color temperature near 3800K

7.2.1 The pupil of the observer’s eye must be brought to

and a strong emission line at 386 nm.

coincidence with the eyepoint of the visual eyepiece to view

8.3.3 Mercury arcs have strong UV and near-UV output,

the entire microscopical image. High-eyepoint eyepieces are

and are particularly useful to obtain maximum resolution with

necessary for eyeglass users to see the entire image field.

a blue filter. The color quality is deficient in red; it cannot be

7.2.2 Most microscopes have built-in photographic capa-

balancedforcolorphotomicrography. Warning—Mercuryhas

bilitiesthatuseanalternateimagepaththroughthemicroscope

been designated by EPAand many state agencies as a hazard-

leading to a camera attachment port or to a viewscreen. A

ousmaterialthatcancausecentralnervoussystem,kidney,and

projection eyepiece delivers the image to the camera port or

liver damage. Mercury, or its vapor, may be hazardous to

screen.

health and corrosive to materials. Caution should be taken

7.3 Intermediate lenses (relay or tube lenses) are often

when handling mercury and mercury-containing products. See

required to transfer the specimen image from the intermediary

the applicable product Material Safety Data Sheet (MSDS) for

plane of the objective to that of the eyepiece. They may also

details and EPA’s website (http://www.epa.gov/mercury/

add their own magnification factor, either fixed or as a zoom

faq.htm)foradditionalinformation.Usersshouldbeawarethat

system.

selling mercury or mercury-containing products, or both, in

your state may be prohibited by state law.

7.4 The objective, the eyepiece, and the compound micro-

scope (including any intermediate lenses) are designed as a

single optical unit. It is recommended to use only objectives

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

and eyepieces which are intended for the microscope in use. this standard.

E883−11 (2017)

8.3.4 Zirconiumarcshavestrongspectraloutputlinesinthe diameter. This can be observed by removing the eyepiece and

near IR, requiring filtration.Within the visible region, they are inspecting the back of the objective, either directly or with a

rated at 3200K color temperature. pinhole eyepiece. The aperture diaphragm should never be

used as a light intensity control.

8.4 Arc lamps require heat protection for filters and other

optical components, and certainly for eye safety. Infrared 9.5 See Fig. 1 for an illustration of a typical vertical

removal may be obtained by: “hot” mirrors in the illumination illumination system.

beam to reflect IR while transmitting visible light; heat-

absorbing filters to transmit visible light while absorbing IR, 10. Focusing

for example, solid glass filters or liquid-filled cells.

10.1 Sharp focus is necessary to obtain good photomicro-

8.5 A detailed discussion of illumination sources and the graphs.

quality of illuminants is given by Loveland (2).

10.2 There are two systems for obtaining sharp focus:

8.6 Some advice on using metallographic microscopes for ground-glass focusing and aerial image focusing.

visual observation has been compiled in Appendix X1.

