ASTM D7591-12

(Test Method)Standard Test Method for Determination of Free and Total Glycerin in Biodiesel Blends by Anion Exchange Chromatography

Standard Test Method for Determination of Free and Total Glycerin in Biodiesel Blends by Anion Exchange Chromatography

SIGNIFICANCE AND USE

Petroleum-based diesel may be blended with biodiesel. High levels of free glycerin in biodiesel can cause injector deposits (“gel effect”), as well as clogging fuel systems. High levels of unreacted glycerides can cause injector deposits and can adversely affect cold weather operation and filter plugging.

SCOPE

1.1 This test method covers and describes an anion exchange chromatography procedure for determining free and total glycerin content of biodiesel (B100) and blends (B0 to B20) with diesel fuel oils defined by Specification D975 Grades 1-D, 2-D, and low sulfur 1-D and 2-D and Specification D6751 (for B100 feedstocks). It is intended for the analysis of biodiesel and blend samples containing between 0.5 to 50 mg/kg glycerin.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7591 − 12

Standard Test Method for

Determination of Free and Total Glycerin in Biodiesel

Blends by Anion Exchange Chromatography

This standard is issued under the fixed designation D7591; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This test method covers and describes an anion ex-

E691 Practice for Conducting an Interlaboratory Study to

change chromatography procedure for determining free and

Determine the Precision of a Test Method

total glycerin content of biodiesel (B100) and blends (B0 to

B20) with diesel fuel oils defined by Specification D975

3. Terminology

Grades1-D,2-D,andlowsulfur1-Dand2-DandSpecification

3.1 Definitions:

D6751 (for B100 feedstocks). It is intended for the analysis of

3.1.1 free glycerin, n—measure of the amount of glycerin

biodiesel and blend samples containing between 0.5 to 50

remaining in the fuel.

mg/kg glycerin.

3.1.2 total glycerin, n—sum of the free glycerin and the

1.2 The values stated in SI units are to be regarded as

glycerin portion of any unreacted or partially reacted oil or fat.

standard. No other units of measurement are included in this

standard.

4. Summary of Test Method

1.3 This standard does not purport to address all of the

4.1 Free Glycerin—A small volume of an extract of the

safety concerns, if any, associated with its use. It is the

blend sample is directly injected into an ion chromatograph

responsibility of the user of this standard to establish appro-

consisting of appropriate ion exchange columns and into an

priate safety and health practices and determine the applica-

electrochemical detector. Glycerin is separated based on its

bility of regulatory limitations prior to use.

affinity for ion exchange sites of the resin with respect to the

resin’s affinity for the eluent. An electrochemical detector is

2. Referenced Documents

employed for detection of glycerin. Glycerin is quantified by

2.1 ASTM Standards:

peak area based on an external calibration curve, and is

D975 Specification for Diesel Fuel Oils

reported as µg/g (mg/kg), or may be converted to wt%.

D1193 Specification for Reagent Water

Calibration standards are prepared from commercially avail-

D4057 Practice for Manual Sampling of Petroleum and

able glycerin (99+% purity) in an aqueous solution.

Petroleum Products

4.2 Total Glycerin—A small volume extract of a saponified

D4177 Practice for Automatic Sampling of Petroleum and

blend sample is directly injected into an ion chromatograph

Petroleum Products

consisting of appropriate ion exchange columns and into an

D6299 Practice for Applying Statistical Quality Assurance

electrochemical detector. Glycerin is separated based on its

and Control Charting Techniques to Evaluate Analytical

affinity for ion exchange sites of the resin with respect to the

Measurement System Performance

resin’s affinity for the eluent. An electrochemical detector is

D6751 Specification for Biodiesel Fuel Blend Stock (B100)

employed for detection of glycerin. Glycerin is quantified by

for Middle Distillate Fuels

peak area based on an external calibration curve, and is

D6792 Practice for Quality System in Petroleum Products

reported as µg/g (mg/kg), or may be converted to wt%.

and Lubricants Testing Laboratories

Calibration standards are prepared from commercially avail-

able glycerin (99+% purity) in an aqueous solution.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

5. Significance and Use

Subcommittee D02.04.0C on Liquid Chromatography.

