ASTM D7240-06(2011)

(Practice)Standard Practice for Leak Location using Geomembranes with an Insulating Layer in Intimate Contact with a Conductive Layer via Electrical Capacitance Technique (Conductive Geomembrane Spark Test)

Standard Practice for Leak Location using Geomembranes with an Insulating Layer in Intimate Contact with a Conductive Layer via Electrical Capacitance Technique (Conductive Geomembrane Spark Test)

SIGNIFICANCE AND USE

Geomembranes are used as barriers to prevent liquids from leaking from landfills, ponds, and other containments. For this purpose, it is desirable that the geomembrane have as little leakage as practical.

The liquids may contain contaminants that if released can cause damage to the environment. Leaking liquids can erode the subgrade, causing further damage. Leakage can result in product loss or otherwise prevent the installation from performing its intended containment purpose.

Geomembranes are often assembled in the field, either by unrolling and welding panels of the geomembrane material together in the field, or unfolding smaller flexible geomembranes in the field.

In exposed geomembrane applications, geomembrane leaks can be caused by poor quality of the subgrade, accidents, poor workmanship, and carelessness.

Electrical leak location methods are an effective final quality assurance measure to locate previously undetected leaks.

SCOPE

1.1 This standard is a performance-based practice for using the spark test to electrically locate leaks in exposed geomembranes with an insulating layer that are in intimate contact with a conductive layer. For clarity, this document uses the term ‘leak’ to mean holes, punctures, tears, cuts, cracks and similar breaches over the partial or entire area of an installed geomembrane (as defined in 3.2.3).

1.2 This test method can be used on exposed geomembranes installed in basins, ponds, tanks, ore and waste pads, landfill cells, landfill caps, and other containment facilities. This standard is applicable for geomembranes in direct and intimate contact with a conductive surface or with a conductive layer integrally included.

1.3 SAFETY WARNING: The electrical methods used for geomembrane leak location use high voltage, low current power supplies, resulting in the potential for electrical shock. The electrical methods used for geomembrane leak location should be attempted by only qualified and experienced personnel. Appropriate safety measures must be taken to protect the leak location operators as well as other people at the site.

1.4 This standard does not purport to address all of the safety and liability concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7240 − 06 (Reapproved 2011)

Standard Practice for

Leak Location using Geomembranes with an Insulating

Layer in Intimate Contact with a Conductive Layer via

Electrical Capacitance Technique (Conductive

Geomembrane Spark Test)

This standard is issued under the fixed designation D7240; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D6747 Guide for Selection of Techniques for Electrical

Detection of Leaks in Geomembranes

1.1 This standard is a performance-based practice for using

the spark test to electrically locate leaks in exposed geomem-

3. Terminology

branes with an insulating layer that are in intimate contact with

a conductive layer. For clarity, this document uses the term 3.1 Definition of terms applying to this test method appear

‘leak’to mean holes, punctures, tears, cuts, cracks and similar

in Terminology D4439.

breaches over the partial or entire area of an installed geomem-

3.2 Definitions:

brane (as defined in 3.2.3).

3.2.1 electrical leak location, n—a method which uses

1.2 Thistestmethodcanbeusedonexposedgeomembranes electrical current or electrical potential to detect and locate

installed in basins, ponds, tanks, ore and waste pads, landfill

leaks.

cells, landfill caps, and other containment facilities. This

3.2.2 geomembrane, n—an essentially impermeable mem-

standard is applicable for geomembranes in direct and intimate

brane used with foundation, soil, rock, earth or any other

contact with a conductive surface or with a conductive layer

geotechnical engineering related material as an integral part of

integrally included.

a man made project, structure, or system.

1.3 SAFETY WARNING: The electrical methods used for

3.2.3 leak, n—For the purposes of this document, a leak is

geomembrane leak location use high voltage, low current

anyunintendedopening,perforation,breach,slit,tear,puncture

power supplies, resulting in the potential for electrical shock.

or crack. Significant amounts of liquids or solids may or may

The electrical methods used for geomembrane leak location

not flow through a leak. Scratches, gouges, dents, or other

should be attempted by only qualified and experienced person-

aberrations that do not completely penetrate the geomembrane

nel. Appropriate safety measures must be taken to protect the

are not considered to be leaks.

leak location operators as well as other people at the site.

Leaks detected during surveys have been grouped into three

1.4 This standard does not purport to address all of the categories:

safety and liability concerns, if any, associated with its use. It • Holes – round shaped voids with downward or upward

is the responsibility of the user of this standard to establish protruding rims

appropriate safety and health practices and determine the • Tears – linear or circular voids with irregular edge borders

applicability of regulatory limitations prior to use. • Linear cuts – linear voids with neat close edges

3.2.4 intimate contact, n—for the purposes of this

2. Referenced Documents

document, intimate contact is when a conductive layer is in

2.1 ASTM Standards:

direct contact with the insulating geomembrane, and there are

D4439 Terminology for Geosynthetics

no gaps between the two layers to prohibit the flow of current.