10.2.1 For ground-glass focusing, relatively glare-free sur-

roundings and a magnifier up to about 3× are required. To

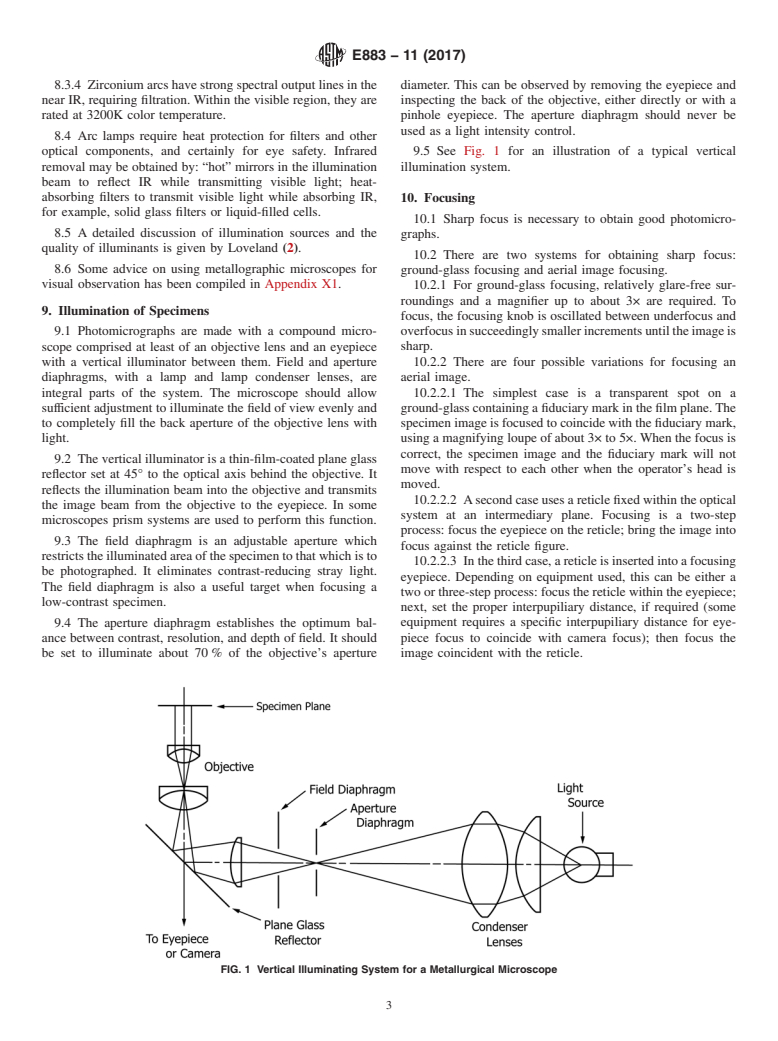

9. Illumination of Specimens

focus, the focusing knob is oscillated between underfocus and

9.1 Photomicrographs are made with a compound micro- overfocusinsucceedinglysmallerincrementsuntiltheimageis

scope comprised at least of an objective lens and an eyepiece sharp.

with a vertical illuminator between them. Field and aperture 10.2.2 There are four possible variations for focusing an

diaphragms, with a lamp and lamp condenser lenses, are aerial image.

integral parts of the system. The microscope should allow 10.2.2.1 The simplest case is a transparent spot on a

sufficient adjustment to illuminate the field of view evenly and ground-glasscontainingafiduciarymarkinthefilmplane.The

to completely fill the back aperture of the objective lens with specimenimageisfocusedtocoincidewiththefiduciarymark,

light. usingamagnifyingloupeofabout3×to5×.Whenthefocusis

correct, the specimen image and the fiduciary mark will not

9.2 Theverticalilluminatorisathin-film-coatedplaneglass

move with respect to each other when the operator’s head is

reflector set at 45° to the optical axis behind the objective. It

moved.

reflects the illumination beam into the objective and transmits

10.2.2.2 Asecondcaseusesareticlefixedwithintheoptical

the image beam from the objective to the eyepiece. In some

system at an intermediary plane. Focusing is a two-step

microscopes prism systems are used to perform this function.

process: focus the eyepiece on the reticle; bring the image into

9.3 The field diaphragm is an adjustable aperture which

focus against the reticle figure.

restrictstheilluminatedareaofthespecimentothatwhichisto

10.2.2.3 Inthethirdcase,areticleisinsertedintoafocusing

be photographed. It eliminates contrast-reducing stray light.

eyepiece. Depending on equipment used, this can be either a

The field diaphragm is also a useful target when focusing a

twoorthree-stepprocess:focusthereticlewithintheeyepiece;

low-contrast specimen.

next, set the proper interpupiliary distance, if required (some

9.4 The aperture diaphragm establishes the optimum bal- equipment requires a specific interpupiliary distance for eye-

ance between contrast, resolution, and depth of field. It should piece focus to coincide with camera focus); then focus the

be set to illuminate about 70% of the objective’s aperture image coincident with the reticle.

FIG. 1 Vertical Illuminating System for a Metallurgical Microscope

E883−11 (2017)

10.2.2.4 The fourth case uses a single-lens reflex camera filter is used with a color complementary to that of the feature

body, where the camera focusing screen is the plane of (forexample,acyanfilterforreddishcopperplating;abluefor

reference. An eyepiece magnifier for the camera is an impor- yellow carbonitride particles). When maximum detail in a

tant accessory for this case.An aerial image focusing screen is colored phase must be shown, choose a filter with the same

preferred. color as the phase.

10.3 Thecriticalfocuspointisaffectedbyboththeprincipal 11.5 Filters for Color Photomicrography:

illumination wavelength in use and the size of the aperture 11.5.1 Color photomicrography generally requires filtration

diaphragm. Final focusing should be checked with all filters, to balance the light at the image pla

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E883 − 11 (Reapproved 2017)

Standard Guide for

Reflected–Light Photomicrography

This standard is issued under the fixed designation E883; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

Electronic photography Appendix

X3

1.1 This guide outlines various methods which may be

1.5 This international standard was developed in accor-

followed in the photography of metals and materials with the

dance with internationally recognized principles on standard-

reflected-light microscope. Methods are included for prepara-

ization established in the Decision on Principles for the

tion of prints and transparencies in black-and-white and in

Development of International Standards, Guides and Recom-

color, using both direct rapid and wet processes.

mendations issued by the World Trade Organization Technical

1.2 Guidelines are suggested to yield photomicrographs of

Barriers to Trade (TBT) Committee.

typical subjects and, to the extent possible, of atypical subjects

as well. Information is included concerning techniques for the

2. Referenced Documents

enhanced display of specific material features. Descriptive

2.1 ASTM Standards:

material is provided where necessary to clarify procedures.