5.1 Petroleum-based diesel may be blended with biodiesel.

Current edition approved Jan. 1, 2012. Published March 2012. DOI:10.1520/

D7591–12

High levels of free glycerin in biodiesel can cause injector

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

deposits (“gel effect”), as well as clogging fuel systems. High

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

levels of unreacted glycerides can cause injector deposits and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. can adversely affect cold weather operation and filter plugging.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7591 − 12

FIG. 1 Typical Chromatogram of a Solution Containing 0.7 mg/kg of Glycerin

6. Interferences 7.5 Container—standard HDPE plastic 100 mL bottle with

cap.

6.1 Interferences can be caused by substances with similar

ion chromatographic retention times, especially if they are in 7.6 Ion Chromatograph—Analytical system with all re-

high concentration compared to the analyte of interest. Sample quired accessories including syringes, columns, high-pressure

dilution can be used to minimize or resolve most interference dual piston pump, and detector.

problems.Also,anexcessofunreactedhydroxide(base)during

7.6.1 Injection System—capable of delivering 5 to 25 µL

the sample preparation step for total glycerin can cause a pH

with a precision better than 1%.

imbalance on the anion exchange column, resulting in a

7.6.2 Pumping System—capable of delivering mobile phase

negative dip in front of the glycerin peak.

flows between 0.1 and 5.0 mL/min with a precision better than

2%. Due to the corrosive nature of the eluent, a PEEK pump

6.2 A water dip (system void, negative peak as shown in

head is recommended.

Fig. 1) can cause interference with some integrators. This dip

7.6.3 Guard Column—for protection of the analytical col-

can be eliminated by dilution with the eluent. The water dip

umn from strongly retained constituents.

should not be a problem since the glycerin peak is resolved

7.6.4 Anion Exchange Column—capable of producing sat-

from the void peak.

isfactory analyte separation.

6.3 Interferences can be caused by contamination of

7.6.5 Electrochemical Detector—integrated, temperature

glassware, eluent, reagents, etc. Take care to ensure that

controlled to 0.1°C, capable of measuring at least 0 to 200 µA

contamination is kept at the lowest possible levels. The use of

on a linear scale. Detector has a pulsed amperometric detection

nitrile gloves is highly recommended to prevent contamination

mode for required sensitivity. Consult with the manufacturer

during sample preparation.

for optimal cell settings.

6.4 There are several known additives based on natural

7.6.6 Electrochemical Detector Cell—minimum 3 mm gold

products that might have similar retention times and detector

working electrode surface with wall jet design, solid state

response similar to glycerin. In the case of higher than

reference and counter electrodes. Ensure a minimal volume in

expected values for biodiesel blends, it is highly recommended

the cell for enhanced sensitivity.Aplatinum working electrode

that the user needs to verify these higher than expected values

may also be used.

for glycerin using a different analytical technique.

7.6.7 Integrator or Chromatography Data System

Software—capable of measuring peak areas and retention

6.5 Pre-rinsing of the sample preparation containers with

times, and performing a baseline correction.

deionized water is mandatory.

7.6.8 Sample Digestion System—capable of heating, and

7. Apparatus

stirring with integrated reflux. Reflux is needed to minimize

loss of petroleum diesel in biodiesel blend samples.Achiller is

7.1 Analytical Balance—capable of weighing up to 200 g

recommended for providing water to the reflux condenser for

accurately to 60.0001 g.

efficiency and to conserve water resources.

7.2 Desiccator—containing freshly activated silica gel (or

7.7 Mechanical Wrist Shaker.

equivalent desiccant) with moisture content indicator.

