ASTM F2522-05(2011)

(Test Method)Standard Test Method for Determining the Protective Performance of a Shield Attached on Live Line Tools or on Racking Rods for Electric Arc Hazards

Standard Test Method for Determining the Protective Performance of a Shield Attached on Live Line Tools or on Racking Rods for Electric Arc Hazards

SCOPE

1.1 This test method is used to determine the heat attenuation factor (HAF), the effective heat attenuation factor (EHAF), and the shields mechanical strength (SMS) of a shield attached on live line tools or racking rods intended for protection of workers exposed to electric arcs.

1.2 The materials used in this test method of worker protection are in the form of a shield attached on live line tools or on the racking rods.

1.3 The protective shield described in this test method shall be transparent and shall be easily attached and removed from live line tools or from racking rods.

1.4 The protective shield described in this test method has 24-in. (0.61-m) diameter and can be used for most applications, however for special cases, the shield can have different sizes to suit the protective requirements of the application.

1.5 This standard shall be used to measure and describe the properties of materials, products, or assemblies in response to incident energies (thermal-convective, and radiant and pressure wave) generated by an electric arc under controlled laboratory conditions and does not purport to predict damage from light, resultant pressure impact other than the pressure and thermal aspects measured.

1.6 UnitsThe values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard shall not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire assessment, which takes into account all of the factors, which are pertinent to an assessment of the fire hazard of a particular end use.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautions, see Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2522 − 05(Reapproved 2011)

Standard Test Method for

Determining the Protective Performance of a Shield

Attached on Live Line Tools or on Racking Rods for Electric

1

Arc Hazards

This standard is issued under the fixed designation F2522; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method is used to determine the heat attenua-

responsibility of the user of this standard to establish appro-

tionfactor(HAF),theeffectiveheatattenuationfactor(EHAF),

priate safety and health practices and determine the applica-

and the shields mechanical strength (SMS) of a shield attached

bility of regulatory limitations prior to use. For specific

on live line tools or racking rods intended for protection of

precautions, see Section 7.

workers exposed to electric arcs.

1.2 The materials used in this test method of worker

2. Referenced Documents

protection are in the form of a shield attached on live line tools

2

2.1 ASTM Standards:

or on the racking rods.

D4391 Terminology Relating to The Burning Behavior of

1.3 The protective shield described in this test method shall

Textiles

be transparent and shall be easily attached and removed from

F1959/F1959M TestMethodforDeterminingtheArcRating

live line tools or from racking rods.

of Materials for Clothing

1.4 The protective shield described in this test method has

3. Terminology

24-in.(0.61-m)diameterandcanbeusedformostapplications,

however for special cases, the shield can have different sizes to 3.1 Definitions:

suit the protective requirements of the application.

3.1.1 arc, n—conductive path in air for the electric current

caused by ionization of air between two electrodes.

1.5 This standard shall be used to measure and describe the

properties of materials, products, or assemblies in response to 3.1.2 arc duration, n—time duration of the arc, s.

incidentenergies(thermal-convective,andradiantandpressure

3.1.3 arc energy, vi dt, n—sum of the instantaneous arc

wave) generated by an electric arc under controlled laboratory

voltage values multiplied by the instantaneous arc current

conditions and does not purport to predict damage from light,

values multiplied by the incremental time values during the

resultant pressure impact other than the pressure and thermal

arc, J.

aspects measured.

3.1.4 arc gap, n—distance between the arc electrodes.

1.6 The values stated in inch-pound units are to be regarded

3.1.5 arc voltage, n—voltage across the gap caused by the

as standard. The values given in parentheses are mathematical

current flowing through the resistance created by the arc gap,

conversions to SI units that are provided for information only

V. See also Terminology D4391.

and are not considered standard.

3.1.6 asymmetrical arc current, n—the total arc current

1.7 This standard shall not be used to describe or appraise

produced during closure; it includes a direct component and a

the fire hazard or fire risk of materials, products, or assemblies

symmetrical component, A.

under actual fire conditions. However, results of this test may

3.1.7 blowout, n—the extinguishing of the arc caused by a

be used as elements of a fire assessment, which takes into

magnetic field.

account all of the factors, which are pertinent to an assessment

3.1.8 closure, n—point on supply current wave form where

of the fire hazard of a particular end use.

arc is initiated.

1

This test method is under the jurisdiction of ASTM Committee F18 on

Electrical Protective Equipment for Workers and is the direct responsibility of

2

Subcommittee F18.35 on Tools and Equipment. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2011. Published September 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2005. Last previous edition approved in 2005 as F2522-05. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2522-05R11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2522 − 05 (2011)

3.1.9 delta peak temperature, n—difference between the EHAF test at the probable location of the worker’s hand, head,

maximum temperature and the initial temperature of the sensor side of the face, chest, and legs when exposed to the heat

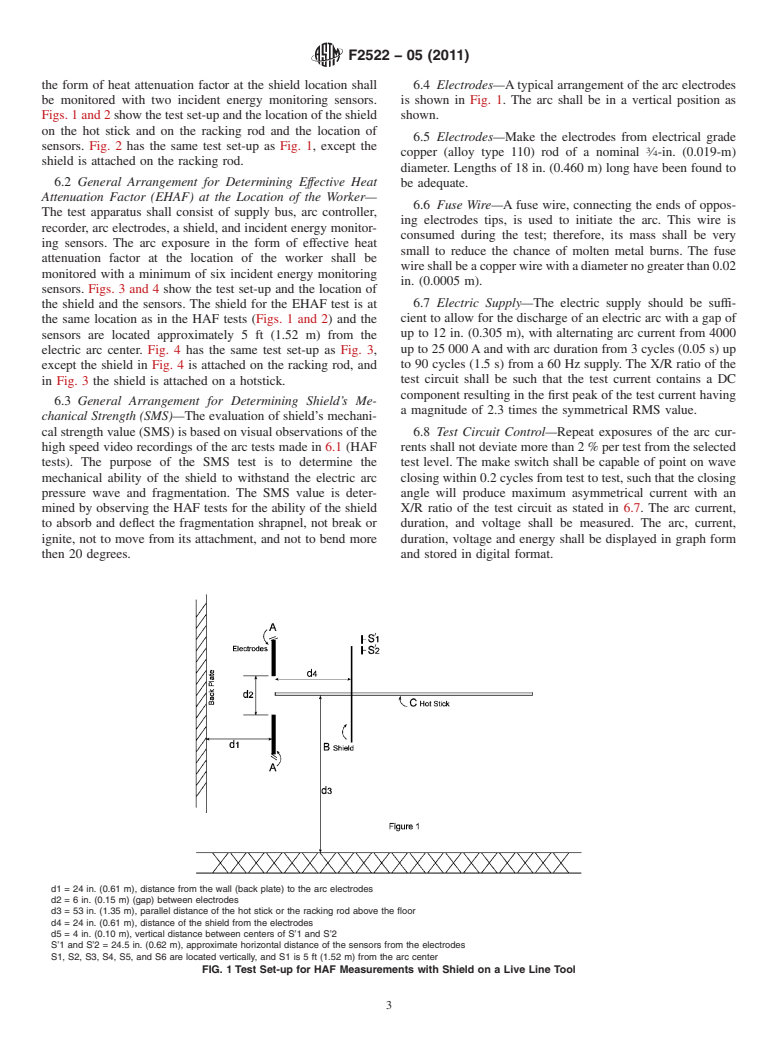

during the test, °C. energy from a controlled electric arc. The S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.