E7 Terminology Relating to Metallography

References are cited where detailed descriptions may be

E175 Terminology of Microscopy

helpful.

E768 Guide for Preparing and Evaluating Specimens for

1.3 This standard does not purport to address all of the

Automatic Inclusion Assessment of Steel

safety concerns, if any, associated with its use. It is the

E1951 Guide for Calibrating Reticles and Light Microscope

responsibility of the user of this standard to establish appro-

Magnifications

priate safety and health practices and determine the applica- 3

2.2 Other Standard:

bility of regulatory requirements prior to use. Specific precau-

MSDS Mercury-Material Safety Data Sheet

tionary statements are given in X1.7.

1.4 The sections appear in the following order:

3. Terminology

Referenced documents 2

3.1 Definitions—For definitions of terms used in this guide,

Terminology 3

Significance and use 4 see Terminologies E7 and E175.

Magnification 5

Reproduction of photomicrographs 6

4. Significance and Use

Optical systems 7

Illumination sources 8

4.1 This guide is useful for the photomicrography and

Illumination of specimens 9

photomacrography of metals and other materials.

Focusing 10

Filters for photomicrography 11

4.2 The subsequent processing of the photographic materi-

Illumination techniques 12

als is also treated.

Instant-processing films 13

Photographic materials 14

Photographic exposure 15

5. Magnification

Photographic processing 16

Keywords 17

5.1 Photomicrographs shall be made at preferred

Suggestions for visual use of metallographic Appendix

magnifications, except in those special cases where details of

microscopes X1

the microstructure are best revealed by unique magnifications.

Guide for metallographic photomacrography Appendix

X2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This guide is under the jurisdiction of ASTM Committee E04 on Metallogra- Standards volume information, refer to the standard’s Document Summary page on

phyand is the direct responsibility of Subcommittee E04.03 on Light Microscopy. the ASTM website.

Current edition approved June 1, 2017. Published June 2017. Originally Available from United States Environmental Protection Agency (EPA), William

approved in 1982. Last previous edition approved in 2011 as E883 – 11. DOI: Jefferson Clinton Bldg., 1200 Pennsylvania Ave., NW, Washington, DC 20460,

10.1520/E0883-11R17. http://www.epa.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E883 − 11 (2017)

5.2 The preferred magnifications for photomicrographs, are: 7.5 The resolution of the microscope depends primarily on

25×, 50×, 75×, 100×, 200×, 250×, 400×, 500×, 750×, 800×, the numerical aperture of the objective in use (1) . The term

and 1000×. empty magnification is used to describe high magnifications

(above approximately 1100 times the numerical aperture of an

5.3 Magnifications are normally calibrated using a stage

objective), which have been shown to offer no increase in

micrometer. Calibration procedures in Guide E1951 should be

image resolution. Nevertheless, some types of information,

followed.

such as the distance between two constituents, may be more

easily obtained from microstructures examined at moderate

6. Reproduction of Photomicrographs

empty magnifications.

6.1 Photomicrographs should be at one of the preferred

8. Illumination Sources

magnifications. A milli- or micrometre marker shall be super-

imposed on the photomicrograph to indicate magnification, in

8.1 Metallographic photomicrography typically uses Köhler

a contrasting tone. The published magnification, if known,

illumination. To obtain Köhler illumination, an image of the

should be stated in the caption.

field diaphragm is focused in the specimen plane, and an image

of the lamp filament or arc is focused in the plane of the

6.2 Photomicrograph captions should include basic back-

aperture diaphragm. Specific steps to obtain Köhler illumina-

ground information (for example, material identification,

tion vary with the microscope used. The manufacturer’s

etchant, mechanical or thermal treatment details) and should

instructions should be followed closely.

briefly describe what is illustrated so that the photomicrograph

can stand independent of the text. 8.2 For incandescent lamps, the applied voltage determines

the unit brightness and the color temperature of the source.

6.3 Arrows or other markings, in a contrasting tone, shall be

Evaporated tungsten blackens the envelope, resulting in dimin-

used to designate specific features in a photomicrograph. Any

ished brightness and color temperature as the lamp ages.

marking used shall be referenced in the caption.