7.8 Gloves, nitrile.

7.3 Pipettes or Volumetric Transfer Devices—1and5mL

class A volumetric pipettes or calibrated variable volume

automatic pipettes fitted with disposable polypropylene tips. 8. Reagents and Materials

7.4 Volumetric Flasks—25, 50, 100 and 1000 mL class A 8.1 Purity of Reagents—Reagent grade or higher purity

volumetric flasks. chemicals shall be used for the preparation of all samples,

D7591 − 12

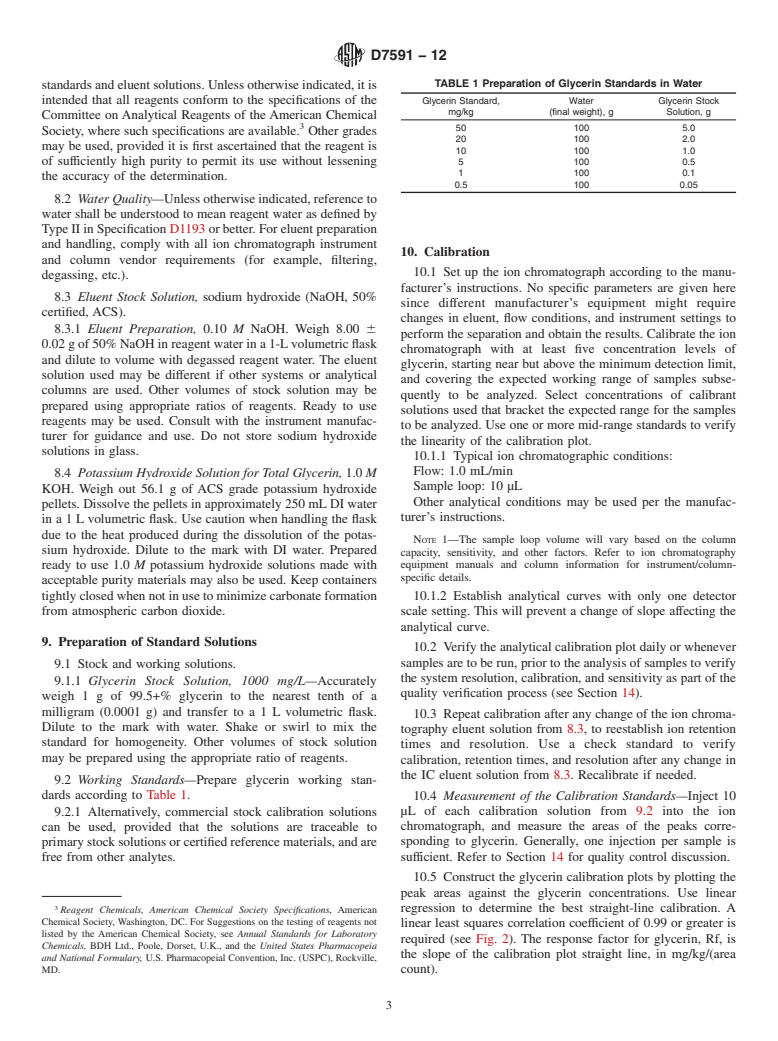

TABLE 1 Preparation of Glycerin Standards in Water

standardsandeluentsolutions.Unlessotherwiseindicated,itis

intended that all reagents conform to the specifications of the Glycerin Standard, Water Glycerin Stock

mg/kg (final weight), g Solution, g

Committee on Analytical Reagents of the American Chemical

50 100 5.0

Society, where such specifications are available. Other grades

20 100 2.0

may be used, provided it is first ascertained that the reagent is

10 100 1.0

of sufficiently high purity to permit its use without lessening 5 100 0.5

1 100 0.1

the accuracy of the determination.

0.5 100 0.05

8.2 Water Quality—Unless otherwise indicated, reference to

water shall be understood to mean reagent water as defined by

Type II inSpecificationD1193orbetter.Foreluentpreparation

and handling, comply with all ion chromatograph instrument

10. Calibration

and column vendor requirements (for example, filtering,

10.1 Set up the ion chromatograph according to the manu-

degassing, etc.).

facturer’s instructions. No specific parameters are given here

8.3 Eluent Stock Solution, sodium hydroxide (NaOH, 50%

since different manufacturer’s equipment might require

certified, ACS).

changes in eluent, flow conditions, and instrument settings to

8.3.1 Eluent Preparation, 0.10 M NaOH. Weigh 8.00 6

perform the separation and obtain the results. Calibrate the ion

0.02gof50%NaOHinreagentwaterina1-Lvolumetricflask

chromatograph with at least five concentration levels of

and dilute to volume with degassed reagent water. The eluent

glycerin, starting near but above the minimum detection limit,

solution used may be different if other systems or analytical

and covering the expected working range of samples subse-

columns are used. Other volumes of stock solution may be

quently to be analyzed. Select concentrations of calibrant

prepared using appropriate ratios of reagents. Ready to use

solutions used that bracket the expected range for the samples

reagents may be used. Consult with the instrument manufac-

to be analyzed. Use one or more mid-range standards to verify

turer for guidance and use. Do not store sodium hydroxide

the linearity of the calibration plot.

solutions in glass.