3.2.5 leak detection sensitivity, n—The smallest size leak

This practice is under the jurisdiction of ASTM Committee D35 on Geosyn- that the leak location equipment and survey methodology are

thetics and is the direct responsibility of Subcommittee D35.10 on Geomembranes.

capable of detecting under a given set of conditions. The leak

Current edition approved June 1, 2011. Published July 2011 Originally published

detection sensitivity specification is usually stated as a diam-

in 2006. Last previous edition approved 2006 as D7240–06. DOI: 10.1520/D7240-

eter of the smallest leak that can be reliably detected.

06R11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.2.6 wand, n—for the purposes of this document, any rod

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

that has a conductive brush that is attached to a power source

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. to initiate the spark test.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7240 − 06 (2011)

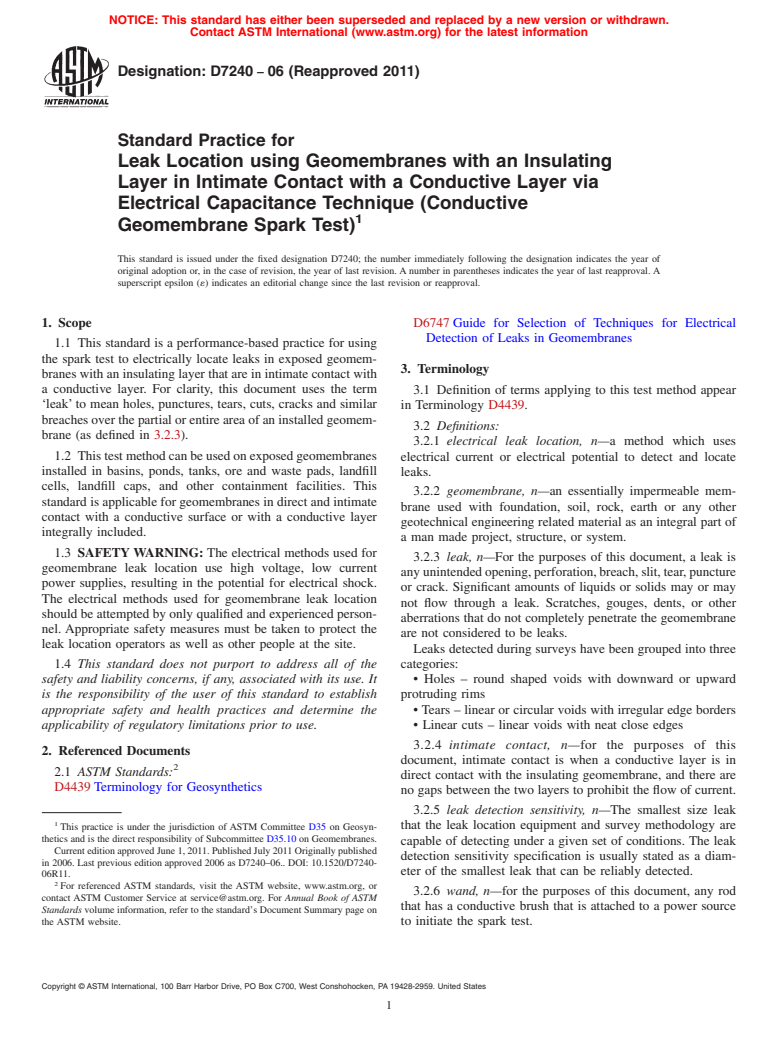

4. Summary of Practice 4.2.1 Fig. 1 shows a wiring diagram of the coupling pad,

power supply and test wand for the electrical leak location

4.1 The principle of this electrical leak location method is to

methodofageomembranewithalowerconductivelayer.Once

use a high voltage pulsed power supply to charge a capacitor

all necessary connections are made, the pad is placed on the

formed by the underlying conductive layer, the non-conductive

upper surface of the geomembrane. The nonconductive (insu-

layer of the geomembrane and a coupling pad. The area is then

lating layer(s)) of the geomembrane act as a dielectric in a

swept with a test wand to locate points where the capacitor

capacitor which stores electrical potential across the geomem-

discharges through a leak. Once the system senses the dis-

brane.

charge current, it is converted into an audible alarm.

4.2 General Principles

FIG. 1 Wiring Diagram of the Equipment Required for Spark Testing Geomembrane in Intimate Contact With a Conductive Surface.

D7240 − 06 (2011)

4.2.2 Agrid, test lanes or other acceptable system should be over the deliberate defect without touching the edges of the test

used to ensure that the entire area is tested with the test wand. piece or the coupling pad.

4.2.3 Either a hand held wand or a larger wand mounted to

6.3 Place the test piece on a large scrap of geome

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.