Tungsten-halogen lamps minimize envelope blackening, main-

taining constant brightness and color temperature for most of

7. Optical Systems

their life. The high brightness and 3200 K color temperature of

7.1 Microscope objectives are available in increasing order

these lamps makes them especially suitable for color photomi-

of correction as achromats, semiapochromats (fluorites) and

crography.

apochromats (see Terminologies E7 and E175). Plan objectives

8.3 With arc sources, brightness per unit area is substan-

are recommended for photographic purposes because their

tially higher than that from any incandescent source. Their

correction provides a flatter image. The objective lens forms an

spectral output contains high energy spikes superimposed on a

image of the specimen in a specific plane behind the objective

white-light continuum. They also contain significant ultraviolet

called the back focal plane. (This is one of several possible real

(UV) and infrared (IR) emissions that should be removed for

image planes, called intermediary planes, where reticles may

eye safety (and for photographic consistency, with UV); see

be inserted as optical overlays on the image.)

8.4, 11.3.1, and 11.5.2.

7.2 The eyepiece magnifies the back focal plane (or other) 8.3.1 Xenon arcs produce a spectral quality close to daylight

intermediary image for observation or photomicrography. Eye- (5600K), with a strong spike at 462 nm. Strong emissions in

pieces are sometimes also used to accomplish the full correc- the IR should be removed. Xenon arcs that do not produce

tion of the objective’s spherical aberration and to improve the ozone are recommended.

flatness of field. 8.3.2 Carbon arcs have a continuous output in the visible

portion of the spectrum, with a color temperature near 3800K

7.2.1 The pupil of the observer’s eye must be brought to

and a strong emission line at 386 nm.

coincidence with the eyepoint of the visual eyepiece to view

8.3.3 Mercury arcs have strong UV and near-UV output,

the entire microscopical image. High-eyepoint eyepieces are

and are particularly useful to obtain maximum resolution with

necessary for eyeglass users to see the entire image field.

a blue filter. The color quality is deficient in red; it cannot be

7.2.2 Most microscopes have built-in photographic capa-

balanced for color photomicrography. Warning—Mercury has

bilities that use an alternate image path through the microscope

been designated by EPA and many state agencies as a hazard-

leading to a camera attachment port or to a viewscreen. A

ous material that can cause central nervous system, kidney, and

projection eyepiece delivers the image to the camera port or

liver damage. Mercury, or its vapor, may be hazardous to

screen.

health and corrosive to materials. Caution should be taken

7.3 Intermediate lenses (relay or tube lenses) are often

when handling mercury and mercury-containing products. See

required to transfer the specimen image from the intermediary

the applicable product Material Safety Data Sheet (MSDS) for

plane of the objective to that of the eyepiece. They may also

details and EPA’s website (http://www.epa.gov/mercury/

add their own magnification factor, either fixed or as a zoom

faq.htm) for additional information. Users should be aware that

system.

selling mercury or mercury-containing products, or both, in

your state may be prohibited by state law.

7.4 The objective, the eyepiece, and the compound micro-

scope (including any intermediate lenses) are designed as a

single optical unit. It is recommended to use only objectives 4

The boldface numbers in parentheses refer to the list of references at the end of

and eyepieces which are intended for the microscope in use. this standard.

E883 − 11 (2017)

8.3.4 Zirconium arcs have strong spectral output lines in the diameter. This can be observed by removing the eyepiece and

near IR, requiring filtration. Within the visible region, they are inspecting the back of the objective, either directly or with a

rated at 3200K color temperature. pinhole eyepiece. The aperture diaphragm should never be

used as a light intensity control.

8.4 Arc lamps require heat protection for filters and other

optical components, and certainly for eye safety. Infrared 9.5 See Fig. 1 for an illustration of a typical vertical

removal may be obtained by: “hot” mirrors in the illumination illumination system.

beam to reflect IR while transmitting visible light; heat-

absorbing filters to transmit visible light while absorbing IR,

10. Focusing

for example, solid glass filters or liquid-filled cells.

10.1 Sharp focus is necessary to obtain good photomicro-

8.5 A detailed discussion of illumination sources and the

graphs.

quality of illuminants is given by Loveland (2).

10.2 There are two systems for obtaining sharp focus:

8.6 Some advice on using metallographic microscopes for

ground-glass focusing and aerial image focusing.

visual observation has been compiled in Appendix X1.