10.1.1 Typical ion chromatographic conditions:

Flow: 1.0 mL/min

8.4 Potassium Hydroxide Solution for Total Glycerin, 1.0 M

Sample loop: 10 µL

KOH. Weigh out 56.1 g of ACS grade potassium hydroxide

Other analytical conditions may be used per the manufac-

pellets. Dissolve the pellets in approximately 250 mLDI water

turer’s instructions.

ina1L volumetric flask. Use caution when handling the flask

due to the heat produced during the dissolution of the potas-

NOTE 1—The sample loop volume will vary based on the column

sium hydroxide. Dilute to the mark with DI water. Prepared

capacity, sensitivity, and other factors. Refer to ion chromatography

equipment manuals and column information for instrument/column-

ready to use 1.0 M potassium hydroxide solutions made with

specific details.

acceptable purity materials may also be used. Keep containers

tightlyclosedwhennotinusetominimizecarbonateformation 10.1.2 Establish analytical curves with only one detector

from atmospheric carbon dioxide.

scale setting. This will prevent a change of slope affecting the

analytical curve.

9. Preparation of Standard Solutions

10.2 Verify the analytical calibration plot daily or whenever

samples are to be run, prior to the analysis of samples to verify

9.1 Stock and working solutions.

the system resolution, calibration, and sensitivity as part of the

9.1.1 Glycerin Stock Solution, 1000 mg/L—Accurately

quality verification process (see Section 14).

weigh1gof 99.5+% glycerin to the nearest tenth of a

milligram (0.0001 g) and transfer toa1L volumetric flask.

10.3 Repeat calibration after any change of the ion chroma-

Dilute to the mark with water. Shake or swirl to mix the

tography eluent solution from 8.3, to reestablish ion retention

standard for homogeneity. Other volumes of stock solution

times and resolution. Use a check standard to verify

may be prepared using the appropriate ratio of reagents.

calibration, retention times, and resolution after any change in

the IC eluent solution from 8.3. Recalibrate if needed.

9.2 Working Standards—Prepare glycerin working stan-

dards according to Table 1.

10.4 Measurement of the Calibration Standards—Inject 10

µL of each calibration solution from 9.2 into the ion

9.2.1 Alternatively, commercial stock calibration solutions

can be used, provided that the solutions are traceable to chromatograph, and measure the areas of the peaks corre-

sponding to glycerin. Generally, one injection per sample is

primarystocksolutionsorcertifiedreferencematerials,andare

free from other analytes. sufficient. Refer to Section 14 for quality control discussion.

10.5 Construct the glycerin calibration plots by plotting the

peak areas against the glycerin concentrations. Use linear

regression to determine the best straight-line calibration. A

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

linear least squares correlation coefficient of 0.99 or greater is

listed by the American Chemical Society, see Annual Standards for Laboratory

required (see Fig. 2). The response factor for glycerin, Rf, is

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

the slope of the calibration plot straight line, in mg/kg/(area

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD. count).

D7591 − 12

FIG. 2 Typical Glycerin Calibration Plot

10.5.1 If the plot of the peak area values against the ion If the areas are different by more than 20%, do not continue

concentrations is not linear (the correlation factor should be at running samples, until at least 20% area repeatability can be

least 0.99), the procedure should be checked for errors, and if achieved.

necessary, the calibration should be repeated starting from

11.1.10 If the glycerin concentration exceeds that of the

Section 9.

highest calibration solution, dilute the sample solution with

waterasappropriate,andrepeatthesamplemeasurement.Take

11. Procedure

into account the dilut

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.