10.2.1 For ground-glass focusing, relatively glare-free sur-

roundings and a magnifier up to about 3× are required. To

9. Illumination of Specimens

focus, the focusing knob is oscillated between underfocus and

9.1 Photomicrographs are made with a compound micro- overfocus in succeedingly smaller increments until the image is

scope comprised at least of an objective lens and an eyepiece sharp.

with a vertical illuminator between them. Field and aperture 10.2.2 There are four possible variations for focusing an

diaphragms, with a lamp and lamp condenser lenses, are aerial image.

integral parts of the system. The microscope should allow 10.2.2.1 The simplest case is a transparent spot on a

sufficient adjustment to illuminate the field of view evenly and ground-glass containing a fiduciary mark in the film plane. The

to completely fill the back aperture of the objective lens with specimen image is focused to coincide with the fiduciary mark,

light. using a magnifying loupe of about 3× to 5×. When the focus is

correct, the specimen image and the fiduciary mark will not

9.2 The vertical illuminator is a thin-film-coated plane glass

move with respect to each other when the operator’s head is

reflector set at 45° to the optical axis behind the objective. It

moved.

reflects the illumination beam into the objective and transmits

10.2.2.2 A second case uses a reticle fixed within the optical

the image beam from the objective to the eyepiece. In some

system at an intermediary plane. Focusing is a two-step

microscopes prism systems are used to perform this function.

process: focus the eyepiece on the reticle; bring the image into

9.3 The field diaphragm is an adjustable aperture which

focus against the reticle figure.

restricts the illuminated area of the specimen to that which is to

10.2.2.3 In the third case, a reticle is inserted into a focusing

be photographed. It eliminates contrast-reducing stray light.

eyepiece. Depending on equipment used, this can be either a

The field diaphragm is also a useful target when focusing a

two or three-step process: focus the reticle within the eyepiece;

low-contrast specimen.

next, set the proper interpupiliary distance, if required (some

9.4 The aperture diaphragm establishes the optimum bal- equipment requires a specific interpupiliary distance for eye-

ance between contrast, resolution, and depth of field. It should piece focus to coincide with camera focus); then focus the

be set to illuminate about 70 % of the objective’s aperture image coincident with the reticle.

FIG. 1 Vertical Illuminating System for a Metallurgical Microscope

E883 − 11 (2017)

10.2.2.4 The fourth case uses a single-lens reflex camera filter is used with a color complementary to that of the feature

body, where the camera focusing screen is the plane of (for example, a cyan filter for reddish copper plating; a blue for

reference. An eyepiece magnifier for the camera is an impor- yellow carbonitride particles). When maximum detail in a

tant accessory for this case. An aerial image focusing screen is colored phase must be shown, choose a filter with the same

preferred. color as the phase.

10.3 The critical focus point is affected by both the principal 11.5 Filters for Color Photomicrography:

illumination wavelength

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E883 − 11 E883 − 11 (Reapproved 2017)

Standard Guide for

Reflected–Light Photomicrography

This standard is issued under the fixed designation E883; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This guide outlines various methods which may be followed in the photography of metals and materials with the

reflected-light microscope. Methods are included for preparation of prints and transparencies in black-and-white and in color, using

both direct rapid and wet processes.

1.2 Guidelines are suggested to yield photomicrographs of typical subjects and, to the extent possible, of atypical subjects as

well. Information is included concerning techniques for the enhanced display of specific material features. Descriptive material is

provided where necessary to clarify procedures. References are cited where detailed descriptions may be helpful.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

requirements prior to use. Specific precautionary statements are given in X1.7.

1.4 The sections appear in the following order:

Referenced documents 2

Terminology 3

Significance and use 4

Magnification 5

Reproduction of photomicrographs 6

Optical systems 7

Illumination sources 8

Illumination of specimens 9

Focusing 10

Filters for photomicrography 11

Illumination techniques 12

Instant-processing films 13

Photographic materials 14

Photographic exposure 15

Photographic processing 16

Keywords 17

Suggestions for visual use of metallographic Appendix

microscopes X1

Guide for metallographic photomacrography Appendix

X2

Electronic photography Appendix

X3

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

E7 Terminology Relating to Metallography

E175 Terminology of Microscopy

E768 Guide for Preparing and Evaluating Specimens for Automatic Inclusion Assessment of Steel

This guide is under the jurisdiction of ASTM Committee E04 on Metallographyand is the direct responsibility of Subcommittee E04.03 on Light Microscopy.

Current edition approved May 1, 2011June 1, 2017. Published May 2011June 2017. Originally approved in 1982. Last previous edition approved in 20072011 as

E883 – 02E883 – 11.(2007). DOI: 10.1520/E0883-11.10.1520/E0883-11R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E883 − 11 (2017)

E1951 Guide for Calibrating Reticles and Light Microscope Magnifications

2.2 Other Standard:

MSDS Mercury-Material Safety Data Sheet

3. Terminology

3.1 Definitions—For definitions of terms used in this guide, see Terminologies E7 and E175.

4. Significance and Use

4.1 This guide is useful for the photomicrography and photomacrography of metals and other materials.

4.2 The subsequent processing of the photographic materials is also treated.

5. Magnification

5.1 Photomicrographs shall be made at preferred magnifications, except in those special cases where details of the

microstructure are best revealed by unique magnifications.

5.2 The preferred magnifications for photomicrographs, are: 25×, 50×, 75×, 100×, 200×, 250×, 400×, 500×, 750×, 800×, and

1000×.

5.3 Magnifications are normally calibrated using a stage micrometer. Calibration procedures in Guide E1951 should be

followed.

6. Reproduction of Photomicrographs

6.1 Photomicrographs should be at one of the preferred magnifications. A milli- or micrometre marker shall be superimposed

on the photomicrograph to indicate magnification, in a contrasting tone. The published magnification, if known, should be stated

in the caption.

6.2 Photomicrograph captions should include basic background information (for example, material identification, etchant,

mechanical or thermal treatment details) and should briefly describe what is illustrated so that the photomicrograph can stand

independent of the text.

6.3 Arrows or other markings, in a contrasting tone, shall be used to designate specific features in a photomicrograph. Any

marking used shall be referenced in the caption.

7. Optical Systems

7.1 Microscope objectives are available in increasing order of correction as achromats, semiapochromats (fluorites) and

apochromats (see Terminologies E7 and E175). Plan objectives are recommended for photographic purposes because their

correction provides a flatter image. The objective lens forms an image of the specimen in a specific plane behind the objective

called the back focal plane. (This is one of several possible real image planes, called intermediary planes, where reticles may be

inserted as optical overlays on the image.)

7.2 The eyepiece magnifies the back focal plane (or other) intermediary image for observation or photomicrography. Eyepieces

are sometimes also used to accomplish the full correction of the objective’s spherical aberration and to improve the flatness of field.

7.2.1 The pupil of the observer’s eye must be brought to coincidence with the eyepoint of the visual eyepiece to view the entire

microscopical image. High-eyepoint eyepieces are necessary for eyeglass users to see the entire image field.

7.2.2 Most microscopes have built-in photographic capabilities that use an alternate image path through the microscope leading

to a camera attachment port or to a viewscreen. A projection eyepiece delivers the image to the camera port or screen.

7.3 Intermediate lenses (relay or tube lenses) are often required to transfer the specimen image from the intermediary plane of

the objective to that of the eyepiece. They may also add their own magnification factor, either fixed or as a zoom system.

7.4 The objective, the eyepiece, and the compound microscope (including any intermediate lenses) are designed as a single

optical unit. It is recommended to use only objectives and eyepieces which are intended for the microscope in use.

7.5 The resolution of the microscope depends primarily on the numerical aperture of the objective in use (1) . The term empty

magnification is used to describe high magnifications (above approximately 1100 times the numerical aperture of an objective),

which have been shown to offer no increase in image resolution. Nevertheless, some types of information, such as the distance

between two constituents, may be more easily obtained from microstructures examined at moderate empty magnifications.

Available from United States Environmental Protection Agency (EPA), Ariel Rios William Jefferson Clinton Bldg., 1200 Pennsylvania Ave., NW, Washington, DC

20004,20460, http://www.epa.gov.

The boldface numbers in parentheses refer to the list of references at the end of this standard.

E883 − 11 (2017)

8. Illumination Sources

8.1 Metallographic photomicrography typically uses Köhler illumination. To obtain Köhler illumination, an image of the field

diaphragm is focused in the specimen plane, and an image of the lamp filament or arc is focused in the plane of the aperture

diaphragm. Specific steps to obtain Köhler illumination vary with the microscope used. The manufacturer’s instructions should be

followed closely.

8.2 For incandescent lamps, the applied voltage determines the unit brightness and the color temperature of the source.

Evaporated tungsten blackens the envelope, resulting in diminished brightness and color temperature as the lamp ages.

Tungsten-halogen lamps minimize envelope blackening, maintaining constant brightness and color temperature for most of their

life. The high brightness and 3200 K color temperature of these lamps makes them especially suitable for color photomicrography.

8.3 With arc sources, brightness per unit area is substantially higher than that from any incandescent source. Their spectral

output contains high energy spikes superimposed on a white-light continuum. They also contain significant ultraviolet (UV) and

infrared (IR) emissions that should be removed for eye safety (and for photographic consistency, with UV); see 8.4, 11.3.1, and

11.5.2.

8.3.1 Xenon arcs produce a spectral quality close to daylight (5600K), with a strong spike at 462 nm. Strong emissions in the

IR should be removed. Xenon arcs that do not produce ozone are recommended.

8.3.2 Carbon arcs have a continuous output in the visible portion of the spectrum, with a color temperature near 3800K and a

strong emission line at 386 nm.

8.3.3 Mercury arcs have strong UV and near-UV output, and are particularly useful to obtain maximum resolution with a blue

filter. The color quality is deficient in red; it cannot be balanced for color photomicrography. Warning—Mercury has been

designated by EPA and many state agencies as a hazardous material that can cause central nervous system, kidney, and liver

damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling

mercury and mercury-containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s

website (http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware that selling mercury or

mercury-containing products, or both, in your state may be prohibited by state law.

8.3.4 Zirconium arcs have strong spectral output lines in the near IR, requiring filtration. Within the visible region, they are rated

at 3200K color temperature.

8.4 Arc lamps require heat protection for filters and other optical components, and certainly for eye safety. Infrared removal may

be obtained by: “hot” mirrors in the illumination beam to reflect IR while transmitting visible light; heat-absorbing filters to

transmit visible light while absorbing IR, for example, solid glass filters or liquid-filled cells.

8.5 A detailed discussion of illumination sources and the quality of illuminants is given by Loveland (2).

8.6 Some advice on using metallographic microscopes for visual observation has been compiled in Appendix X1.

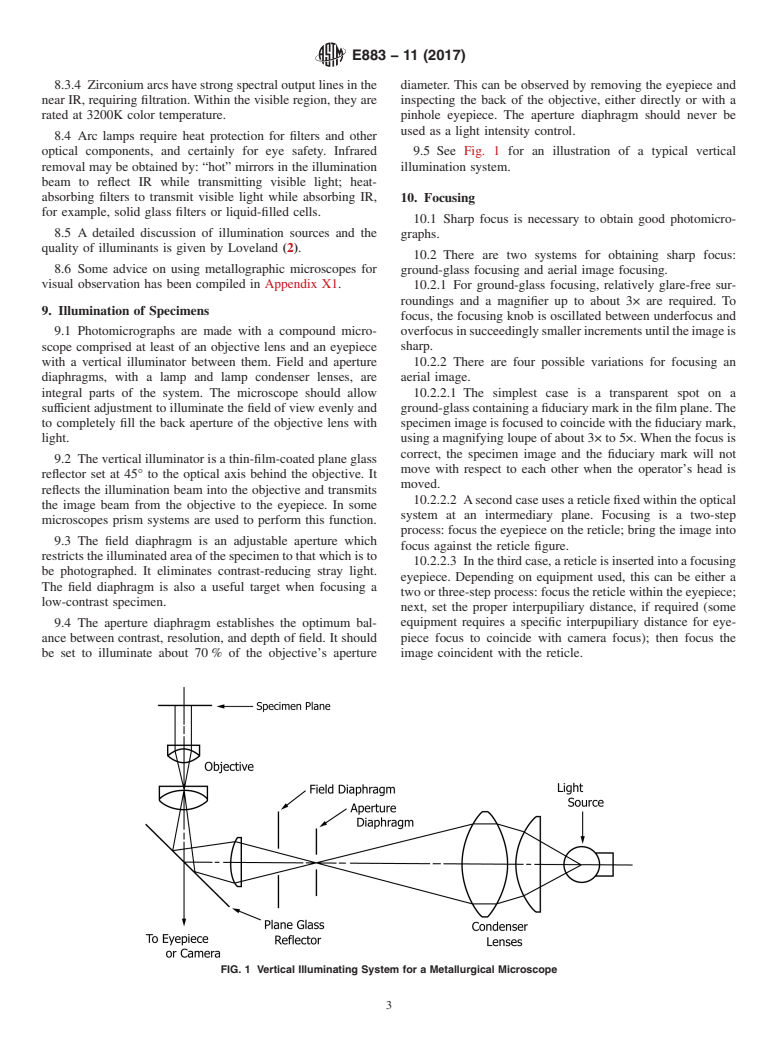

9. Illumination of Specimens

9.1 Photomicrographs are made with a compound microscope comprised at least of an objective lens and an eyepiece with a

vertical illuminator between them. Field and aperture diaphragms, with a lamp and lamp condenser lenses, are integral parts of the

system. The microscope should allow sufficient adjustment to illuminate the field of view evenly and to completely fill the back

aperture of the objective lens with light.

9.2 The vertical illuminator is a thin-film-coated plane glass reflector set at 45° to the optical axis behind the objective. It reflects

the illumination beam into the objective and transmits the image beam from the objective to the eyepiece. In some microscopes

prism systems are used to perform this function.

9.3 The field diaphragm is an adjustable aperture which restricts the illuminated area of the specimen to that which is to be

photographed. It eliminates contrast-reducing stray light. The field diaphragm is also a useful target when focusing a low-contrast

specimen.

9.4 The aperture diaphragm establishes the optimum balance between contrast, resolution, and depth of field. It should be set

to illuminate about 70 % of the objective’s aperture diameter. This can be observed by removing the eyepiece and inspecting the

back of the objective, either directly or with a pinhole eyepiece. The aperture diaphragm should never be used as a light intensity

control.

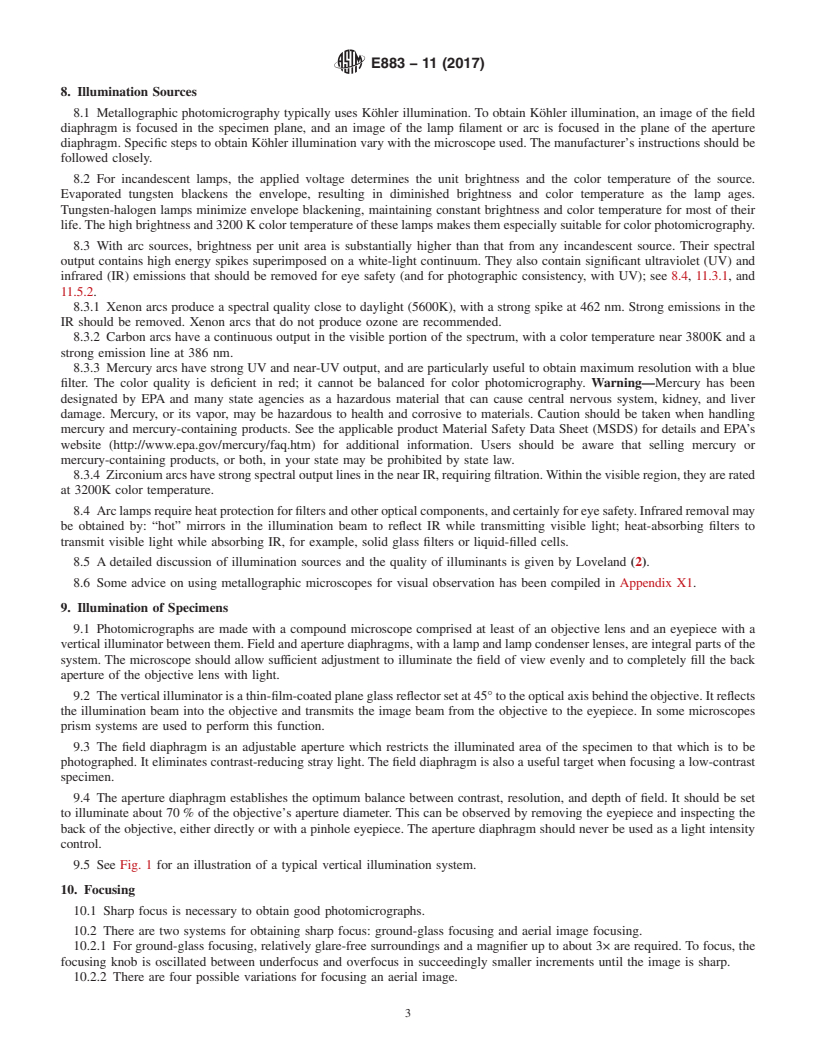

9.5 See Fig. 1 for an illustration of a typical vertical illumination system.

10. Focusing

10.1 Sharp focus is necessary to obtain good photomicrographs.

10.2 There are two systems for obtaining sharp focus: ground-glass focusing and aerial image focusing.

10.2.1 For ground-glass focusing, relatively glare-free surroundings and a magnifier up to about 3× are required. To focus, the

focusing knob is oscillated between underfocus and overfocus in succeedingly smaller increments until the image is sharp.

10.2.2 There are four possible variations for focusing an aerial image.

E883 − 11 (2017)

FIG. 1 Vertical Illuminating System for a Metallurgical Microscope

10.2.2.1 The simplest case is a transparent spot on a ground-glass containing a fiduciary mark in the film plane. The specimen

image is focused to coincide with the fiduciary mark, using a magnifying loupe of about 3× to 5×. When the focus is correct, the

specimen image and the fiduciary mark will not move with respect to each other when the operator’s head is moved.

10.2.2.2 A second case uses a reticle fixed within the optical system at an intermediary plane. Focusing is a two-step process:

focus the eyepiece on the reticle; bring the image into focus against the reticle figure.

10.2.2.3 In the third case, a reticle is inserted into a focusing eyepiece. Depending on equipment used, this can be either a two

or three-step process: focus the reticle within the eyepiece; next, set the proper interpupiliary distance, if required (some equipment

requires a specific interpupiliary distance for eyepiece focus to coincide with camera focus); then focus the image coincident with

the reticle.

10.2.2.4 The fourth case uses a single-lens reflex camera body, where the camera focusing screen is the plane of reference. An

eyepiece magnifier for the camera is an important accessory for this case. An aerial image focusing screen is preferred.

10.3 The critical focus point is affected by both the principal illumination wavelength in use and the size of the aperture

diaphragm. Final focusing shoul

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.